Patents

Literature

71results about How to "Improve deposition accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indirect printing of AGM

ActiveUS20060024433A1High accuracy of distributionHigh accuracy of and patternBaby linensCoatingsEngineeringElectrical and Electronics engineering

The present invention relates to a method of applying absorbent gelling material (AGM) granules by indirect printing onto an carrier layer for use in an absorbent article, particularly diaper for babies or adults, training pants, pull-up diapers (diaper pants), sanitary napkins, panty liners or the like. These articles typically comprise the carrier layer with the AGM particles together with further layers, making up the complete article.

Owner:THE PROCTER & GAMBLE COMPANY

Indirect printing of AGM

ActiveUS7838722B2Accurate distribution profileImprove comfortLiquid surface applicatorsLamination ancillary operationsEngineeringElectrical and Electronics engineering

The present invention relates to a method of applying absorbent gelling material (AGM) granules by indirect printing onto an carrier layer for use in an absorbent article, particularly diaper for babies or adults, training pants, pull-up diapers (diaper pants), sanitary napkins, panty liners or the like. These articles typically comprise the carrier layer with the AGM particles together with further layers, making up the complete article.

Owner:PROCTER & GAMBLE CO

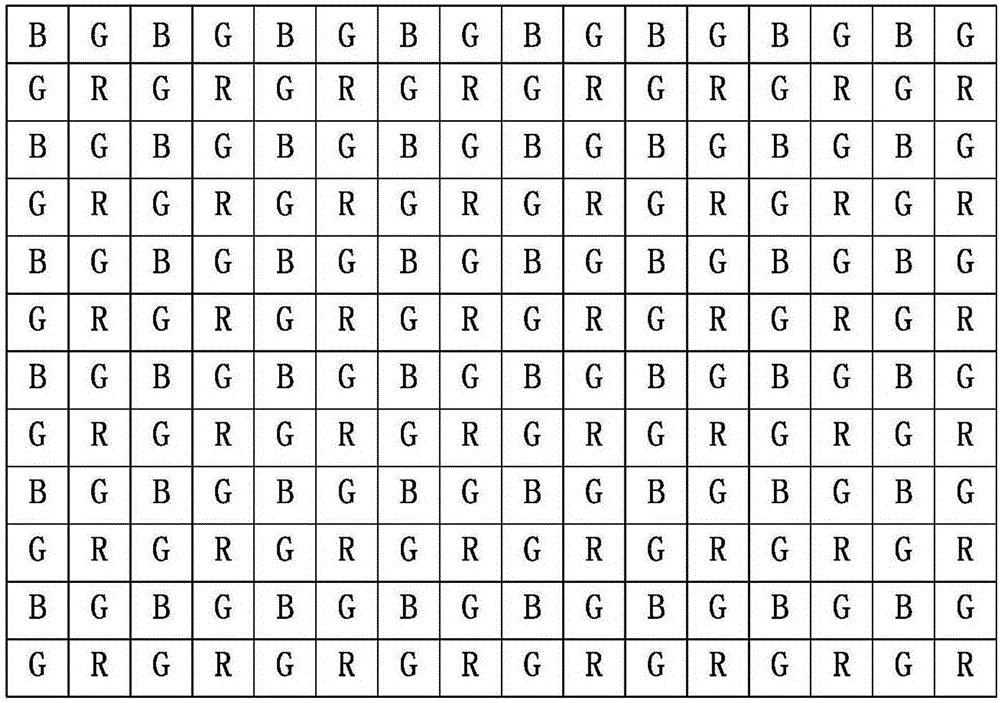

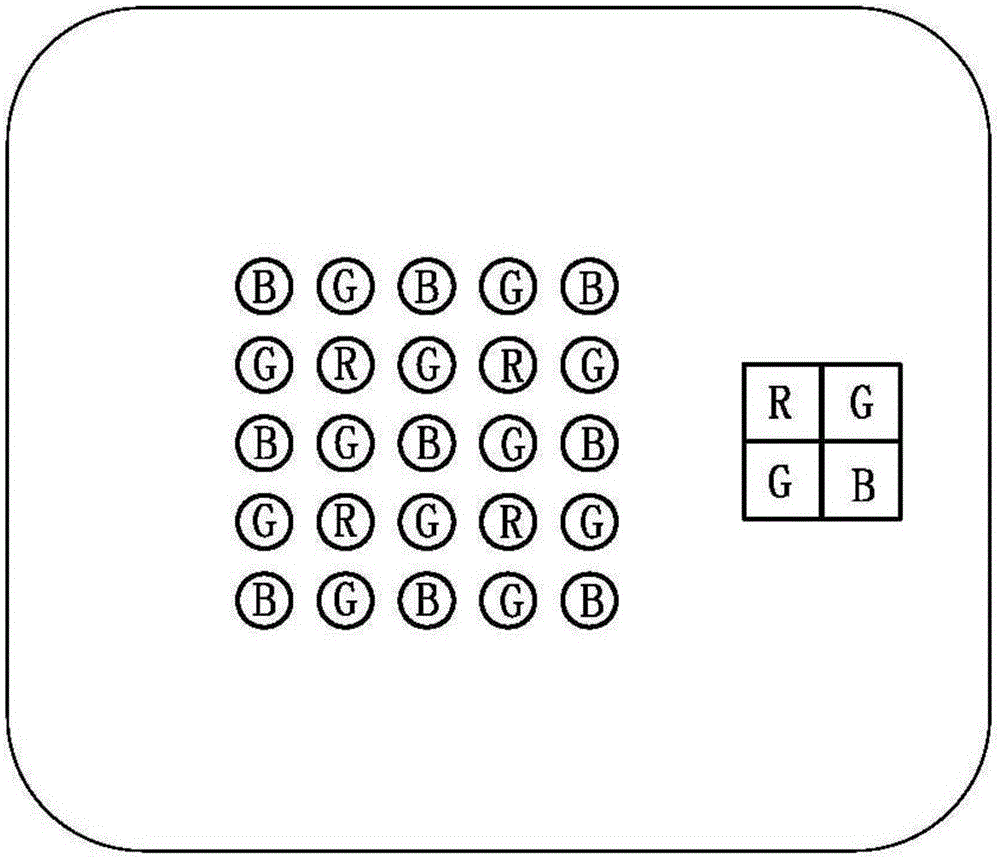

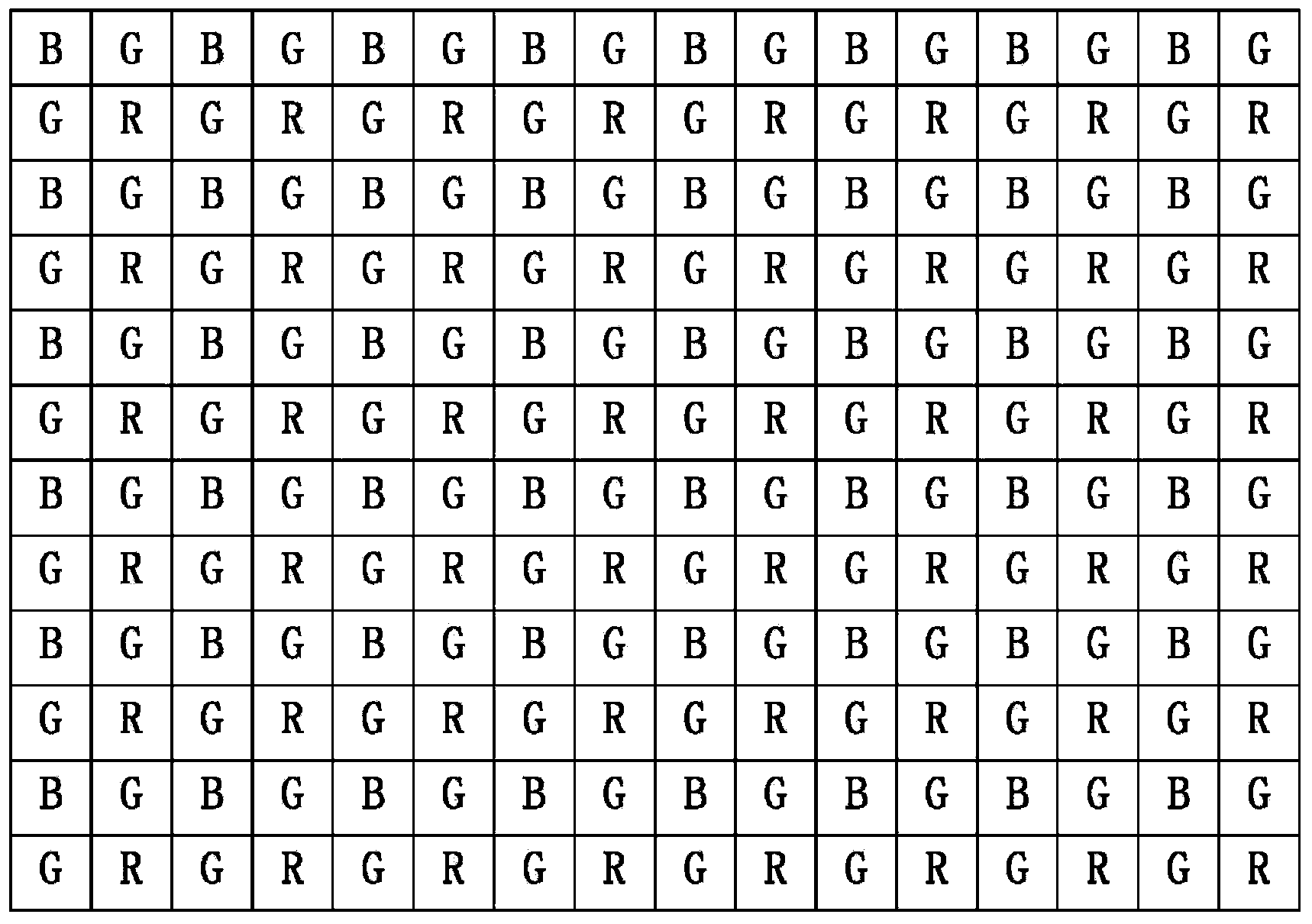

Display and pixel array thereof

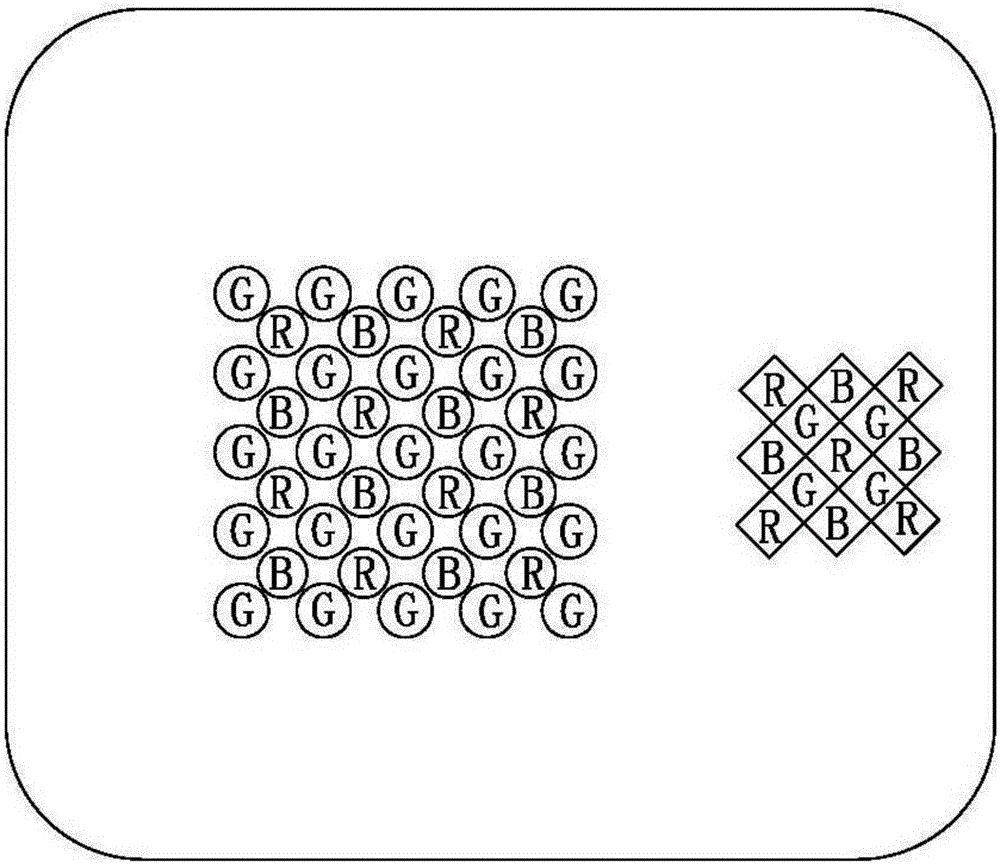

ActiveCN105047092AOvercoming ambiguity flawsFix picture quality issuesStatic indicating devicesSolid-state devicesDisplay deviceComputer science

