High-thermal-conductivity bonding sheet for fluorine-containing resin-based high-frequency copper-clad plate

A technology of fluorine-containing resin and adhesive sheet, which is applied in the field of communication materials, can solve the problems of restricting wide application and low thermal conductivity, and achieve the effects of quick and easy adjustment, reduction of production cost, and improvement of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

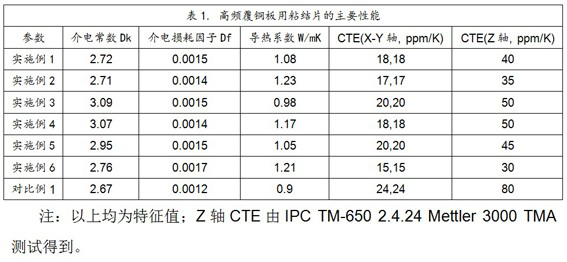

Examples

Synthetic example 1

Take 120 parts of BN (D50=10um) and mix it with 3500 parts of pure water. After dispersing by ball milling for 30 minutes, add 70 parts of NaOH to it. After 8 hours of ultrasonic-assisted reaction at 80 °C, add acetic acid to adjust the pH value to 6- Between 7 and 7, a reaction solution of activated BN is obtained.

[0043] Prepare 100 parts of a 2wt% H2O / ethanol mixed solution, add 0.7 parts of coupling agent KH550 and 2.3 parts of coupling agent KH570, stir at 55 ° C for 5 minutes, adjust the pH of the system to 3-5, and continue to stir 15min to obtain an activated composite coupling agent solution.

[0044] Pour the activated composite coupling agent solution into the activated BN reaction solution, continue stirring at 60 ° C for 4 hours, filter and wash the product with water for several times until the pH value of the filtrate is between 7-8; After washing with ethanol and toluene, the modified BN co-modified by KH570 / KH550 was obtained.

[0045] A homogeneous dispers...

Synthetic example 2

Take 120 parts of BN (D50=20um) and mix it with 3500 parts of pure water. After dispersing by ball milling for 30 minutes, add 80 parts of NaOH to it. After 12 hours of ultrasonic-assisted reaction at 80 °C, add acetic acid to adjust the pH value to 6- Between 7 and 7, a reaction solution of activated BN is obtained.

[0047] Prepare 100 parts of a 2wt% H2O / ethanol mixed solution, add 0.8 parts of coupling agent perfluorodecyltrimethoxysilane and 3.5 parts of coupling agent KH570, stir at 50 °C for 10 minutes, and adjust the pH of the system to 3- 5, and continue to stir for 20 min to obtain an activated composite coupling agent solution.

[0048] Pour the activated composite coupling agent solution into the activated BN reaction solution, continue stirring at 60 ° C for 5 hours, filter and wash the product with water for several times until the pH value of the filtrate is between 7-8; After rinsing with ethanol and toluene, the modified BN co-modified with perfluorodecyltrime...

Embodiment 1

Weigh 75 parts PTFE (Japan Daikin PTFE M-18), 75 parts PFA (DuPont Teflon PFA340), 15 parts FEP (Japan Daikin Neoflon FEP NC-1539), 40 parts silica, 2 parts mica powder, 5 parts PVDF and 120 parts of modified BN in Synthesis Example 1 were stirred in liquid nitrogen by a high-speed mixer for 2 hours to mix uniformly, the liquid nitrogen was volatilized, and after adding excess water, stirring and dispersing uniformly, 50 parts of commercially available ammonia solution (100% by mass) were added. 26%), stirred and mixed at 25°C for 24 hours, and then dried at 100°C to obtain a fluororesin mixture.

[0051] The fluorine-containing resin mixture is placed in a mold and pressed into a compact, under a nitrogen atmosphere at 360 ° C, 70 kg / cm 2 After sintering under hot pressing for 24 hours, a bonding sheet with a thickness of about 0.095-0.105 mm is obtained by turning; the bonding sheet and the PTFE-based prepreg are pressed together at high temperature to obtain a substrate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com