Aluminum lithium alloy for spaceflight and method for preparing proximate matter through aluminum lithium alloy

A technology of aluminum-lithium alloy and aluminum alloy, which is applied in the field of manufacturing aluminum-lithium alloy and aluminum-lithium alloy profiles, can solve the problems of high difficulty of aluminum-lithium alloy and low strength of aluminum-lithium alloy, and achieves great difficulty in solving, simple production equipment, Resolve low-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific Embodiment 1: In this embodiment, the aluminum-lithium alloy for aerospace is composed of Mg, Li, Ti, Zr and Al; the mass percentages of elements in the aluminum-lithium alloy are: Mg: 5.5%-6.5%, Li: 2.2%-2.5% , Ti: 0.03% to 0.12%, Zr: 0.15% to 0.20% and the rest of Al, wherein Zr+Ti≤0.25%; the mass percentage of impurity elements is: Cu: ≤0.01%, Si: ≤0.15%, Fe : ≤0.20%.

[0031] This embodiment has the following beneficial effects:

[0032] 1. Excessive Zr in the aluminum-lithium alloy will cause the generation of coarse compounds in the alloy, thereby affecting the mechanical properties of the aluminum alloy. In this embodiment, Ti: 0.03% to 0.12%, Zr: 0.15% to 0.20%, and Zr+Ti ≤0.25%, the present invention limits the content of Zr and Ti, and also limits the total amount of Zr and Ti, wherein Zr with a content of 0.15% to 0.20% will not cause coarse compounds in the aluminum-lithium alloy At the same time, Ti with a content of 0.03% to 0.12% can supplement...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the aluminum-lithium alloy is composed of Mg, Li, Ti, Zr and Al; the mass percentage of elements in the aluminum-lithium alloy is: Mg: 6%, Li: 2.4%, Ti: 0.12%, Zr: 0.15%, and the rest of Al; the mass percentages of impurity elements are: Cu: ≤0.01%, Si: ≤0.15%, Fe: ≤0.20%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

