Manufacture method of aluminum alloy sectional material for building formwork

A technology for aluminum alloy profiles and building formwork, which is applied to the on-site preparation of building components, building structure, and construction, etc., can solve the problems of low elongation after fracture and corrosion resistance, and achieve excellent comprehensive mechanical properties, good surface quality, Good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

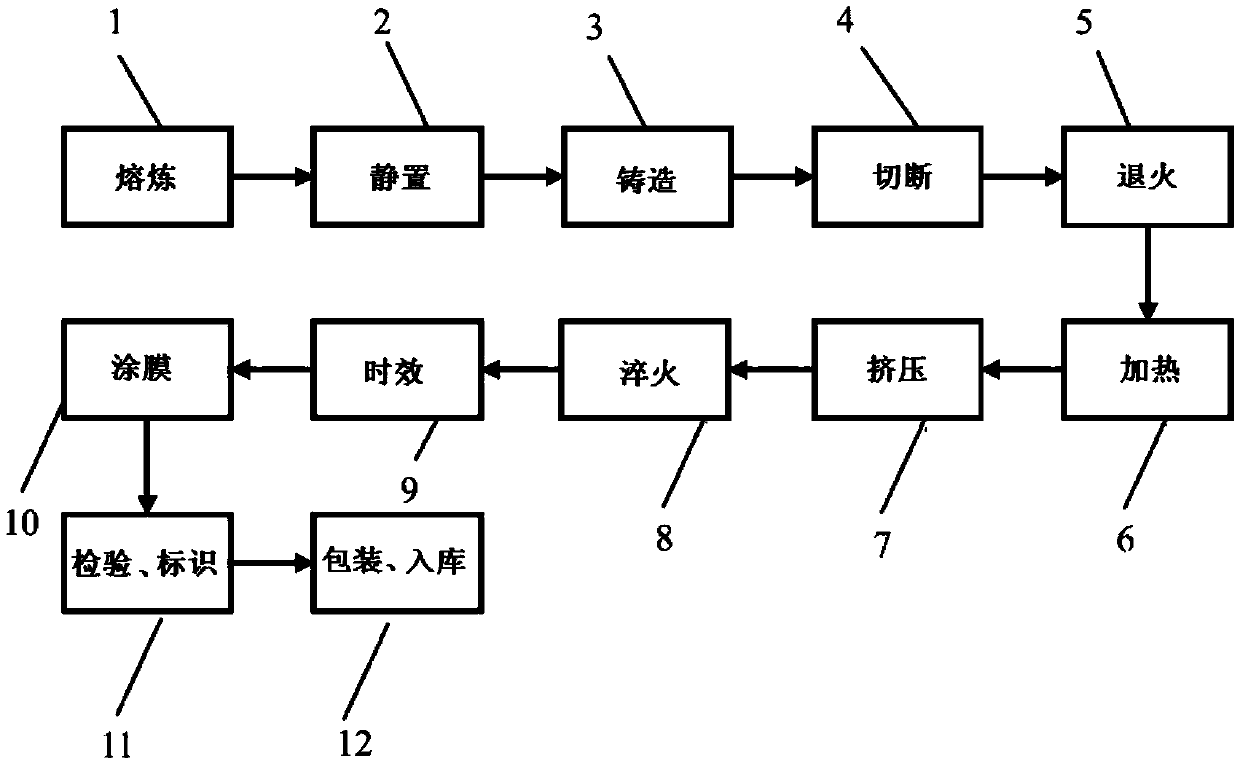

[0027] like figure 1 As shown, a kind of manufacturing method of aluminum alloy profile for building formwork provided by the present invention is specifically prepared according to the following steps:

[0028] 1-Smelting, using 6005A alloy, according to the mass percentage of elements, Si: 0.65% ~ 0.7%, Mg: 0.5% ~ 0.6%, Fe: ≤0.2%, Cu: ≤0.2%, Mn: ≤0.25%, Cr: ≤0.15%, Ti: ≤0.05%, Zn: ≤0.05%, and the balance is Al to prepare ingredients, using gradient refining treatment technology, and put into dry In the smelting furnace, the aluminum alloy solution is obtained by smelting at a temperature of 730°C-40°C for 5h-7h; during this period, the stirring operation is carried out after 30-40min of feeding, which can improve the melting efficiency, reduce the smelting time, and improve production efficiency. Reduce element burning loss; and the use of gradient refining treatment technology can reduce element loss and improve the quality of aluminum alloy solution;

[0029] 2- Stand st...

specific Embodiment approach 2

[0040] The difference between this embodiment and the specific embodiment one is: in step 1, the mass percentages of elements are Si: 0.67%, Mg: 0.56%, Fe: 0.08%, Cu: 0.12%, Mn: 0.05%, Cr: 0.02 %, Ti: 0.03%, Zn: 0.02%, and the balance are Al to prepare ingredients. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] This embodiment differs from specific embodiments 1 to 2 in that: in step 1, melting is performed at a temperature of 735° C. for 6 hours. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com