Patents

Literature

106 results about "Non proportional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proportional and non proportional graphs : If a relationship is nonlinear, it is nonproportional. If it is linear, it may be either proportional or nonproportional.

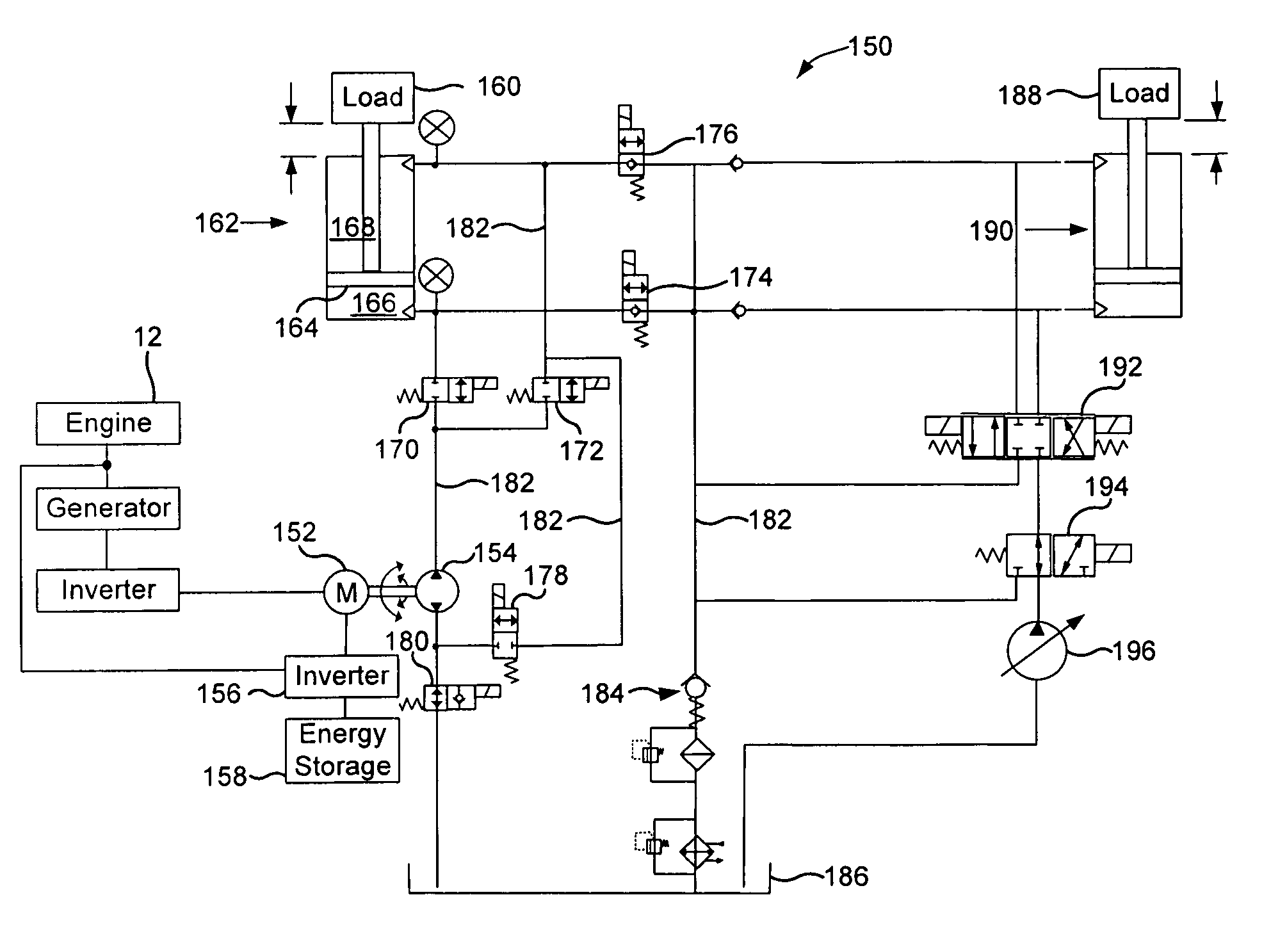

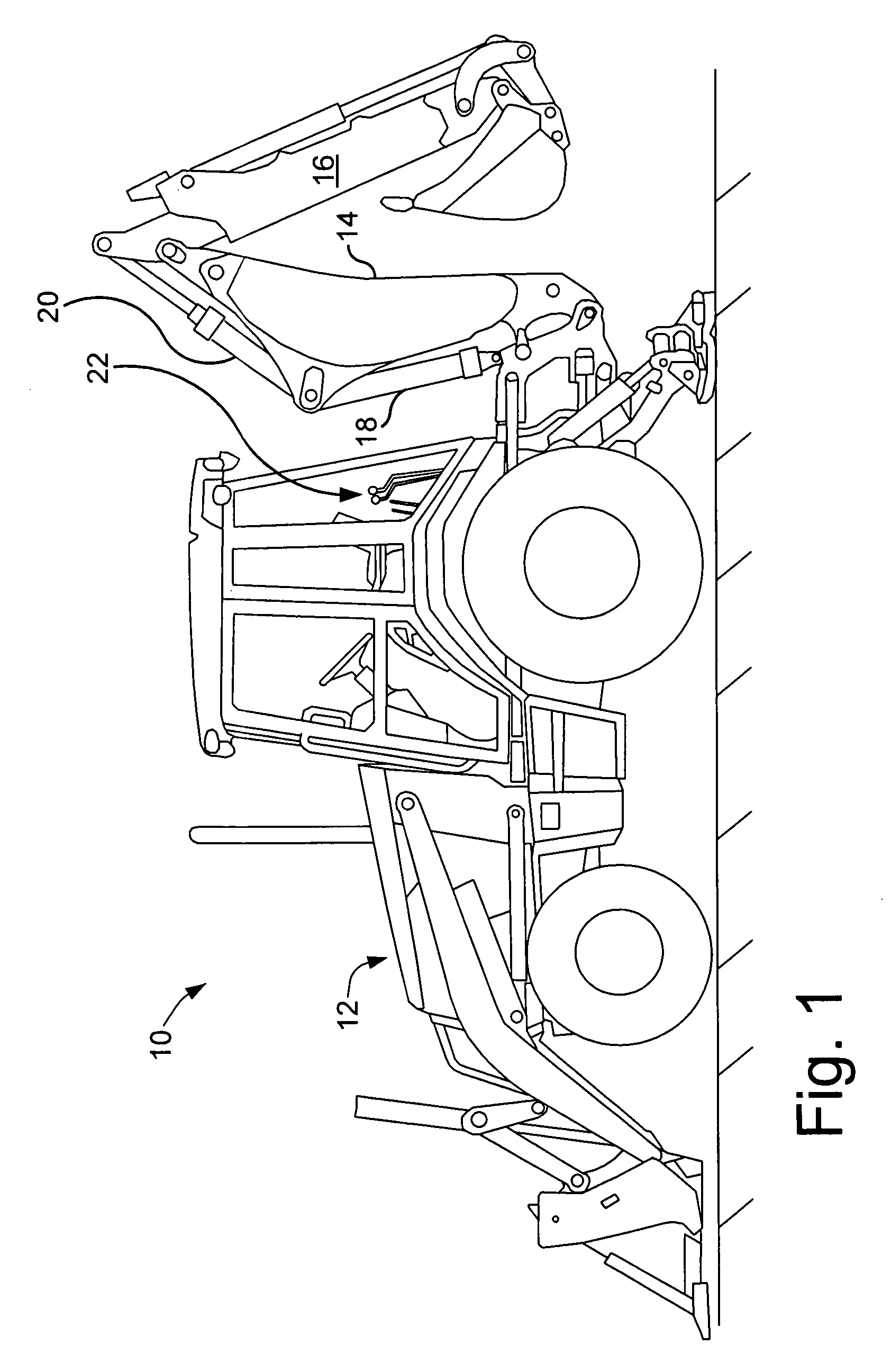

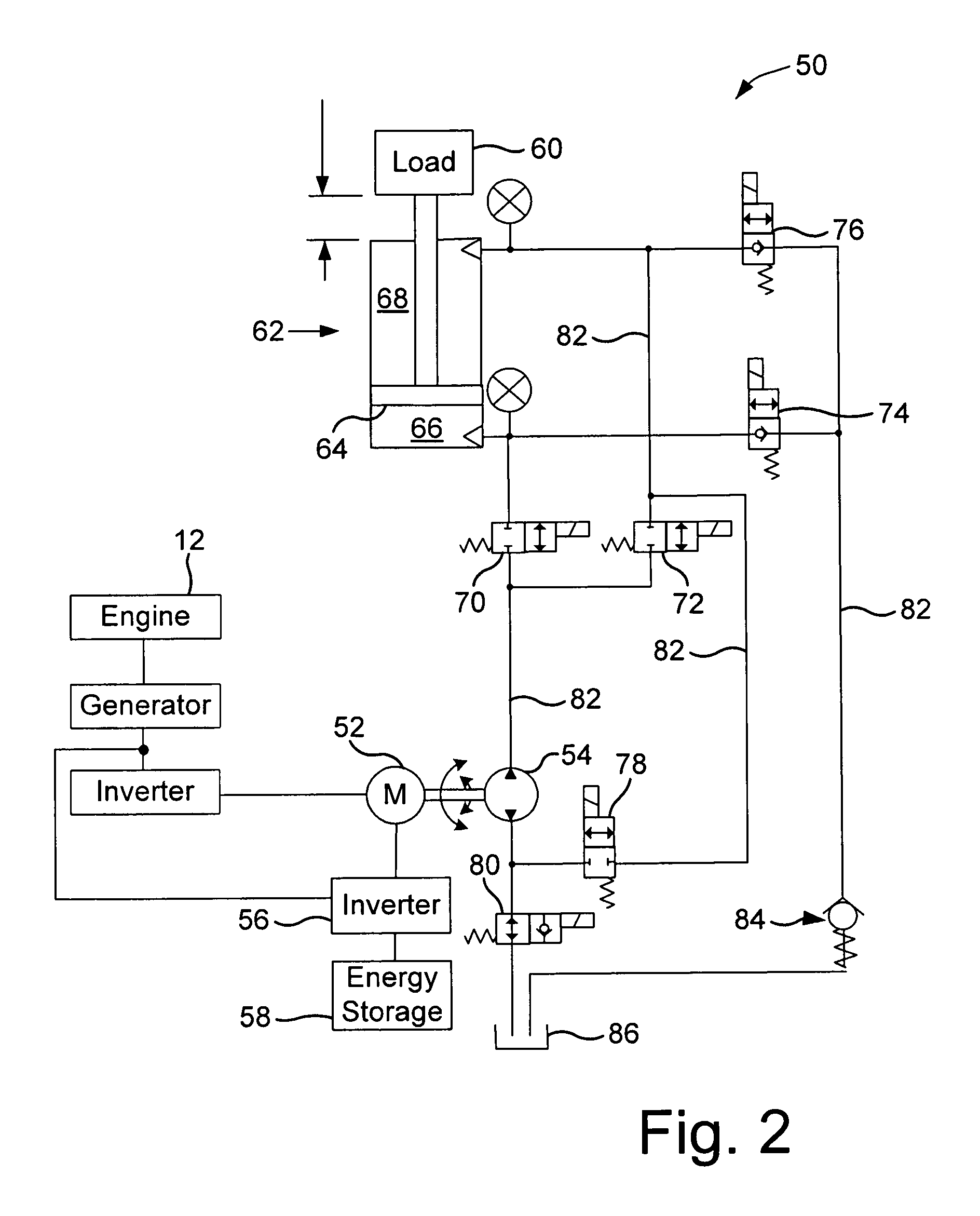

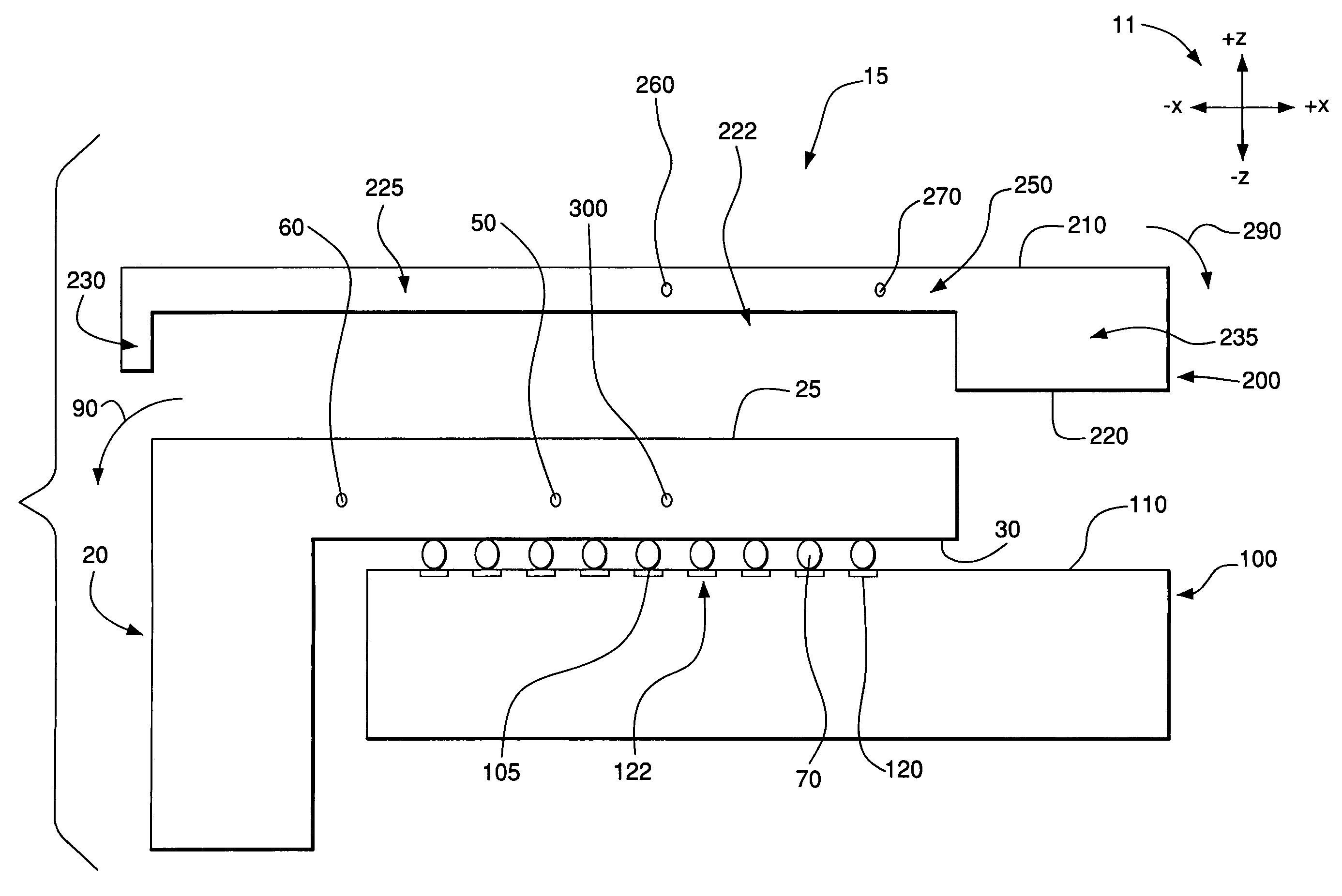

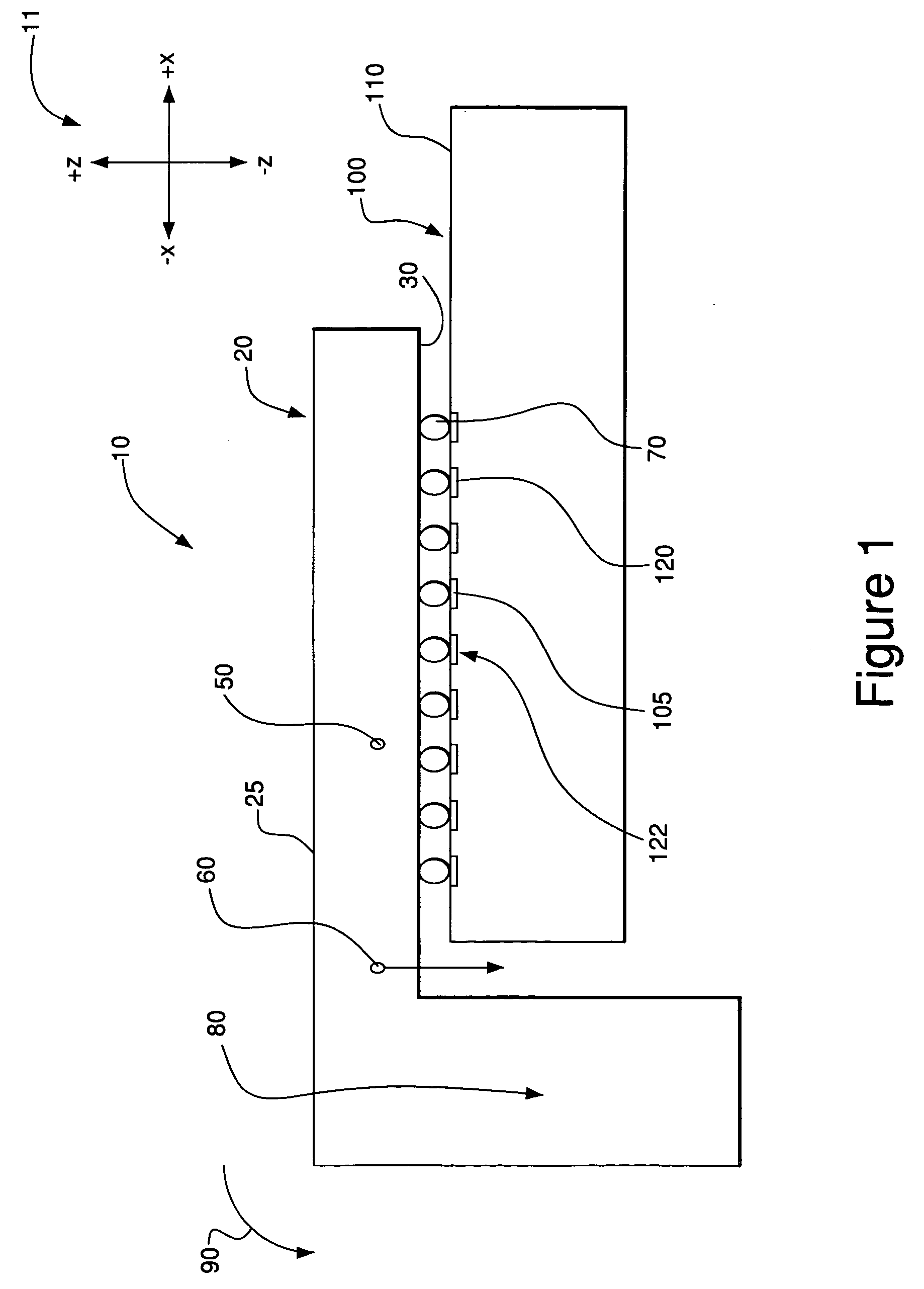

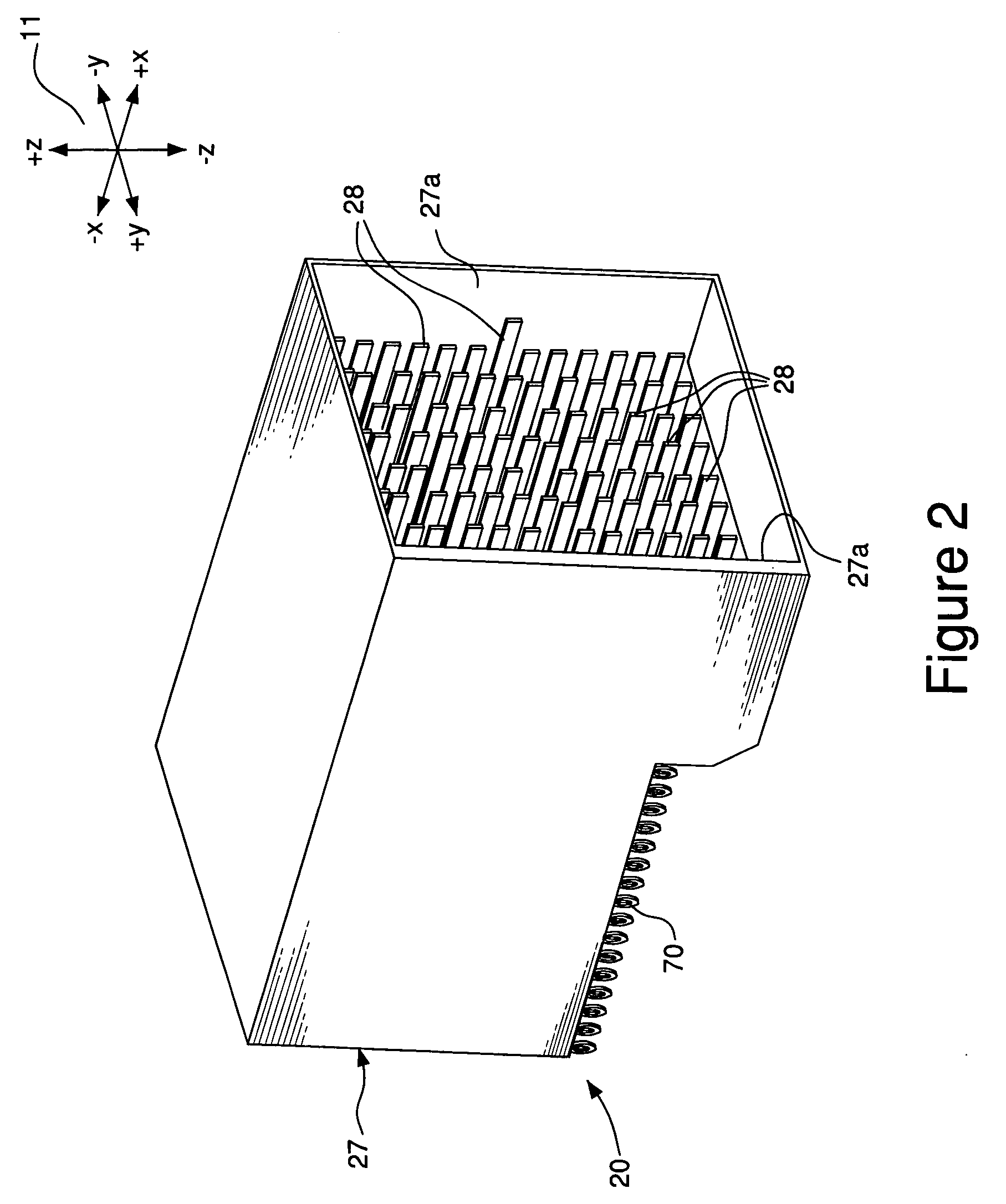

Hydraulic system

A ground engaging vehicle including a movable member, a hydraulically driven actuator, a hydraulic pump, a plurality of valves and at least one hydraulic conduit. The hydraulically driven actuator is coupled to the movable member and the actuator has a first chamber and a second chamber. The plurality of non-proportional valves include a first valve, a second valve, a third valve and a fourth valve. The at least one hydraulic conduit couples the pump with the first valve and the second valve. The first valve is in direct fluid communication with the first chamber. The second valve is in direct fluid communication with the second chamber. The third valve is in direct fluid communication with the first chamber and the fourth valve is in direct fluid communication with the second chamber. The first valve and the second valve each include an open position and a closed position.