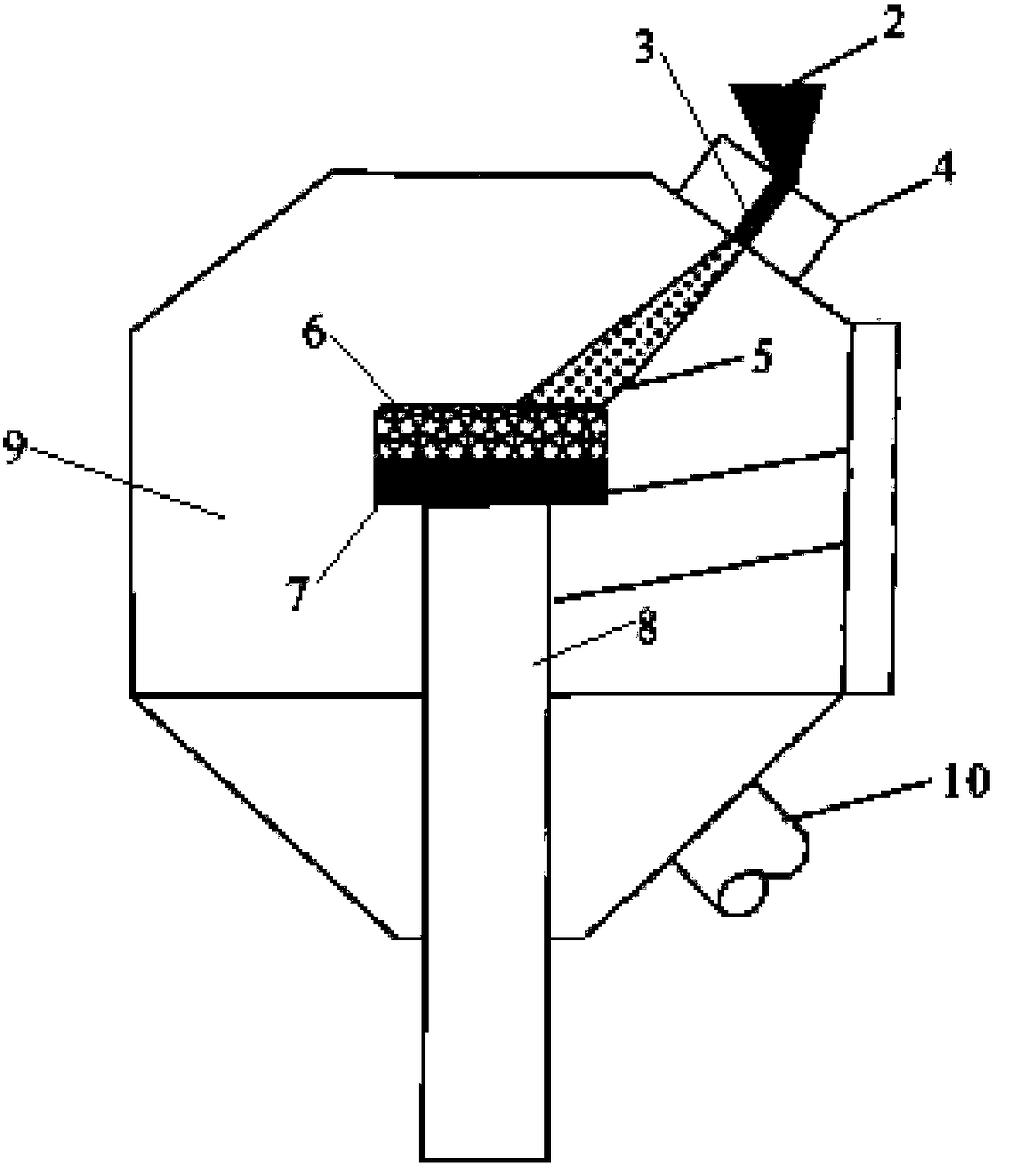

[0035] Specific implementation mode three: In this implementation mode, the method for preparing profiles using aluminum-lithium alloys for aerospace is carried out in the following steps:

[0036] 1. According to the mass percentage of elements: Mg: 5.5% ~ 6.5%, Li: 2.2% ~ 2.5%, Ti: 0.03% ~ 0.12%, Zr: 0.15% ~ 0.20%, Zr+Ti≤0.25% and the balance Weighing pure magnesium ingots, Al-Li master alloys, Al-Zr master alloys, Al-Ti master alloys and high-purity aluminum ingots as raw materials for Al;

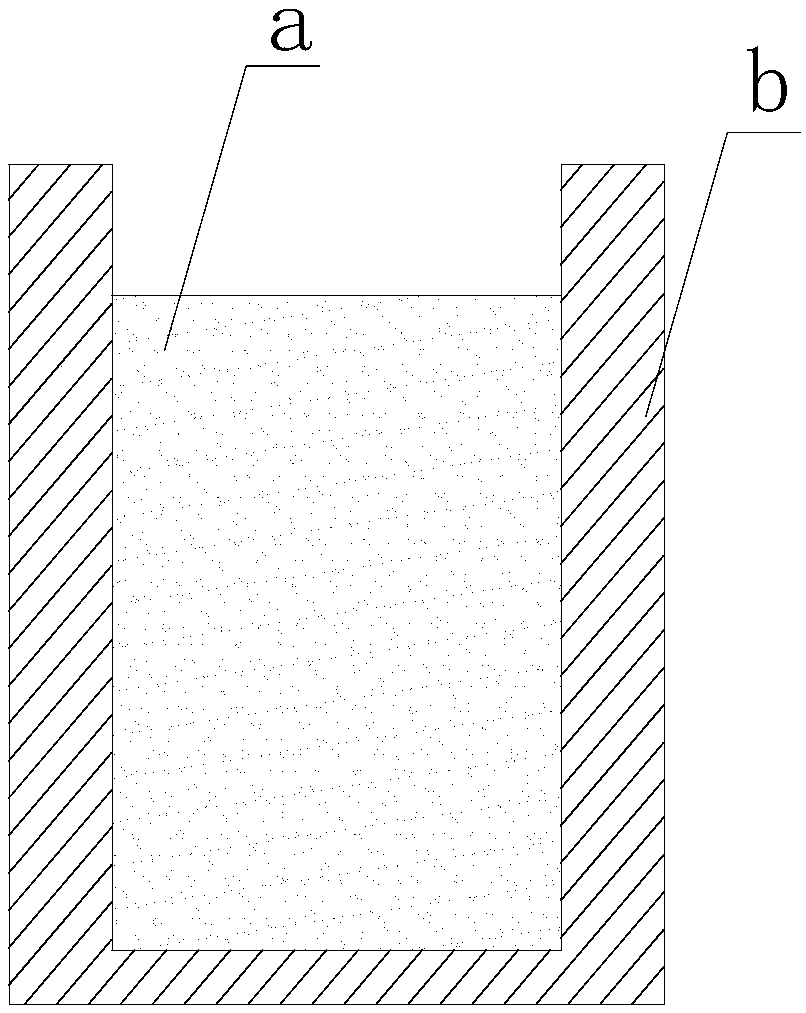

[0037] 2. Add the high-purity aluminum ingot weighed in step 1 into the melting furnace, melt it at 720°C-740°C for 6-8 hours to obtain molten aluminum, cool the molten aluminum to 670°C-690°C, and then Pass protective gas into the smelting furnace, add pure magnesium ingot and Al-Li master alloy to the cooled aluminum melt and raise the temperature to 720℃~740℃, then add Al-Zr master alloy and Al-Ti master alloy, keep warm 0.5 to 1.5 hours to obtain molten aluminum alloy;

[0038] 3. R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com