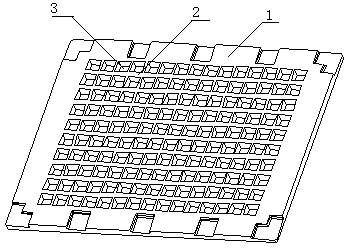

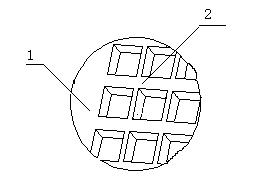

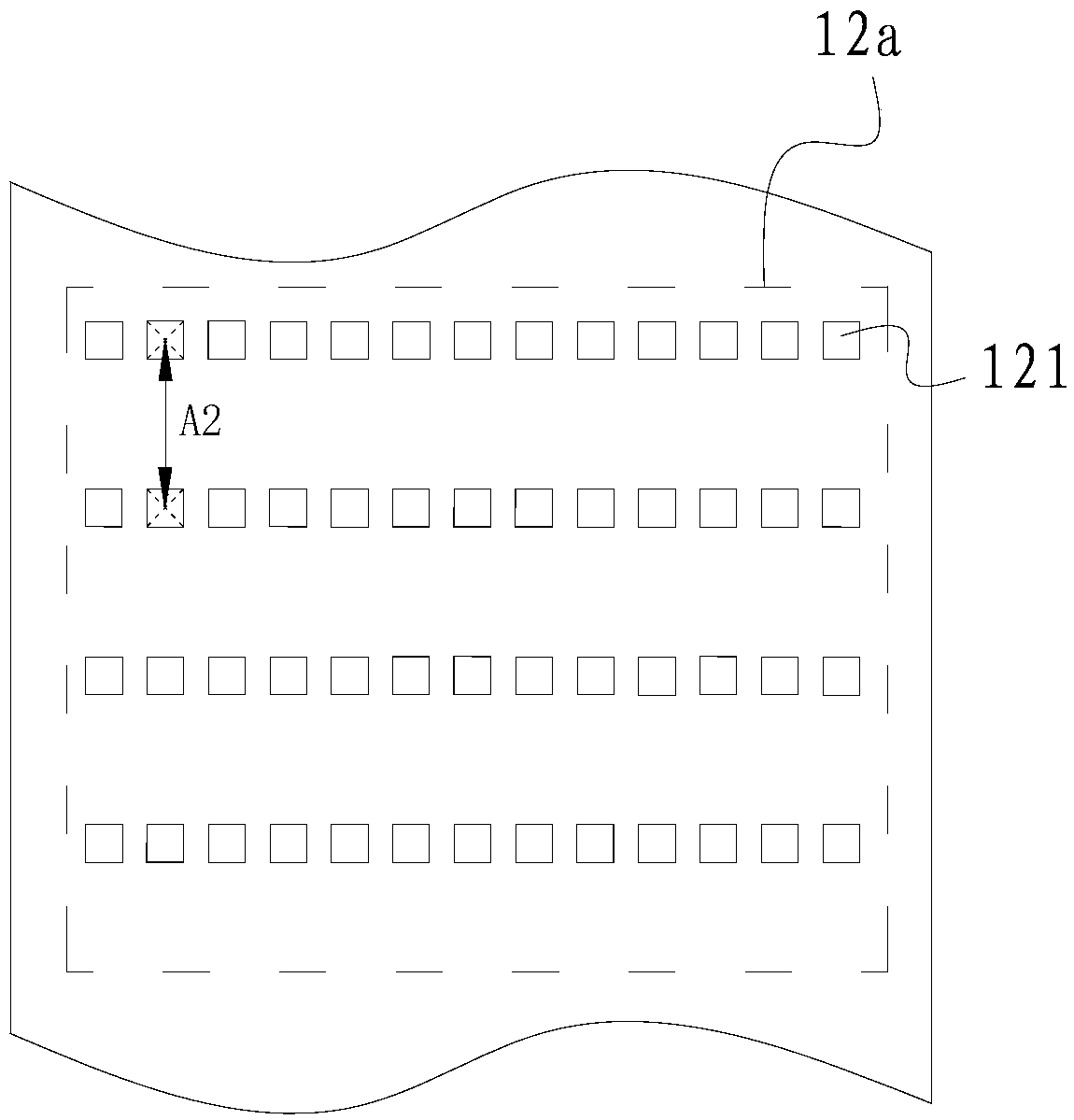

The invention provides a display and a pixel array thereof. The pixel array is composed of multiple basic pixel units which are repeatedly arranged along rows and columns. Each basic pixel unit comprises m*n pixel groups, and x*y pixel points are formed. Each pixel group comprises a first column and a second column; the first column is composed of a first type sub-pixel, a second type sub-pixel and a third type sub-pixel which are sequentially arranged at first intervals in the column direction; the second column is composed of a third type sub-pixel, a first type sub-pixel and a second type sub-pixel which are sequentially arranged at first intervals in the column direction; and the second column and the first column are staggered with the second interval in the row direction. In the pixel array, m=n, y=x / 2, m, n, x and y are positive integers, and y is larger than m. The display and the pixel array thereof can solve a zigzag problem in oblique line displaying.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

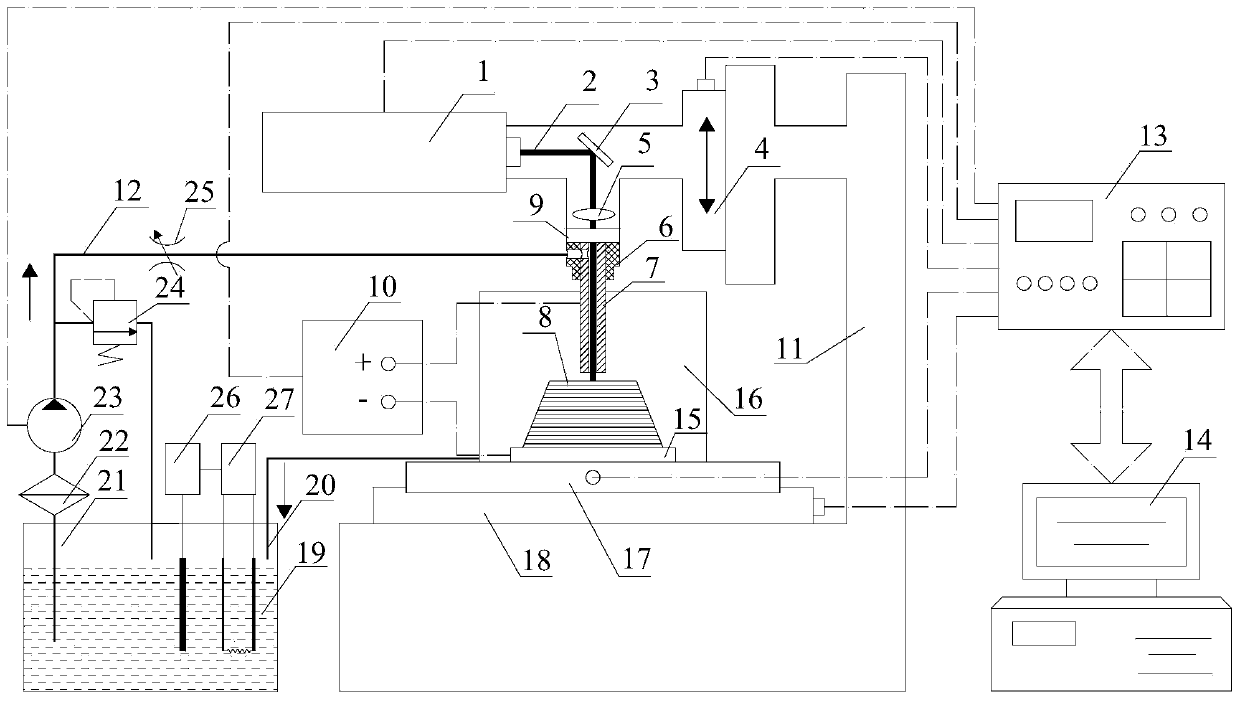

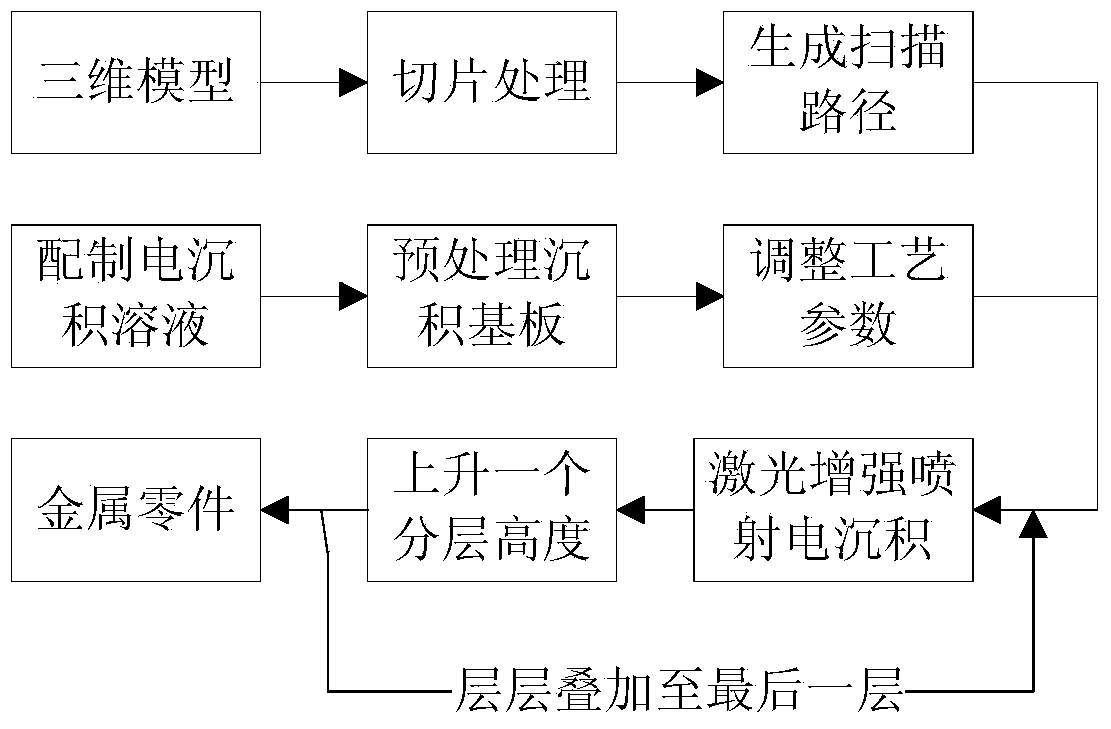

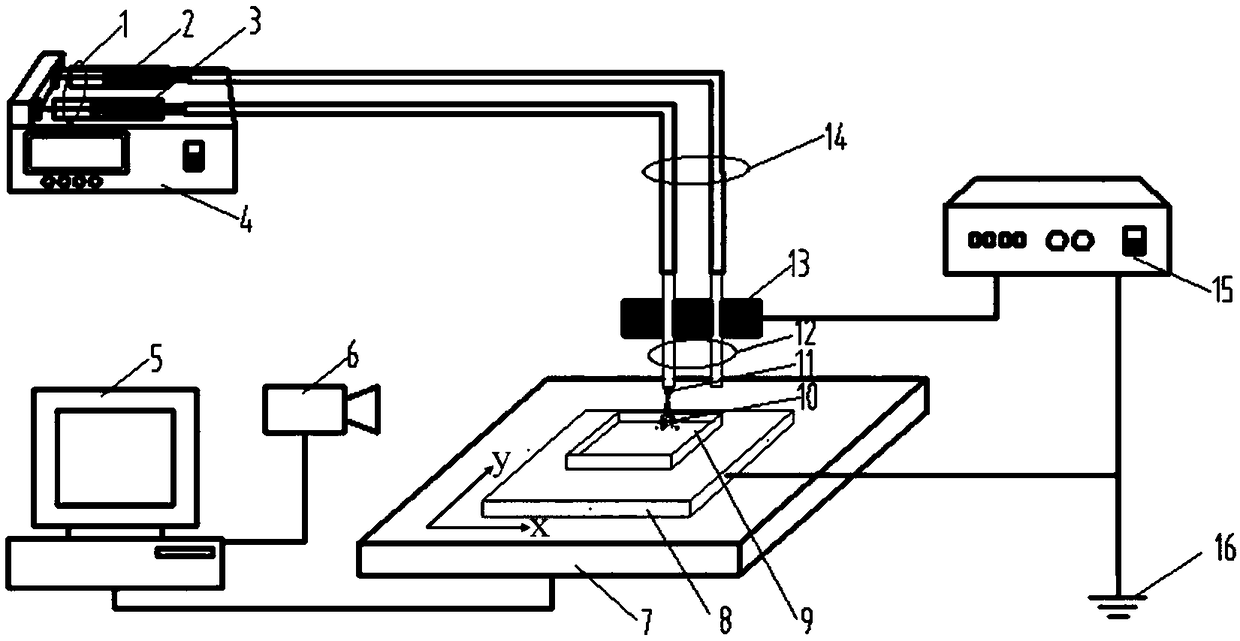

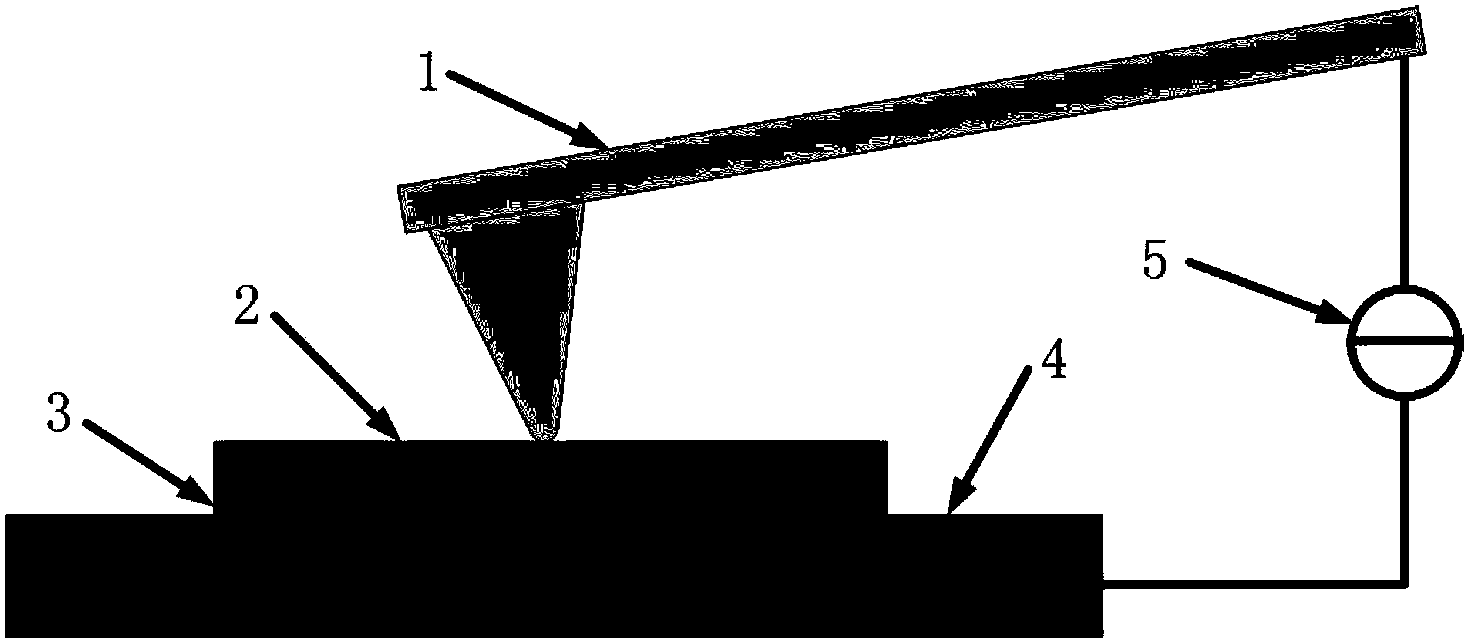

Laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method

The invention discloses a laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method. An anode is connected with a laser generation mechanism, an eye shield is located between the laser generation mechanism and the anode, a cathode is a deposition substrate which is arranged in a deposition groove, and a power supply is connected with the cathode and the anode; a Z-axis mobile platform is connected with the anode and the laser generation mechanism, and an X-axis mobile platform and a Y-axis mobile platform are successively arranged below the deposition groove; the liquid inlet end of a constant temperature liquid storage mechanism is connected with the anode, the liquid returning end of the constant temperature liquid storage mechanism is connected with the deposition groove, and a controller is connected with the laser generation mechanism, the power supply, the X-axis mobile platform, the Y-axis mobile platform, the Z-axis mobile platform and the constant temperature liquid storage mechanism. According to the invention, a high-energy density laser beam and a high-speed electrodeposition solution are synchronously jetted to the surface of the cathode through a tubular passive anode centre bore, combination of laser reinforced electrodeposition technology and electrodeposition solution injection is realized, and a high deposition speed is obtained.