Owner:DEERE & CO

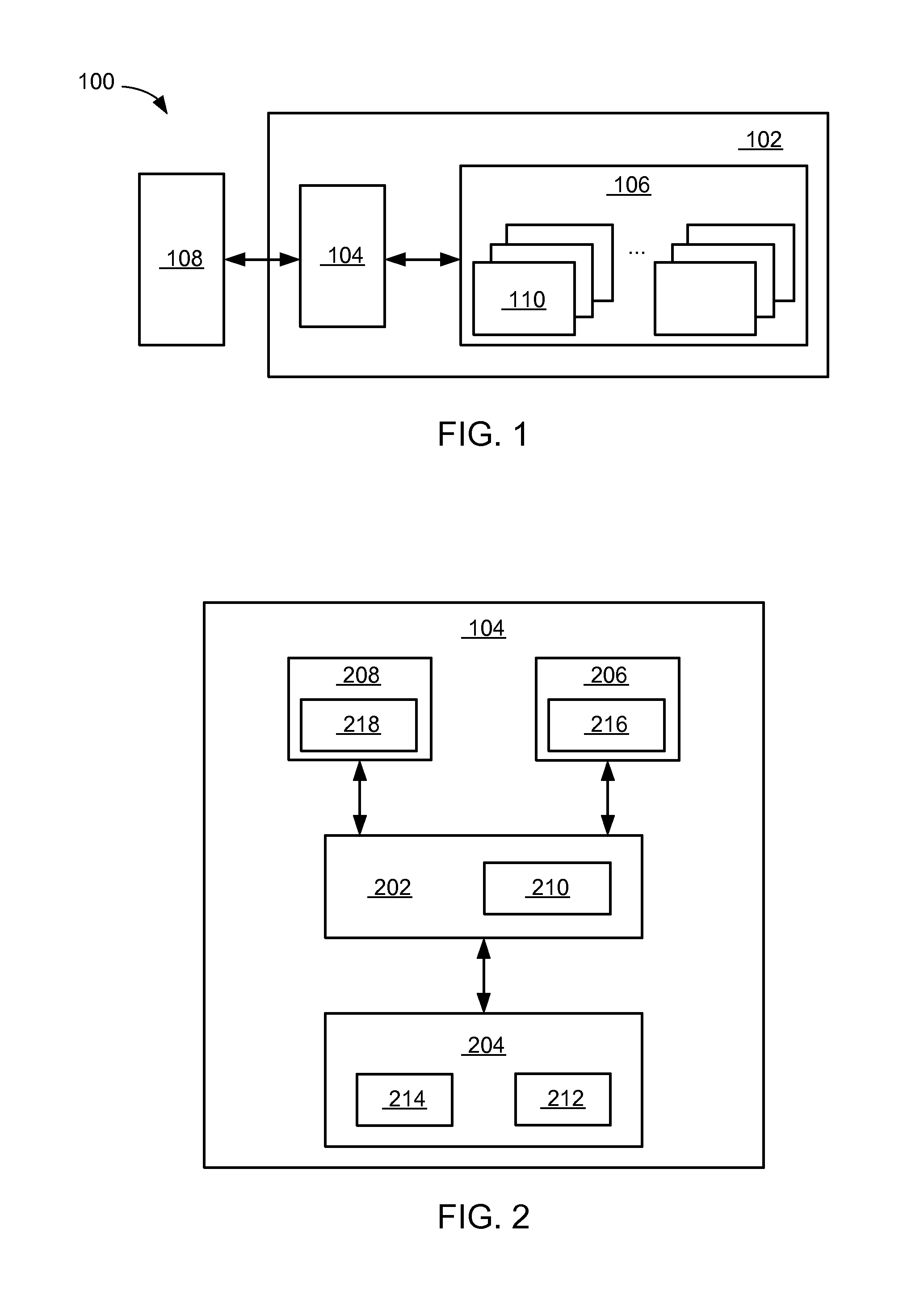

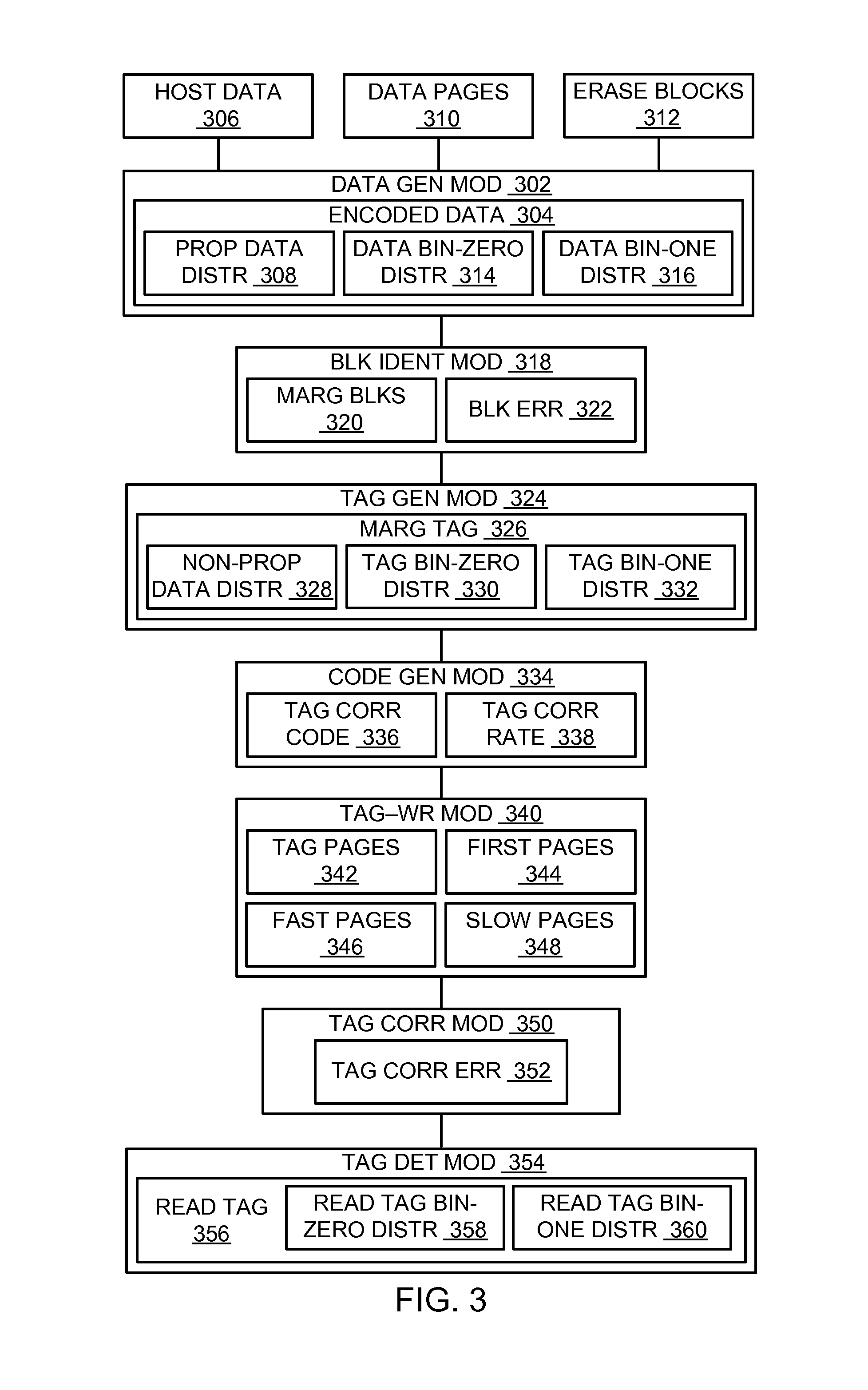

Storage control system with data management mechanism and method of operation thereof

ActiveUS20130332796A1Error correction/detection using block codesStatic storageControl systemData management

A method of operation of a storage control system includes: generating encoded data having a proportional data distribution for writing to a memory device; identifying a marginal block when an erase block is read from the memory device; and generating a marginal tag for the marginal block, the marginal tag having a non-proportional data distribution different from the proportional data distribution.

Owner:SANDISK TECH LLC

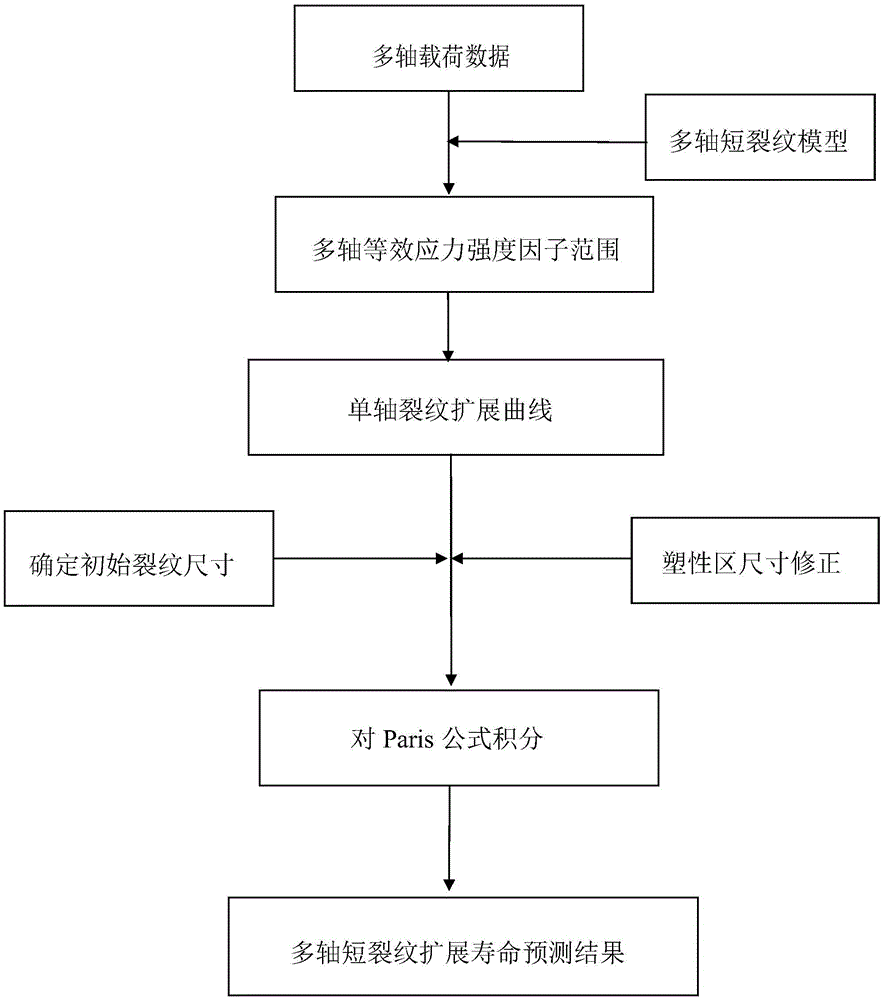

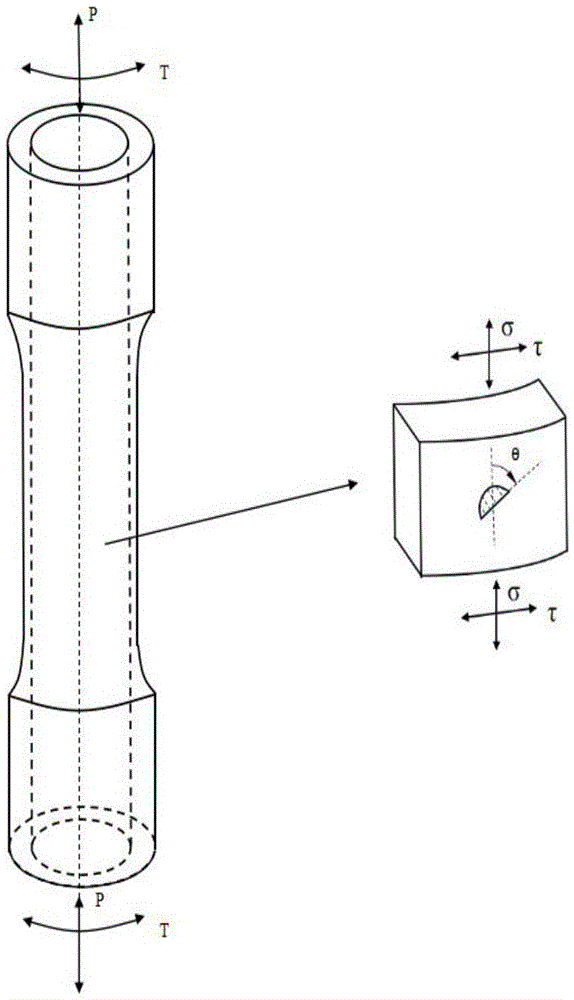

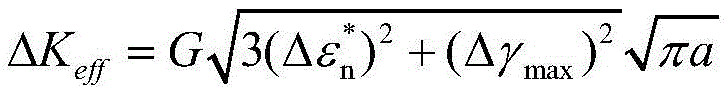

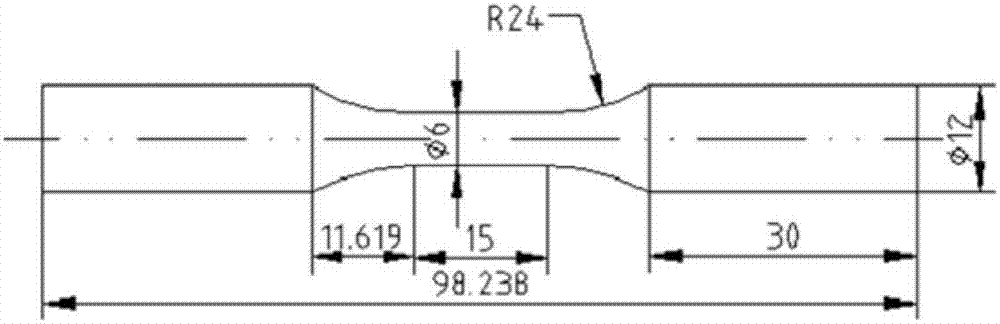

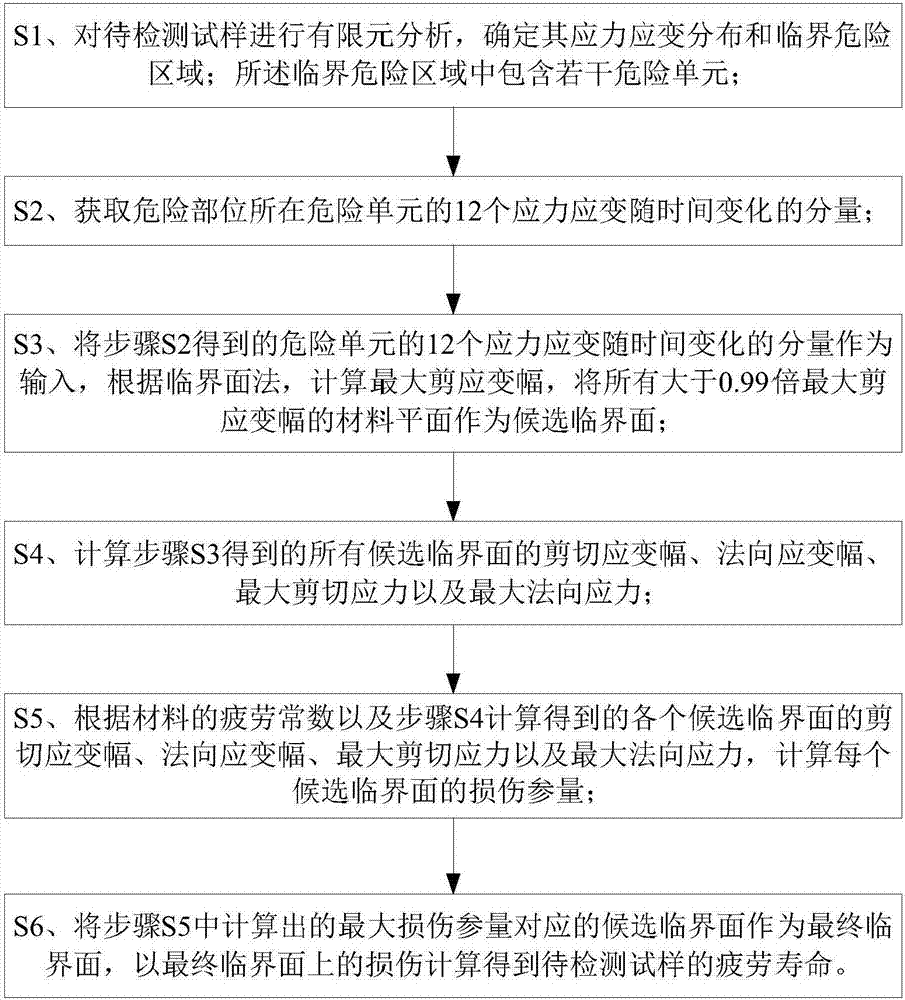

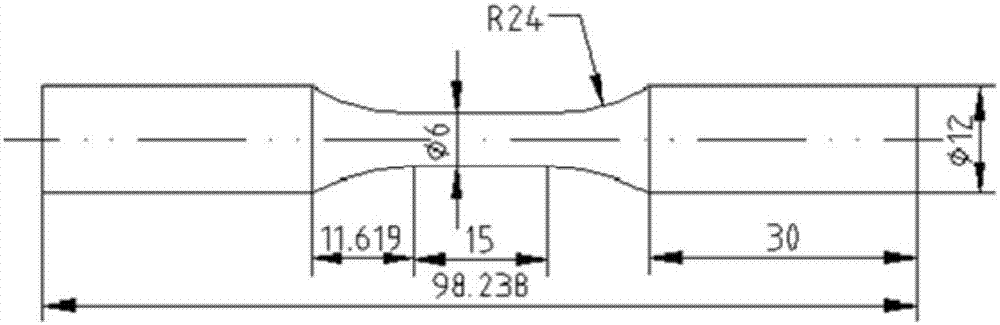

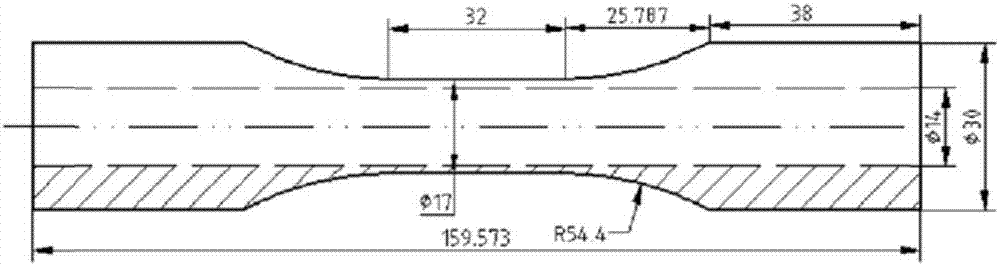

Multiaxial short crack propagation life prediction method based on critical surface method

ActiveCN105466772APromote engineering applicationMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesFatigue damageEngineering

The present invention provides a multiaxial short crack propagation life prediction method based on a critical surface method, and relates to the field of multiaxial fatigue strength theory. The algorithm comprises the steps of: (1) selecting a plane, which contains the maximum shearing strain range, as a critical surface, and using the damage parameters on the critical surface to characterize a short crack propagation driving force; (2) based on the shear-type multiaxial fatigue damage parameters, establishing an equivalent crack stress intensity factor applicable to the multiaxial stress state; (3) fitting the short crack propagation rate data under uniaxial loading to obtain an uniaxial short crack propagation curve; and (4) carrying out plastic zone size correction on the crack tip, and calculating the short crack propagation life by a fracture mechanics method. The method can well descript the influence of non-proportional loading on crack propagation. The results show that the method can well predict the short crack propagation life under multiaxial proportional and non-proportional loading.

