Magnesium alloy microcapillary and preparation method thereof

A magnesium alloy and microtube technology, which is applied in medical science, surgery, etc., can solve the problems of immature plastic processing technology of magnesium alloy, inability to produce metal processing methods, small size of magnesium alloy microtube, etc., and achieve good surface quality and low cost. The effect of low and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

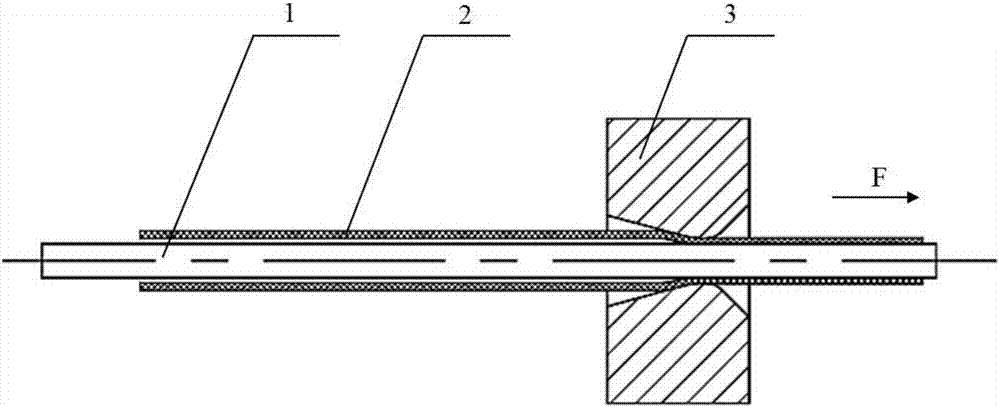

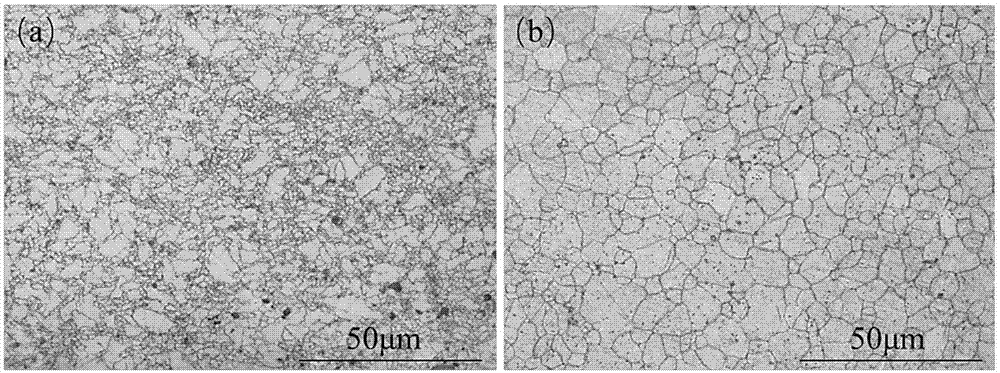

[0024] This implementation case is a method for preparing a magnesium alloy microtube, the method comprising the following steps:

[0025] (1) Apply lubricant to the inner wall of the extrusion cylinder, the extrusion die and the surface of the extrusion punch, put it in a resistance furnace and heat it to 400°C, put in Mg-4.15Zn-0.27Mn-0.21Ca magnesium alloy for extrusion The billet is kept warm for 5 minutes; the extrusion cylinder, extrusion die, and extrusion billet are taken out from the resistance furnace, installed, and extruded when the temperature drops to 360°C. The extrusion speed is 3mm / s, and the outer diameter is 8mm. , a tube blank with an inner diameter of 6mm;

[0026] (2) In a box-type furnace, under the condition of 250° C., the magnesium alloy tube blank is subjected to stress relief annealing for 30 minutes;

[0027] (3) The annealed tube blank is subjected to multi-pass air drawing, the drawing deformation of each pass is 1% to 28%, the drawing speed is ...

Embodiment 2

[0031] This implementation case is a method for preparing a magnesium alloy microtube, the method comprising the following steps:

[0032] (1) Apply lubricant to the inner wall of the extrusion cylinder, the extrusion die and the surface of the extrusion punch, put it in a resistance furnace and heat it to 400°C, put in Mg-3.95Zn-0.30Mn-0.18Ca magnesium alloy for extrusion The billet is kept warm for 5 minutes; the extrusion cylinder, extrusion die, and extrusion billet are taken out from the resistance furnace, installed, and extruded when the temperature drops to 380°C. The extrusion speed is 3mm / s, and the outer diameter is 8mm. , a tube blank with an inner diameter of 6mm;

[0033] (2) In a box furnace, under the condition of 300°C, the magnesium alloy tube blank is subjected to stress relief annealing for 30 minutes;

[0034] (3) The annealed tube blank is subjected to multi-pass air drawing, the drawing deformation of each pass is 1% to 28%, the drawing speed is 5 to 8m...

Embodiment 3

[0038] This implementation case is a method for preparing a magnesium alloy microtube, the method comprising the following steps:

[0039] (1) Apply lubricant to the inner wall of the extrusion cylinder, the extrusion die and the surface of the extrusion punch, put it in a resistance furnace and heat it to 400°C, put in Mg-4.04Zn-0.18Mn-0.18Ca magnesium alloy for extrusion The billet is kept warm for 5 minutes; the extrusion cylinder, extrusion die, and extrusion billet are taken out from the resistance furnace, installed, and extruded when the temperature drops to 360°C. The extrusion speed is 3mm / s, and the outer diameter is 8mm. , a tube blank with an inner diameter of 6mm;

[0040] (2) In a box-type furnace, under the condition of 250° C., the magnesium alloy tube blank is subjected to stress relief annealing for 30 minutes;

[0041] (3) The annealed tube blank is subjected to multi-pass air drawing, the drawing deformation of each pass is 1% to 28%, the drawing speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com