Rubber buffering and vibration isolating elastomer structure

An elastomer structure, rubber technology, applied in the direction of springs, etc., to avoid uneven deformation, improve the buffer effect, and increase the damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

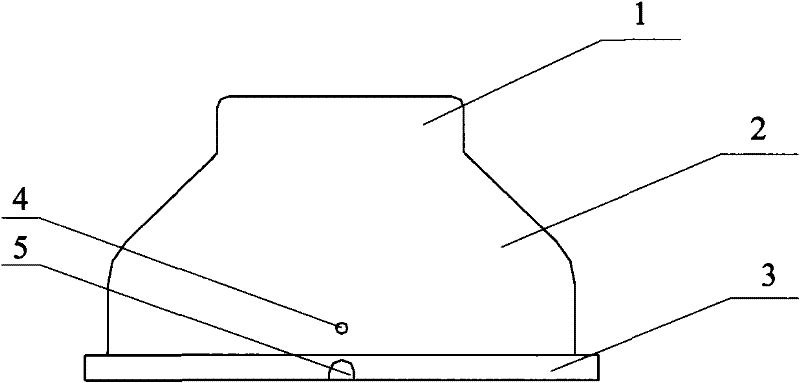

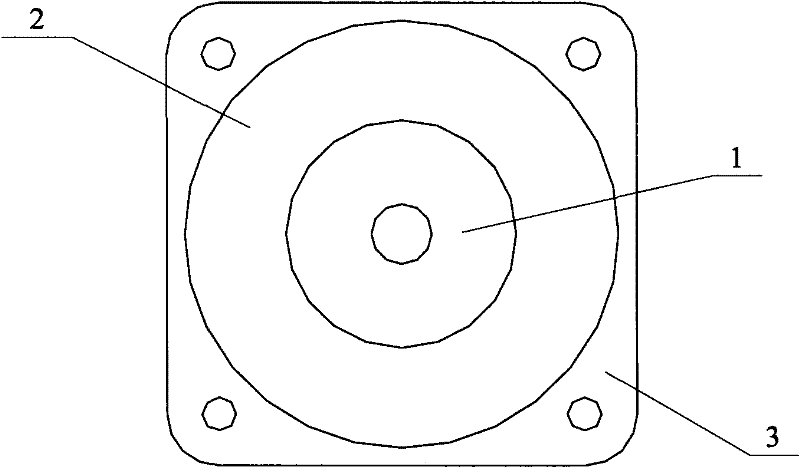

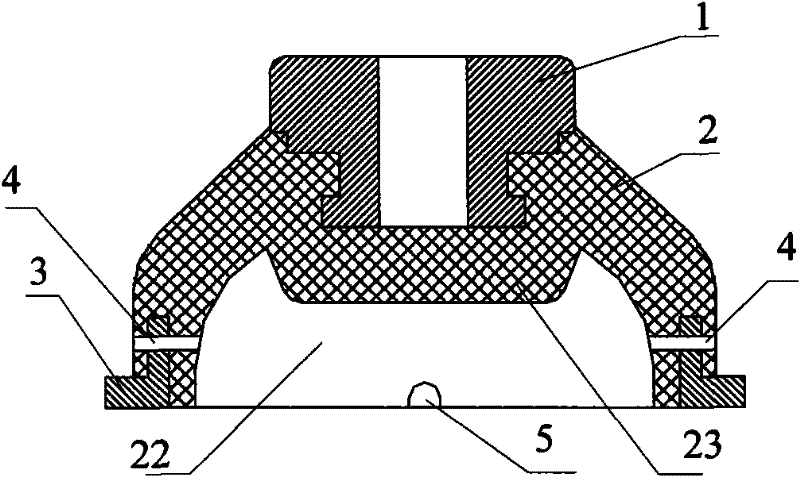

[0030] Such as figure 1 , 2 , 3, the present invention is made up of upper metal part 1, rubber part 2 and lower metal part 3, upper metal part 1 is installed on the top of rubber part 2, lower metal part 3 is installed on the bottom of rubber part 2, upper metal part 1, The rubber part 2 and the lower metal part 3 are connected as a whole through rubber vulcanization.

[0031] Upper metal part 1 such as image 3 , 7 As shown in , 8, it is a stepped cylindrical structure with variable diameter, and the hole in the middle can be designed as a threaded hole or a through hole according to the installation requirements. The stepped cylindrical structure with variable diameter of the upper metal part 1 can increase the contact area between the upper metal part 1 and the rubber body 2, and improve the bonding strength of the rubber after vulcanization.

[0032] Rubber parts 2 such as Figure 4 , 5 As shown in , 6, it is an inverted bowl-shaped structure. Rubber bosses 23 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com