Extrusion processing technology of cylinder block aluminum alloy section

An aluminum alloy profile, extrusion processing technology, applied in the field of aluminum alloy manufacturing, can solve the problems of high price of aluminum materials, affecting the performance of the cylinder block, complex manufacturing process, etc., to achieve superior performance, improve control performance, and reduce fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

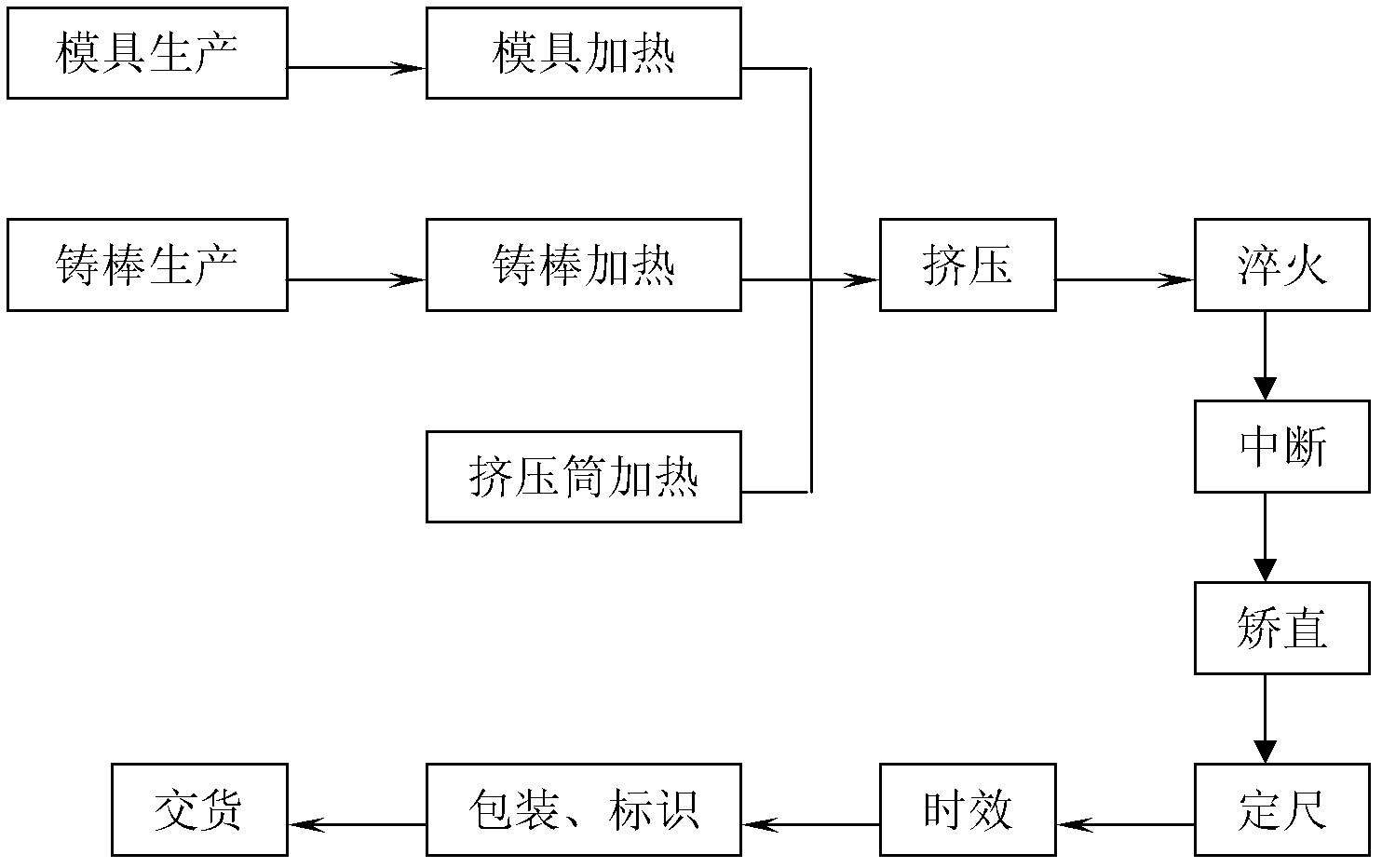

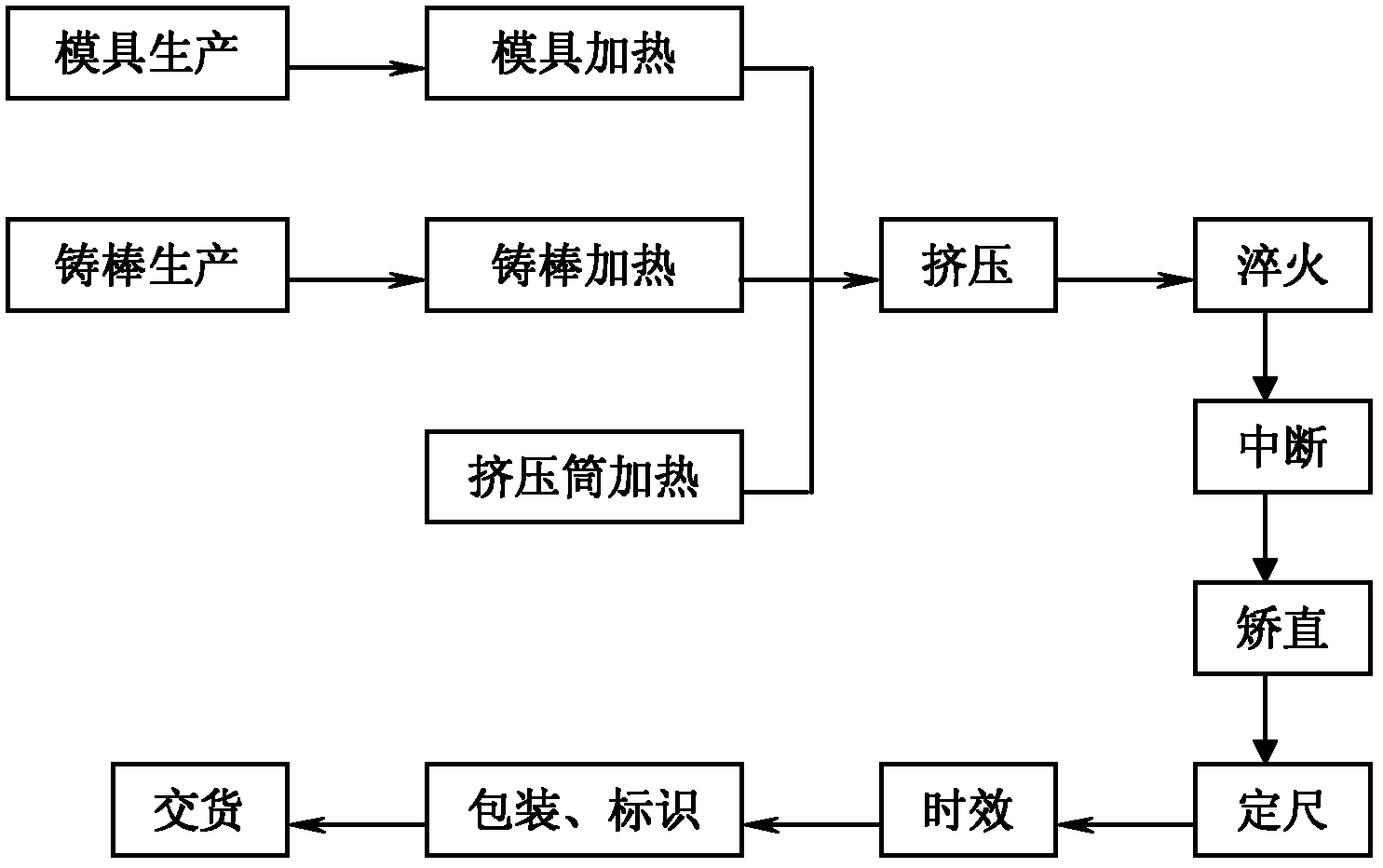

[0020] Embodiment 1, a process for extrusion processing of aluminum alloy profiles of a cylinder block, comprising the following steps:

