Anti-rebound and anti-off door stop

A technology of collision head and elastic parts, applied in the field of door collision, can solve the problems of affecting the service life of door collision and easily damaged door collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

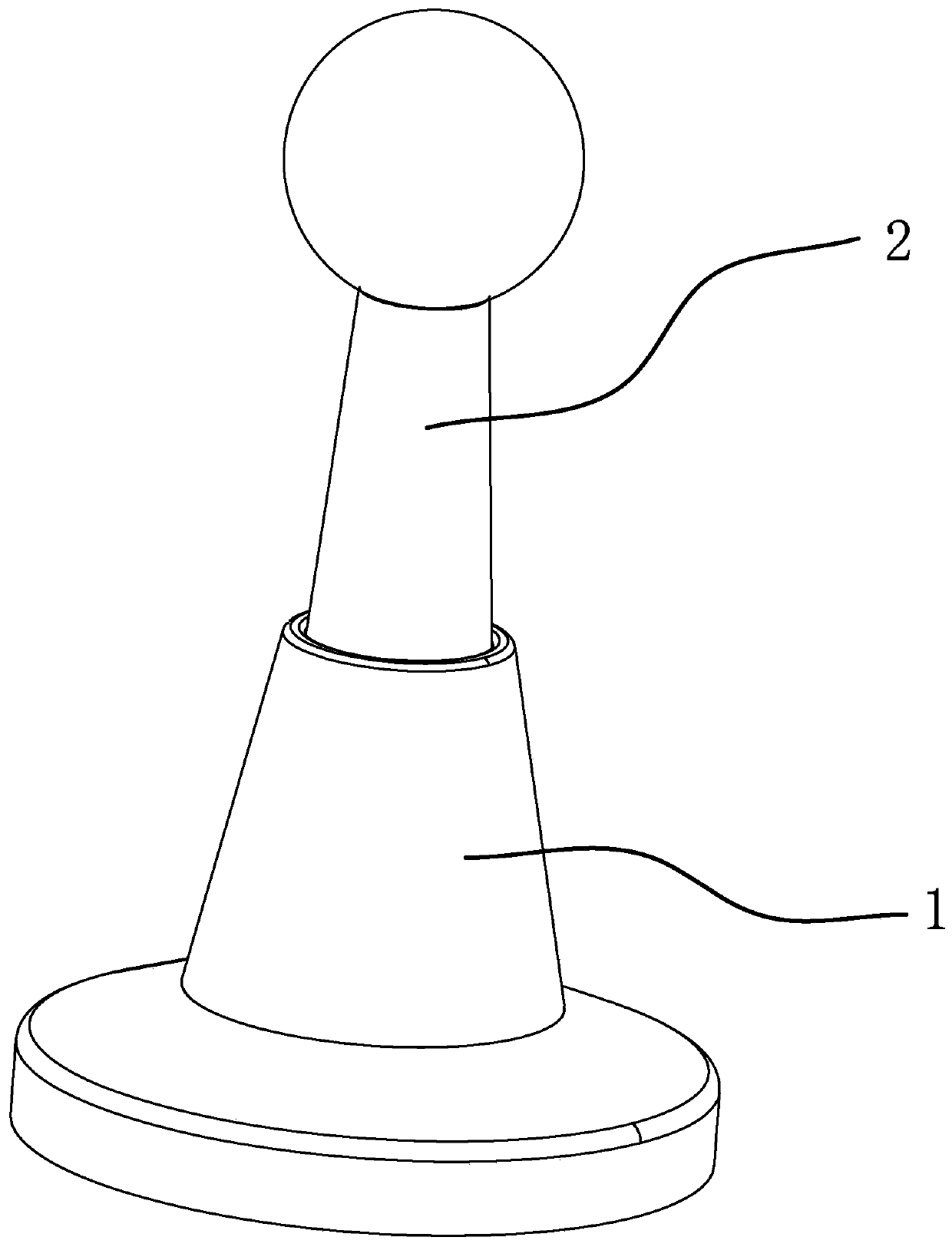

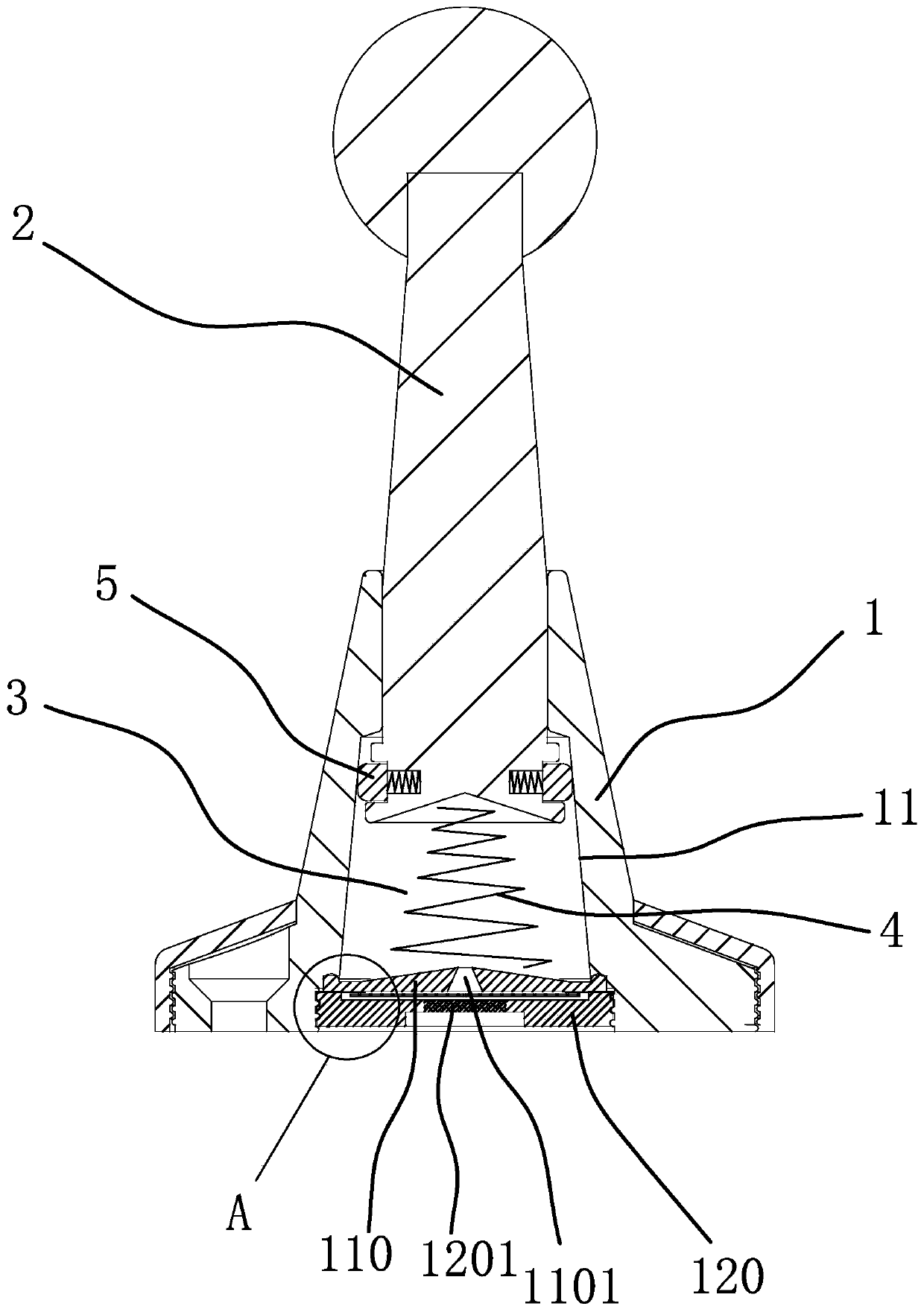

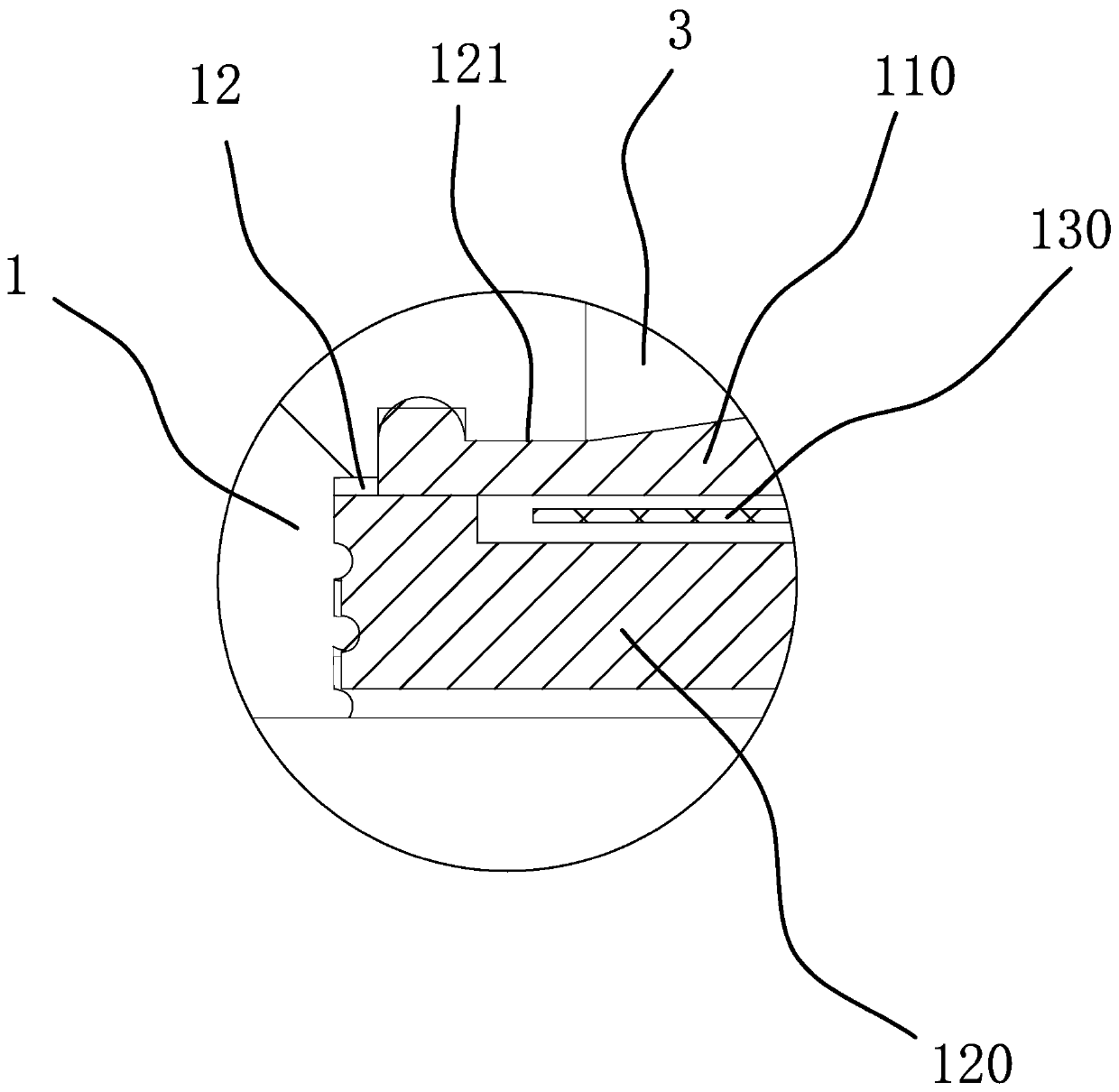

[0063] Such as Figure 1-3As shown, the bulletproof door bumper includes a seat body 1 and a columnar collision head 2, the seat body 1 has a stroke chamber 3, the inner end of the collision head 2 is slidingly fitted in the stroke chamber 3, and the inner end of the collision head 2 is in contact with the stroke chamber 3. A damping member 4 is provided between the seat body 1 to prevent the collision head 2 from sliding toward the interior of the seat body 1. The collision head 2 is provided with a friction member 5 that can move radially along the collision head 2. The friction member 5 can be connected with the stroke cavity 3 The inner wall is against, and damping oil or lubricating oil is coated between the friction member 5 and the