Owner:TONGLING UNIV

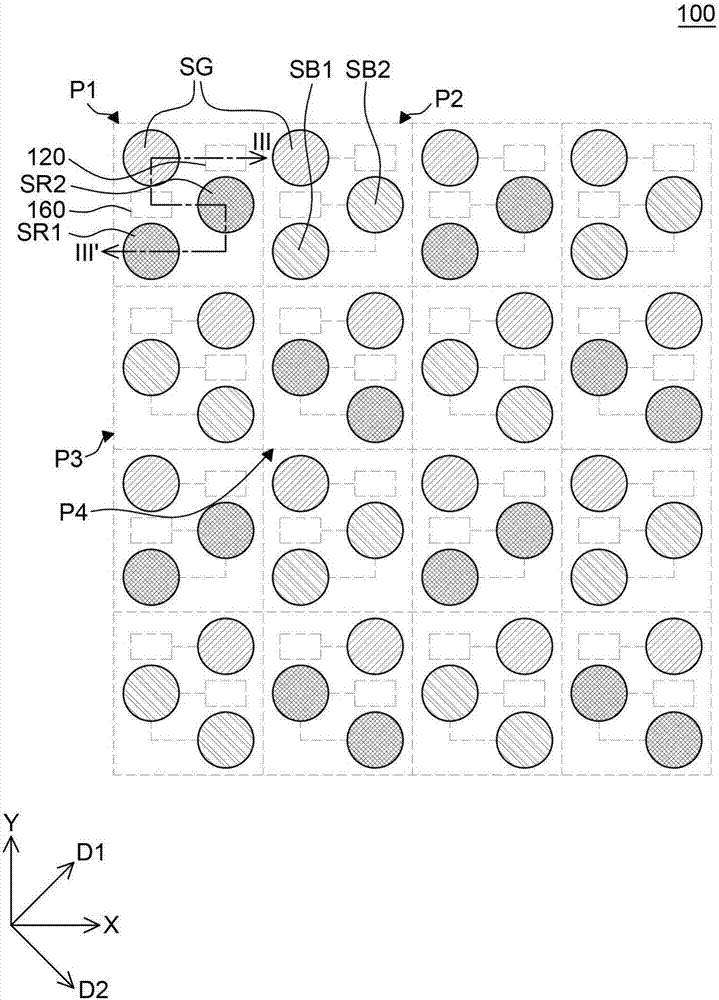

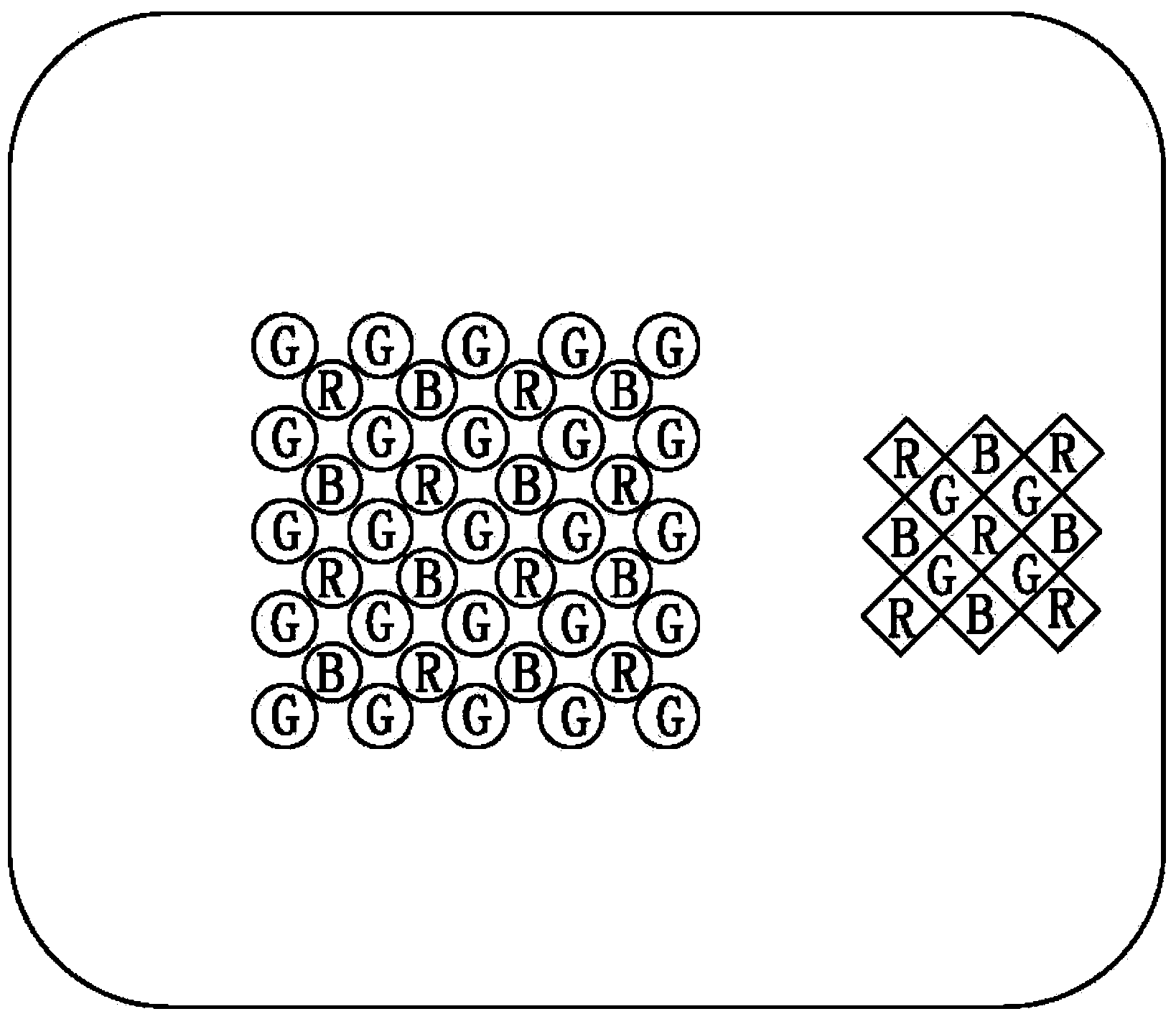

Oganic light emitting display device

ActiveCN107275361AReduce artifactsImprove image qualityStatic indicating devicesSolid-state devicesDisplay deviceComputer vision

An organic light emitting display device including a plurality of pixels is provided according to an embodiment. Each of the plurality of pixels includes three sub pixels. The plurality of pixels include a first pixel having a green sub pixel and two red sub pixels, a second pixel having a green sub pixel and two blue sub pixels, the second pixel being adjacent to the first pixel in a first direction, a third pixel having a green sub pixel and two blue sub pixels, the third pixel being adjacent to the first pixel in a second direction, and a fourth pixel having a green sub pixel and two red sub pixels, the fourth pixel being adjacent to the second pixel in the second direction. In the organic light emitting display device according to an example embodiment of the present disclosure, sub pixels are asymmetrically disposed in pixels which are disposed in at least one direction, to reduce lattice artifact by the regular arrangement of the sub pixels.

