Multiaxial short crack propagation life prediction method based on critical surface method

A crack growth life and prediction method technology, which is applied in the field of multiaxial short crack growth life prediction based on the critical surface method, can solve the lack of stress intensity factor, multiaxial fatigue short crack test data difficulty, multiaxial fatigue short crack growth model Problems such as slow research progress, to achieve the effect of clear physical meaning and easy engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is illustrated in conjunction with the accompanying drawings.

[0033] The present invention further illustrates the present invention through the fatigue test, the test is divided into two parts, one part is the short crack test under uniaxial constant amplitude loading, the stress ratio is -1, and the short crack growth data is observed. In the range of high cycle fatigue life, there is mainly a single dominant crack, which is convenient for measuring and calculating the crack growth curve. The other part is the multiaxial proportional and non-proportional loading test, which calculates the range of equivalent stress intensity factors under multiaxial loading conditions.

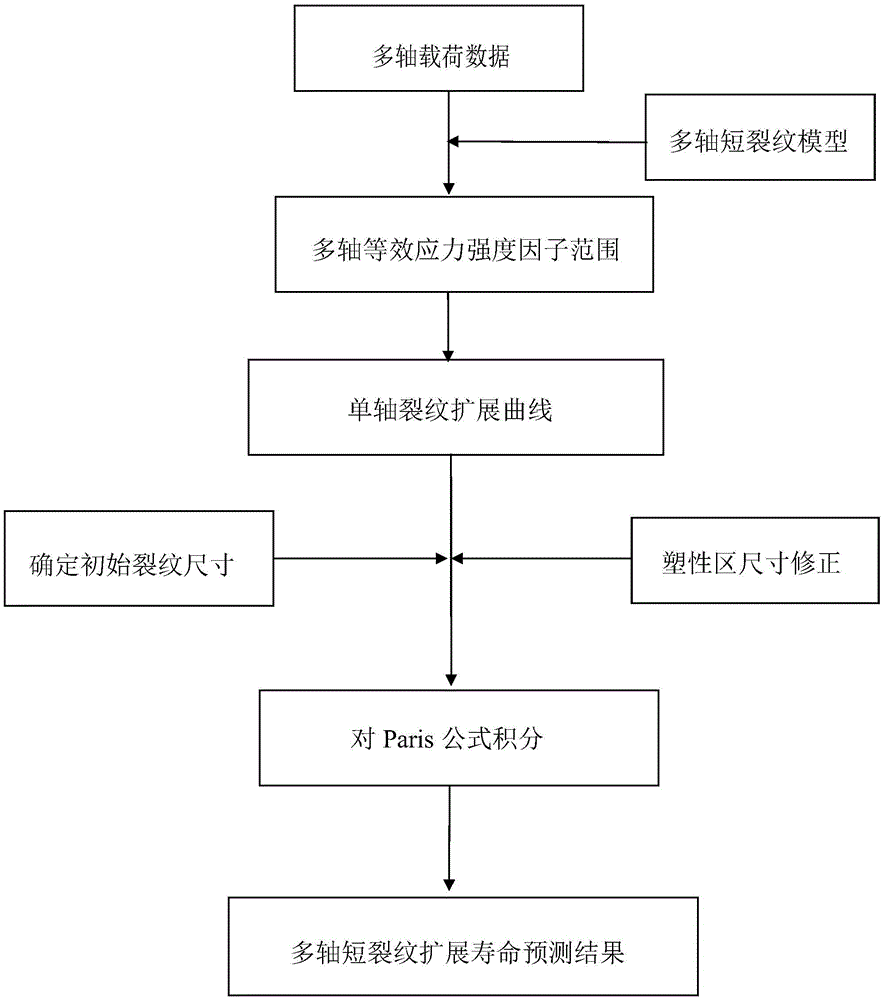

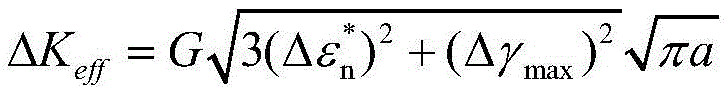

[0034] A multi-axial short crack growth life prediction method based on the critical surface method, the specific calculation method is as follows:

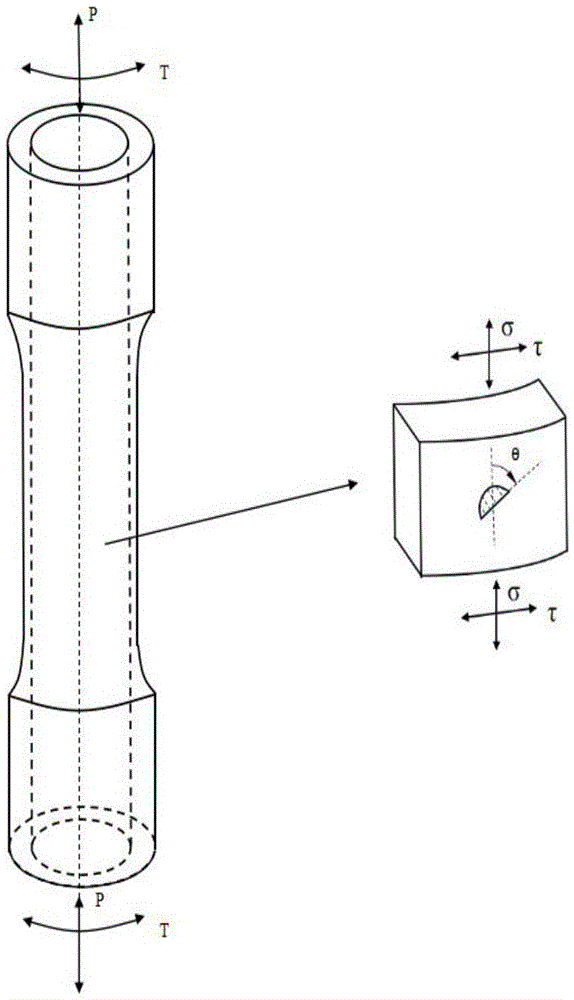

[0035] Step 1): If figure 2 As shown in , the cracks of thin-walled pipes mainly originate in the plane where the maximum she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com