Cobalt-based alloy powder and preparation method and application thereof

A cobalt-based alloy and powder technology, applied in the field of cobalt-based alloy powder and its preparation, can solve the problems of repair failure and insufficient alloy strength, and achieve the effects of reducing loss, good fluidity and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

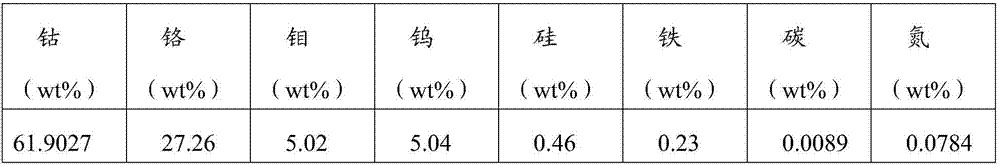

[0040] The consumption of the metal raw material of table 1 embodiment 1

[0041] raw material

cobalt

Dosage (wt%)

62

28

5

5

[0042] The preparation method of the cobalt-based alloy powder of this embodiment comprises the following steps:

[0043] (1) According to the dosage in Table 1, get chromium, molybdenum, tungsten and cobalt, remove the metal oxide layer on the surface of chromium, molybdenum, tungsten and cobalt, get the chromium that removes the metal oxide layer, remove the molybdenum of the metal oxide layer, remove the metal oxide layer layer of tungsten and cobalt to remove the metal oxide layer;

[0044] (2) 35wt% of the cobalt from the removal of the metal oxide layer is added to the smelting furnace as a matrix, then the chromium from the removal of the metal oxide layer is added, after heating and melting, the molybdenum and tungsten from the removal of the metal oxide layer are adde...

Embodiment 2

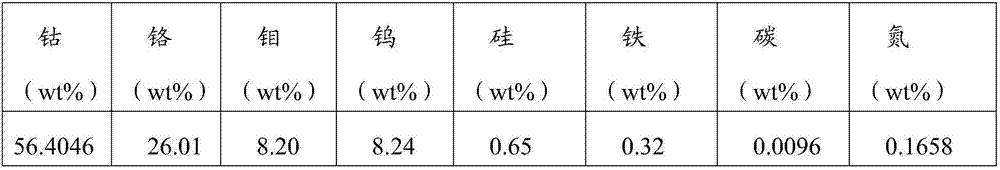

[0053] The consumption of the metal raw material of table 3 embodiment 2

[0054] raw material

cobalt

chromium

molybdenum

tungsten

Dosage (wt%)

57

27

8

8

[0055] The cobalt-based alloy powder described in this embodiment is processed by 3D printing technology, comprising the steps of:

[0056] (1) According to the dosage in Table 3, get chromium, molybdenum, tungsten and cobalt, remove the metal oxide layer on the surface of chromium, molybdenum, tungsten and cobalt, get the chromium that removes the metal oxide layer, remove the molybdenum of the metal oxide layer, remove the metal oxide layer layer of tungsten and cobalt to remove the metal oxide layer;

[0057] (2) 68wt% of the cobalt from the removal of the metal oxide layer is added to the smelting furnace as a matrix, then the chromium from the removal of the metal oxide layer is added, after heating and melting, the molybdenum and tungsten from the removal of the metal ...

Embodiment 3

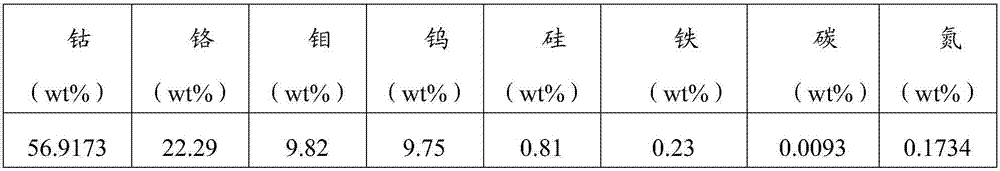

[0066] The consumption of the metal raw material of table 5 embodiment 3

[0067] raw material

cobalt

chromium

molybdenum

tungsten

Dosage (wt%)

58.2

23

9.4

9.4

[0068] The cobalt-based alloy powder described in this embodiment is processed by 3D printing technology, comprising the steps of:

[0069] (1) According to the dosage in Table 5, get chromium, molybdenum, tungsten and cobalt, remove the metal oxide layer on the surface of chromium, molybdenum, tungsten and cobalt, get the chromium that removes the metal oxide layer, remove the molybdenum of the metal oxide layer, remove the metal oxide layer layer of tungsten and cobalt to remove the metal oxide layer;

[0070] (2) Add 55wt% of the cobalt from the removal of the metal oxide layer to the smelting furnace as a matrix, then add the chromium from the removal of the metal oxide layer, heat and melt, then add the molybdenum and tungsten from the removal of the metal oxide l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com