Owner:LG DISPLAY CO LTD

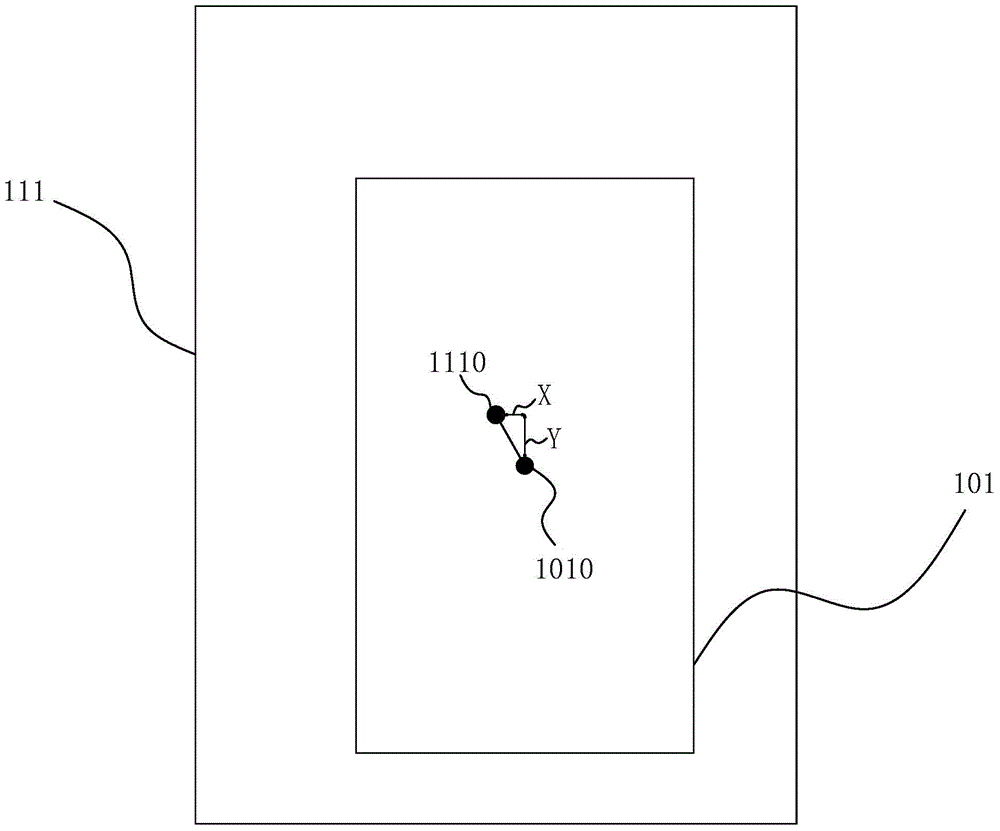

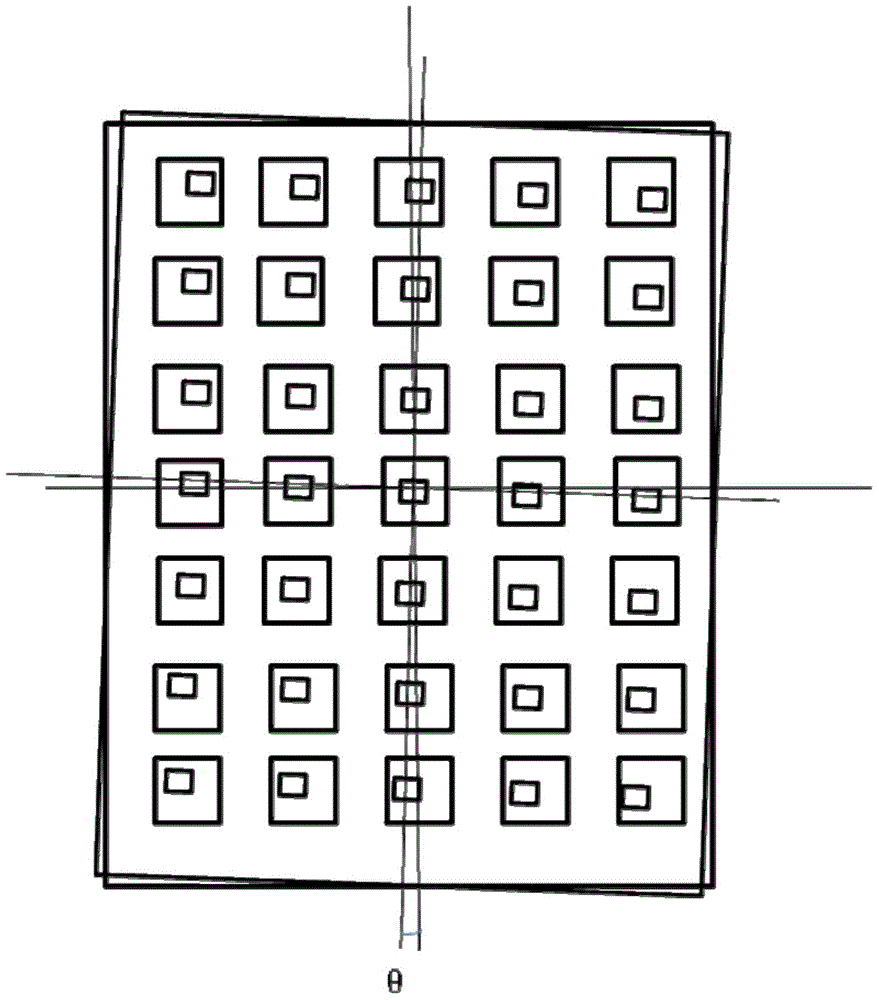

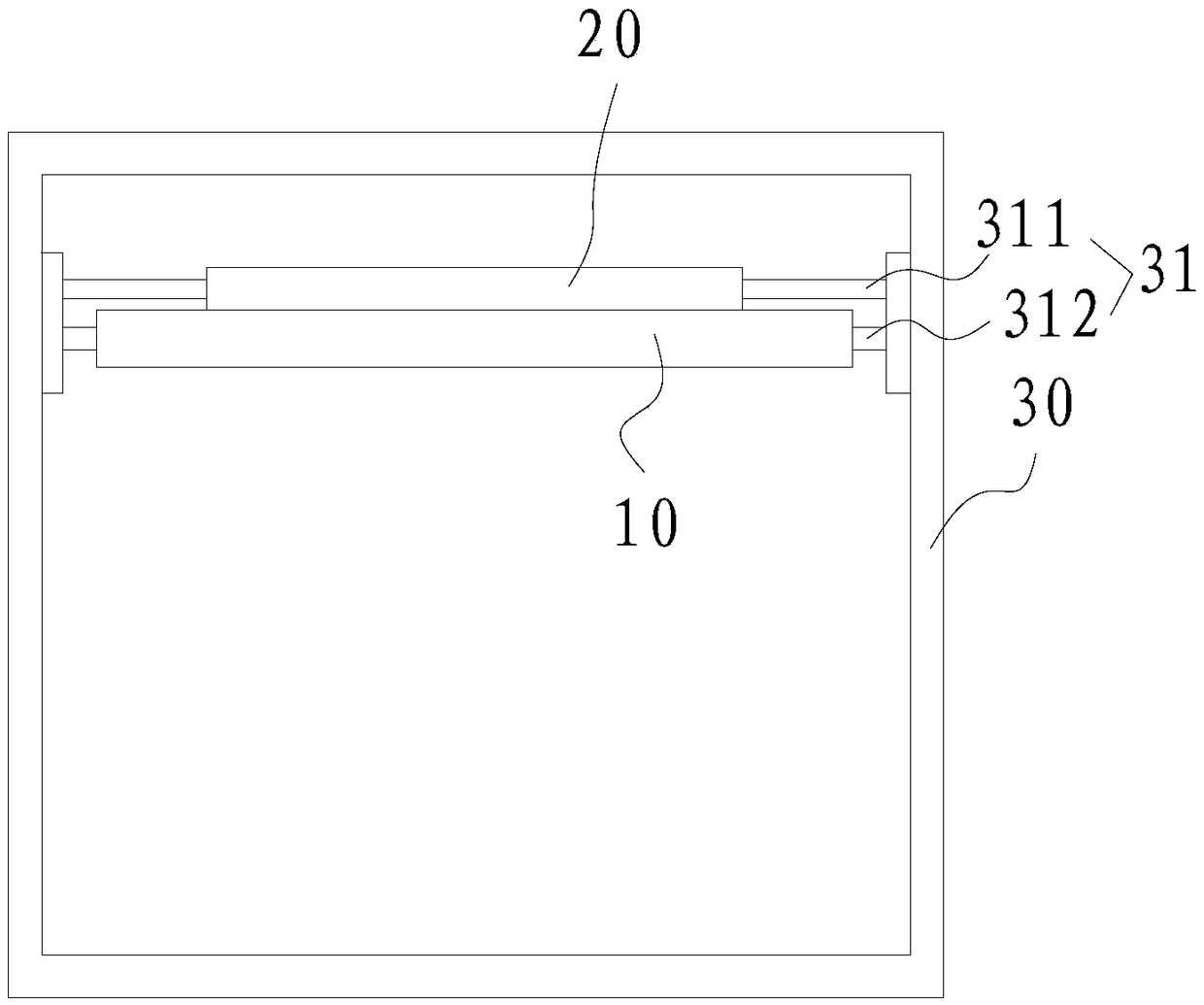

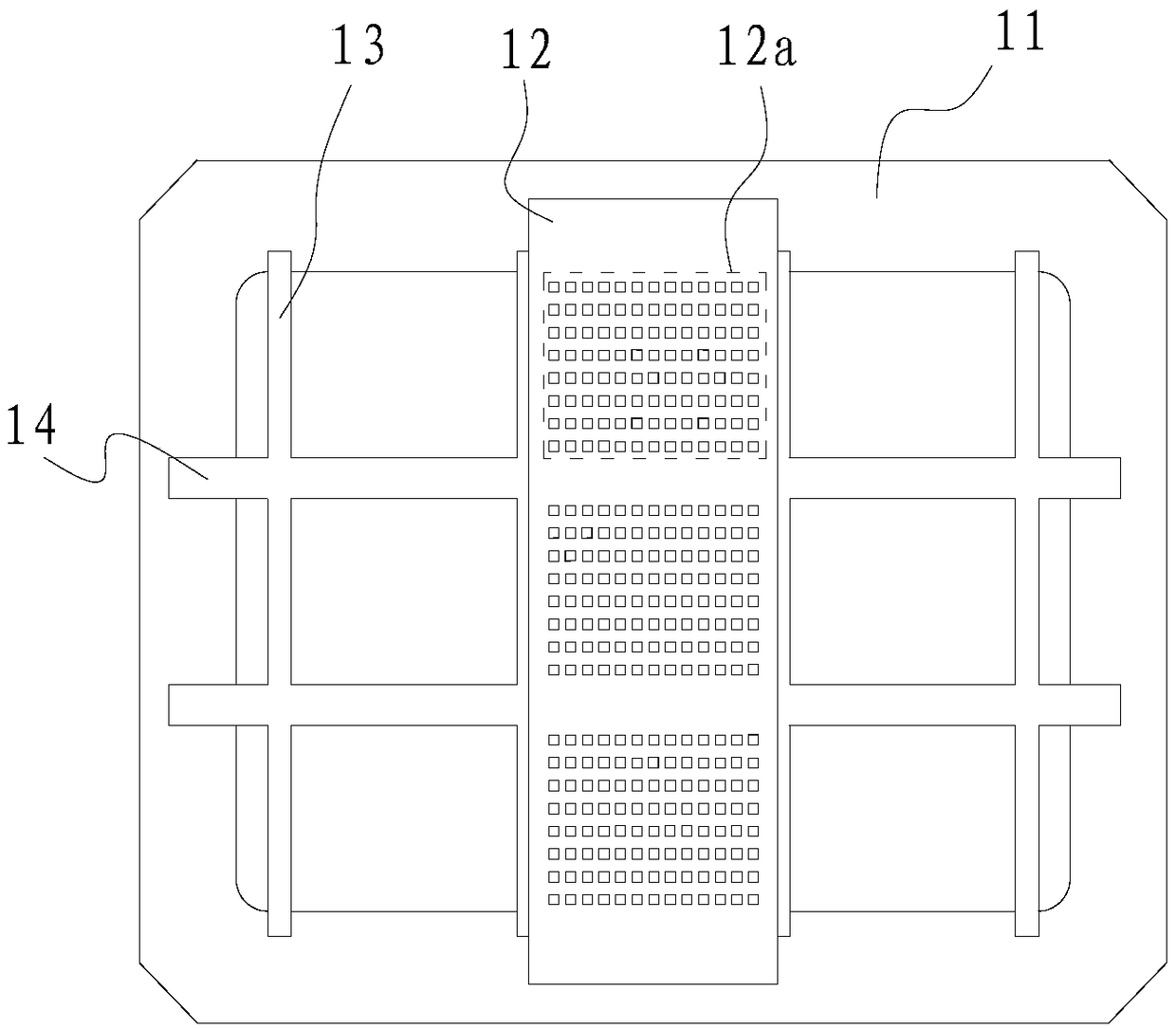

Optical alignment compensation device, contact degree detecting device, evaporation system and method

ActiveCN105702880AReduce manufacturing costImprove deposition accuracyVacuum evaporation coatingSolid-state devicesEvaporationData acquisition

The invention discloses an optical alignment compensation device, a contact degree detecting device, an evaporation system and an evaporation method. An optical alignment compensation data acquisition device comprises an image acquisition mechanism and a processing mechanism, wherein the image acquisition mechanism is used for acquiring images of openings of a metal mask and pixel opening of a substrate corresponding to the metal mask when the substrate is overlapped with the metal mask; and the processing mechanism is used for acquiring an offset between the openings of the metal mask and the pixel opening of the substrate according to the acquired images of the openings of the metal mask and the pixel opening of the substrate, and calculating a position compensation data between the substrate and the metal mask. According to the optical alignment compensation device, the contact degree detecting device, the evaporation system and the evaporation method, images of the pixel opening of the substrate and the openings of the metal mask can be acquired before evaporation, alignment compensation and contact degree detection on the metal mask and the substrate can be carried out, organic materials do not need to be evaporated, and a substrate can be reused, thereby reducing the production cost, and increasing evaporation precision.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