inner wall of the stroke chamber 3 to make the door bumper work more stable. When the collision head 2 slides toward the outside of the seat body 1, the friction member 5 and the stroke chamber The pressing force between the inner walls of th...

Embodiment 2

[0066] Such as Figure 4-7 As shown, this embodiment is basically the same as the first embodiment, except that the friction member 5 is ring-shaped and sleeved around the periphery of the collision head 2 , and a fracture 51 is opened on the friction member 5 . By setting the friction member 5 in an annular shape and sleeved on the periphery of the collision head 2, a fracture 51 is provided on the friction member 5, so that the friction member 5 is similar to a piston ring, and the design of the fracture 51 can ensure that the friction member 5 itself can be elastically deformed It has a tendency of outward expansion and a simplified structure. The outer peripheral surface of the collision head 2 has a limit ring groove 21 extending in the circumferential direction, and the friction member 5 is located in the limit ring groove 21 . Specifically, a limit ring groove 21 extending in the circumferential direction is set on the collision head 2, so that the friction member 5 is...

Embodiment 3

[0069] Such as Figure 8-12 As shown, the present embodiment is basically the same as the second embodiment, the difference is that there are two friction members 5 in the shape of circular arcs, and the two friction members 5 are sequentially arranged on the periphery of the collision head 2 along the circumferential direction. A pre-compressed elastic piece 6 is provided between the friction pieces 5 , and the two ends of the elastic piece 6 respectively abut against two adjacent friction pieces 5 . By arranging two friction members 5 in an arc shape, the two friction members 5 are successively arranged on the periphery of the collision head 2 along the circumferential direction, and elastic members 1-6 are arranged between adjacent two friction members 5, so that A plurality of elastic members 1 can work together to eject the friction member 5 outward in the radial direction, so as to ensure the force between the friction member 5 and the side wall of the stroke chamber 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com