Owner:BEIJING UNIV OF TECH

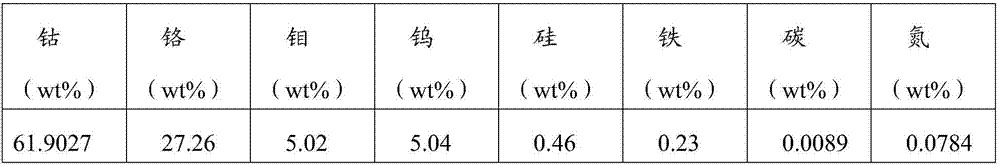

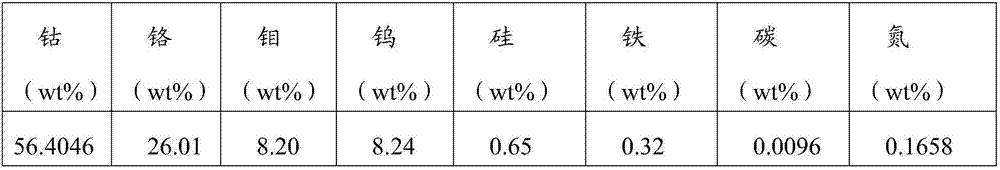

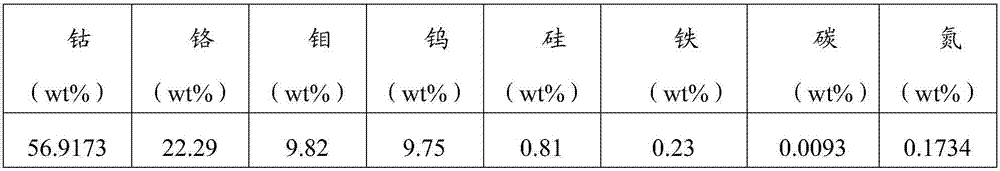

Cobalt-based alloy powder and preparation method and application thereof

ActiveCN107513642AImprove liquiditySmall particle sizeAdditive manufacturing apparatusTransportation and packagingChemical compositionNitrogen

The invention relates to cobalt-based alloy powder and a preparation method and application thereof. The cobalt-based alloy powder is prepared from, by weight percentage, 22-32% of chromium, 4-10% of molybdenum, 4-10% of tungsten, 0-1% of silicon, 0-0.75% of iron, 0-0.35% of carbon, 0.05-0.2% of nitrogen and the balance cobalt. The cobalt-based alloy powder is good in fluidity, small in particle size and concentrated in particle size distribution; the mechanical performance of a cobalt-based alloy material prepared through the cobalt-based alloy powder can reach the 5 type / type 5 of the GB17168 / ISO 22674 requirement, the tensile strength reaches 1326 MPa, and the non-proportional extension strength reaches 948 MPa; and the elastic modulus reaches 206 GPa, and the fracture elongation rate reaches 13.8%.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

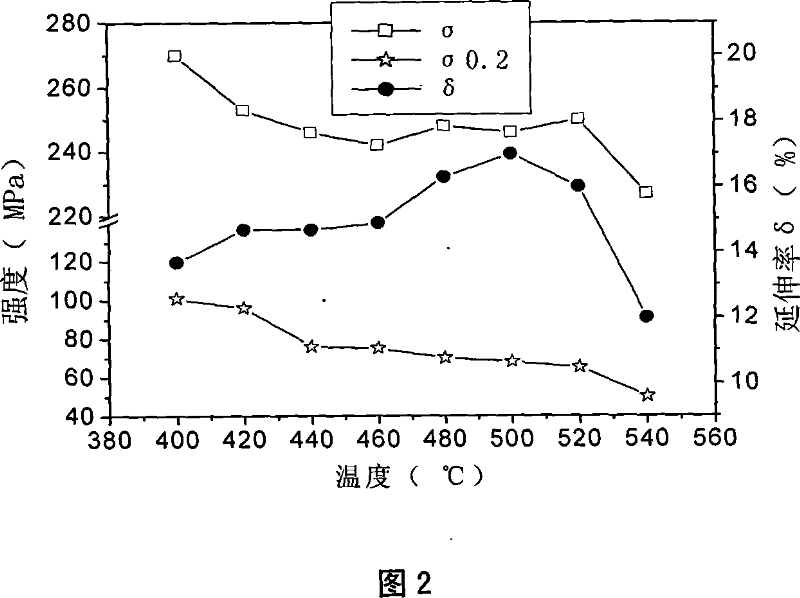

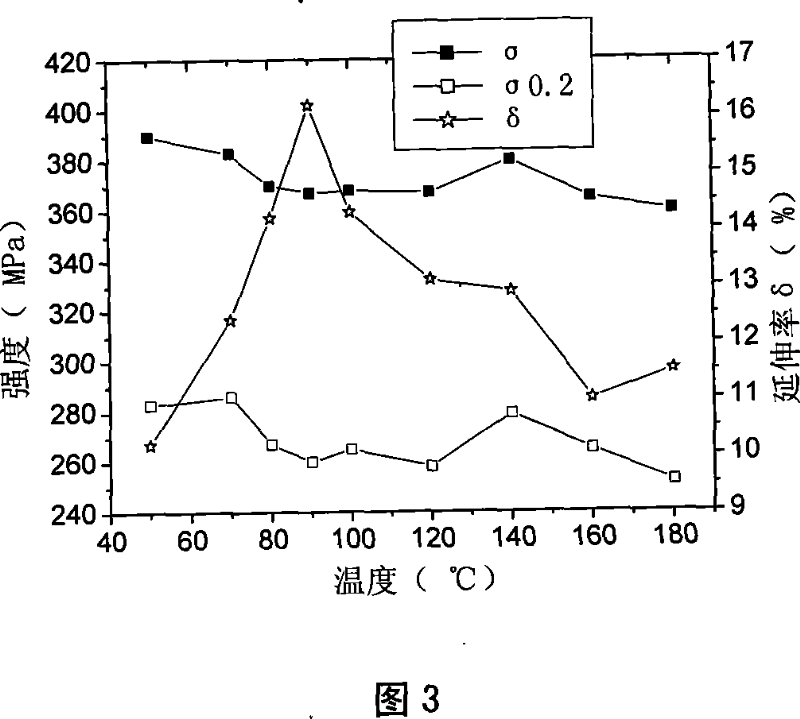

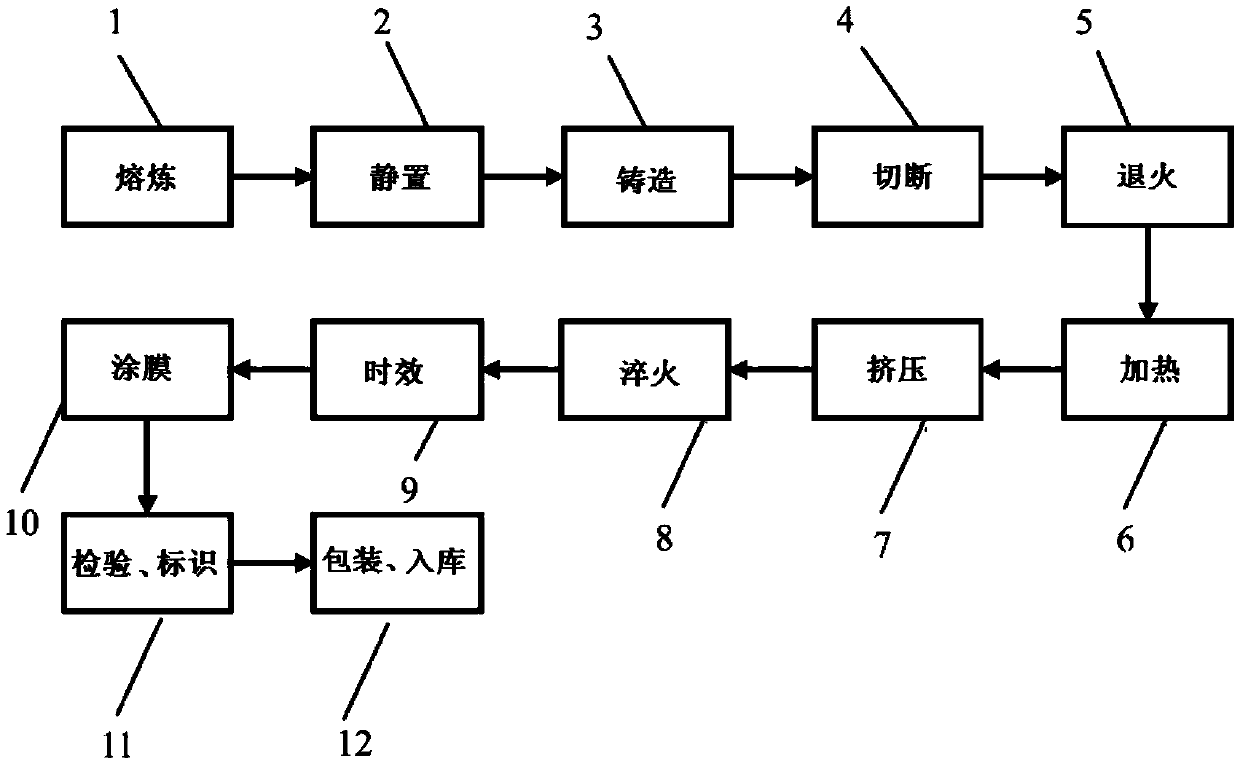

Manufacturing method of aluminum alloy plate for train compartment

The invention relates to a method for producing aluminium alloy plates for body of train. The invention solves the problem that 5380 alloy plates have the crack in hot rolling process, low non-proportional extended intansity, buckling deformation in the machining. The plates comprises, based on weight percentage, Si <= 0.25%, Fe <= 0.25%, Cu <= 0.20%, Mn: 0.7-1.0%, Mg: 4.0-5.2%, Cr <= 0.25%, Zn <= 0.40%, Ti <= 0.15%, Zr <= 0.20%, and the residuel of Al. The method for producing includes tha steps of : smelting and casting alloy cast ingot; homogenizing annealing at the temperature of 450-480 DEG C for 35 hours; hot rolling at the temperature of 450-480 DEG C; cold rolling to reach the thichness of the plates; stabilizing treatment at the temperature of 80-100 DEG C for 6 hours.

