Control method for reducing specified non-proportional extension strength fluctuation

A technology of elongation strength and control method, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., and can solve problems such as large fluctuations, low yield strength, and reduced uniform elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

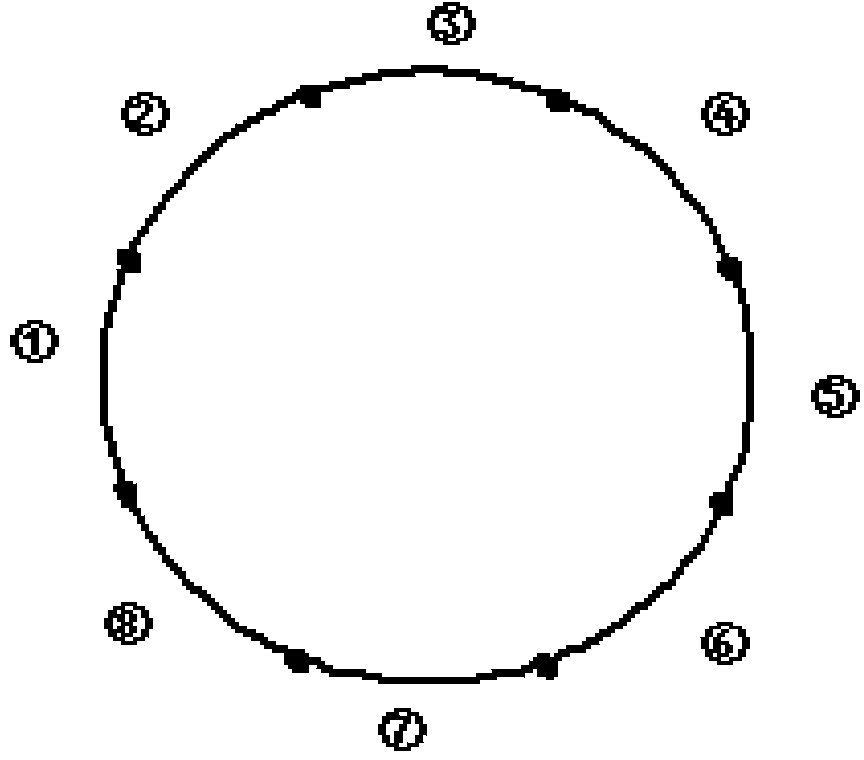

Image

Examples

Embodiment 1

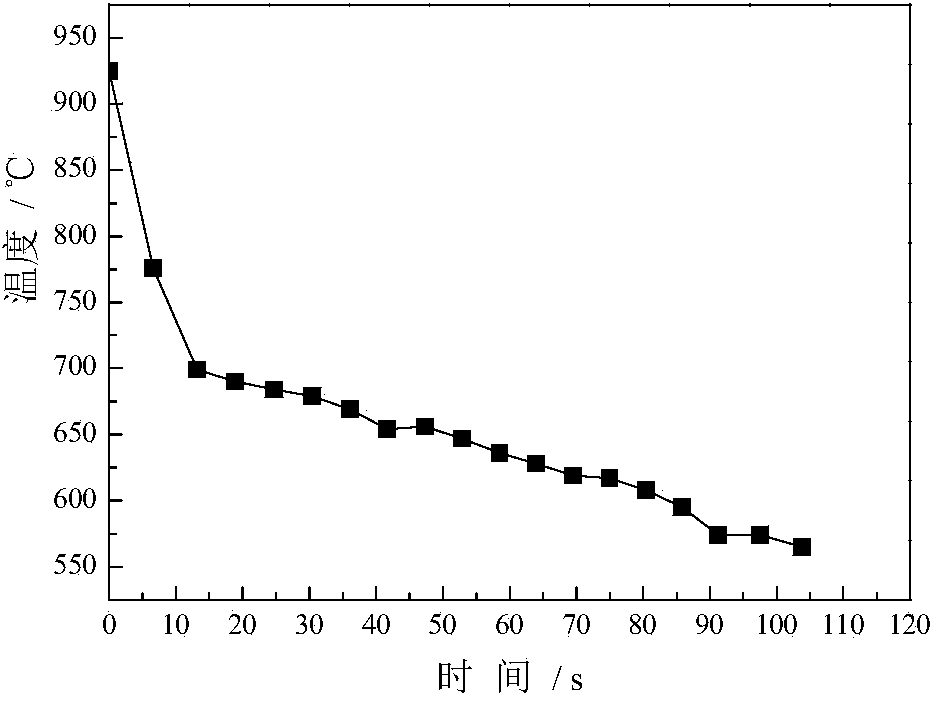

[0027] Specification ∮ 8mm; grade: pan snail HRB400E; starting rolling and exiting furnace temperature 965°C; entering and finishing rolling temperature 810°C; spinning temperature 945°C. Its chemical composition, roller table speed, and fan parameters are shown in Tables 2, 3, and 4 below, and the air-cooling curve is as follows Figure 4 As shown, R o p0.2 and other seismic index control results are shown in Table 5.

[0028] Table 2 ∮ 8mm disc snail HRB400E chemical composition w.t.%

[0029] C

Si

mn

V

P

S

N

Ceq

0.22

0.5

1.47

0.013

0.022

0.017

0.011

0.48

[0030] Table 3 ∮ 8mm disc screw HRB400E roller table speed

[0031] header

1

2

3

4

5

6

7

8

9

10

tail section

0.60

0.70

0.80

0.90

0.91

0.92

0.93

0.94

0.95

0.80

0.68

0.58

[0032] Table 4 Fan parameter settings (insulation cover ful...

Embodiment 2

[0037] Specification ∮ 8mm; grade: pan snail HRB500E; VN microalloying, in which the V content is 0.05%, and the N content is 115ppm; the starting rolling temperature is 1010°C; the finishing rolling temperature is 845°C; the spinning temperature: 945°C. Fan and Carling parameters are shown in Table 6, and the air-cooling curve is shown in Figure 5 As shown, R o p0.2 and other seismic indicators are shown in Table 7.

[0038] Table 6 Fan and Carling settings

[0039] fan

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com