Comfortable damping anti-bottoming shock absorber and three-wheeled motorcycle

A shock absorber, anti-touch technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of affecting the handling, comfort, safety and reliability of the whole vehicle, unable to form compression damping force, Problems such as compression damping cannot be formed to achieve the effect of improving sudden changes, improving driving comfort, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

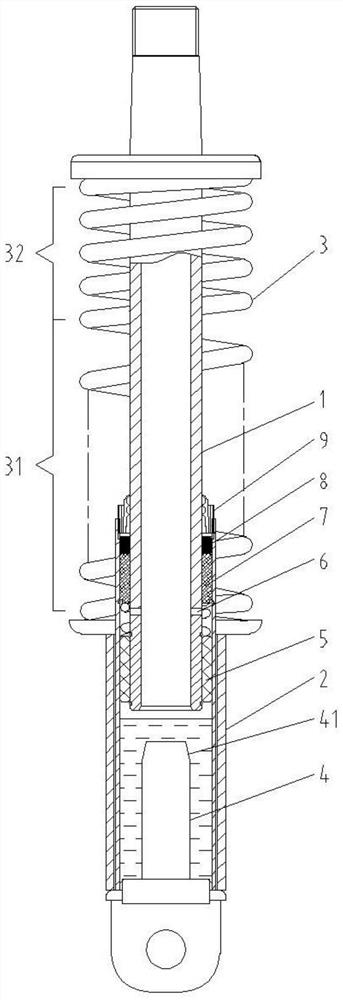

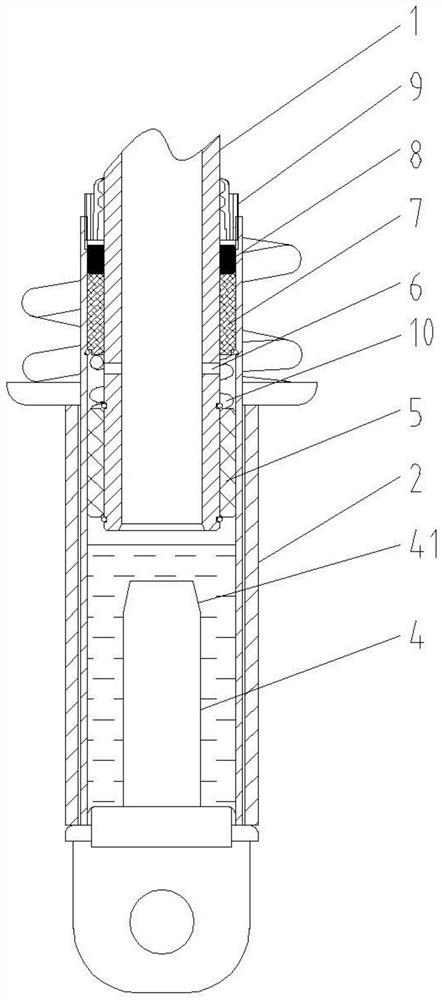

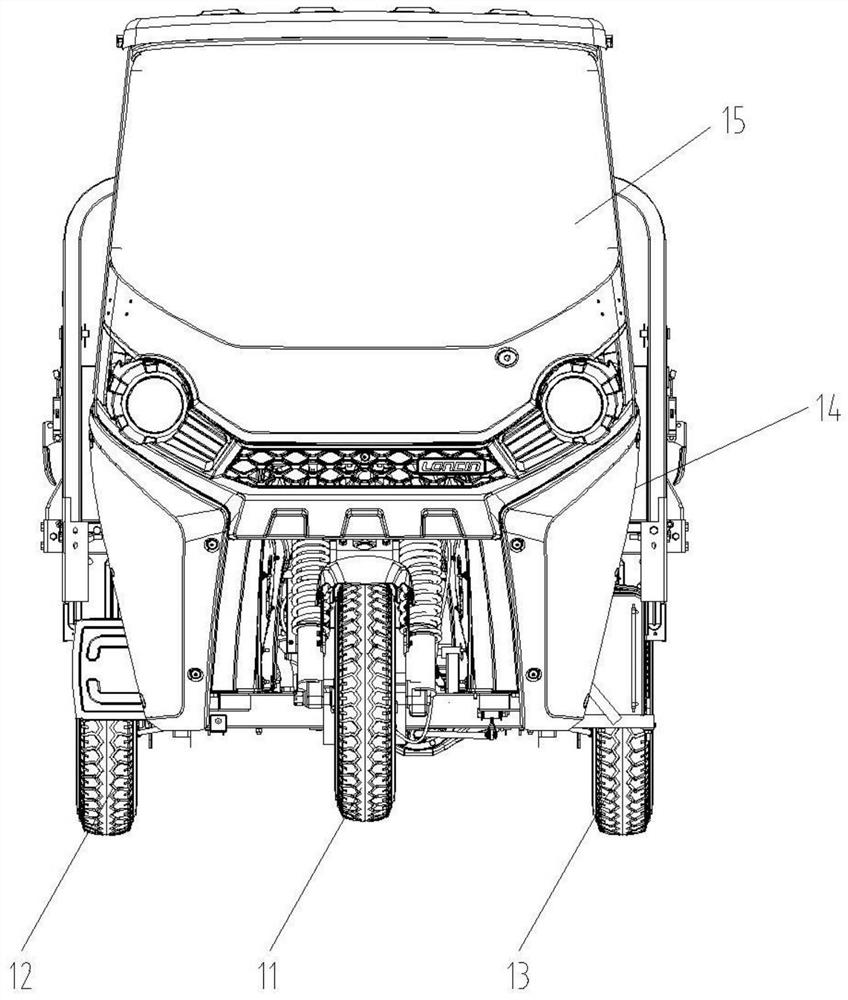

[0025] figure 1 It is a schematic diagram of the overall structure of the shock absorber; figure 2 It is a schematic diagram of the partial structure of the shock absorber; image 3 It is a schematic diagram of the front view structure of a three-wheeled motorcycle; Figure 4 It is a schematic diagram of the inspection structure of a three-wheeled motorcycle; Figure 5 It is a schematic diagram of the partial structure of the three-wheeled motorcycle;

[0026] In this embodiment, a comfort-shaped damping anti-bottom shock absorber is provided, which includes an inner cylinder 1, an outer cylinder 2 and a main shock-absorbing spring 3. The shock-absorbing main spring is simultaneously sleeved on the inner and outer cylinders, and further includes The anti-bottoming damping member 4 is installed on the inner bottom of the outer cylinder towards the inner cylinder. When the inner cylinder is down-coated on the anti-bottoming damping member, there is a lateral gap with the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com