Owner:NORTHEAST LIGHT ALLOY CO LTD

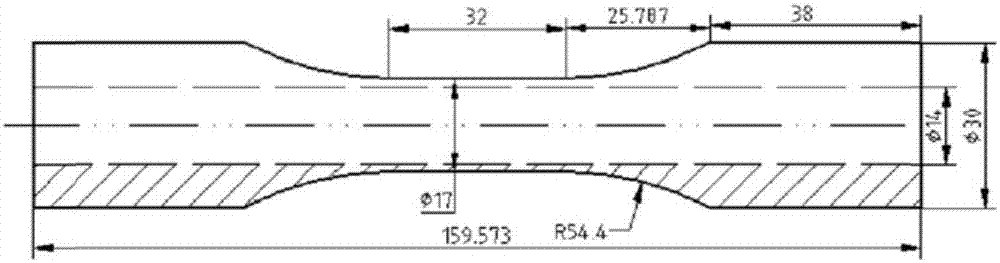

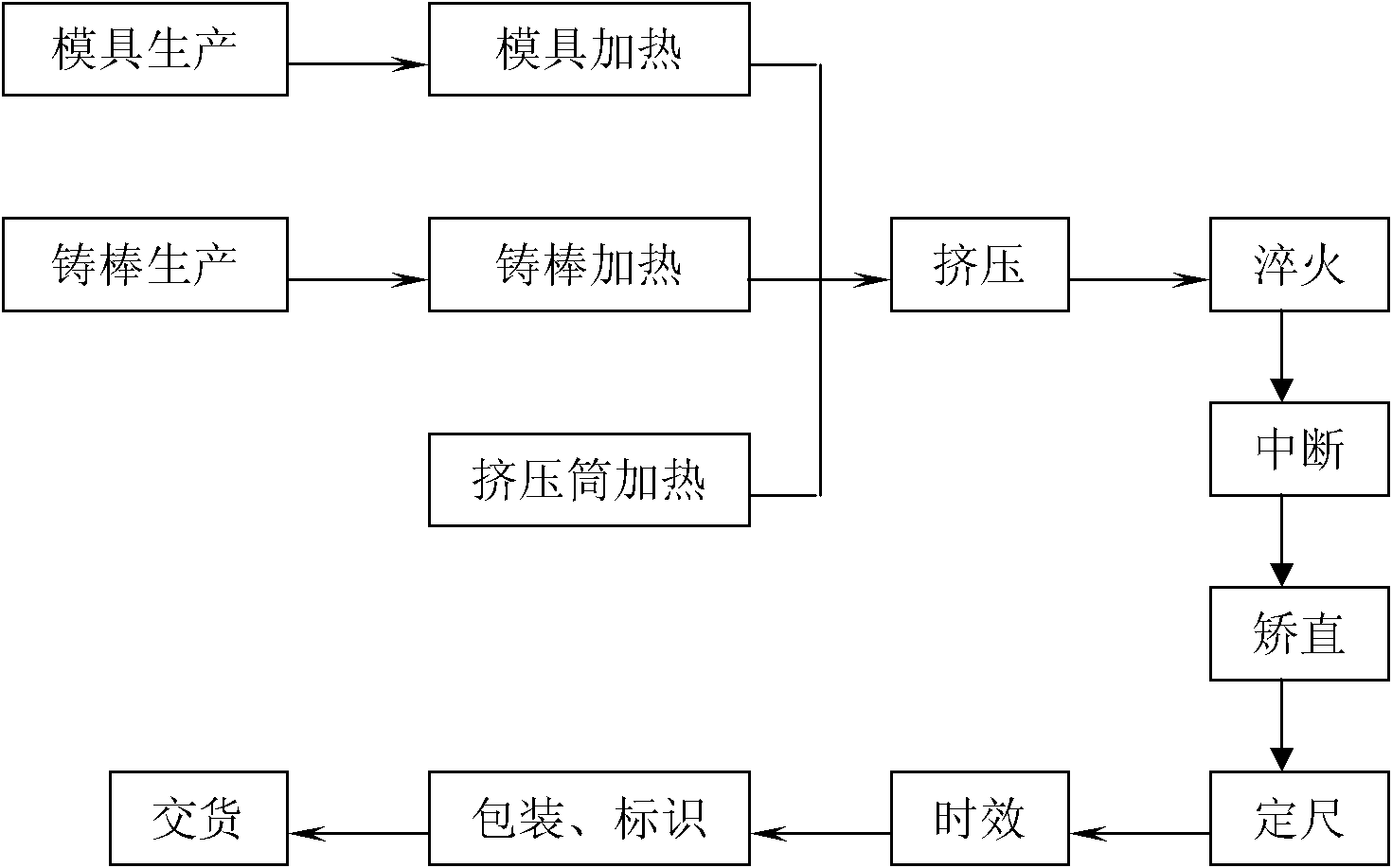

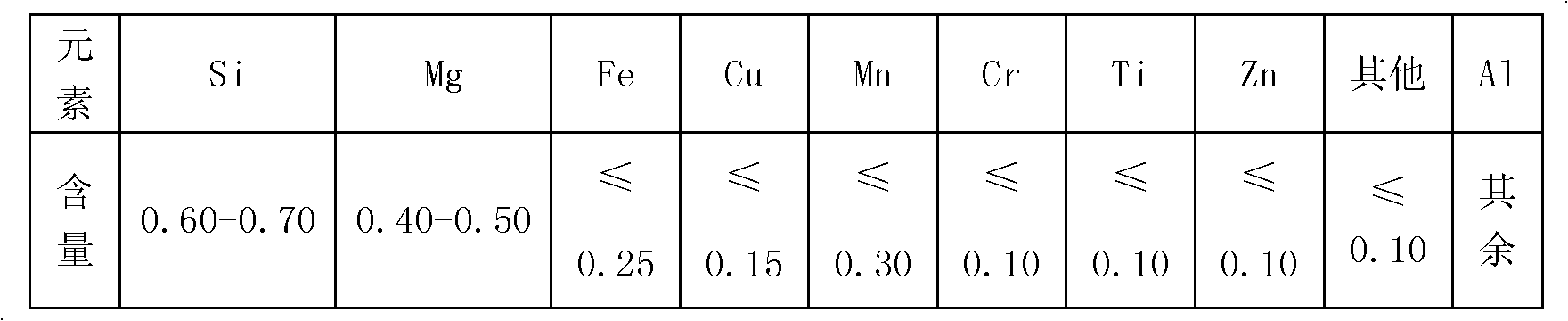

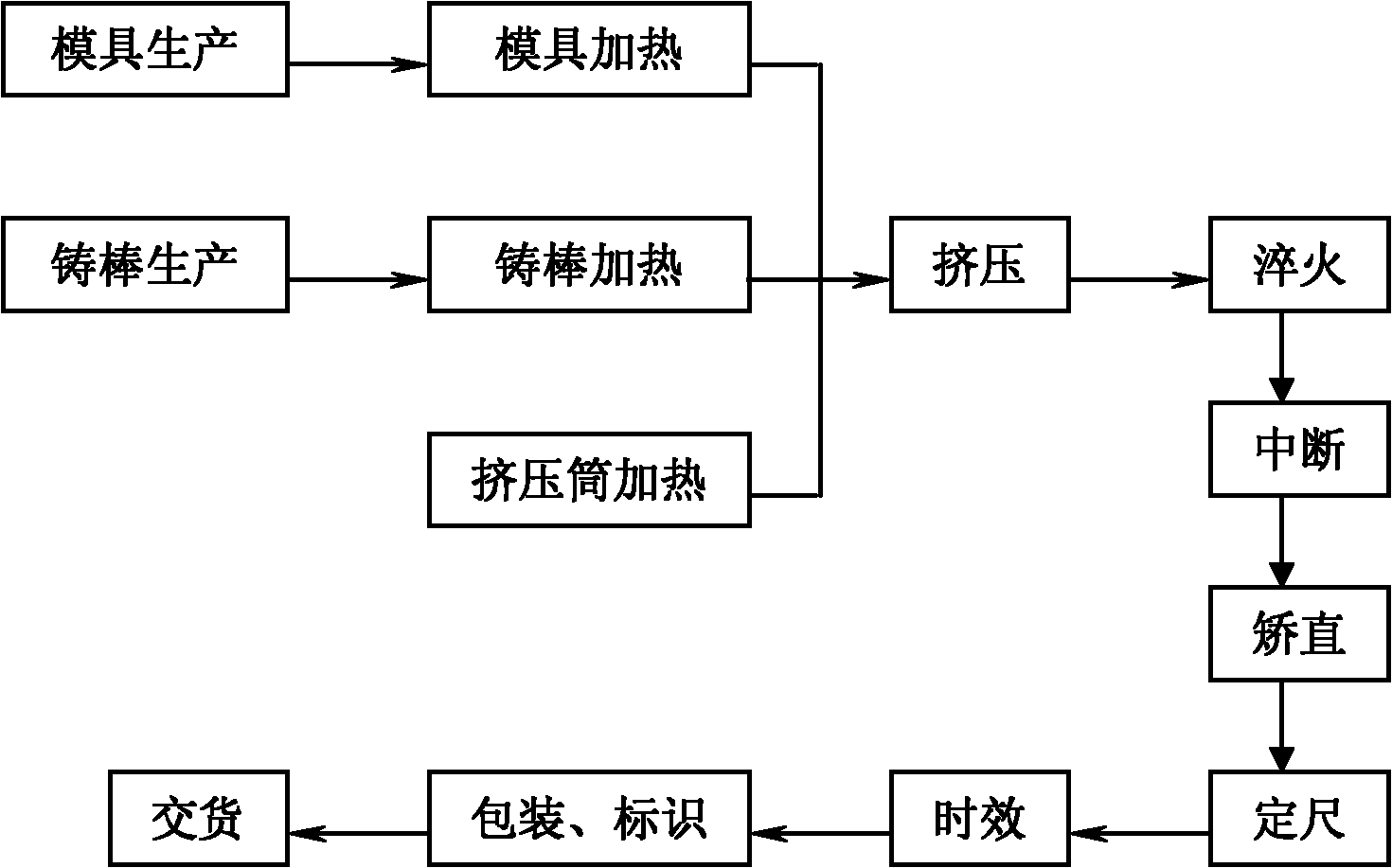

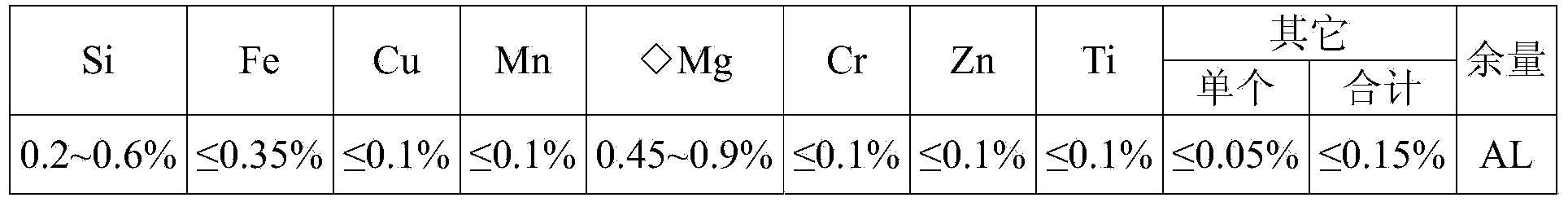

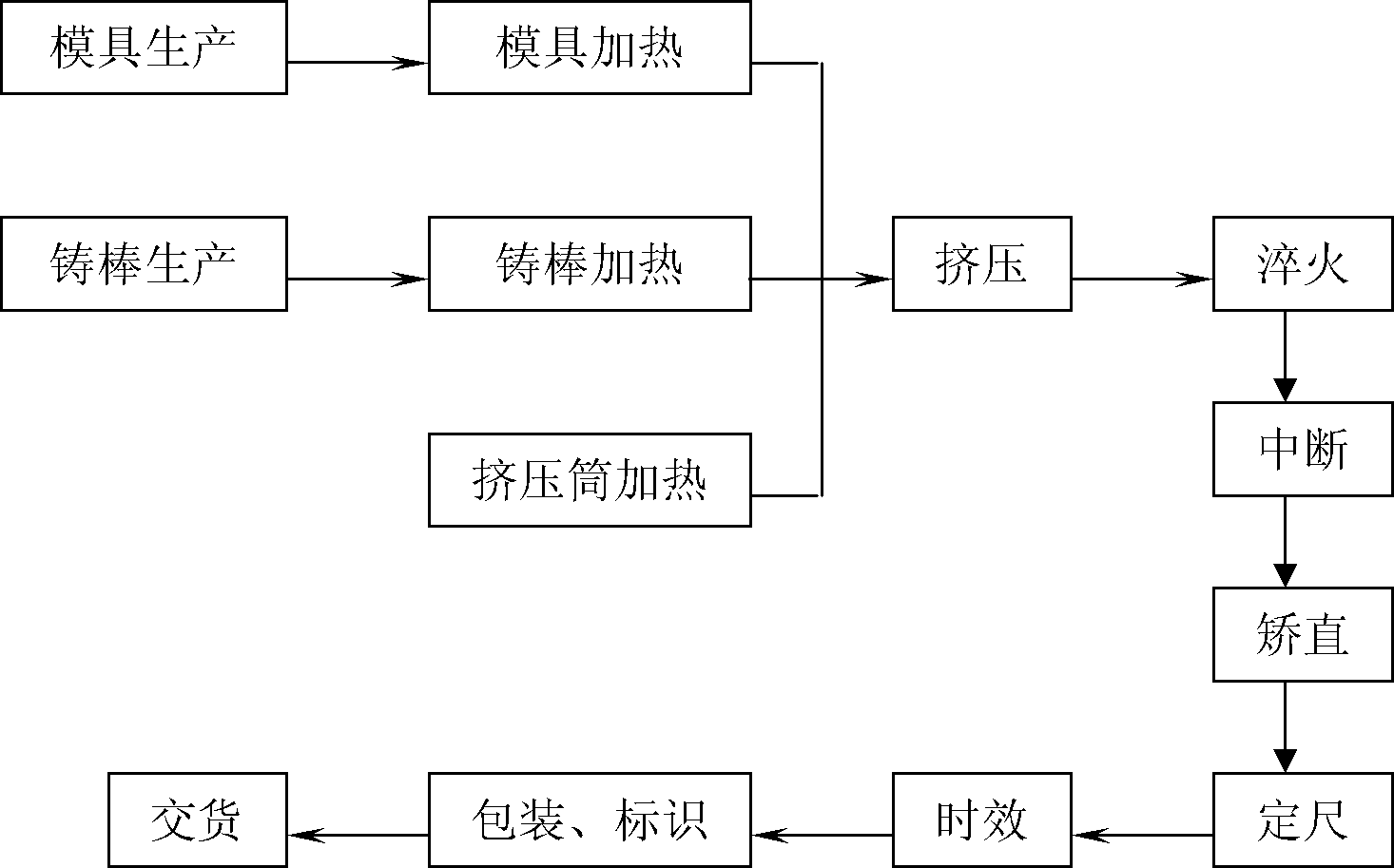

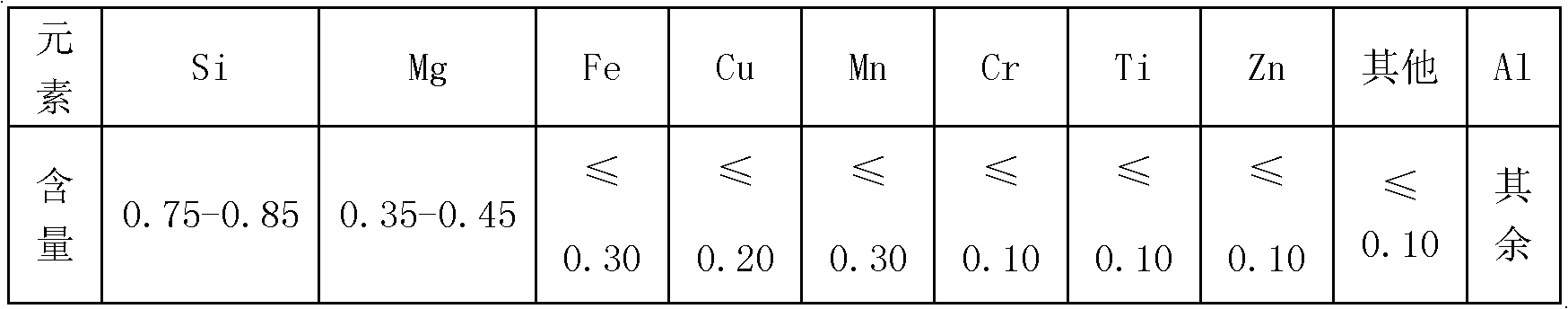

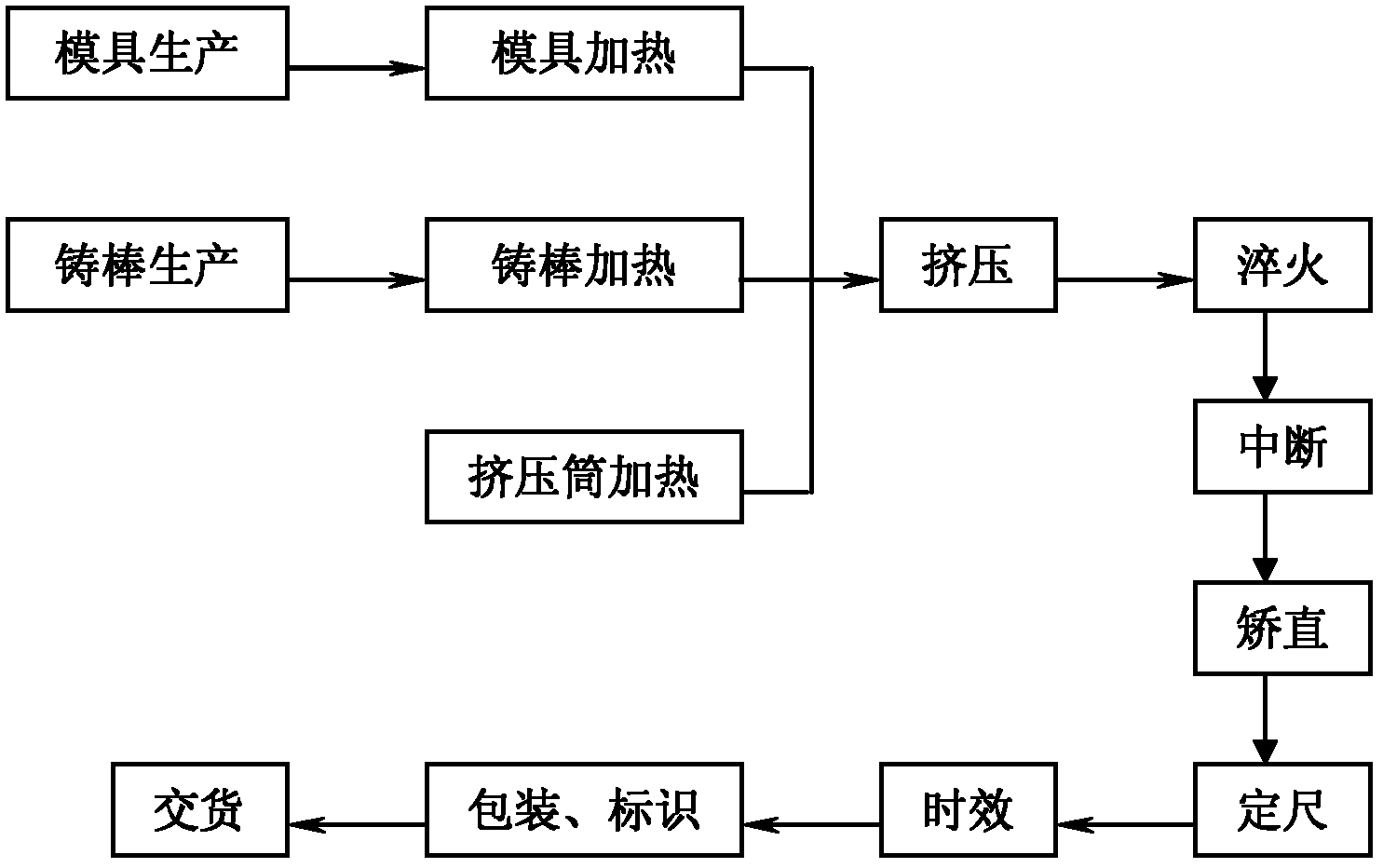

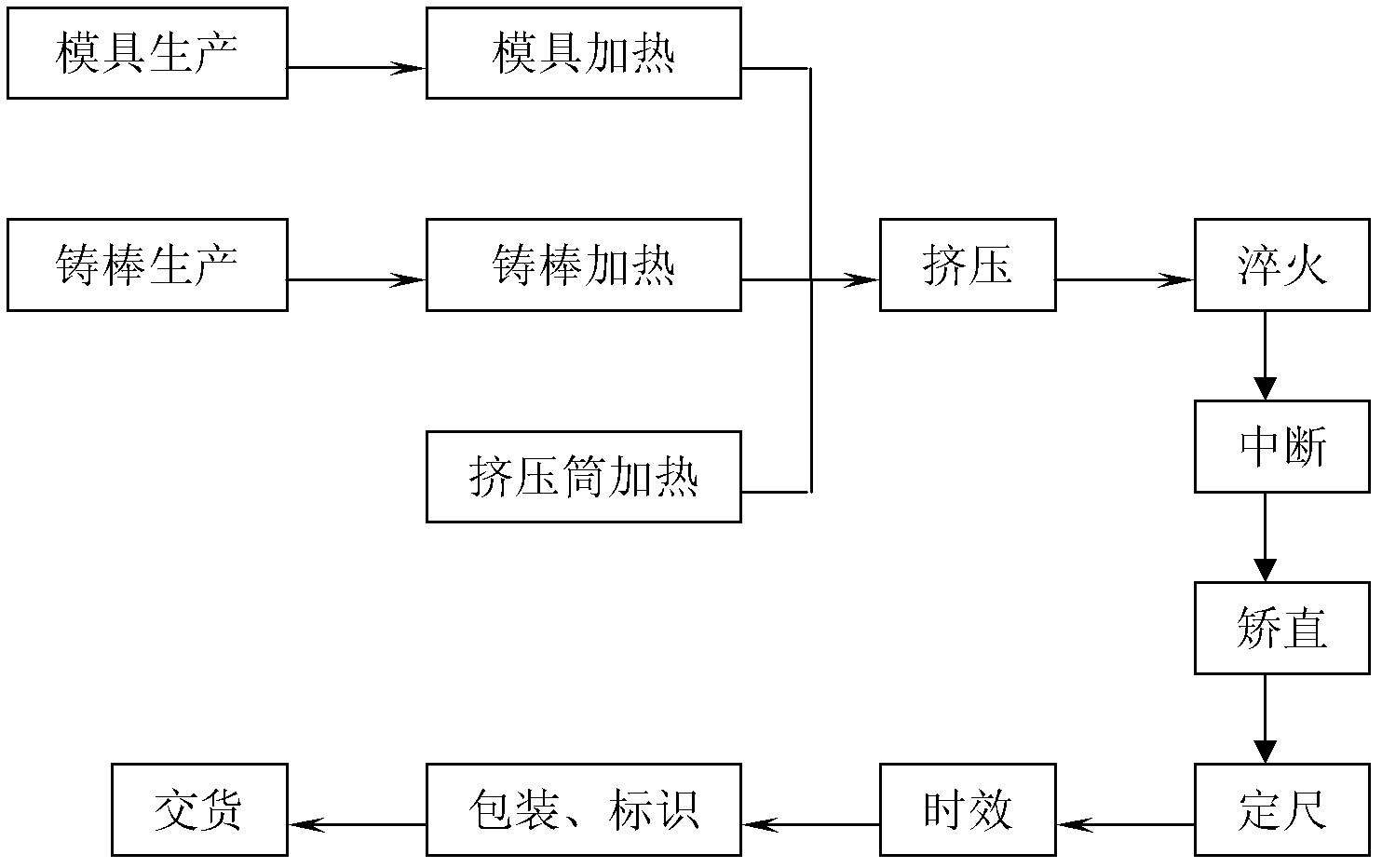

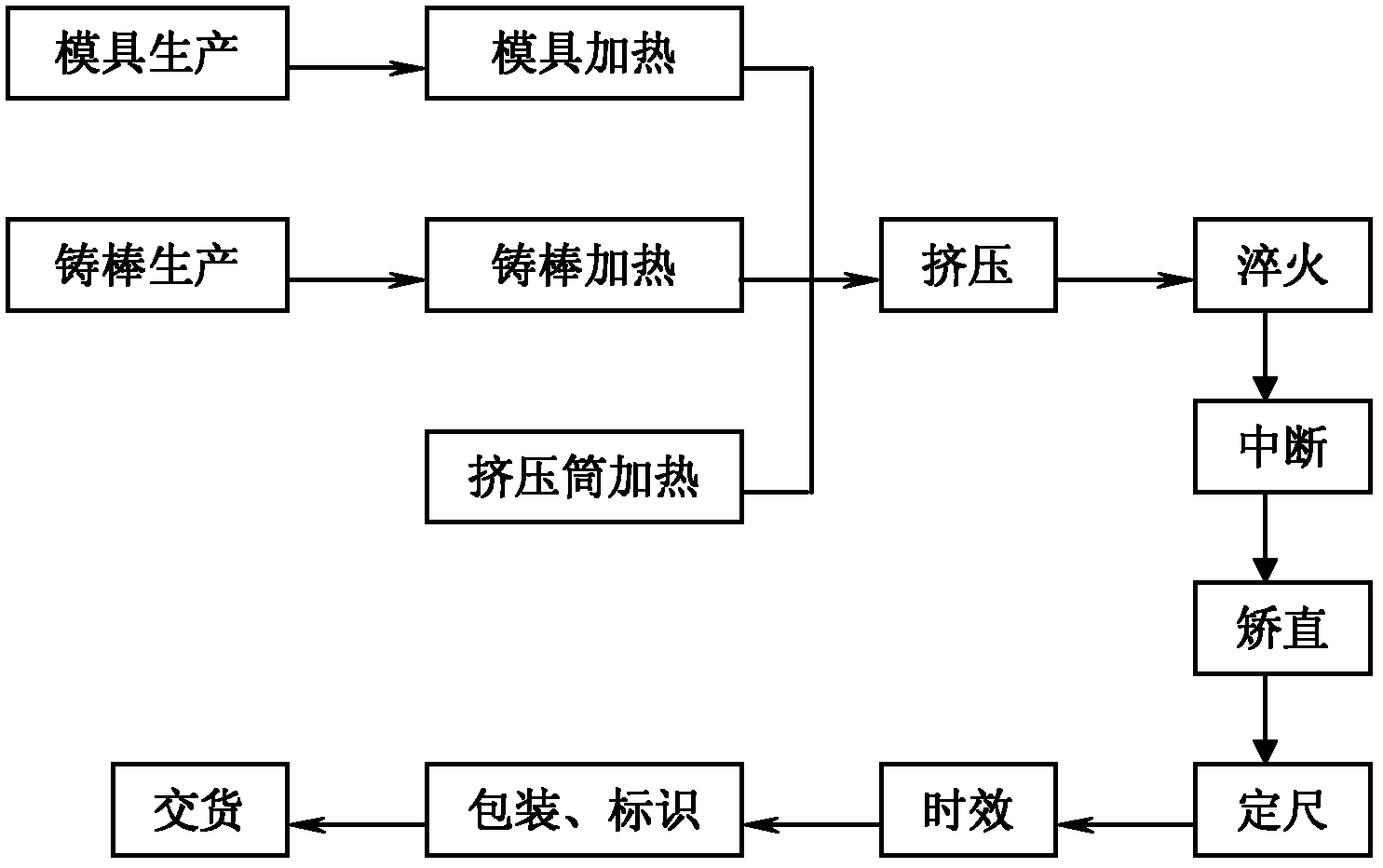

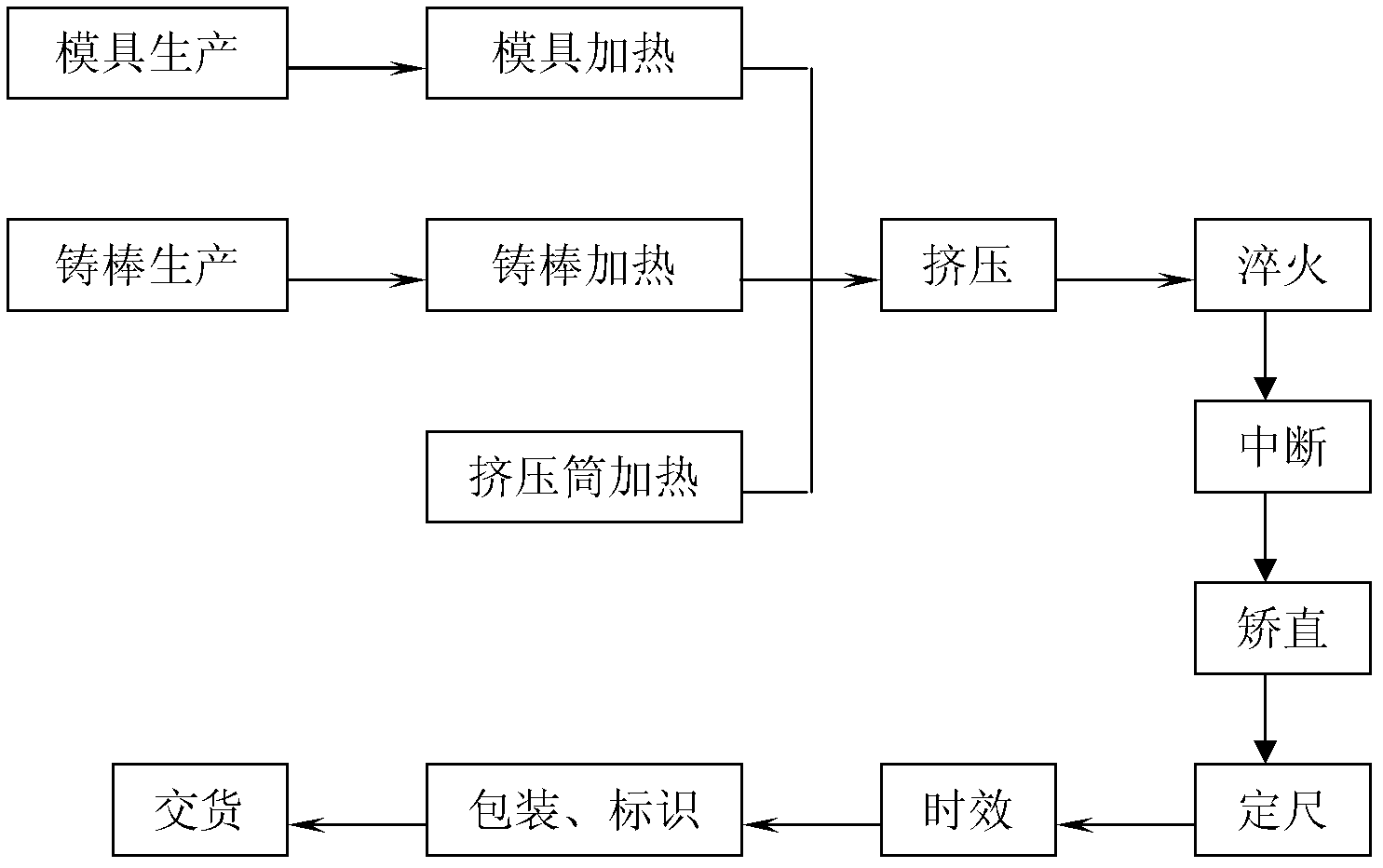

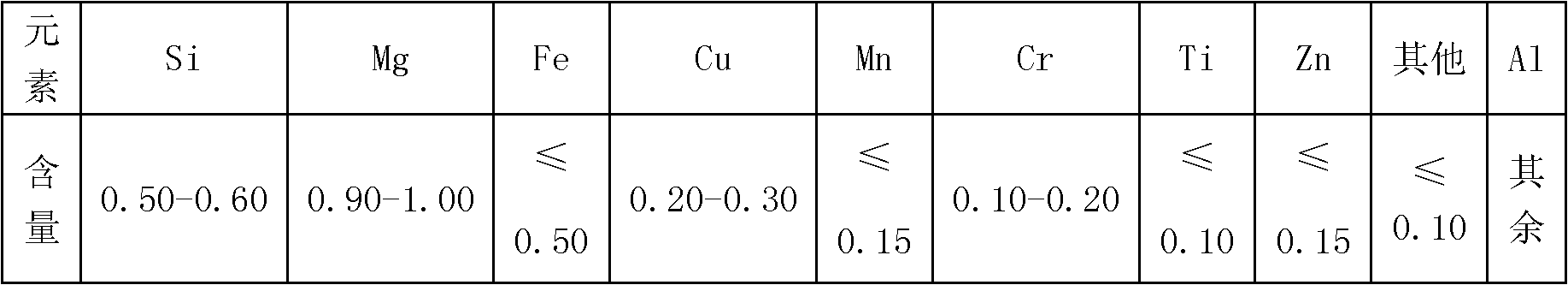

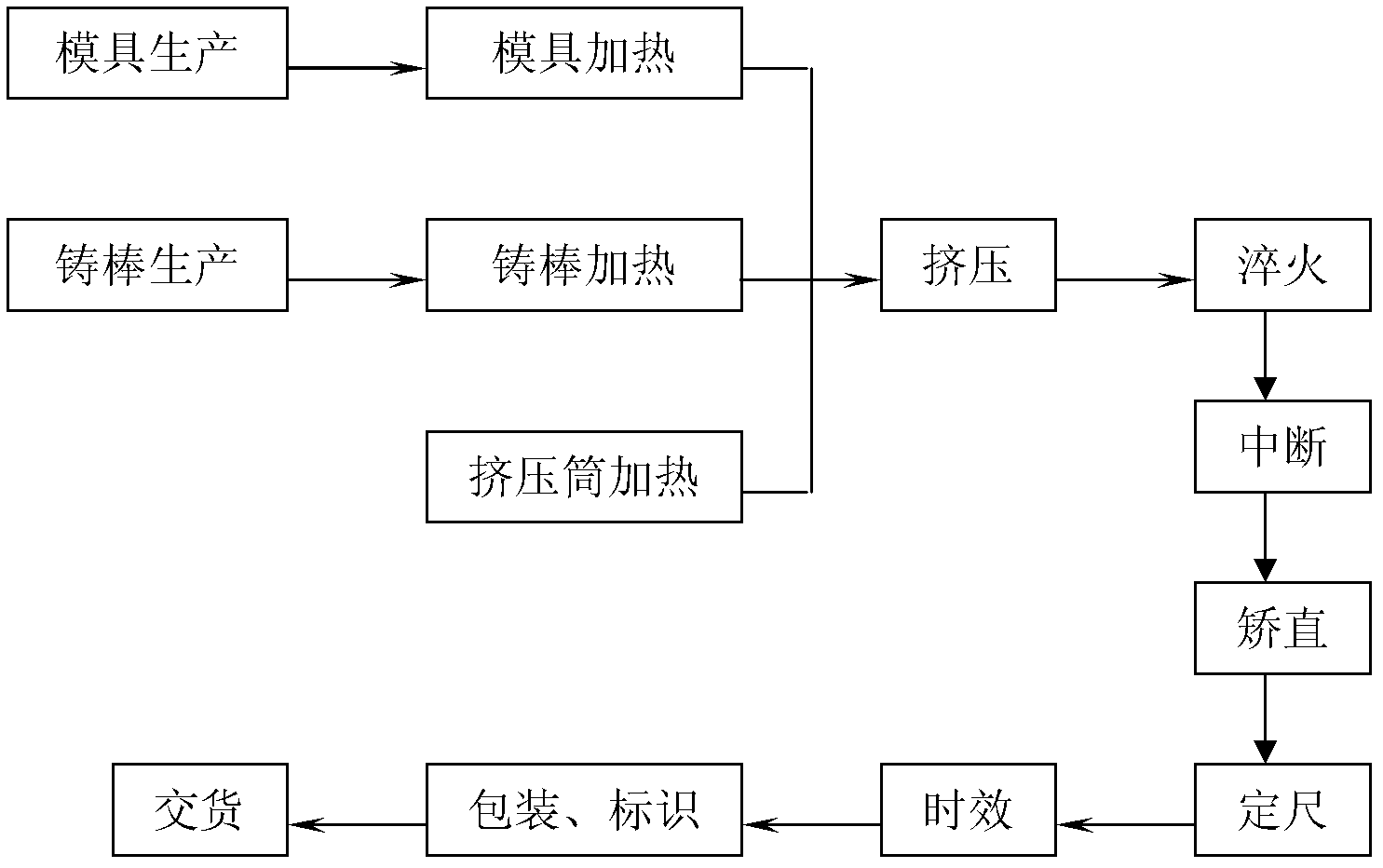

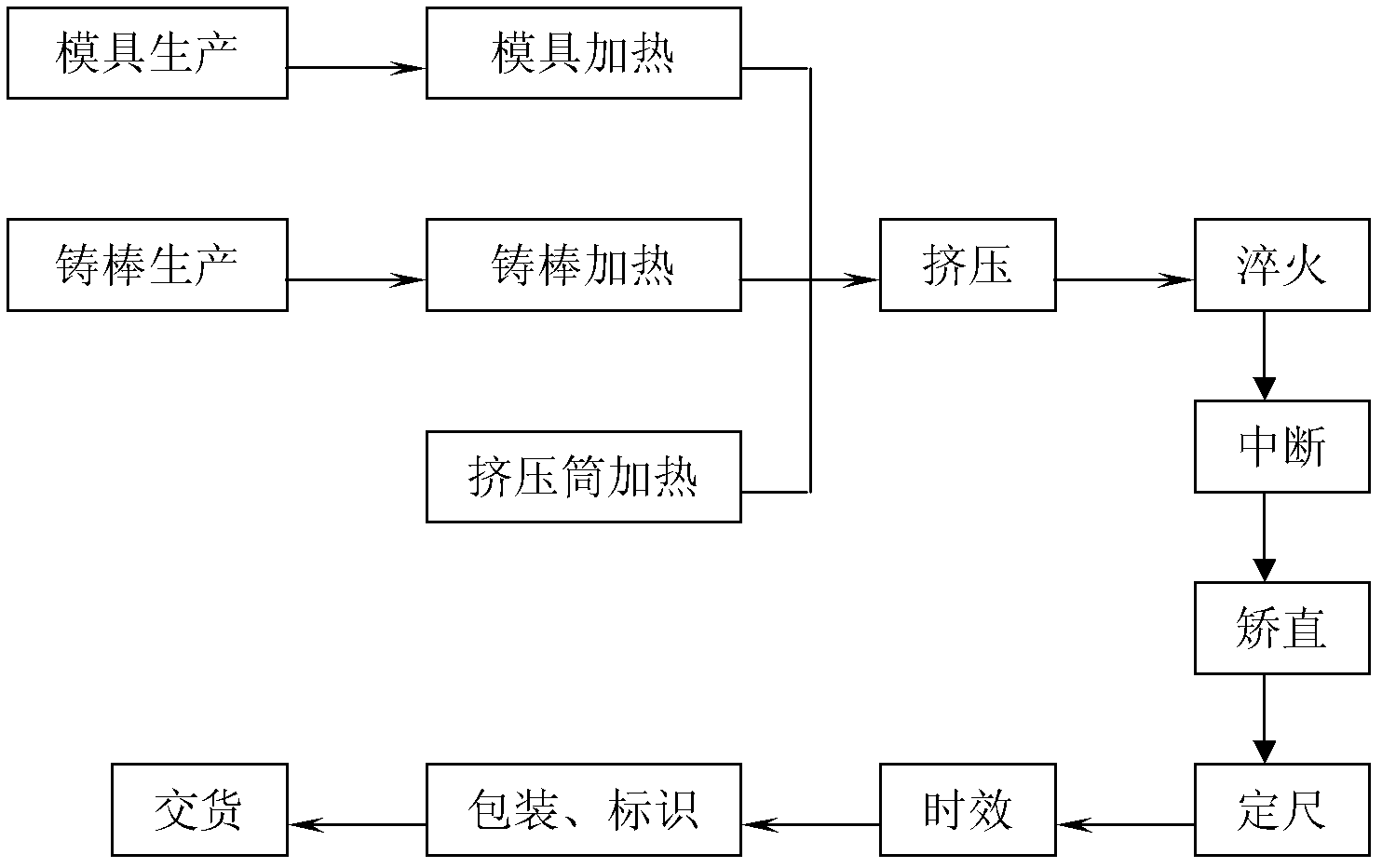

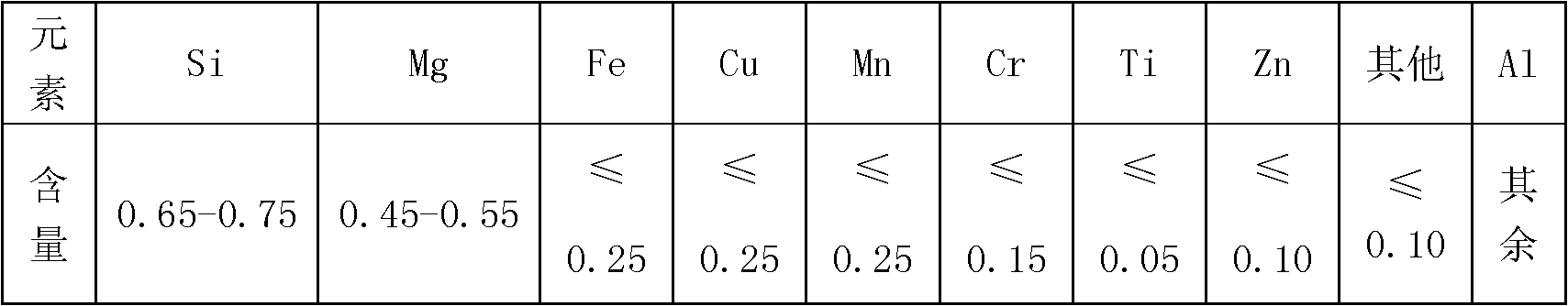

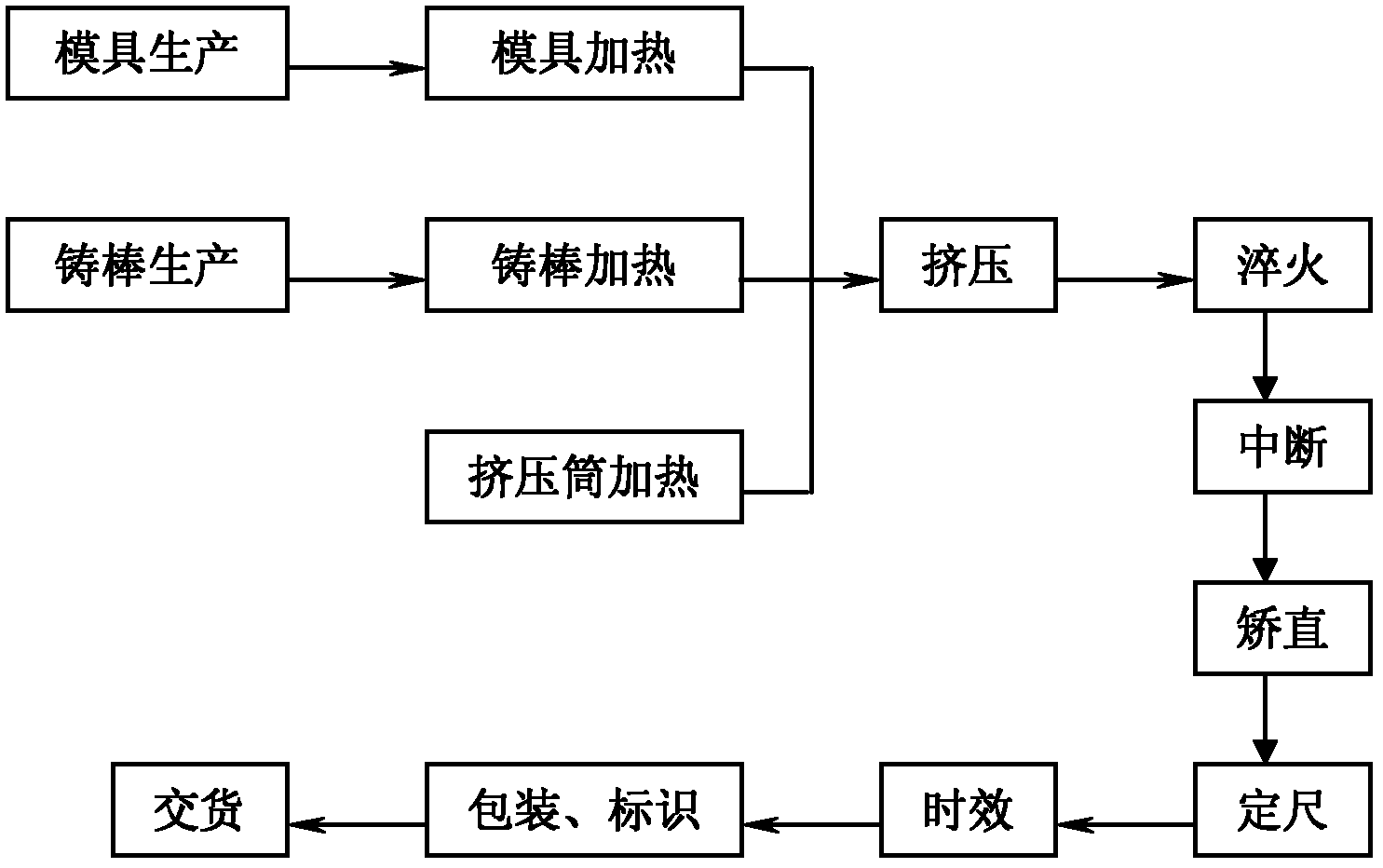

Method for manufacturing aluminum alloy hollow section for sedan bumper

The invention discloses a method for manufacturing an aluminum alloy hollow section for a sedan bumper, relates to a method for manufacturing an aluminum alloy hollow section, and aims to solve the problem that domestic limousine bumpers are low in tensile strength and non-proportional extension strength and dependent on import. The method comprises the following steps of: 1, preparing alloy melt; 2, casting an alloy cast rod; 3, cutting the cast rod off; 4, turning the cast rod to remove oxide; 5, performing homogenizing annealing; 6, heating a cast ingot; 7, extruding; 8, pre-straightening;9, quenching; 10, straightening; 11, aging; and 12, cutting according to length to obtain the