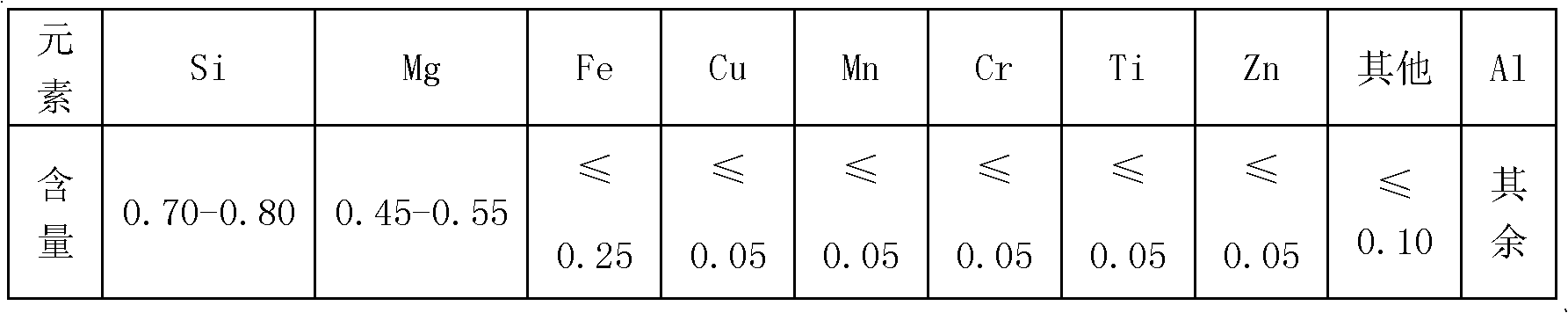

[0021] a. Cast rod ingredients: 6005 alloy is used, and the ratio of element mass percentage meets the following requirements;

[0022] the element

Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

other

Al

content

0.70

0.55

0.25

0.05

0.05

0.05

0.05

0.05

0.10

the remaining

[0023] b. Casting rod smelting: Put the ingredients into the smelting furnace in turn for smelting. The furnace is controlled at 710°C, and the flux is used for refining and covering; after 60 minutes of feeding, when aluminum water appears in the furnace, start stirring, and then refining, grilling After the slag has obtained the qualified composition, pour the molten aluminum from the melting furnace into the holding furnace, keep the furnace temperature at 720°C for 20...

Embodiment 2

[0032] Embodiment 2, a process for extrusion processing of aluminum alloy profiles of a cylinder block, comprising the following steps:

[0033] a. Cast rod ingredients: 6005 alloy is used, and the ratio of element mass percentage meets the following requirements;

[0034] the element

Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

other

Al

content

0.80

0.45

0.20

0.05

0.05

0.05

0.05

0.05

0.10

the remaining

[0035] b. Casting rod smelting: Put the ingredients into the melting furnace in turn for smelting. The furnace is controlled at 760°C, and the flux is used for refining and covering; after 30 minutes of feeding, when aluminum water appears in the furnace, start stirring, and then refining, grilling After the slag has qualified components, the molten aluminum is injected from the melting furnace into the holding furnace, and the furnace temperature is kept at 750°C for 30 ...

Embodiment 3

[0044] Embodiment 3, a process for extrusion processing of aluminum alloy profiles of a cylinder block, comprising the following steps:

[0045] a. Cast rod ingredients: 6005 alloy is used, and the ratio of element mass percentage meets the following requirements;

[0046] the element

Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

other

Al

content

0.5

0.5

0.20

0.05

0.05

0.05

0.05

0.05

0.10

the remaining

[0047] b. Casting rod smelting: Put the ingredients into the smelting furnace in turn for smelting. The furnace is controlled at 730°C, and the flux is used for refining and covering; after 50 minutes of feeding, when aluminum water appears in the furnace, start stirring, and then refining, grilling After the slag has qualified components, pour the molten aluminum from the smelting furnace into the holding furnace, keep the furnace temperature at 740°C for 25 minutes, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com