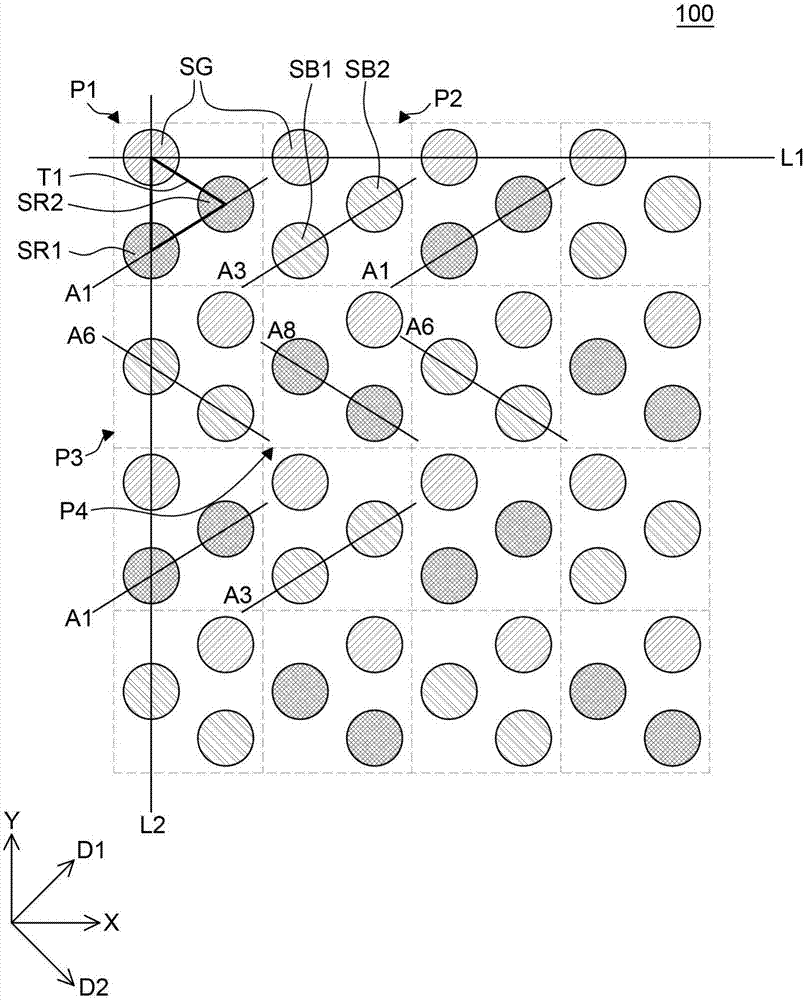

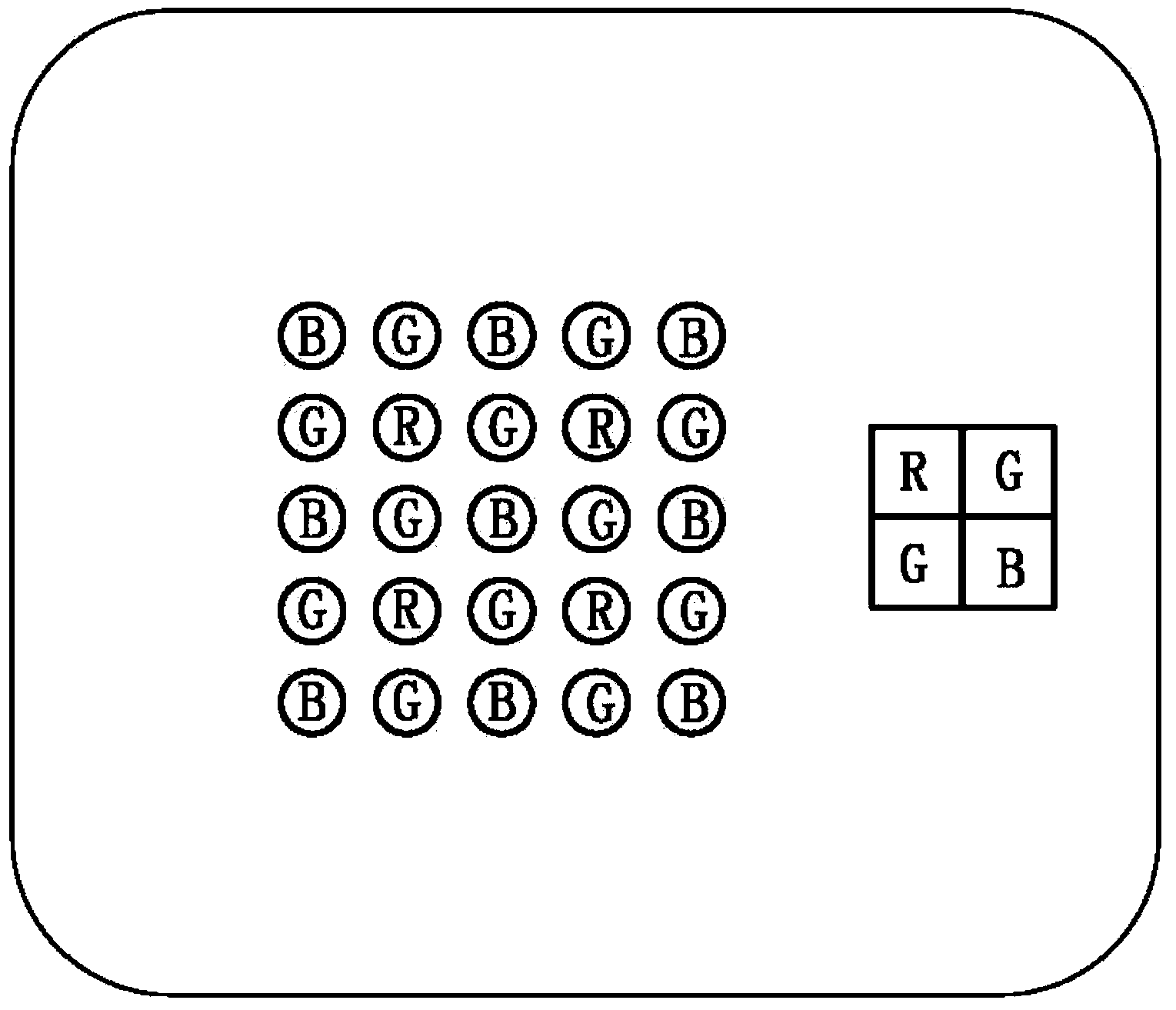

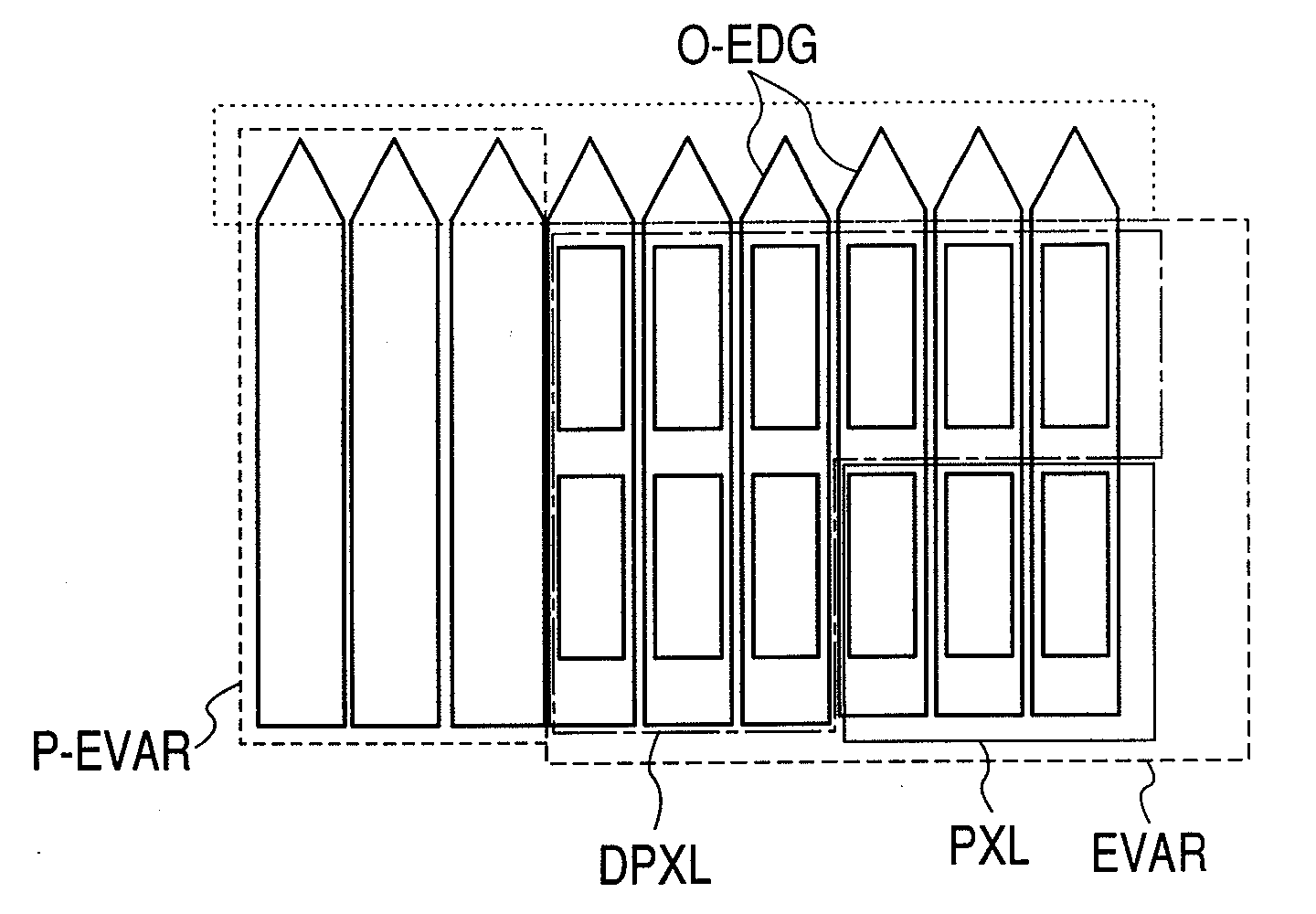

Pixel array, display and method for presenting images on display

ActiveCN104037201AIncrease finenessRaise the ratioStatic indicating devicesSolid-state devicesLong axisPixel array

The invention discloses a pixel array, a display and a method for presenting images on the display. The pixel array is constructed by overlapping a plurality of basic pixel units in a horizontal direction and a vertical direction; the basic pixel units comprise a first sub-pixel group and a second sub-pixel group; the first sub-pixel group consists of first sub-pixels, second sub-pixels and third sub-pixels; the centers of the first sub-pixels, the second sub-pixels and the third sub-pixels are aligned from top to bottom in sequence at first intervals in a vertical direction or aligned from left to right in sequence at the first intervals in a horizontal direction, and the long axis of each sub-pixel is positioned in a direction formed by rotating by 45 degrees in an anti-clockwise direction of the vertical direction; the second sub-pixel group consists of third sub-pixels, first sub-pixels and second sub-pixels; the centers of the third sub-pixels, the first sub-pixels and the second sub-pixels are aligned at the first intervals along the aligning direction of the first sub-pixel group; the long axis of each sub-pixel is in a direction formed by rotating by 45 degrees in a clockwise direction of the vertical direction.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