aluminum alloy hollow section for an automobile bumper. The straightness and size of the hollow section prepared by the method completely meet the standards of imported bumpers, and the hollow section has high comprehensive mechanical properties. The method can be used for processing and manufacturing sections for limousine bumpers.

Owner:NORTHEAST LIGHT ALLOY CO LTD

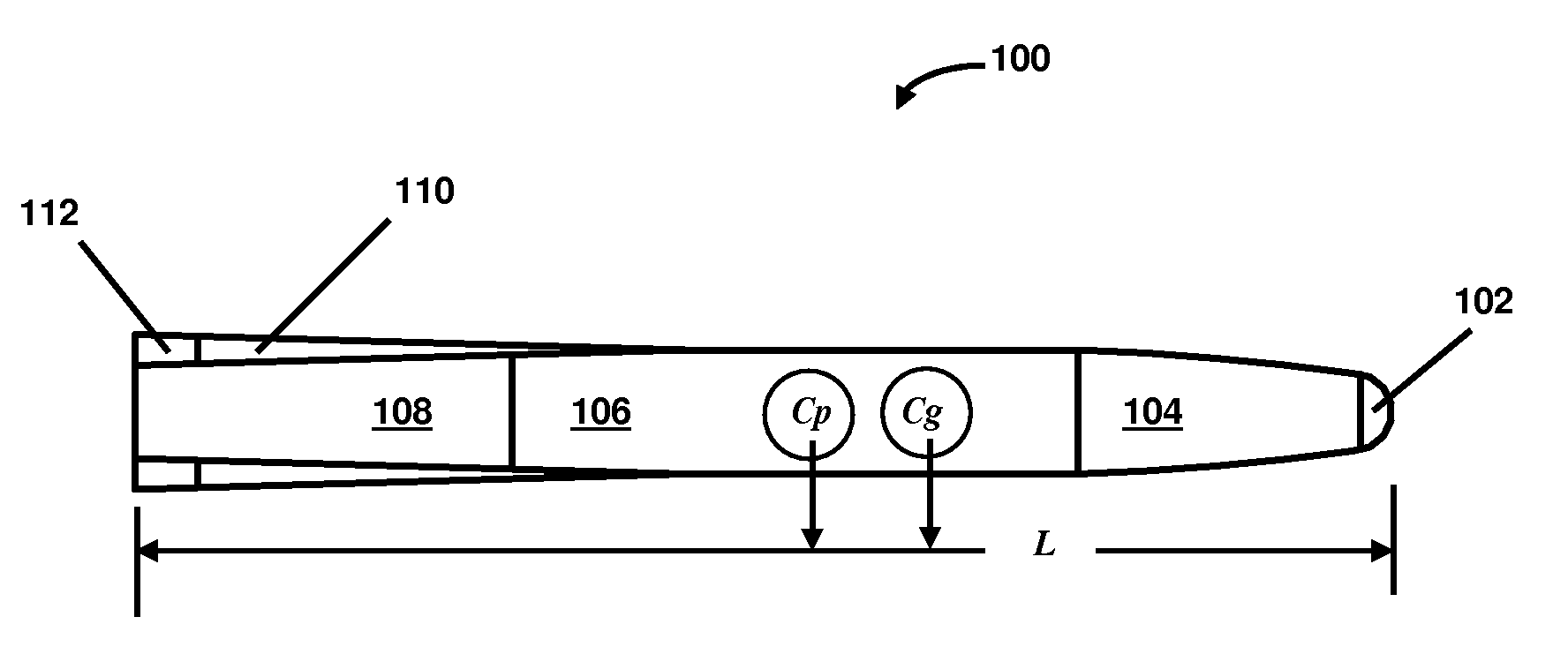

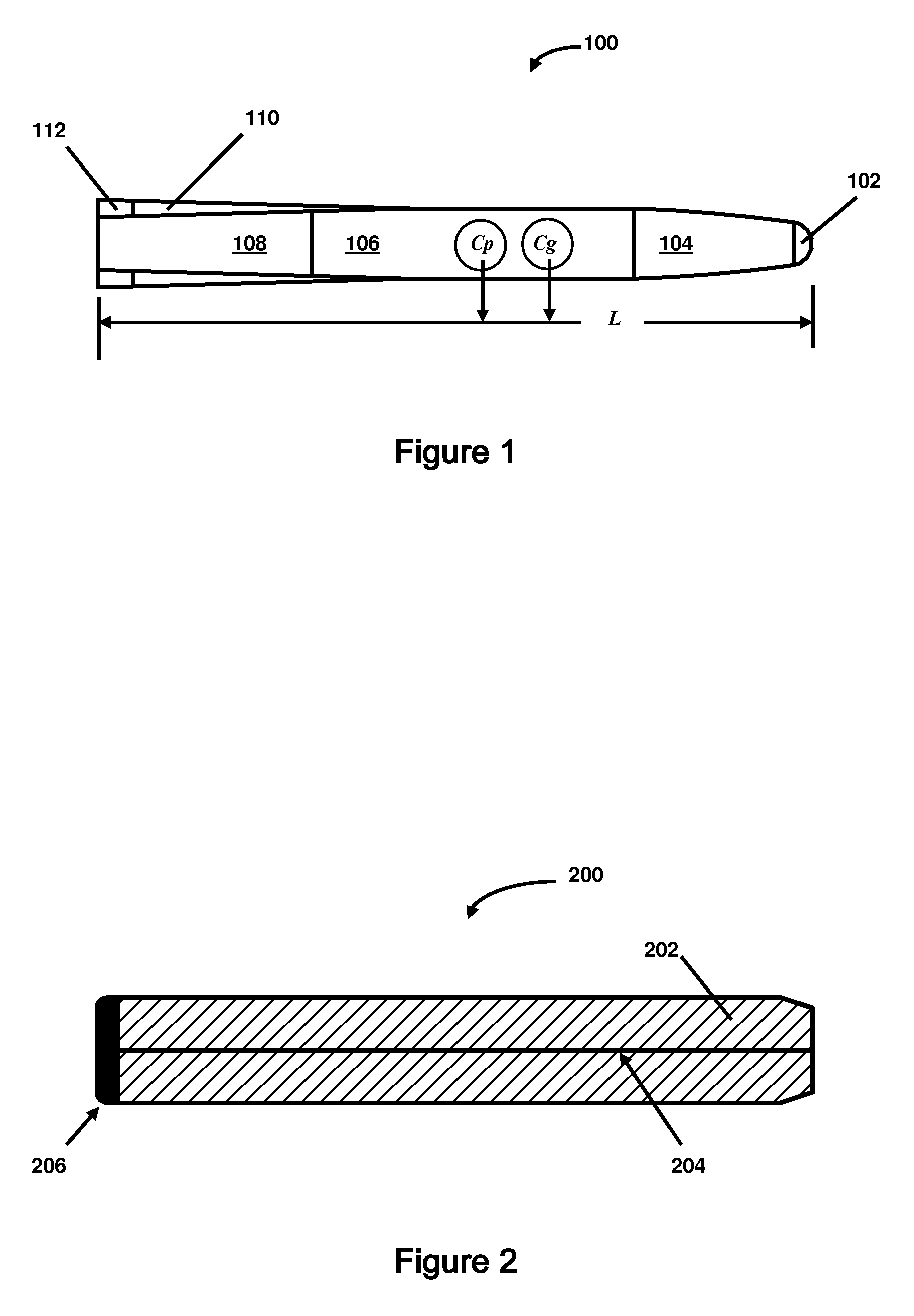

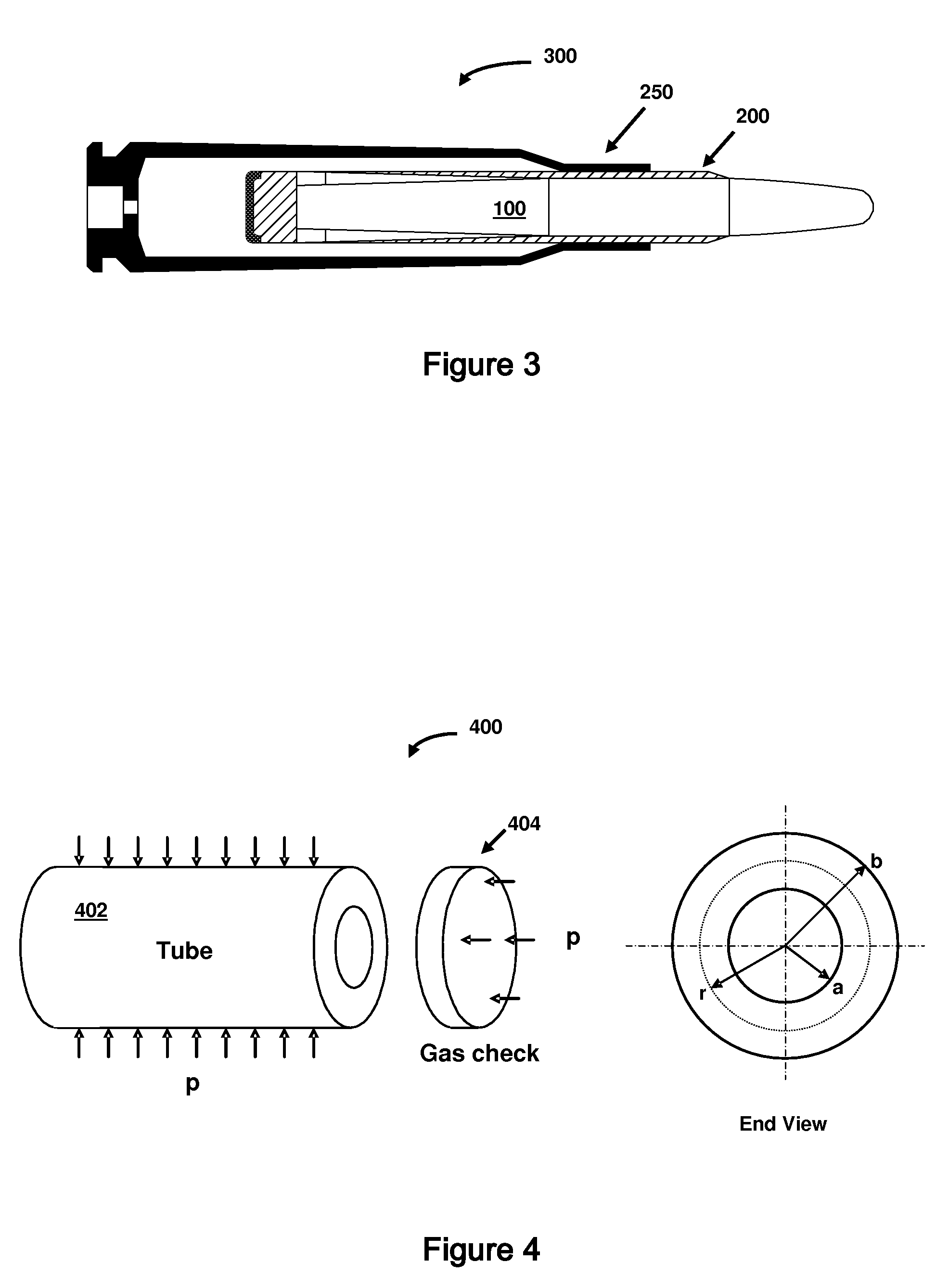

Small caliber guided projectile

A non-spinning projectile that is self-guided to a laser designated target and is configured to be fired from a small caliber smooth bore gun barrel has an optical sensor mounted in the nose of the projectile, a counterbalancing mass portion near the fore end of the projectile and a hollow tapered body mounted aft of the counterbalancing mass. Stabilizing strakes are mounted to and extend outward from the tapered body with control fins located at the aft end of the strakes. Guidance and control electronics and electromagnetic actuators for operating the control fins are located within the tapered body section. Output from the optical sensor is processed by the guidance and control electronics to produce command signals for the electromagnetic actuators. A guidance control algorithm incorporating non-proportional, “bang-bang” control is used to steer the projectile to the target.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

