Stir-welding head for aluminum alloy thick plate welding and welding method thereof

A welding method and aluminum alloy technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of joint performance degradation, stirring needles are easy to break, etc., and achieve improved tensile strength, less breakage, and increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is a stirring head and a method for welding a 20mm thick 7A52 high-strength aluminum alloy, including the following steps:

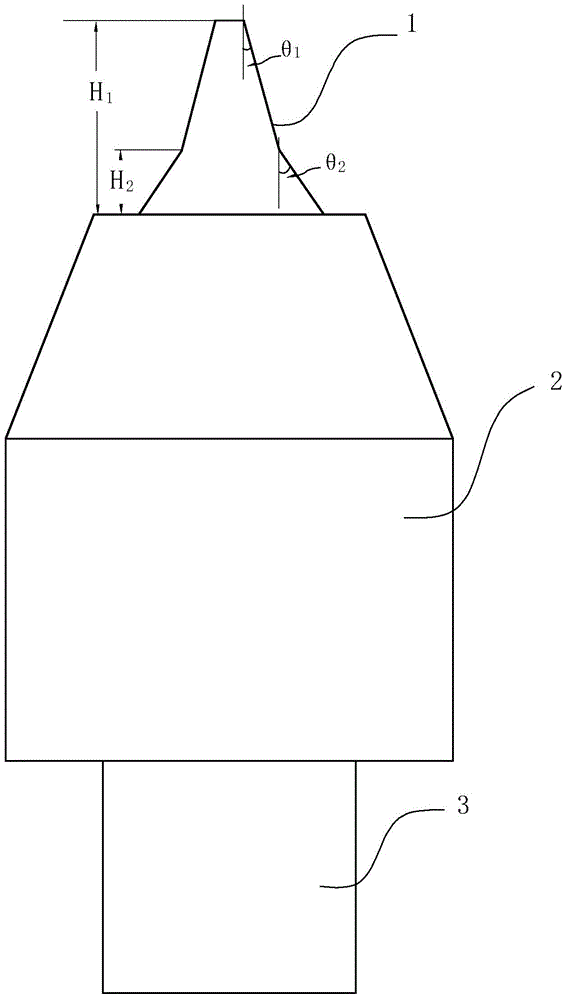

[0023] (1) Material of the stirring head: the material of the stirring head is austenitic high-nitrogen steel containing 0.4% N, and the deformation of the austenitic high-nitrogen steel is 45% during processing. (2) The overall design of the mixing head: The mixing head adopts an overall design, that is, the clamping end 3, the shaft shoulder 2, and the stirring needle 1 are processed from the same austenitic high-nitrogen steel material. (3) Structural design of the stirring head: the head of the stirring needle is in the shape of a truncated cone, and the root of the stirring needle connected to the shaft shoulder adopts a non-proportional thickening design, which is also in the shape of a truncated cone, θ 2 =16°, θ 1 =10°;H 2 =8mm,H 1 =19.7mm. The upper part of the shaft shoulder connected with the stirring needle is in th...

Embodiment 2

[0025] This embodiment is a stirring head and a method for welding a 30mm thick 7A52 high-strength aluminum alloy, including the following steps:

[0026] (1) Material of the stirring head: the material of the stirring head is austenitic high-nitrogen steel containing 0.4% N, and the deformation of the austenitic high-nitrogen steel is 50% during processing. (2) The overall design of the stirring head: the stirring head adopts an overall design, that is, the clamping end 3 of the stirring head, the shaft shoulder 2, and the stirring needle 1 are processed from the same austenitic high-nitrogen steel material. (3) Structural design of the stirring head: the head of the stirring needle is in the shape of a truncated cone, and the root of the stirring needle connected to the shaft shoulder adopts a non-proportional thickening design, which is also in the shape of a truncated cone, θ 2 =14°, θ 1 =10°;H 2 =12mm, H 1 =29.7mm. The upper part of the shaft shoulder connected with t...

Embodiment 3

[0028] This embodiment is a stirring head and a method for welding a 40mm thick 7A52 high-strength aluminum alloy, including the following steps:

[0029] (1) Material of the stirring head: the material of the stirring head is austenitic high-nitrogen steel containing 0.4% N, and the deformation of the austenitic high-nitrogen steel is 50% during processing. (2) The overall design of the stirring head: the stirring head adopts an overall design, that is, the clamping end 3 of the stirring head, the shaft shoulder 2, and the stirring needle 1 are processed from the same austenitic high-nitrogen steel material. (3) Structural design of the stirring head: the head of the stirring needle is in the shape of a truncated cone, and the root of the stirring needle connected to the shaft shoulder adopts a non-proportional thickening design, which is also in the shape of a truncated cone, θ 2 =16°, θ 1 =12°;H 2 =12mm, H 1 =34.7mm. The upper part of the shaft shoulder connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com