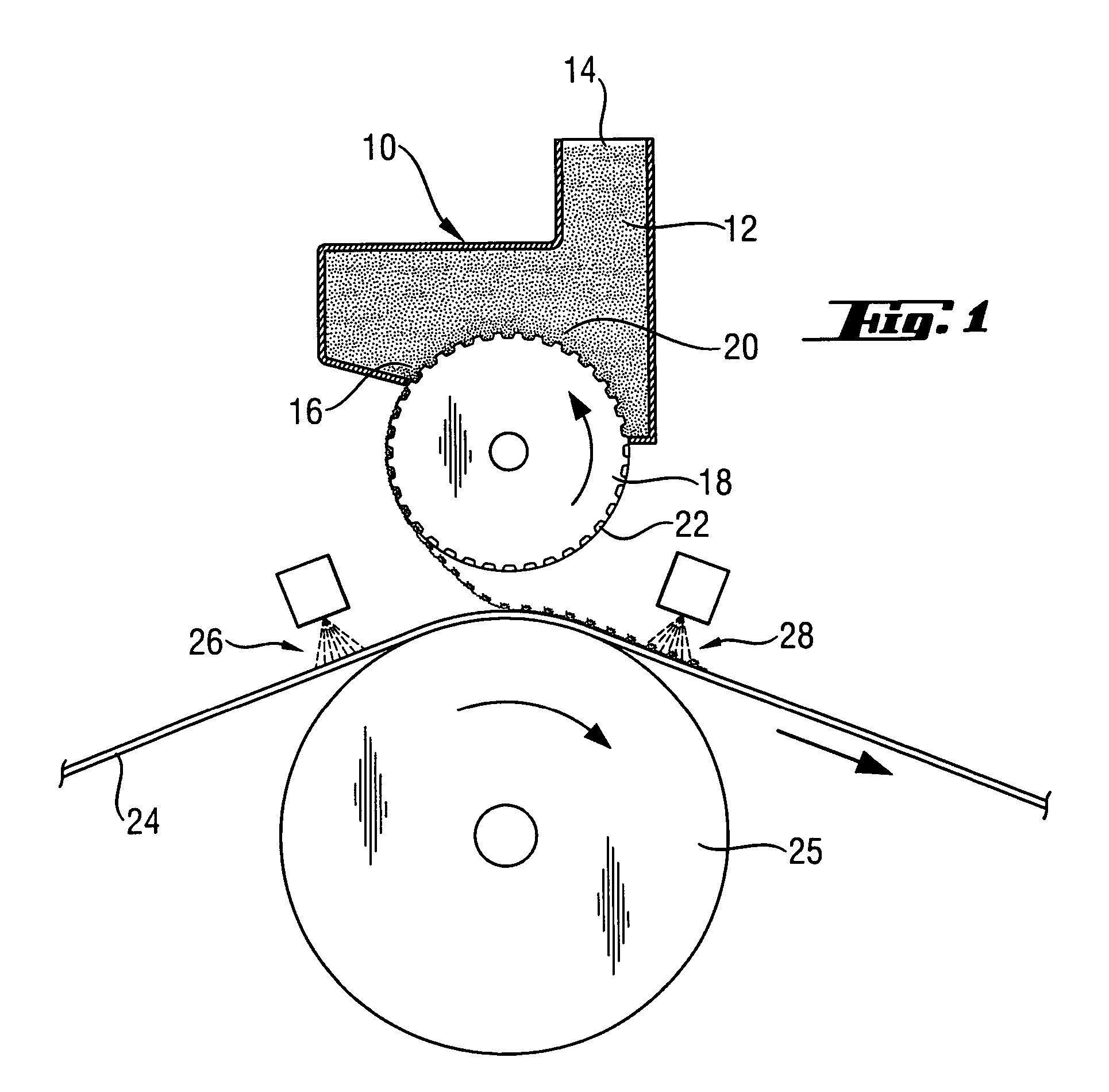

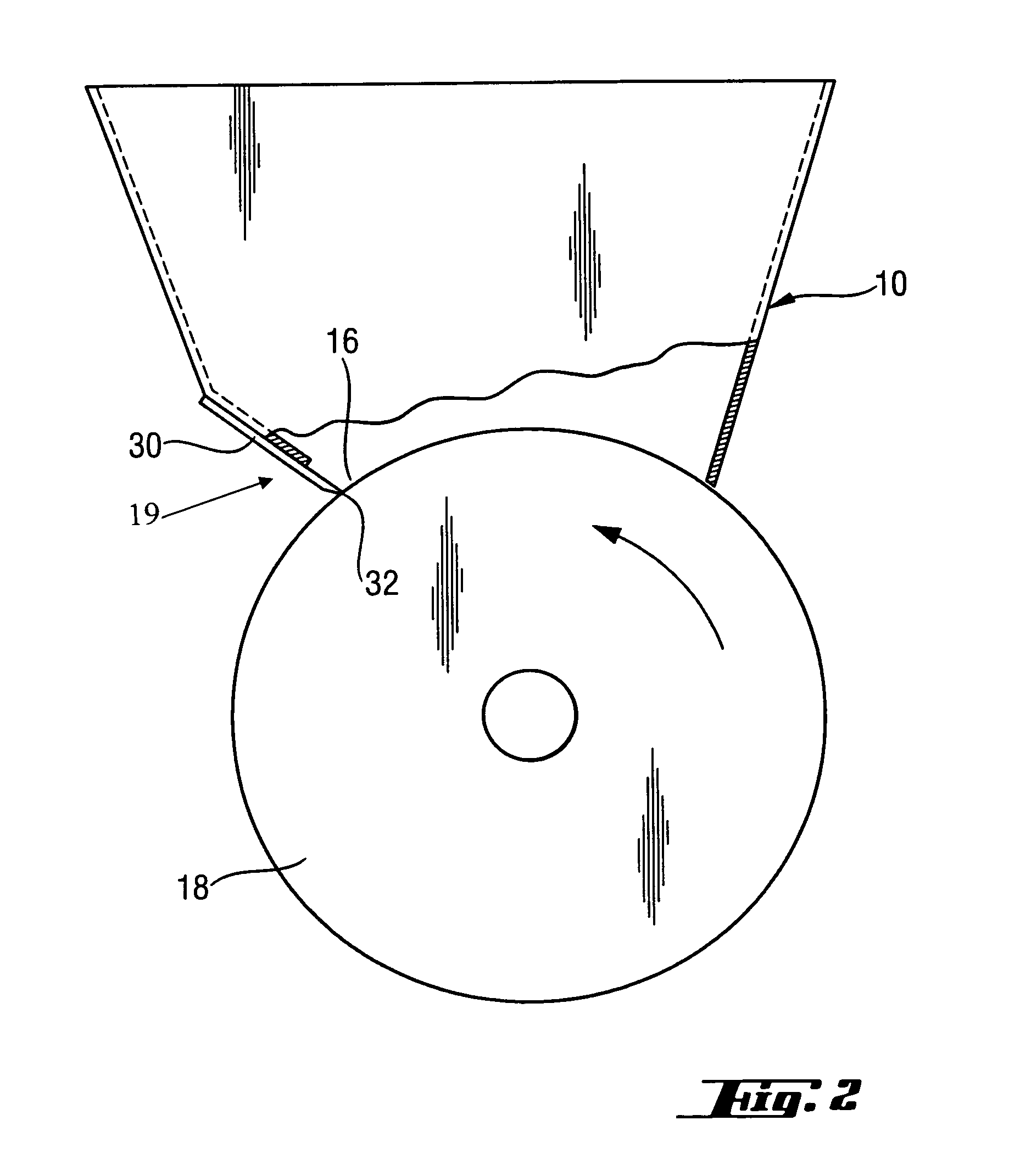

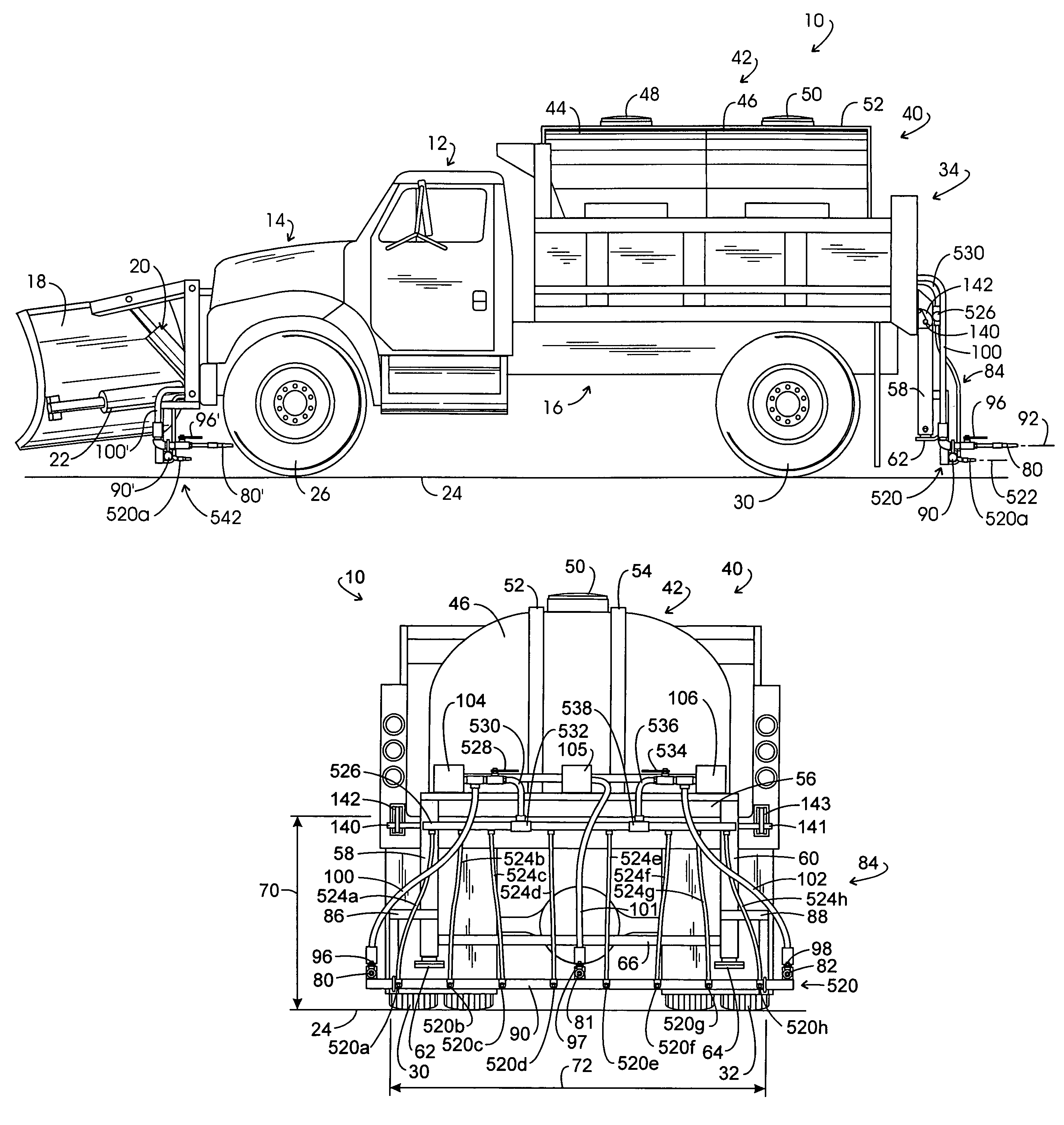

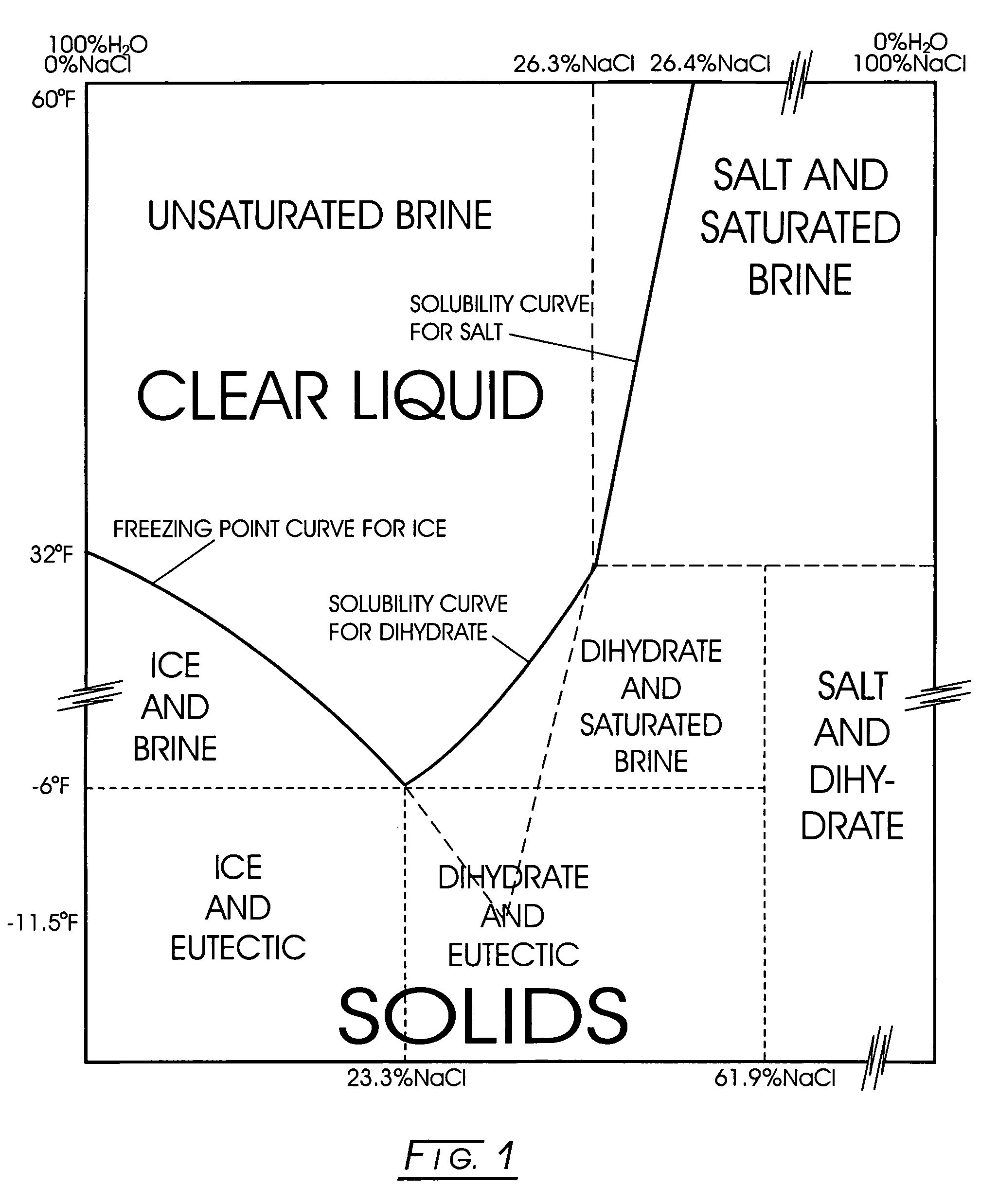

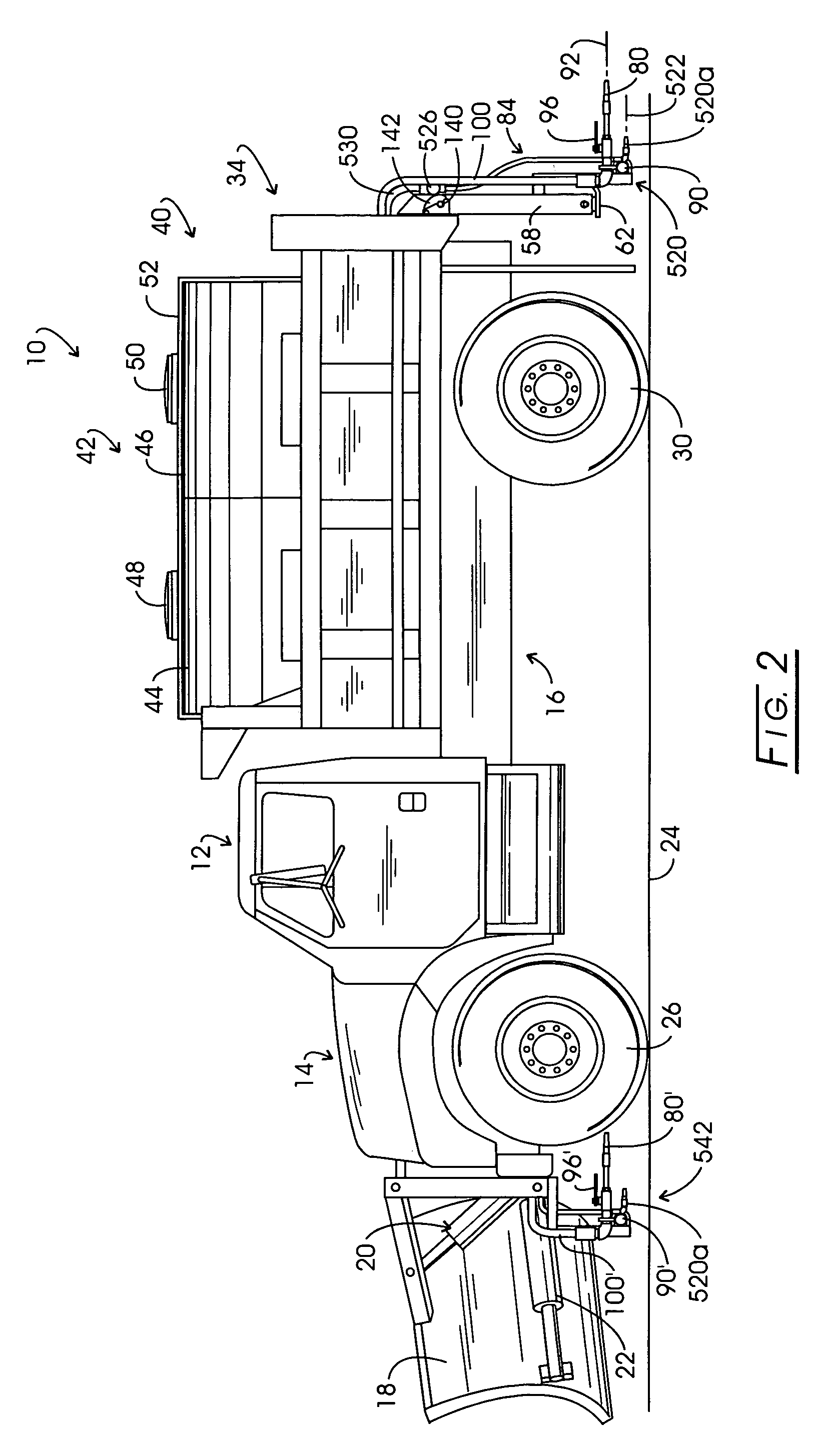

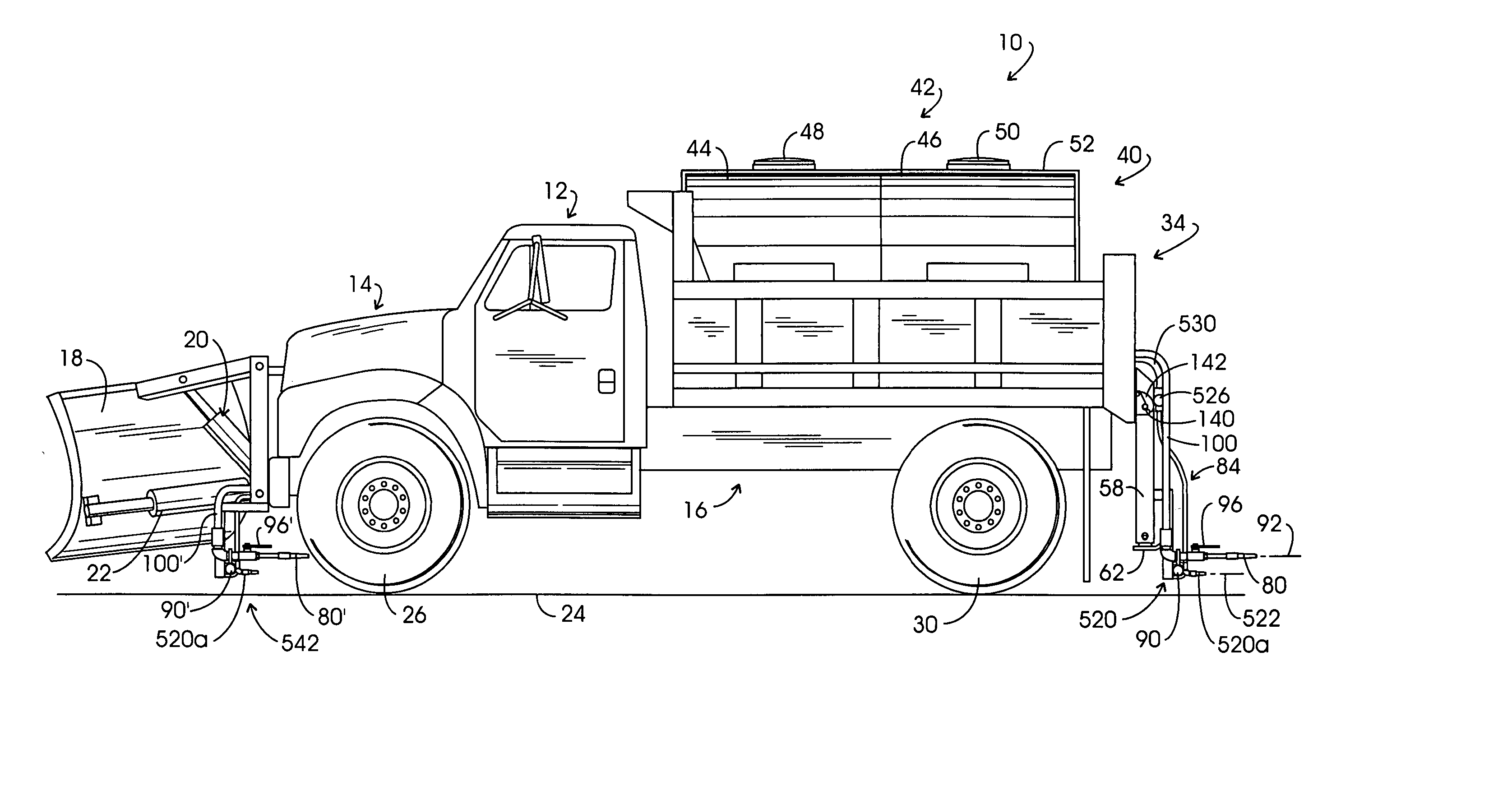

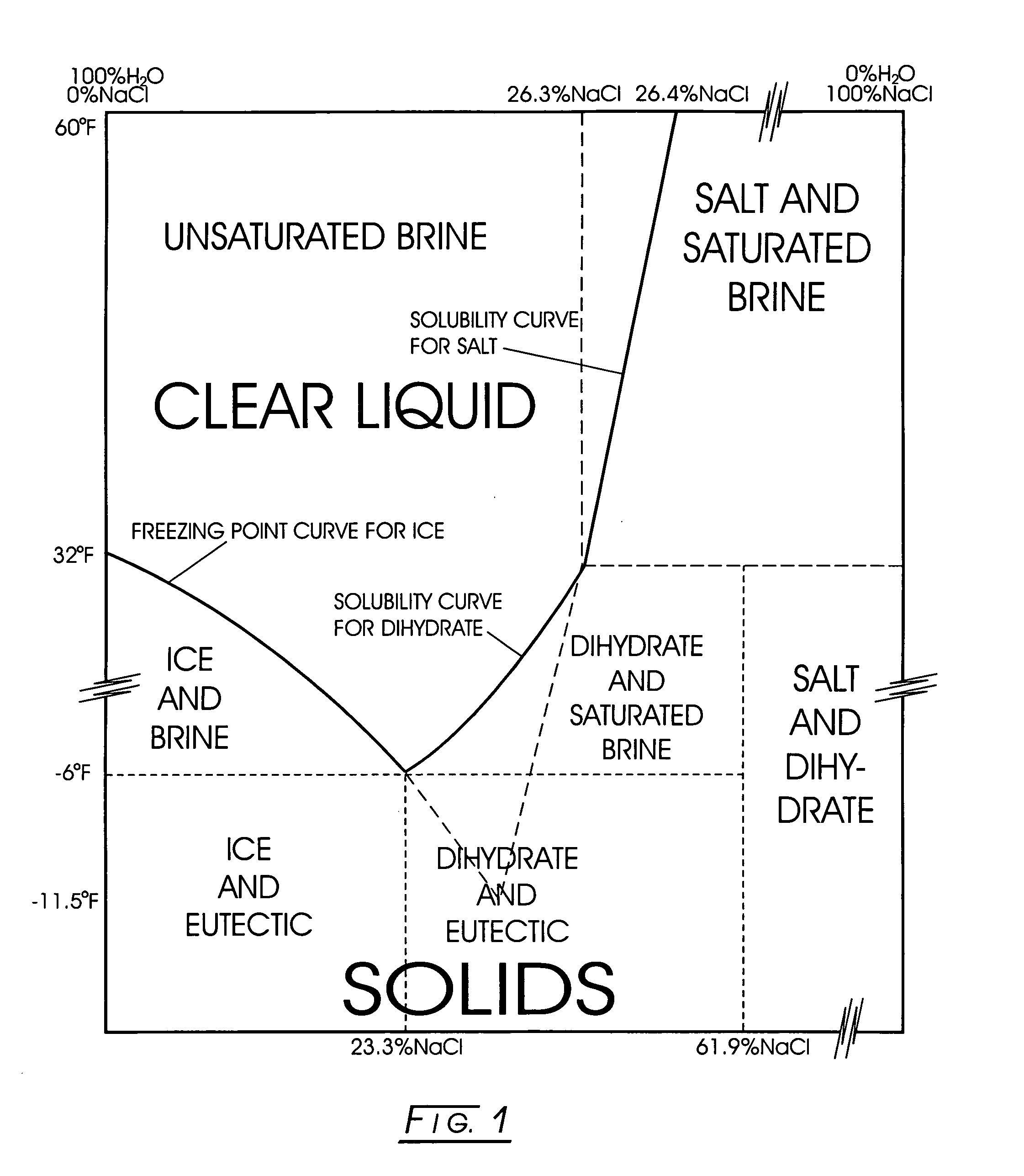

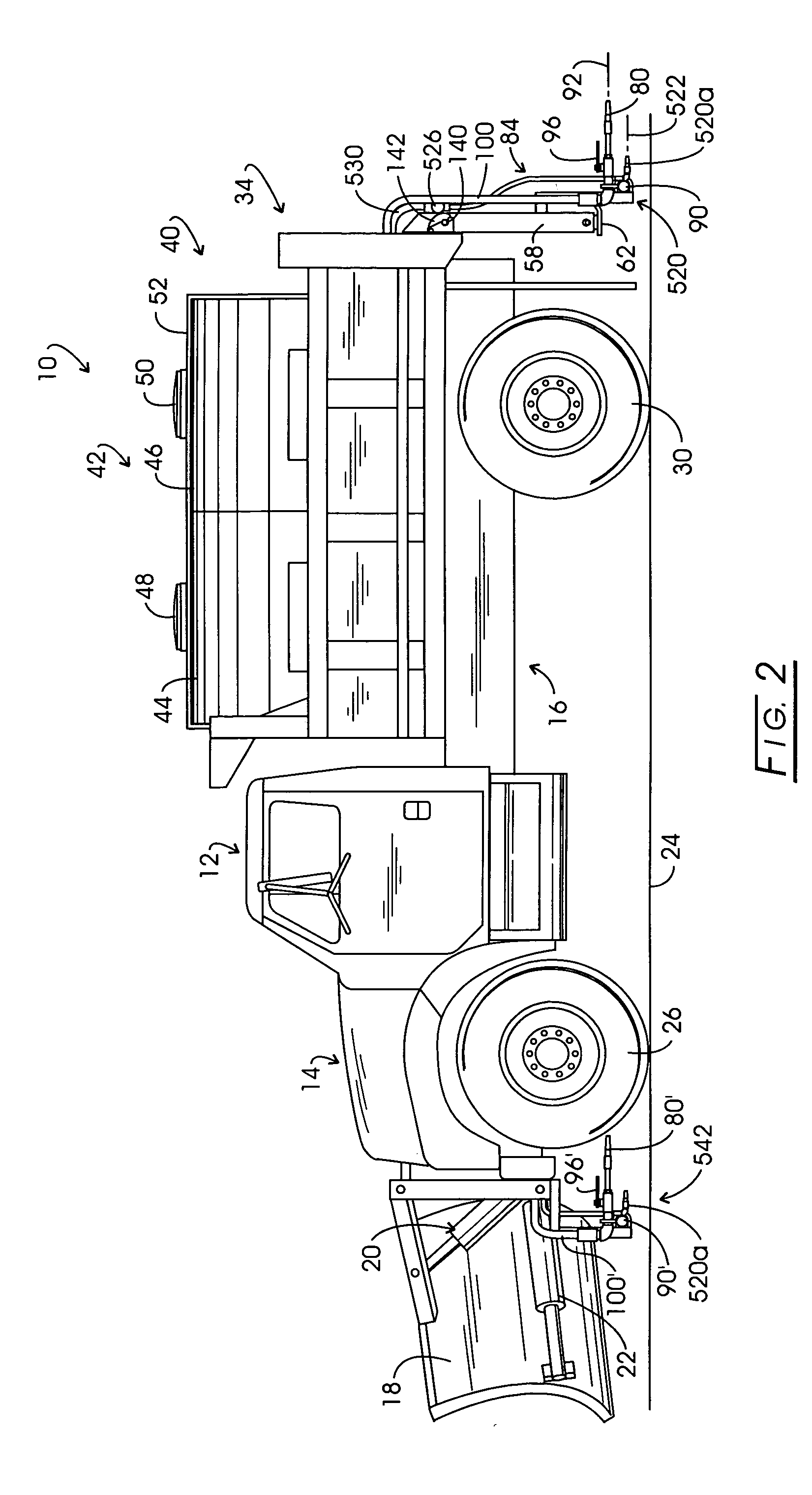

Method and apparatus for depositing snow-ice treatment liquid on pavement

InactiveUS7108196B2Minimizes air turbulenceAccurate storageLiquid surface applicatorsSelf-acting watering devicesEngineeringRoad surface

Method and apparatus for depositing liquid brine on roadway surface. Substantially horizontally disposed streamer nozzles are employed in conjunction with brine pumps which are operated in correspondence with the forward speed of the treatment vehicle. Substantially horizontally disposed streamer nozzles express the fluid at a rate corresponding with the vehicle forward velocity to effect a relative zero velocity relationship between the pavement and liquid. These streamer nozzles are mounted close to the pavement surface at a location effective to avoid truck induced air turbulence.

