Novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube for power station and manufacturing method

A technology of superalloy and manufacturing method, applied in metal rolling, metal processing equipment and other directions, can solve problems such as superalloy, and achieve the effect of small dimensional deviation, improved surface quality and dimensional accuracy, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a new type of nickel-chromium-cobalt-molybdenum superalloy seamless pipe for power stations. The seamless pipe includes the following components by weight percentage: C: 0.062%, Si: 0.012%, Mn: 0.03%, P: 0.005 %, S: 0.002%, Cr: 22.82%, Co: 12.95%, Al: 1.21%, Ti: 0.43%, Mo: 8.78%, Fe: 0.18%, Cu: 0.0089%, B: 0.005%, Pb: 0.001 %, Sb: 0.001%, Bi: 0.001%, Sn: 0.005%, As: 0.005%, the balance is Ni and trace elements, the sum of the above components is 100%.

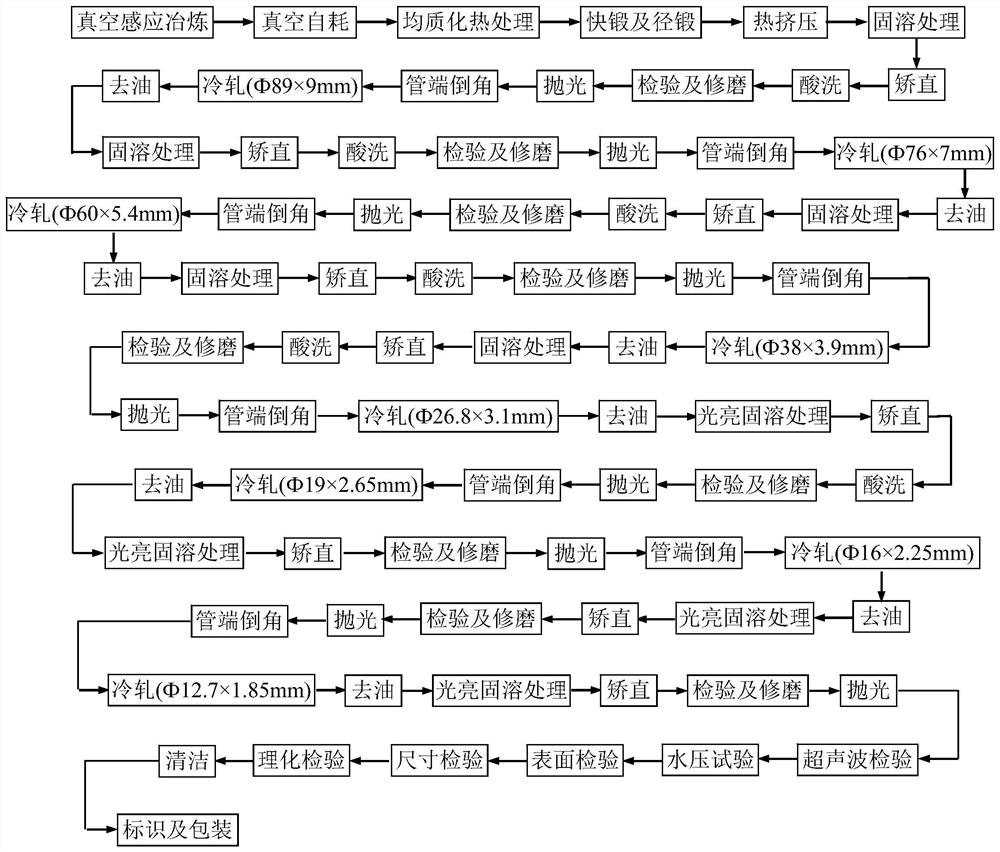

[0057] The manufacturing method of above-mentioned novel power station nickel-chromium-cobalt-molybdenum superalloy seamless pipe, flow process is as follows figure 1 As shown, it specifically includes the following steps:

[0058] (1) Smelting

[0059] The alloy material of the seamless pipe adopts vacuum induction smelting, the smelting temperature is 1500°C±10°C, casting it into an alloy ingot of Ф360×2800mm, annealing at 1000~1100°C×24h×air cooling, and then vacuum self-consumption into an ...

Embodiment 2

[0089] This embodiment provides a new type of nickel-chromium-cobalt-molybdenum high-temperature alloy seamless pipe for power stations. The seamless pipe includes the following components by weight percentage: C: 0.063%, Si: 0.014%, Mn: 0.032%, P: 0.004% , S: 0.003%, Cr: 22.81%, Co: 12.93%, Al: 1.20%, Ti: 0.44%, Mo: 8.77%, Fe: 0.181%, Cu: 0.01%, B: 0.005%, Pb: 0.001% , Sb: 0.001%, Bi: 0.001%, Sn: 0.004%, As: 0.004%, the balance is Ni and trace elements, the sum of the above components is 100%.

[0090] Adopt the manufacturing method of the nickel-chromium-cobalt-molybdenum superalloy seamless pipe used in the novel power station in embodiment 1, adopt the same manufacturing method to manufacture the novel nickel-chromium-cobalt-molybdenum superalloy seamless pipe used in the power station, its inner and outer surface roughness Ra≤0.7μm; outer diameter is ±0.02mm, wall thickness is ±0.05; grain size is 5.5; mechanical properties at room temperature: R m =815MPa, R p0.2 =359M...

Embodiment 3

[0092] This embodiment provides a new type of nickel-chromium-cobalt-molybdenum high-temperature alloy seamless pipe for power stations. The seamless pipe includes the following components by weight percentage: C: 0.063%, Si: 0.014%, Mn: 0.032%, P: 0.004% , S: 0.003%, Cr: 22.81%, Co: 12.93%, Al: 1.20%, Ti: 0.44%, Mo: 8.77%, Fe: 0.181%, Cu: 0.01%, B: 0.005%, Pb: 0.001% , Sb: 0.001%, Bi: 0.001%, Sn: 0.004%, As: 0.004%, the balance is Ni and trace elements, the sum of the above components is 100%.

[0093] Adopt the manufacturing method of the nickel-chromium-cobalt-molybdenum superalloy seamless pipe used in the novel power station in embodiment 1, adopt the same manufacturing method to manufacture the novel nickel-chromium-cobalt-molybdenum superalloy seamless pipe used in the power station, its inner and outer surface roughness Ra≤0.8μm; outer diameter is ±0.04mm, wall thickness is ±0.04; grain size is 5.5; mechanical properties at room temperature: R m =818MPa, R p0.2 =356M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com