A kind of corrosion-resistant casting magnesium alloy and preparation method thereof

A casting magnesium alloy, corrosion-resistant technology, applied in surgery, medical science and other directions, can solve the problems of restricting the in-depth promotion and application of cast magnesium alloys, difficult to adapt to the requirements of implants, and the rapid degradation rate of magnesium alloys. Avoid high energy consumption for special processing and coating, improve uniformity and density, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The corrosion-resistant cast magnesium alloy and its preparation method are specifically:

[0016] Preheat each raw material to 300 °C. When the temperature of the crucible reaches 500 °C, add uniformly preheated pure magnesium, and then raise the temperature to 750 °C. After the pure magnesium is completely melted, add a uniformly preheated Zr source and stir for 5 min for fluxing. When the furnace temperature rises to 770 ℃, add the preheated Mg-Yb alloy and stir for 5 minutes to help the melting, then set the furnace temperature to 710 ºC and keep it for 20 minutes to remove the slag, and immediately pour the molten metal into the steel water-cooled mold Cast magnesium alloys are obtained in the process, and the whole process of melting is carried out under gas protection;

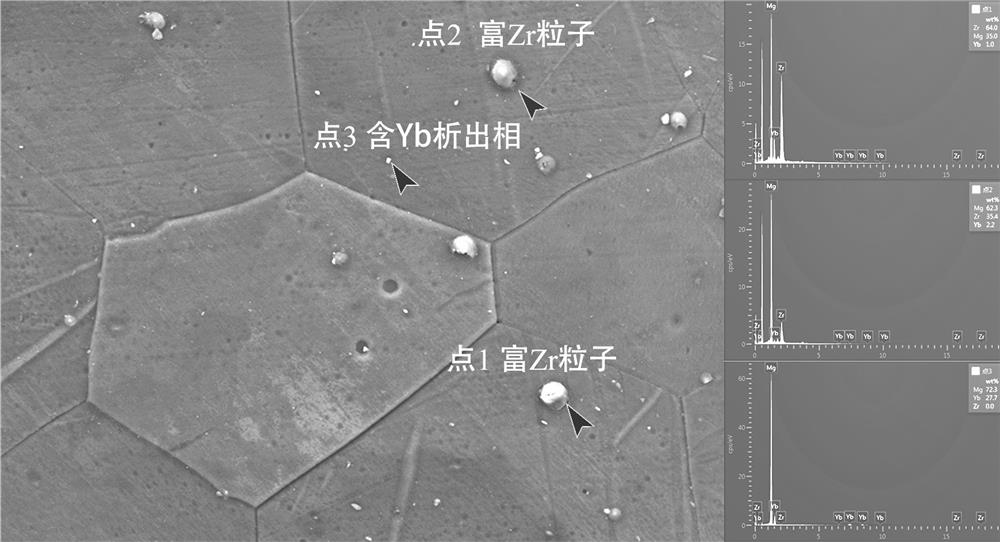

[0017] The composition of the cast magnesium alloy is: Zr=1.0%, Yb=1.0%, and the rest is Mg; figure 1 As shown, its microstructure is uniform equiaxed grains, and Zr-rich particles and submicron...

Embodiment 2

[0021] A corrosion-resistant cast magnesium alloy and a preparation method thereof of the present invention, specifically:

[0022] The raw materials were preheated to 350 °C. When the crucible temperature reached 510 °C, uniformly preheated pure magnesium was added, and then the temperature was raised to 760 °C. After the pure magnesium was completely melted, a uniformly preheated Zr source was added and stirred for 6 min for fluxing. When the furnace temperature rises to 770 ℃, add the preheated Mg-Yb alloy and stir for 8 minutes to help the melting, then set the furnace temperature to 720 ºC and keep it for 25 minutes to remove the slag, and immediately pour the molten metal into the steel water-cooled mold Cast magnesium alloys are obtained in the process, and the whole process of melting is carried out under gas protection;

[0023] The composition of the cast magnesium alloy is: Zr=1.2%, Yb=1.0%, and the rest is Mg; its microstructure is uniform equiaxed grains, and Zr-r...

Embodiment 3

[0027] A corrosion-resistant cast magnesium alloy and a preparation method thereof of the present invention, specifically:

[0028] Preheat each raw material to 330 °C, add preheated pure magnesium when the temperature of the crucible reaches 520 °C, then raise the temperature to 770 °C, add preheated uniform Zr source after the pure magnesium is completely melted, and stir for 10 min to help the melting. When the furnace temperature rises to 780°C, add the preheated Mg-Yb alloy and stir for 10 minutes to boost the melting, then set the furnace temperature to 700°C and keep it for 20 minutes to remove the slag, and immediately pour the molten metal into the steel water-cooled mold To obtain cast magnesium alloy, the whole process of smelting is carried out under gas protection;

[0029] Preheat each raw material to 330°C, add evenly preheated pure magnesium when the temperature of the crucible reaches 500°C, then raise the temperature to 770°C, add evenly preheated Mg-Yb alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com