Aluminium alloy with high strength and excellent cutting property and preparation method thereof

A high-strength, aluminum alloy technology, applied in the field of alloys, can solve the problems of broken tools, sticky tools, and uncontrollable comprehensive properties of profiles, etc., and achieve the effect of improving chip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

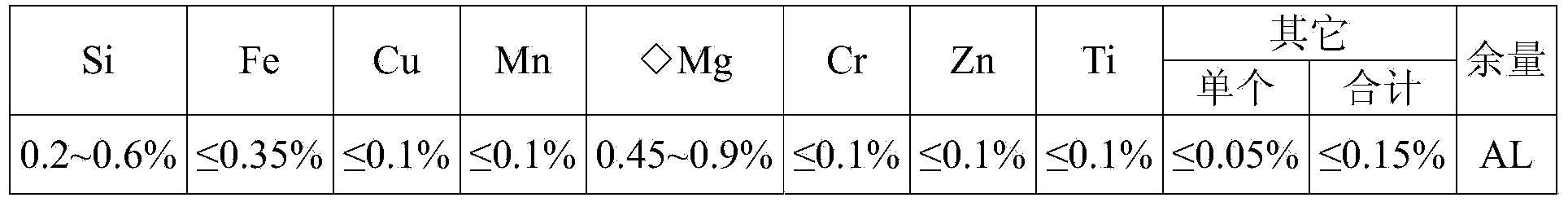

[0027] An aluminum alloy with high strength and excellent chipping performance, the formula ratio is as follows by weight percentage: Si 0.55%, Mg 0.55%, Mn 0.02%, Cu 0.05%, Ti 0.02%, Fe 0.2%, Bi 0.02%, the balance for aluminum;

[0028] After the aluminum ingot is melted, slag removal, alloying, refining, standing, casting, homogenization, extrusion and artificial aging are performed to obtain an aluminum alloy with high strength and excellent chipping performance.

[0029] The preparation method of the aluminum alloy with high strength and excellent chip performance, the steps are as follows in terms of mass percentage:

[0030] (1) Melting: Put the aluminum ingot into the furnace and heat it to 720°C to melt it;

[0031] (2) Slag removal: When the temperature is 710°C, sprinkle the slag removal agent evenly into the furnace and fully stir for 5-10 minutes, and remove the scum on the surface of the aluminum liquid with a rake; the amount of the slag removal agent is 0.3 per...

Embodiment 2

[0044] An aluminum alloy with high strength and excellent chipping performance, the formula ratio is as follows by weight percentage: Si 0.6%, Mg 0.62%, Mn 0.05%, Cu 0.1%, Ti 0.04%, Fe 0.25%, Bi 0.05%, the balance for aluminum;

[0045]After the aluminum ingot is melted, slag removal, alloying, refining, standing, casting, homogenization, extrusion and artificial aging are performed to obtain an aluminum alloy with high strength and excellent chipping performance.

[0046] The preparation method of the aluminum alloy with high strength and excellent chip performance, the steps are as follows in terms of mass percentage:

[0047] (1) Melting: Put the aluminum ingot into the furnace and heat it to 760°C to melt it;

[0048] (2) Slag removal: When the temperature is 710-760°C, sprinkle the slag removal agent evenly into the furnace and stir it fully for 10 minutes, and remove the scum on the surface of the aluminum liquid with a rake; the amount of the slag removal agent is 0.3 ...

Embodiment 3

[0061] An aluminum alloy with high strength and excellent chipping performance, the formula ratio is as follows by weight percentage: Si 0.58%, Mg 0.60%, Mn 0.04%, Cu 0.08%, Ti 0.03%, Fe 0.22%, Bi 0.04%, the balance for aluminum;

[0062] After the aluminum ingot is melted, slag removal, alloying, refining, standing, casting, homogenization, extrusion and artificial aging are performed to obtain an aluminum alloy with high strength and excellent chipping performance.

[0063] The preparation method of the aluminum alloy with high strength and excellent chip performance, the steps are as follows in terms of mass percentage:

[0064] (1) Melting: Put the aluminum ingot into the furnace and heat it to 750°C to melt it;

[0065] (2) Slag removal: when the temperature is 730°C, sprinkle the slag removal agent evenly into the furnace and fully stir for 8 minutes, and use a rake to remove the scum on the surface of the aluminum liquid; the amount of the slag removal agent is 0.3kg p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com