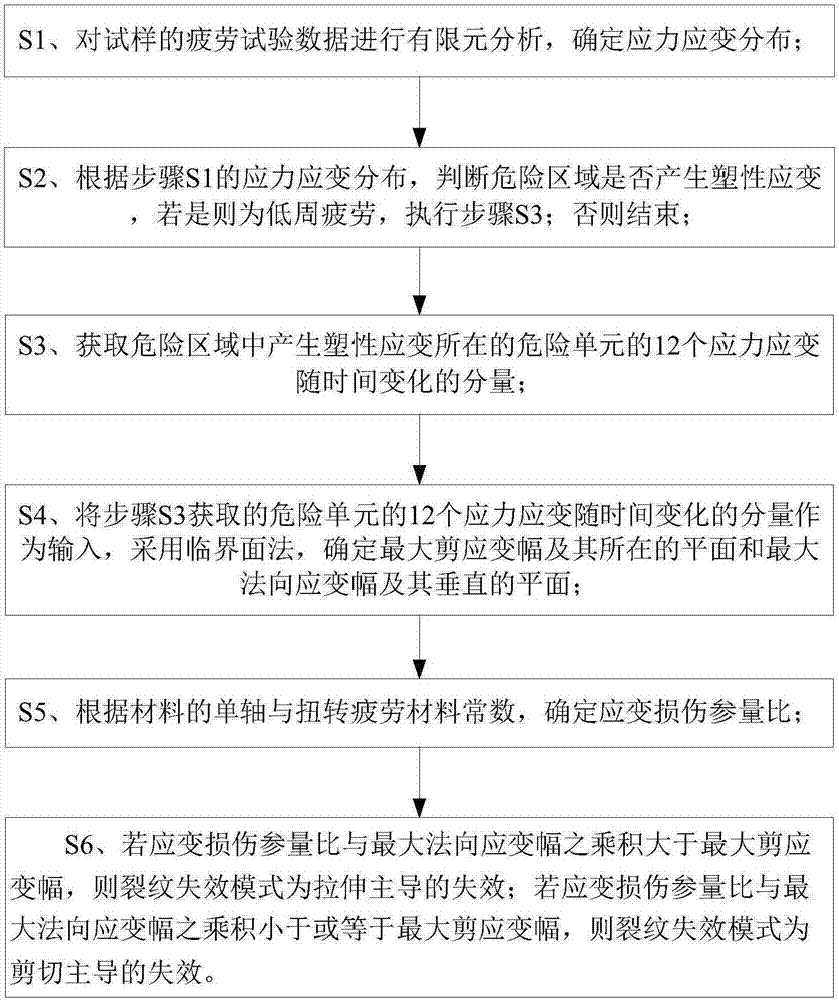

Crack failure mode determination method and fatigue life prediction method based on crack failure mode determination method

ActiveCN107389471AControlling the Problem of Excessive Prediction ErrorsSymmetric fatigue lifeMaterial strength using steady shearing forcesFatigue damageMean stress

The invention discloses a crack failure mode determination method and a fatigue life prediction method based on the crack failure mode determination method and is applied to the field of reliability. A crack failure mode of a part is determined based on contribution made by normal strain and shear strain to fatigue damage, energy and critical plane approach are combined, fatigue life prediction models in two modes such as a stretching dominated failure mode and a shearing dominated failure mode are established, and the problem that the prediction error is too large due to the material dispersion property can be effectively solved, so that the prediction life does not far deviate from experiment life; and moreover, a critical plane stress-strain curve relation and a related material constant are introduced into the model establishing process, the influence on mean stress can be reflected, and the model is capable of predicting the fatigue life under proportional and non-proportional symmetrical or asymmetrical loads.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for manufacturing aluminum alloy section material for floor of rail transport car body

The invention discloses a method for manufacturing an aluminum alloy section material for a floor of a rail transport car body. The method comprises the following steps of: (a) preparing raw materials of cast rod; (b) smelting a cast rod; (c) casting the cast rod; (d) performing homogenization treatment; (e) performing surface treatment of the cast rod, (f) heating the cast rod, (g) heating a mould, (h) extruding, (i) performing on-line quenching, and (j) aging to obtain the section material. The method can strictly control various parameters in the process steps, endows the aluminum alloy section material with higher cross-section and better overall performance, meets the requirements for application in aluminum alloy section material car bodies, reduces the manufacturing cost and weight of the car body, and eliminates the problems such as heavy weight of steel structure car body, difficulty in repair and maintenance and high cost of auxiliary equipment. Besides, the energy consumption is 1 / 5 that of stainless steel, the water consumption is 1 / 5 that of stainless steel carriages, the weight of carriage is reduced by 1 / 3, the performance of product is excellent, the proof strength (non-proportional extension strength) can reach more than 255 MPa, the tensile strength can reach more than 300 MPa, and the percentage elongation after fracture can reach more than 11%.

Owner:CHINA ZHONGWANG

Multi-axis fatigue life prediction method based on critical strain damage parameter

ActiveCN107506535AFit closelyDifferential Failure ContributionMachine bearings testingDesign optimisation/simulationEngineeringMulti axis

The invention discloses a multi-axis fatigue life prediction method based on a critical strain damage parameter, and is applied to the field of multi-axis fatigue life prediction. On the basis of shearing strain damage and normal strain damage on a maximum damage parameter plane near a maximum shearing strain plane, different shearing strain correction factors and normal strain correction factors are adopted to obtain a life prediction model; and planes near the shearing strain plane are taken as candidate critical planes, and a plane where maximum damage is positioned is selected as the critical plane. By use of the method, a crack occurrence direction can be favorably matched; and in addition, a multi-axis fatigue life prediction model disclosed by the invention does not need additional material constants, fatigue test data does not need to be fit, and a corresponding program is directly adopted to calculate the fatigue life so as to be simple and quick. Meanwhile, the life prediction model which is put forward by the invention can represent an average strain influence, can adapt to various complex path loads, also can reflect non-proportional loading additional hardening, exhibits high adaptation for different materials and is high in life prediction accuracy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

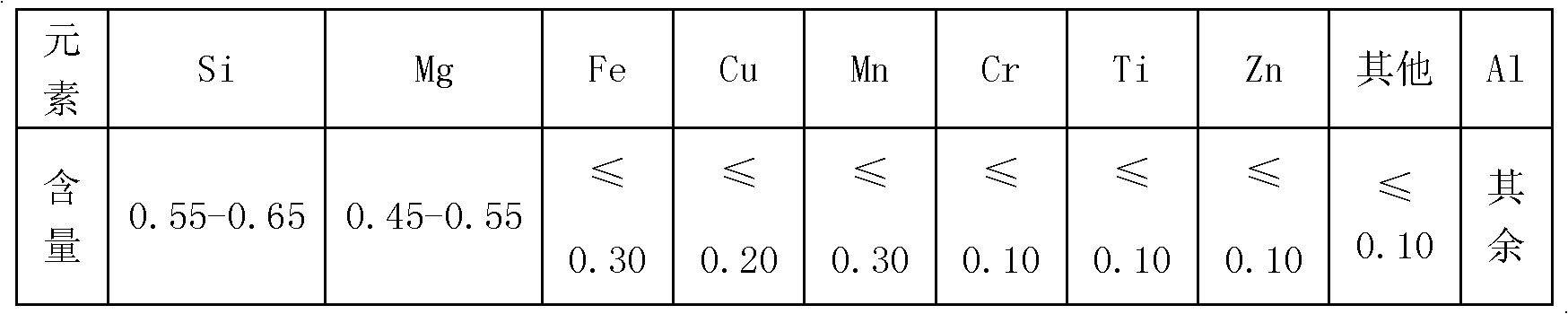

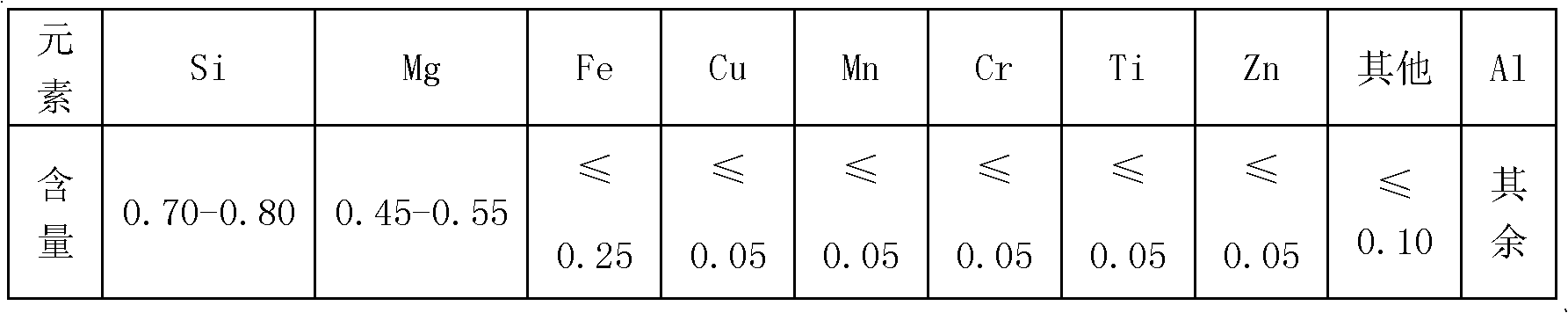

Manufacture method of aluminum alloy sectional material for building formwork

ActiveCN105506407AMeet the comprehensive performance requirementsImprove performanceForming/stuttering elementsManufacturing technologyUltimate tensile strength

The invention discloses a manufacture method of an aluminum alloy sectional material for a building formwork and belongs to the technical field of aluminum alloy sectional material manufacture. The objective of the invention is to solve the problems that the aluminum alloy sectional material for the building formwork, produced by the existing technology, is low in tensile strength, low in specified non-proportional extension strength, low in percentage elongation after fracture and low in corrosion performance. The method comprises the following steps of smelting, standing, casting, cutting, annealing, heating, extruding, quenching, aging and coating. Parameters in the technical step process are strictly controlled, and the aluminum alloy sectional material is enabled to have bigger cross section and better comprehensive performance, so that the use requirements on the building formwork are met, and the manufacture cost is reduced. Besides, through optimizing alloy components, and after extrusion, adopting an optimized aging technology and brushing a formwork protecting agent, the requirements of users on the comprehensive performance of the aluminum alloy sectional material are met, and the prepared aluminum alloy sectional material has the advantages of being high in strength, low in inclusion content, high in surface quality and outstanding in comprehensive mechanical property. The manufacture method is used for preparing the aluminum alloy sectional material for the building formwork.

Owner:CHINA ZHONGWANG

Aluminium alloy with high strength and excellent cutting property and preparation method thereof

The invention relates to an aluminium alloy with high strength and excellent cutting property and a preparation method thereof, and belongs to the technical field of alloys. The product, namely the aluminium alloy with high strength and excellent cutting property, is obtained through slagging-off, alloy preparing, refining, standing, casting, homogenizing, extruding and carrying out artificial aging after melting an aluminium ingot. According to the invention, by means of proportioning alloy composition, controlling a production process and the like, the alloy bar can achieve the tensile strength of greater than or equal to 280MPa, the regulated non-proportional extension strength of greater than or equal to 250MPa, the elongation A of greater than or equal to 10 percent and the HV hardness of 98 to 108; the cutting property of the material is greatly improved.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Method for producing aluminum alloy bar material

InactiveCN103160720APerformance is not affectedMeet the comprehensive performance requirementsNon proportionalOxide

The invention relates to a method for producing an aluminum alloy bar material, and relates to the method for preparing the bar material. The method provided by the invention solves the technical problem that the strength and conductivity of the alloy bar materials prepared by the current methods can not be satisfied. The production method comprises the following steps: 1)weighting; 2) melting; 3) casting; 4) cutting, removing oxide skin; 5) performing uniformization annealing; 6) heating and extruding; 7) performing solid solution treatment; 8) stretching and straightening; 9) performing roll straightening; and 10) performing aging treatment. The tensile strength of the prepared aluminum alloy bar material is no less than 650N / mm<2>, the non-proportional extension strength is no less than 610N / mm<2>, the heat conductivity is more than 120W / m.K at 25 DEG C, and the conductivity is greater than 1.67*107S / m at 25 DEG C. The prepared aluminum alloy bar material is used for high and new technology field.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method of superplastic aluminum alloy plates for track traffic

InactiveCN101736183AGood mechanical propertiesGood forming performance at high temperatureMetal rolling arrangementsIngotUltimate tensile strength

A preparation method of superplastic aluminum alloy plates for track traffic relates to the manufacturing method of superplastic aluminum alloy plates. The method solves the problems of bad superplastic formability and bad mechanical properties at high temperature when the existing common aluminum alloy is prepared into plates. The method comprises the steps as follows: (1) smelting and casting alloy ingots; (2) homogenization annealing; (3) hot rolling; (4) intermediate annealing; and (5) secondary rolling the finished product thickness, and then the superplastic aluminum alloy plates for track traffic are obtained after oil scouring and finishing. The plates prepared by the method have good mechanical properties in which the tensile strength is not less than 458N / mm<2>, the non-proportional extension strength is not less than 405N / mm<2> and the elongation percentage after fracture is not less than 6.3%; the plates have good formability performance, the transverse elongation percentage is more than 200% and the longitudinal elongation percentage is more than 250% when the temperature is 500 DEG C; and the surface quality is good after hot forming.

Owner:NORTHEAST LIGHT ALLOY CO LTD

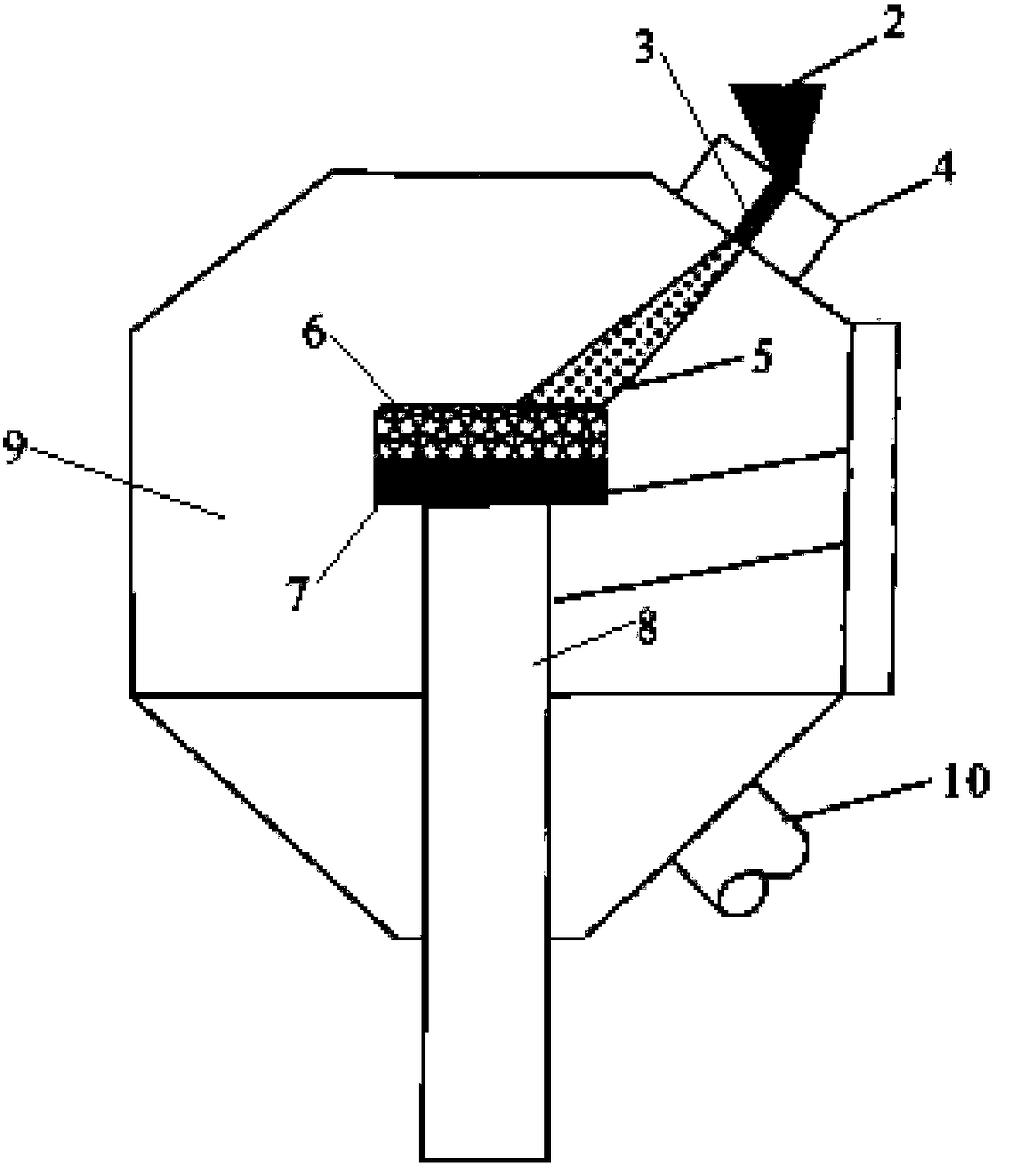

Stir-welding head for aluminum alloy thick plate welding and welding method thereof

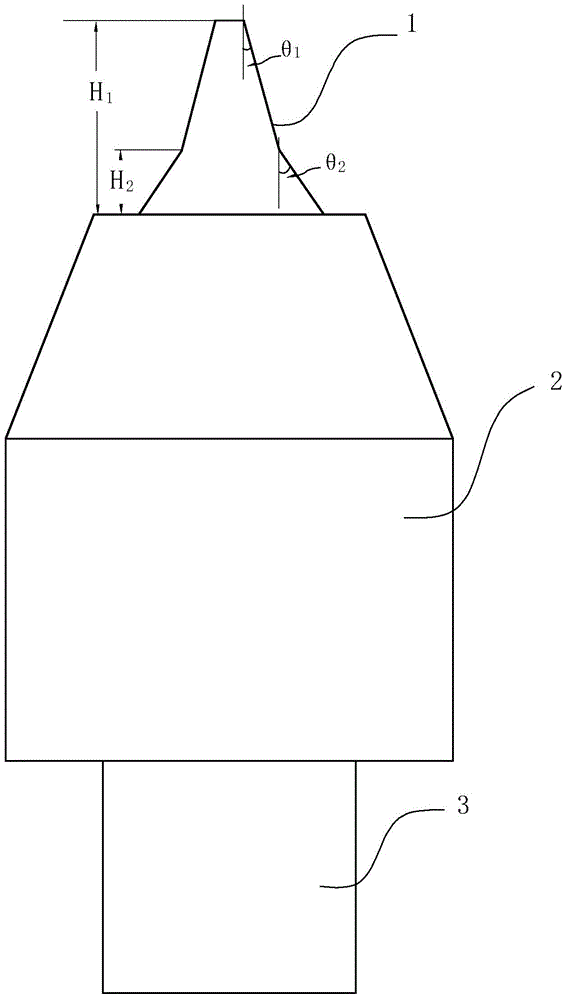

ActiveCN104646820AExtended service lifeReduce the chance of breakageNon-electric welding apparatusThick plateNitrogen

The invention discloses a stir-welding head for aluminum alloy thick plate welding and a welding method thereof. The stir-welding head for the aluminum alloy thick plate welding comprises a stir-welding needle, a shaft shoulder and a clamping end; the stir-welding needle is installed at the center of the upper end of the shaft shoulder; the stir-welding head is the integral structure formed by processing austenitic high nitrogen steel in which the nitrogen content is 0.4%-0.7%, and the root of the connection between the stir-welding needle and the shaft shoulder presents the non-proportional overstriking design; and the double-faced friction stir welding method is used for welding. The stir-welding head is the integral structure formed by processing the austenitic high nitrogen steel, and the stir-welding needle connected with the shaft shoulder uses the non-proportional overstriking design, so the intensity of the stir-welding head is greatly improved, the probability of stir-welding needle fracture is reduced, and the service life is prolonged; and the double-faced friction stir welding method is used for welding, the tensile strength of a welded joint is improved more than 1% compared with the single-faced welding, the welded joint has not the defects, such as welding bubble, crack, loose and lack of fusion, the internal quality of the welded joint is up to the level 1, and the mechanical property of the welded joint is improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

