Crack failure mode determination method and fatigue life prediction method based on crack failure mode determination method

A failure mode and judgment method technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as low predicted life, conservative model prediction, uncertain crack failure mode, etc., to achieve control The effect of excessive forecast error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

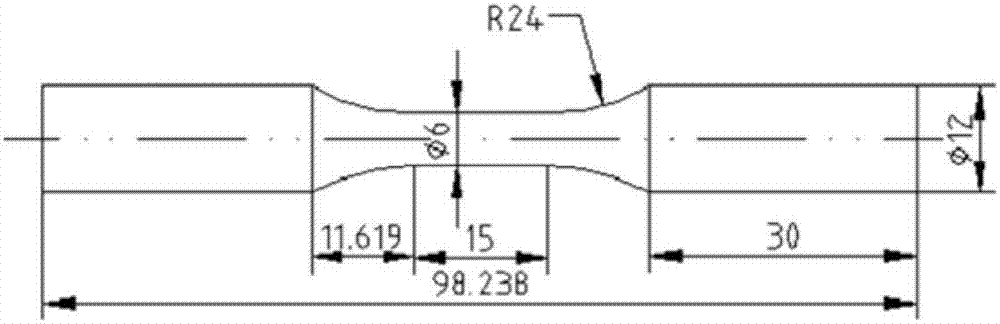

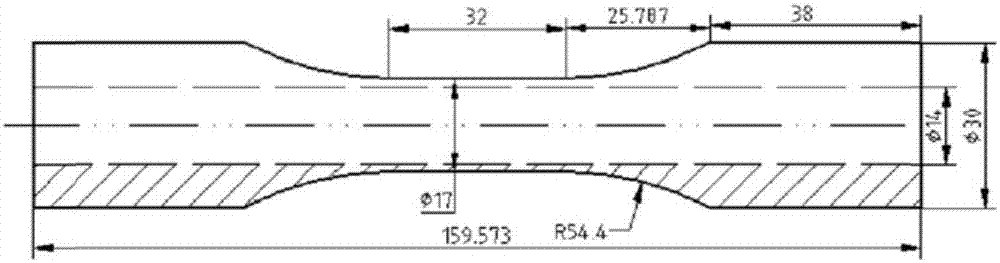

[0033] In this embodiment, the model is verified by the fatigue test data of TC4 material. The fatigue test data is divided into two parts. The first part is the fatigue test data under symmetrical load, including uniaxial tension and compression fatigue, pure torsion Fatigue, and multiaxial fatigue under 0° proportional, 45° and 90° non-proportional loads; the second part is for fatigue test data under asymmetric loading, including multiaxial fatigue under 0° proportional and 90° non-proportional loads .

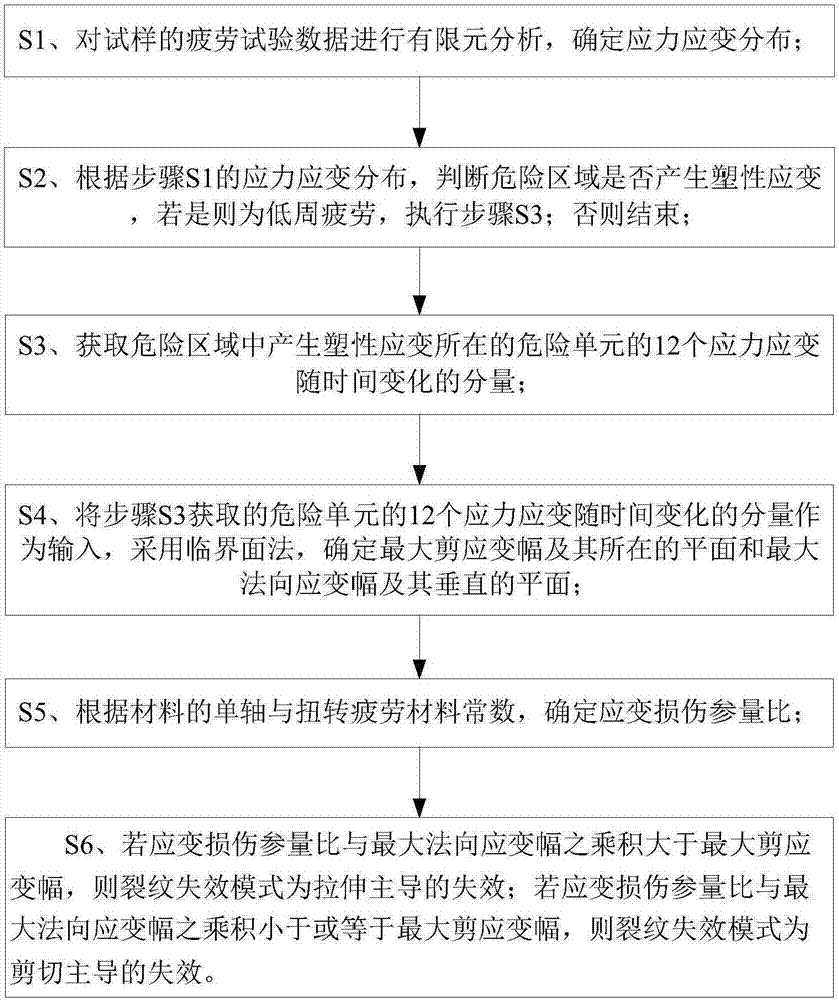

[0034] Such as figure 1 Shown is the solution flow chart of the present invention, the technical solution of the present invention is: a crack failure judgment method, comprising:

[0035] S1. Perform finite element analysis on the fatigue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com