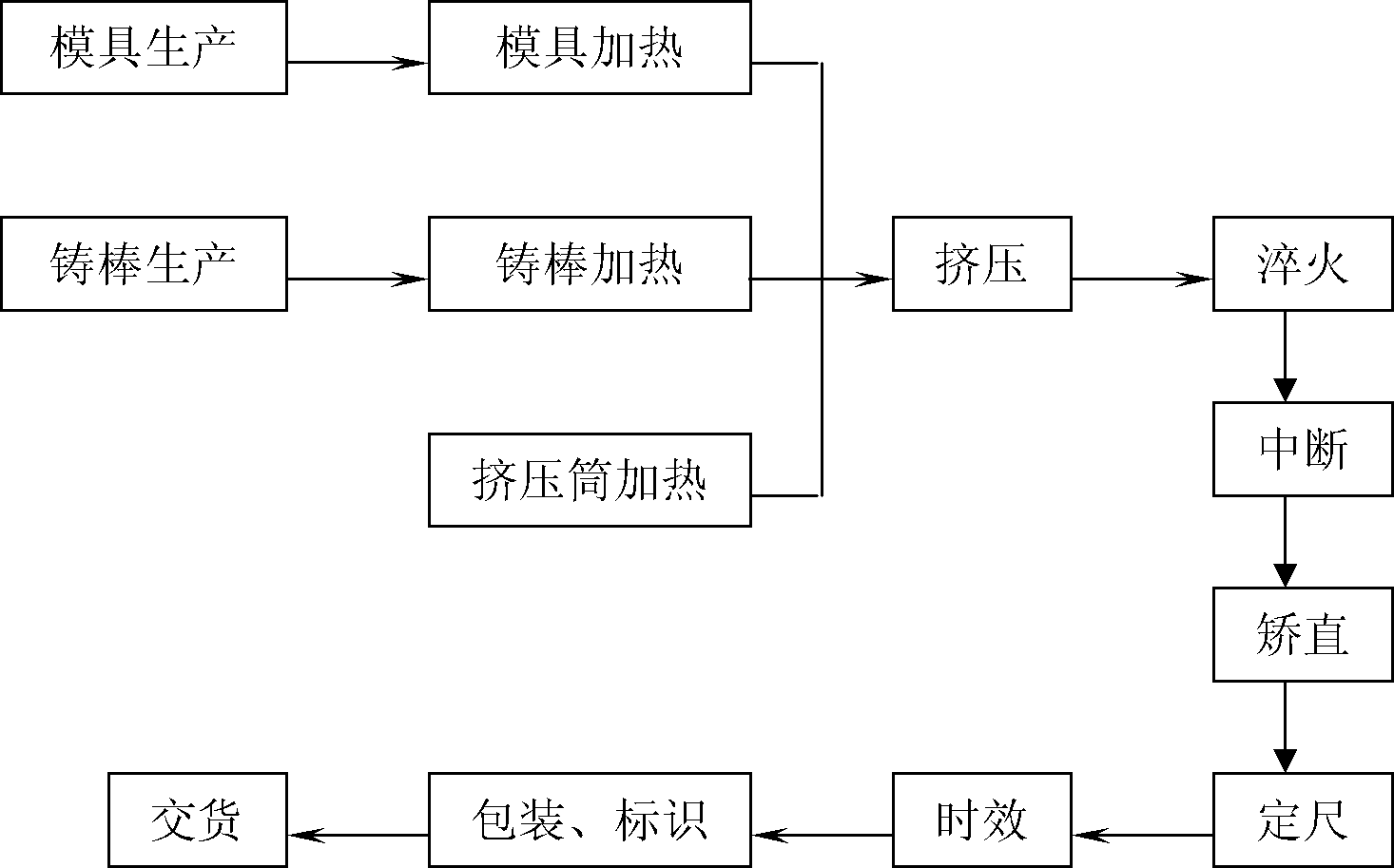

Method for manufacturing aluminum alloy section for top plate of rail transit vehicle body

The invention discloses a method for manufacturing an aluminum alloy section for a top plate of a rail transit vehicle body. The method comprises the following steps of: (a) preparing materials for a cast rod; (b) smelting the cast rod; (c) casting the cast rod; (d) performing homogenization treatment; (e) performing surface treatment on the cast rod; (f) heating the cast rod; (g) heating a mold; (h) performing extrusion production; (i) quenching on line; and (j) aging the section. Each parameter in the process is strictly controlled; the aluminum section can achieve a larger cross section and higher comprehensive properties, the using requirement of an aluminum section vehicle body is met, the manufacturing cost and self weight of the vehicle body are reduced, and the defects of large mass, high maintenance difficulty, high auxiliary equipment cost and the like of a steel structure vehicle body are overcome; energy consumption is only 1 / 5 of that of stainless steel, water consumption is only 1 / 5 of that of a stainless steel carriage, and the weight of a carriage is reduced by 1 / 3; and the product has superior properties, wherein stipulated non-proportional extension strength is more than 245MPa, tensile strength is more than 290MPa, and elongation after fracture is over 10 percent.

Owner:CHINA ZHONGWANG

Manufacturing method of aluminum alloy rivet wire for aerospace

The invention relates to a manufacturing method of an aluminum alloy rivet wire, in particular to a manufacturing method of an aluminum alloy rivet wire for aerospace, and aims at solving the problems that an existing rivet wire is low in tensile strength, regulated non-proportional extension strength, post-fracture percentage elongation and anti-shearing strength. The method comprises the steps that firstly, an aluminum alloy solution is prepared; secondly, an alloy cast bar is cast; thirdly, the cast bar is cut off according to the fixed size; fourthly, the cast bar is turned for descaling; fifthly, homogenizing annealing is carried out on an aluminum alloy ingot; sixthly, the ingot is heated; seventhly, the aluminum alloy wire is formed through extrusion; eighthly, the middle of the wire is annealed; and ninthly, cold-drawing deformation is carried out, and the aluminum alloy rivet wire is manufactured. The tensile strength of an H13 state wire rod of the obtained aluminum alloy rivet wire is not smaller than 205 MPa; the tensile strength of a T4 state wire rod of the aluminum alloy rivet wire is not smaller than 380 MPa, the regulated non-proportional extension strength of the T4 state wire rod of the aluminum alloy rivet wire is not smaller than 220 MPa, the post-fracture percentage elongation of the T4 state wire rod of the aluminum alloy rivet wire is not smaller than 10%, and the anti-shearing strength of the T4 state wire rod of the aluminum alloy rivet wire is not smaller than 225 MPa. The method is applied to machining and manufacturing the aluminum alloy rivet wire for aerospace.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for manufacturing aluminum alloy profiles for side walls of rail transit vehicles

The invention discloses a method for manufacturing aluminum alloy profiles for side walls of rail transit vehicles, which includes steps of a, billet batching, b, billet smelting, c, billet casting, d, homogenizing, e, billet surface treatment, f, billet heating, g, mould heating, h, extruding, i, online quenching, and j, profile aging. Parameters of the processing steps are controlled well. Larger sections and better comprehensive properties of aluminum profiles can be achieved, requirements of the aluminum profiles on vehicle use are met, vehicle manufacturing cost is lowered, vehicle weight can be reduced, and the shortages of heavy weight, high maintenance difficulty, high auxiliary equipment cost and the like of the steel-structured vehicles are overcome. In addition, energy consumption in manufacture by the method is only one fifth of that in stainless manufacture, water consumption is only one fifth of that in manufacture of stainless steel cars, and weight of the cars is reduced by one third. Proof strength of non-proportional extension can reach more than 255MPa, tensile strength can reach more than 300MPa, and elongation after facture can reach more than 11%.

Owner:CHINA ZHONGWANG

High-strength coarse-grain-ring-free aluminum alloy bar for automotive control arm and preparation method of aluminum alloy bar

The invention discloses a high-strength coarse-grain-ring-free aluminum alloy bar for an automotive control arm. The high-strength coarse-grain-ring-free aluminum alloy bar for the automotive control arm comprises the following components: 0.9-1.2% of Si, 0.3% of Fe, 0.15-0.2% of Cu, 0.4-0.6% of Mn, 0.7% of Mg, 0.17-0.25% of Cr, 0.15% of Zn, 0.02-0.04% of Zr and the balance of Al. By fusing, drossing, alloy preparing, refining, standing, casting, homogenizing and extruding, the finished bar is obtained finally. When the high-strength coarse-grain-ring-free aluminum alloy bar for the automotive control arm is in an extruded state, coarse grain rings do not exist, after forging and T6 heat treatment, the grain size in the center of a forge piece reaches level-one grain (inspection is carried out according to the standard of GB / T 3246.2, and the average area of the grain is smaller than or equal to 0.026 mm<2>), a coarse grain ring on the outer ring of the force piece is smaller than 2 mm, after forging and heat treatment, grains cannot be expanded easily, the mechanical property of a material can be as follows: the tensile strength is greater than or equal to 385 Mpa, the specified non-proportional extension strength is greater than or equal to 365 Mpa, and the elongation A is greater than or equal to 11%. Requirements on strength of a high-end automotive aluminum alloy steering control arm material are met.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

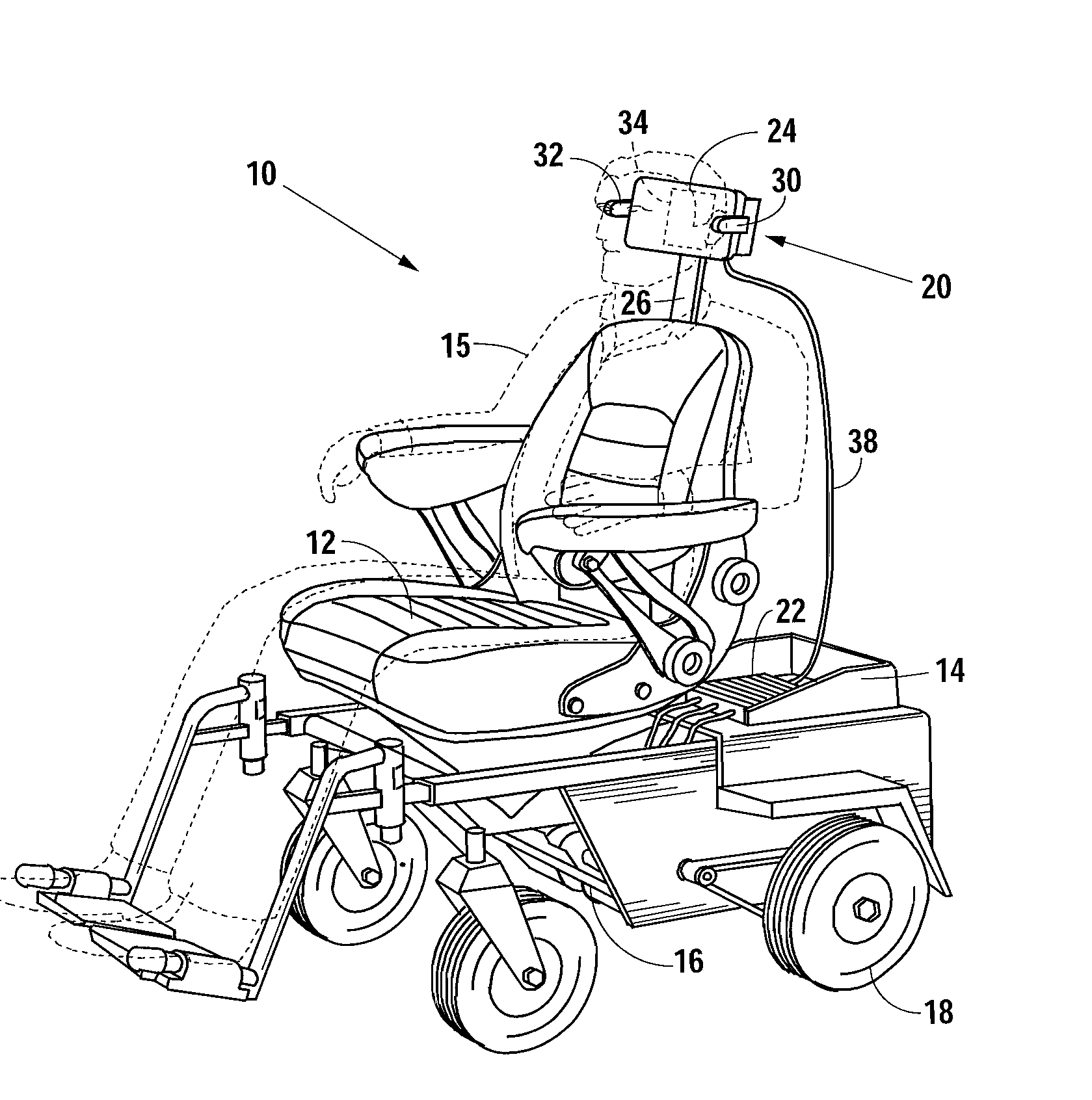

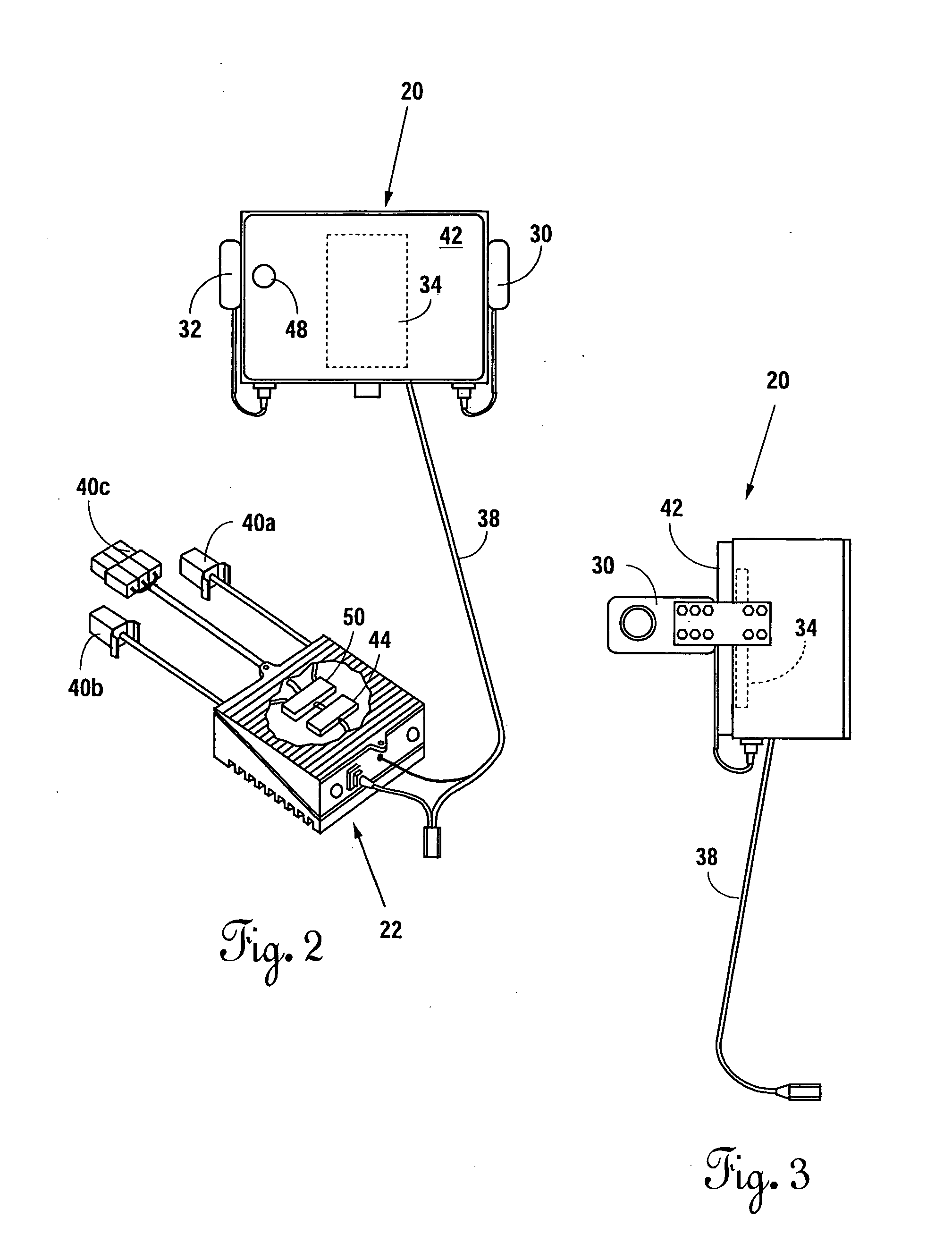

Method and apparatus for electronically controlling a motorized device

InactiveUS20080294300A1Wheelchairs/patient conveyanceInvalid friendly devicesProximity sensorElectronic controller

An electronic controller for a motorized device includes a signal generator generating an output signal to the motorized device. A non-proportional proximity sensor communicates with the signal generator. A proportional proximity sensor communicates with the signal generator. The output signal is determined as a function of respective signals communicated from the proximity sensors to the signal generator. A direction and speed of the motorized device is determined as a function of the output signal.

Owner:ASHMORE C RUCKER +1

A multiaxial fatigue life prediction method

InactiveCN108984926AGood reflection of the synergistic effect of fatigue damageApplicable Life PredictionDesign optimisation/simulationSpecial data processing applicationsFatigue damageStress factor

The invention provides a multiaxial fatigue life prediction method, which relates to the field of fatigue strength design. Based on the stress-strain state on the critical surface of the material, a stress factor which can reflect both multiaxiality and non-proportional additional hardening is provided. By introducing this parameter and considering the synergistic effect of normal stress and shearstress on fatigue crack initiation on critical plane, a new fatigue damage parameter is obtained. A new multiaxial fatigue life prediction model is established by utilizing the parameter and combining with a modified Manson-Coffin equation. This model is suitable for uniaxial loading, proportional loading, non-proportional loading and so on.

Owner:HUNAN UNIV

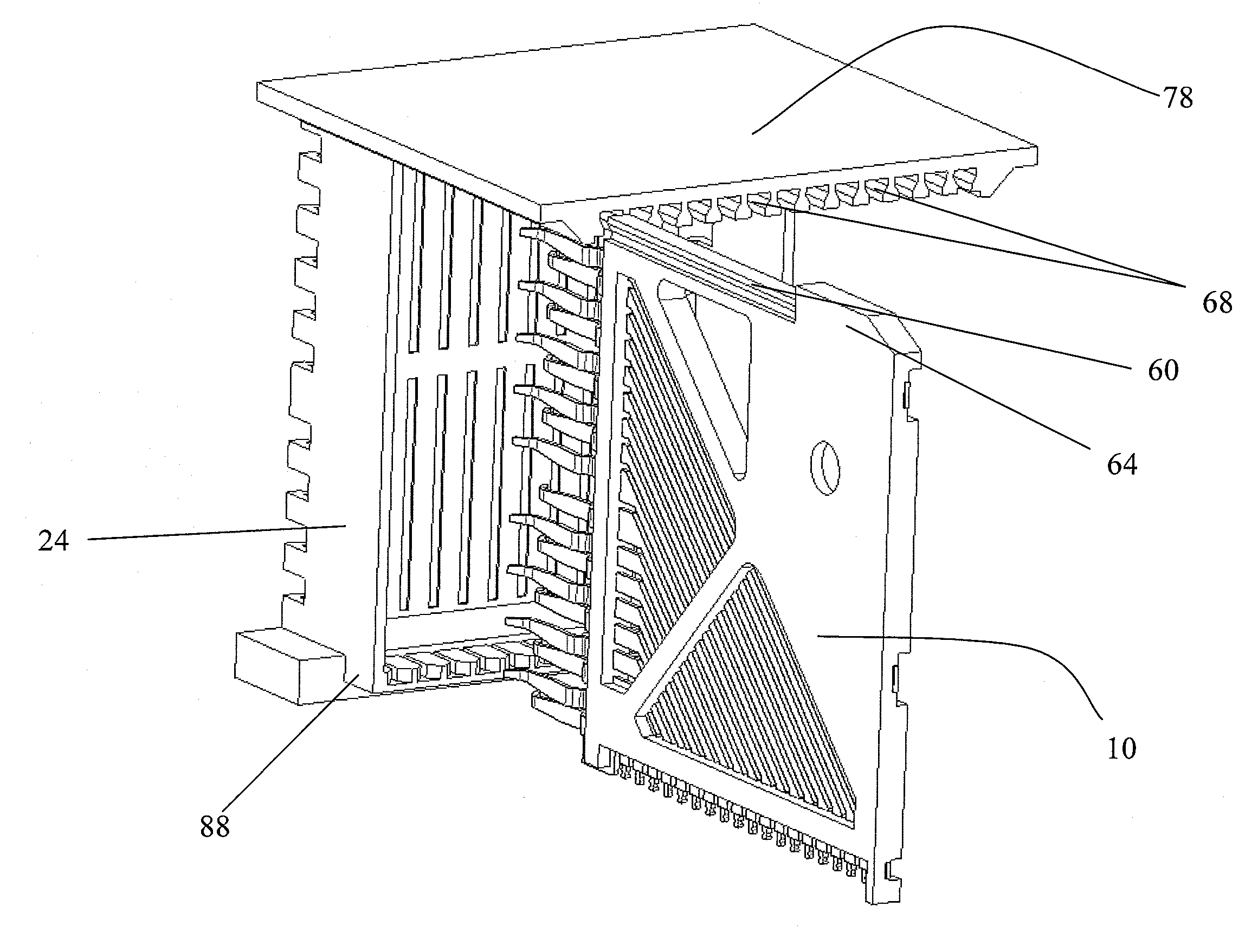

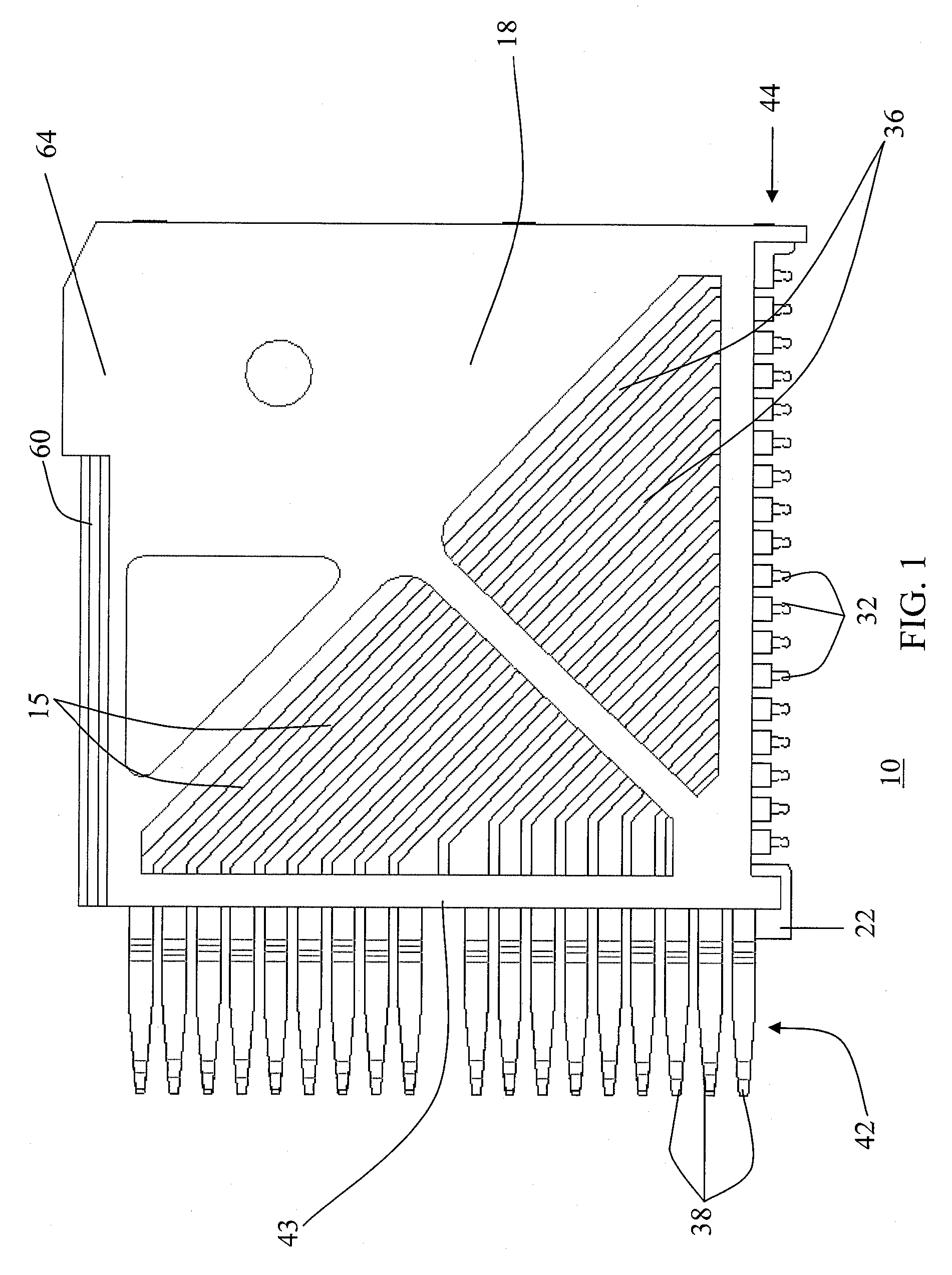

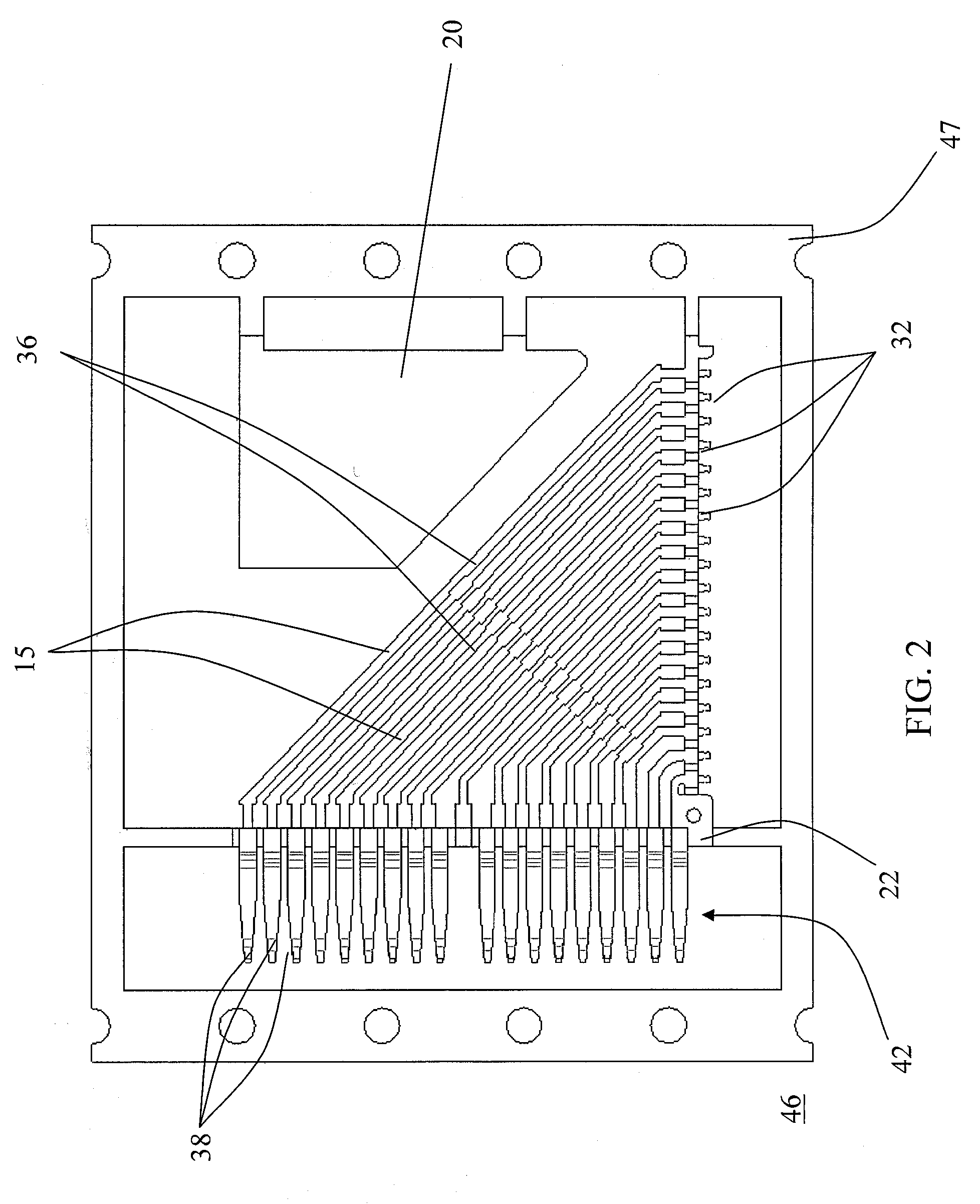

Insert molded leadframe assembly

InactiveUS20080203547A1Uniform weightContact member manufacturingContact member assembly/disassemblyElectrical connectorLead frame

An insert molded leadframe assembly (IMLA) for an electrical connector is disclosed. The IMLA may include an array of electrically conductive contacts, a dielectric leadframe housing overmolded onto the array of contacts, and a mass disposed within the leadframe housing. The additional mass may shift the IMLA's center of gravity, thereby providing a counterbalance to a non-proportional ball-grid array connector.

Owner:FCI AMERICAS TECH LLC

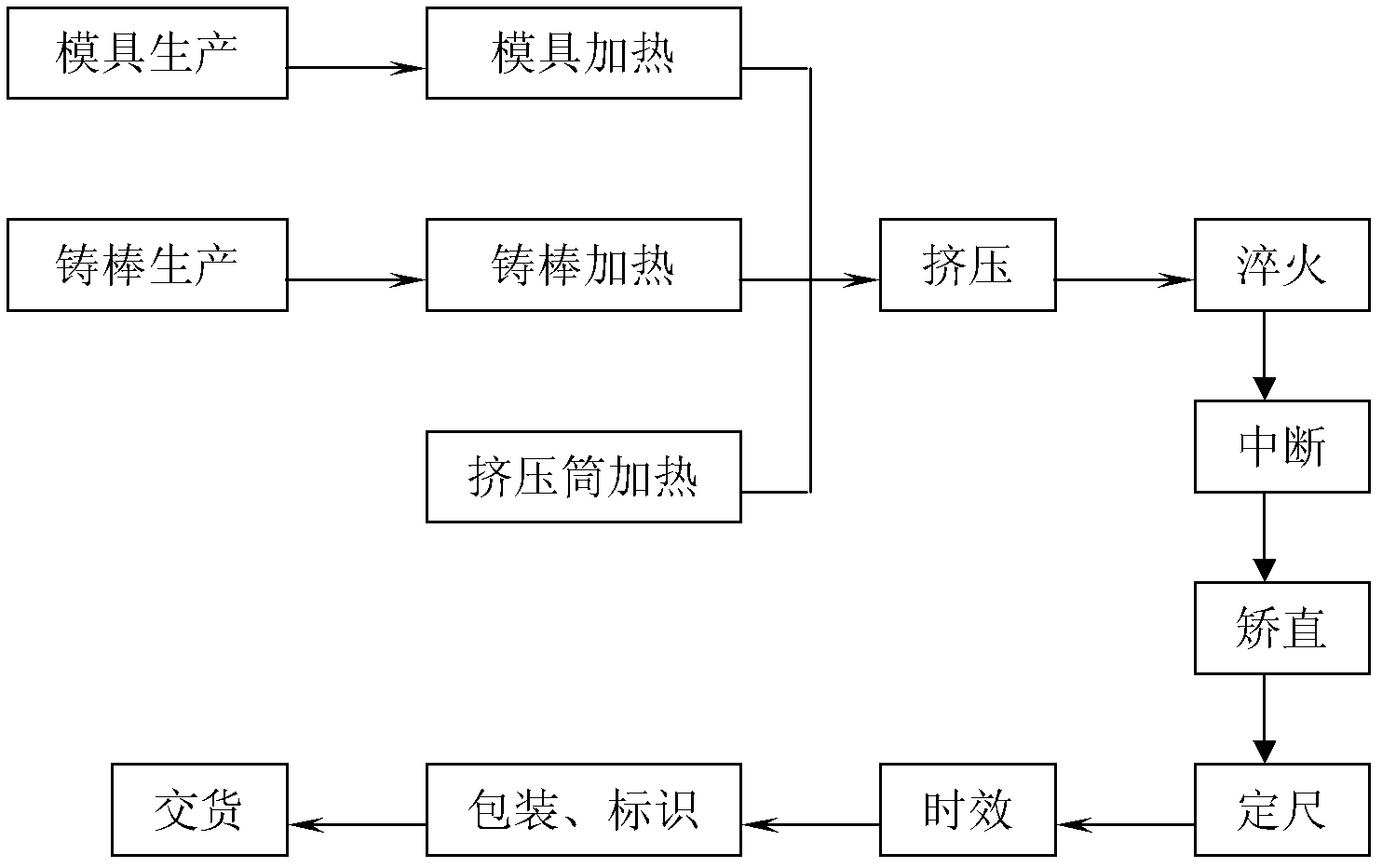

Extrusion processing technology of cylinder block aluminum alloy section

The invention discloses an extrusion processing technology of a cylinder block aluminum alloy section. The technology comprises the steps of: a. casting rod batching, b. casting rod melting, c. casting rod casting, d. homogenization treatment, e. casting rod surface treatment, f. casting rod heating, g. die heating, h. extrusion production, i. on-line quenching, and j. section aging. By strictly controlling all parameters of the technological steps, the technology can manufacture a high-quality aluminum alloy cylinder block section, which has superior performance, non-proportional extension strength up to over 245MPa, tensile strength up to over 290MPa, and elongation after fracture up to over 10%. The employment of an aluminum alloy cylinder block can substantially reduce vehicle weight,and can effective reduce fuel oil consumption as well as improve manipulation performance.

Owner:CHINA ZHONGWANG

Aluminum lithium alloy for spaceflight and method for preparing proximate matter through aluminum lithium alloy

The invention relates to an aluminum lithium alloy for spaceflight and an aluminum lithium alloy proximate matter preparing method, and relates to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method. The aim is to solve the problems that the production difficulty of the aluminum lithium alloy is large, and the aluminum lithium alloy strength is low. The aluminum lithium alloy is composed of Mg, Li, Ti, Zr and Al, the Mg accounts for 5.5%-6.5%, the Li accounts for 2.2%-2.5%, the Ti accounts for 0.03%-0.12%, the Zr accounts for 0.15%-0.20%, the Zr+Ti is smaller than or equal to 0.25%, and the balance is the Al. The method includes the steps of raw material weighing, aluminum alloy molten liquid preparing, refining, spray forming, short bar cutting, blind die extrusion, heat extrusion, quenching, tension leveling and aging treatment. According to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method, through spray forming, the problems that the aluminum lithium alloy production difficulty is large, and the quality is poor are solved, the strength of extension reaches 485 Mpa, the ruled non-proportional extending strength reaches 345 Mpa, the percentage elongation after fracture reaches 10.0%, and blind die extrusion enables a casting ingot to be more compact.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for manufacturing aluminum profiles used for coal cars

InactiveCN102505088AGuaranteed Experimental RequirementsSimplify the assembly processEconomic benefitsUltimate tensile strength

The invention discloses a method for manufacturing aluminum profiles used for coal cars, comprising the following steps of: a, casting bar compounding, b, casting bar smelting, c, casting bar casting, d, homogenization treatment, e, casting bar surface treatment, f, casting bar heating, g, mould heating, h, extrusion production, i, on-line quenching, j, profiles aging, etc., each parameter in each step is strictly controlled; through an experimental test, the performances of the aluminum profiles obtained by the method provided in the invention are as follows: the regulated non-proportional extension strength is above 245MPa; the tensile strength is above 265MPa; and the percentage elongation after fracture is above 9%. When ensuring experiment requirement of the aluminum profiles used for the coal cars, the performances can simplify the process flow for assembling car bodies, improve the production efficiency, shorten the production cycle and reduc ethe production cost; and the method has remarkable economic benefit.

Owner:CHINA ZHONGWANG

Manufacture method of aluminum alloy composite plate for tank body of railway tanker

The invention discloses a manufacture method of an aluminum alloy composite plate for a tank body of a railway tanker, relating to the manufacture of aluminum alloy composite plates and solving the problem of low tensile strength and low non-proportional extension strength of the pure aluminum plate adopted by the tank body of the railway tanker. The method comprises the steps of: 1, preparing analloy melt; 2, casting an alloy ingot; 3, uniformly annealing; 4, cladding; 5, thermally rolling, 6, annealing a finished product; and 7, finishing to obtain the aluminum alloy composite plate for the tank body of the railway tanker. The plate prepared by using the method has the advantages of straightness, uniform color, uniform and stable cladding layer thickness, excellent comprehensive mechanical property and better nitric acid corrosion resistance, wherein the excellent comprehensive mechanical property is shown as follows: the tensile strength is not less than 170N / mm<2>, non-proportional extension strength is not less than 70N / mm<2> and percentage elongation after fracture is not less than 20 percent. The invention can be used for processing and manufacturing the tank body of the railway tanker.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Cap for an electrical connector

ActiveUS20060134944A1Line/current collector detailsCoupling device detailsElectrical connectorBall grid array

An electrical assembly that may include a weighted cap. The weighted cap may provide counterbalancing to a non-proportional ball-grid array connector integrated circuit package for connection with a substrate. The weighted cap provides compensation for variations in the imbalance of the electronic connector package against the substrate.

Owner:FCI AMERICAS TECH LLC

Manufacturing method of aluminum alloy hollow section for aircraft empennage

The manufacturing method of an aluminum alloy hollow section for an aircraft empennage, and relates to a manufacturing method of a hollow section. The method solves the problems that the section for the traditional aircraft empennage has low tensile strength, low non-proportional extension strength and lower safety factor. The method comprises the following steps that according to the proportion of 0.7% to 1.3% by mass of Si, less than or equal to 0.5% by mass of Fe, less than or equal to 0.10% by mass of Cu, 0.40 to 0.8% by mass of Mn, 0.40% to 0.8% by mass of Mg, less than or equal to 0.20% by mass of Zn, less than or equal to 0.20% by mass of Ti, and the balance being Al, aluminum alloy ingots, pure magnesium ingots, aluminum-manganese intermediate alloy and aluminum-silicon intermediate alloy are weighed to be added to a drying furnace to obtain molten aluminum to be cast into ingots; the ingots are subjected to homogenizing annealing; the aluminum alloy ingots are extruded by a special mold and a needlepoint; the front end of the section is penetrated by an iron wire and the section is hung to a quenching furnace to be quenched; and the section is straightened. The method is used for manufacturing the aluminum alloy hollow section for the aircraft empennage.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for manufacturing aluminum alloy section for underframe of rail transit vehicle body

InactiveCN102505102ASimplify the assembly processIncrease productivityProviding materialUltimate tensile strength

The invention discloses a method for manufacturing an aluminum alloy section for an underframe of a rail transit vehicle body. The method comprises the following steps of: a, providing materials of a cast rod; b, melting the cast rod; c, casting the cast rod; d, performing homogenization treatment; e, performing surface treatment of the cast rod; f, heating the cast rod; g, heating a mould; h, performing extrusion production; i, performing online quenching; and j, ageing the section. In the method, parameters in the steps are strictly controlled; larger section and better comprehensive performance of the aluminum section can be obtained; the needs in using the aluminum section vehicle body are met; the manufacturing cost of the vehicle body is lowered, and the weight of the vehicle body is reduced; the shortcomings of large mass, great difficulty in maintenance, expensive auxiliary equipment and the like of a steel-structure vehicle body are eliminated; by adopting the method disclosed by the invention, the energy consumption is just 1 / 5 of that of stainless steel, the water consumption is just 1 / 5 of that of a stainless steel carriage, and the weight of the carriage is reduced by1 / 3; and moreover, the strength at non-proportional extension of the section can reach over 245 MPa, the tensile strength can reach over 290 MPA, and the percentage elongation after fracture can reach over 10%.

Owner:CHINA ZHONGWANG

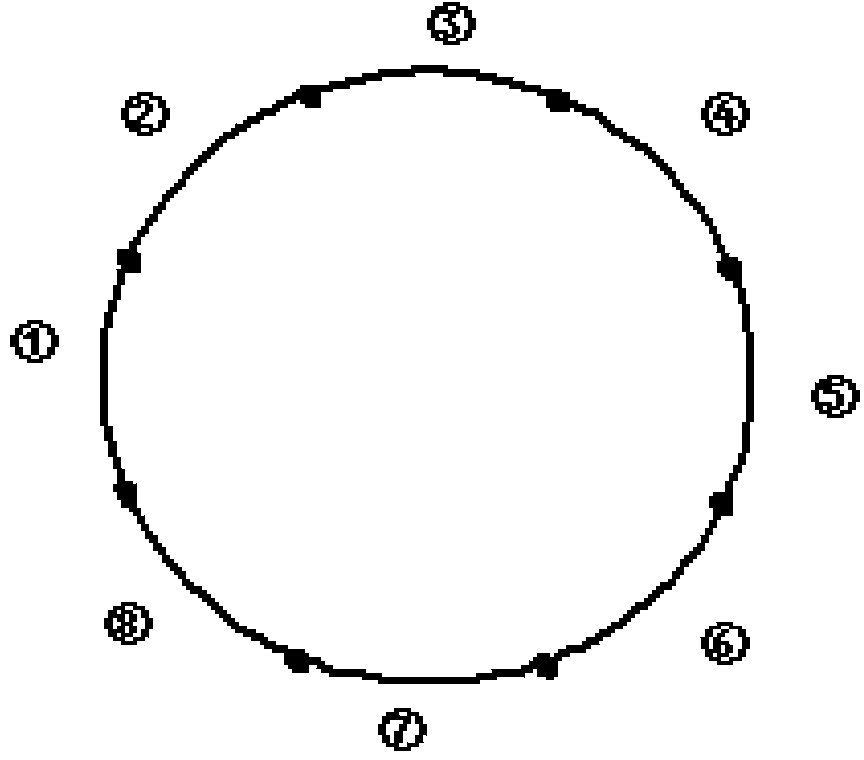

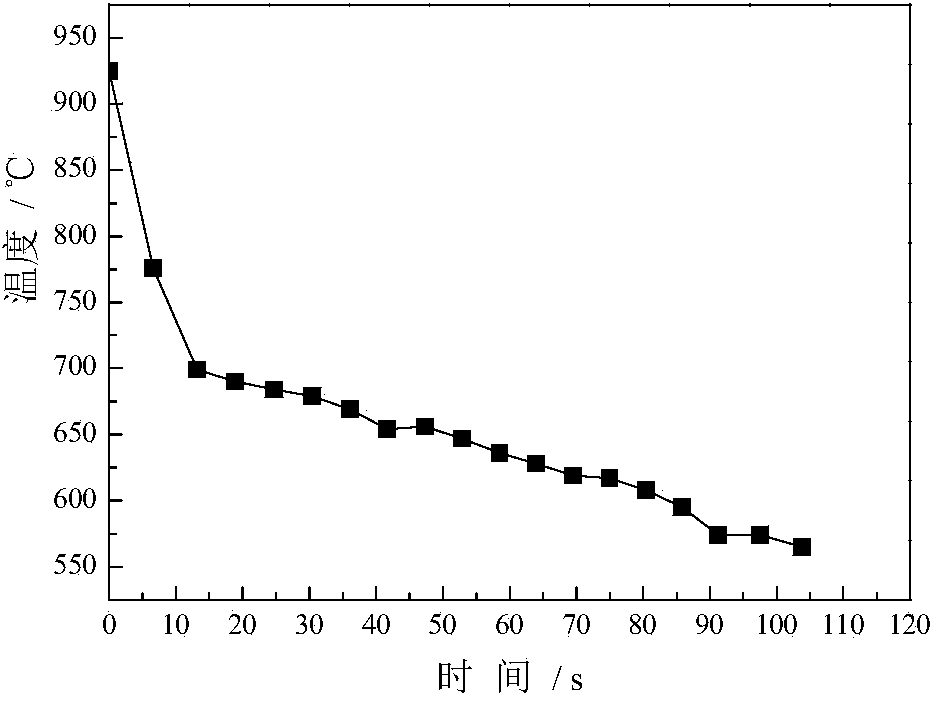

Control method for reducing specified non-proportional extension strength fluctuation

InactiveCN104056862ASmall temperature differenceReduced temperature difference in the same circleRoll mill control devicesMetal rolling arrangementsLap jointTemperature difference

The invention discloses a control method for reducing specified non-proportional extension strength fluctuation, and belongs to the technical field of steel production for anti-seismic coiled reinforced bars. A traditional technology is used for conducting a series of optimization on the microalloy added amount, rolling and the air cooling process through small batch trial manufacture for four times, and the same position (3) of non-lap joint points is selected in stretching sampling positions of different batches as shown in the first picture; according to the test result as shown in the first picture, the Rop0.2 fluctuation is still very large, the Rop0.2 testing range of a phi 8 mm anti-seismic coiled reinforced bar HRB400E on the same day is 394-527 MPa, and the fluctuation range is 133 MPa; after natural aging of seven days, the Rop0.2 range is 396-489 MPa, and the fluctuation range still reaches up to 93 MPa; at last, the bainite content of the center part is controlled to be smaller than or equal to 3%, and the temperature difference of the lap joint and the non-lap joint is smaller than or equal to 15 DEG C. Consequently, it is guaranteed that the same circle Rop0.2 fluctuation of a 400 MPa anti-seismic coiled reinforced bar can be smaller than or equal to 50 MPa, and the same circle Rop0.2 fluctuation of a 500 MPa anti-seismic coiled reinforced bar can be smaller than or equal to 55 MPa.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com