Owner:KIME JAMES A

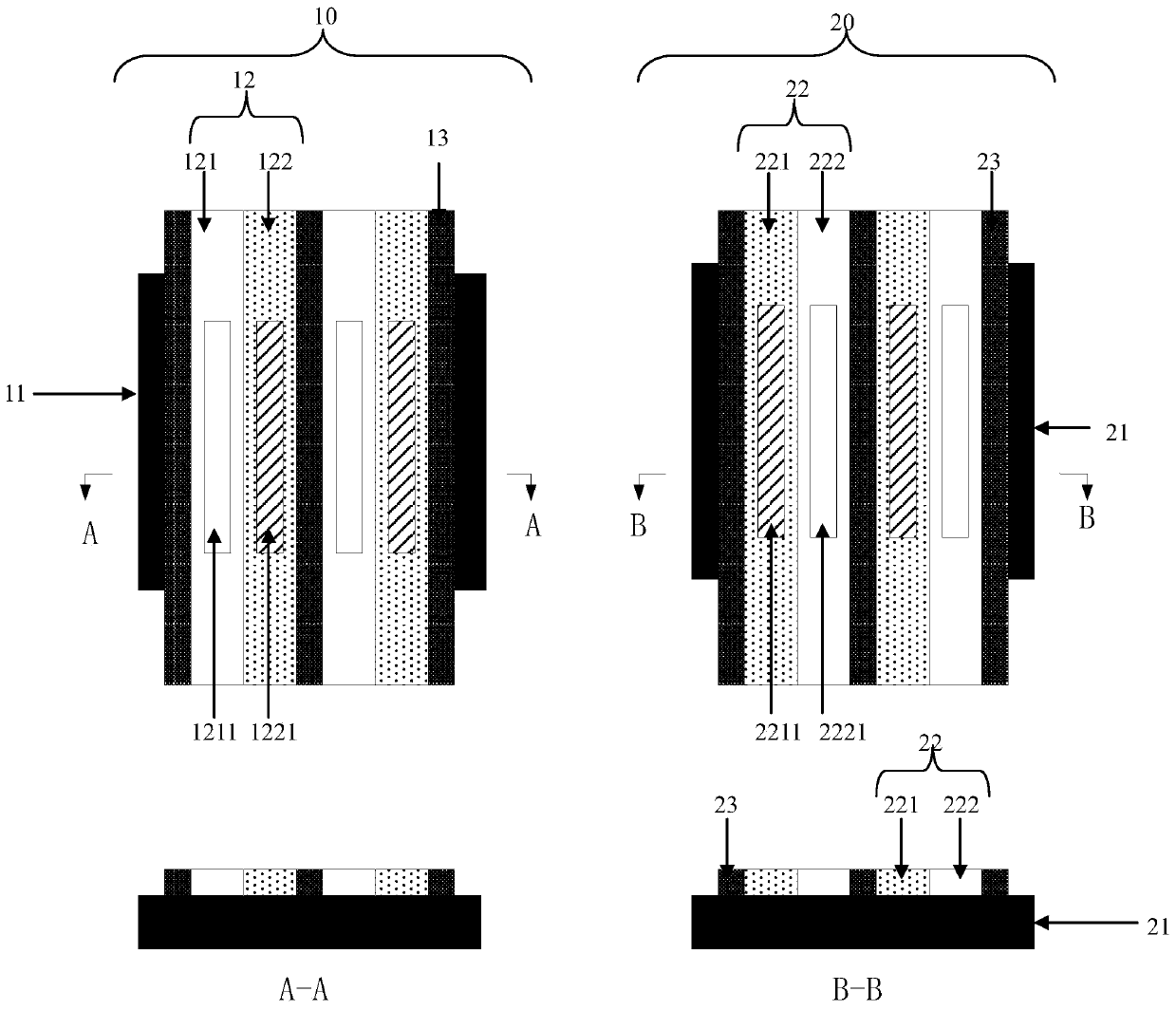

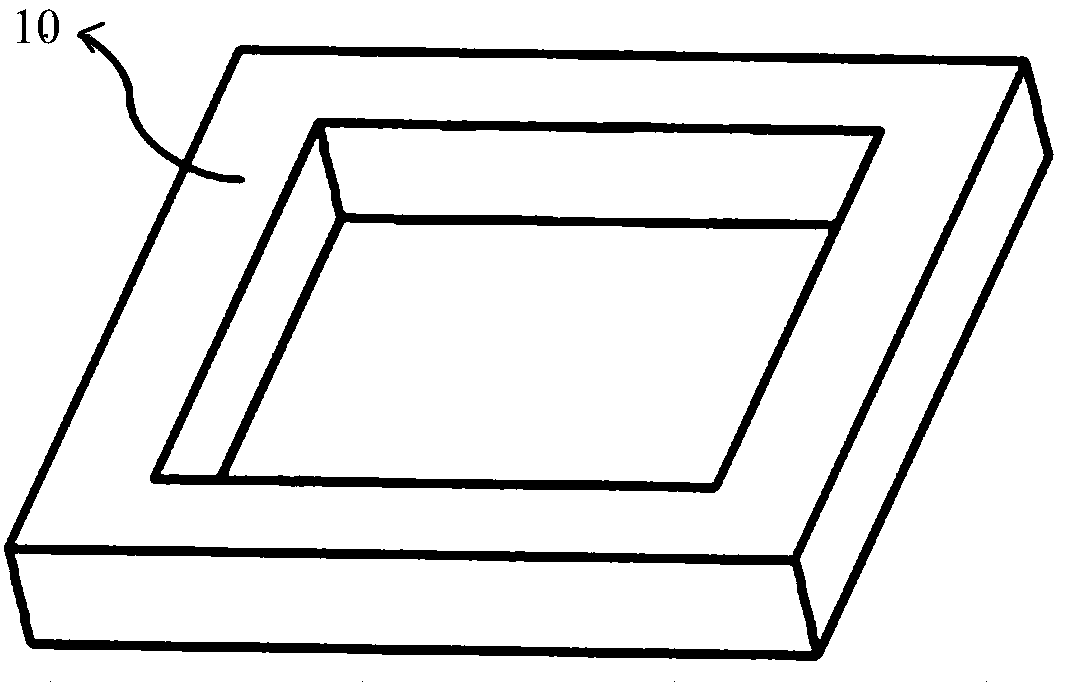

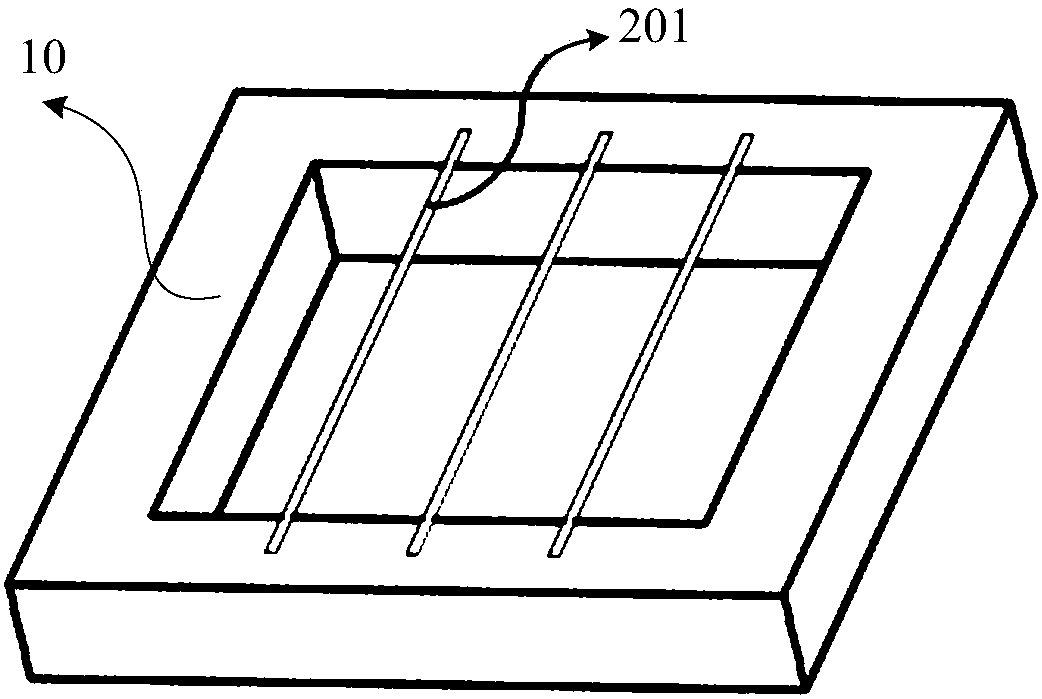

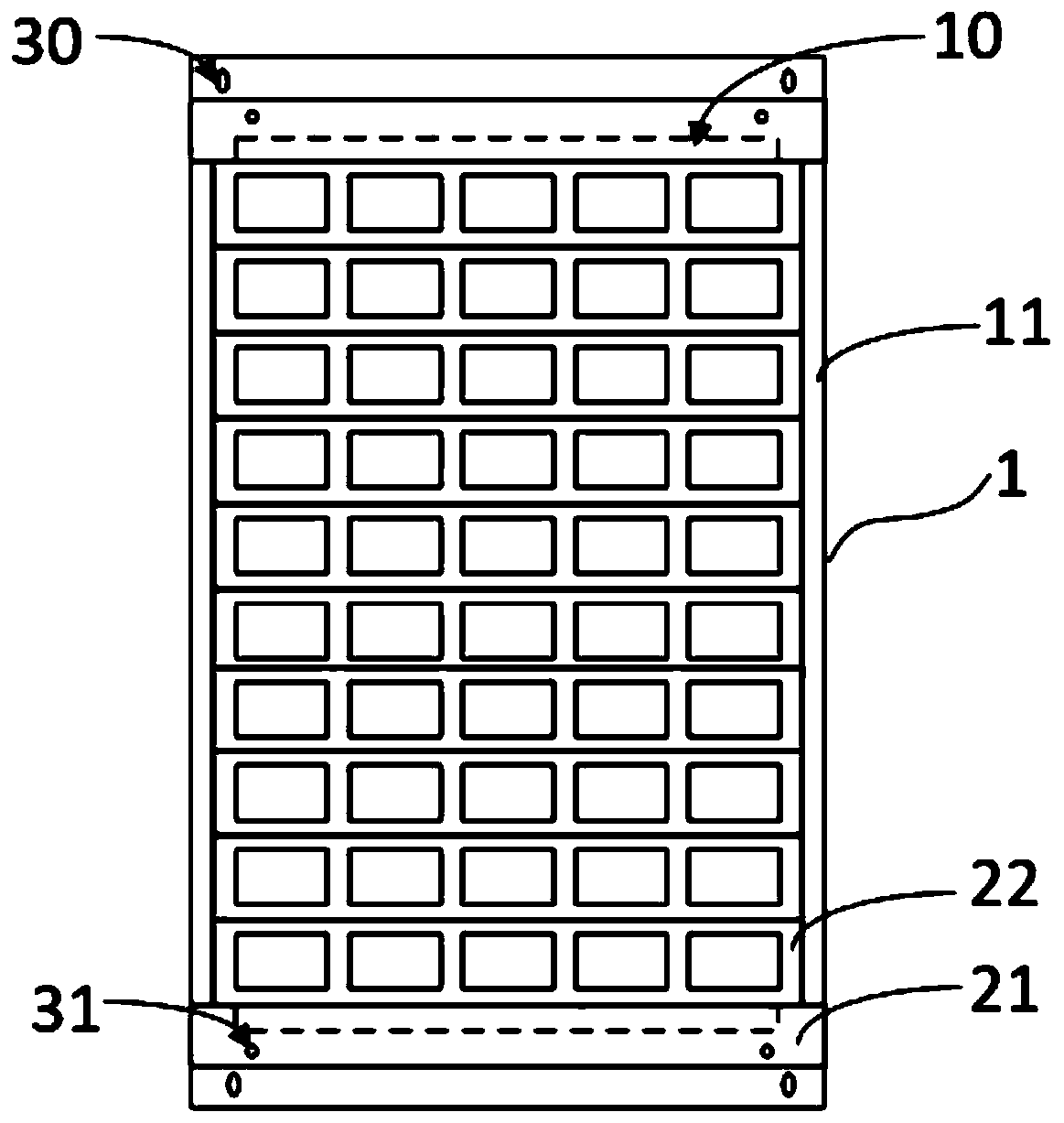

A sagging preventive mask framework and a sagging preventive mask assembly

InactiveCN103207518AAvoid deformationImprove deposition accuracyOriginals for photomechanical treatmentStructural engineeringMechanical engineering

The invention relates to a sagging preventive mask framework and a corresponding mask assembly. The sagging preventive mask framework comprises a side frame and a support bar, and the side frame and the support bar are formed in an integral molding form; the corresponding mask assembly comprises the sagging preventive mask framework and a mask plate, and the mask framework is welded with the mask plate. The mask framework and the anti-sagging mask assembly provided by the invention effectively prevent pattern deformation of the mask plate caused by the gravity of the mask plate on the mask assembly during evaporation, effectively improve the evaporation precision, are low in production cost and high in efficiency, and have a wide market prospect.

Owner:KUN SHAN POWER STENCIL

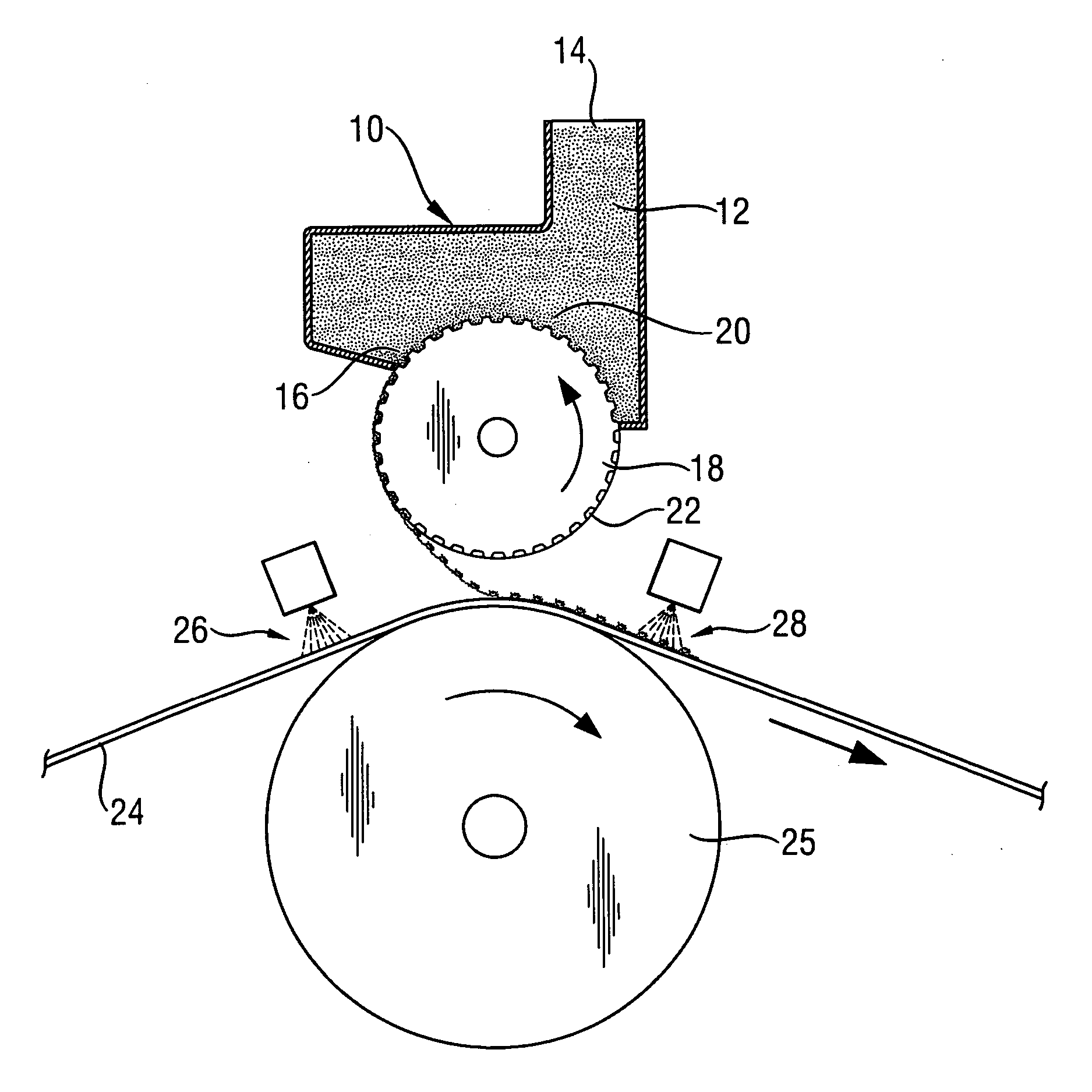

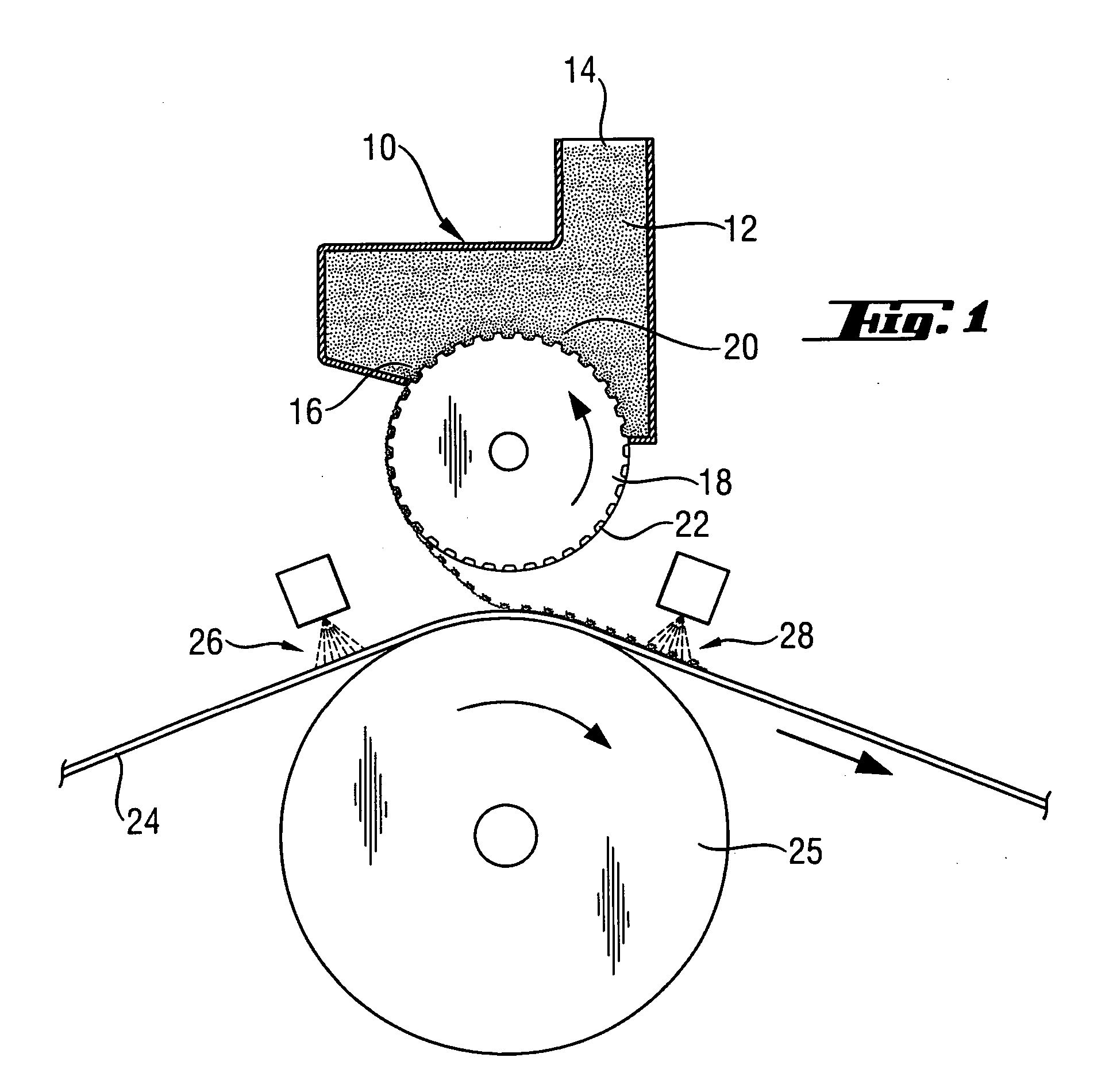

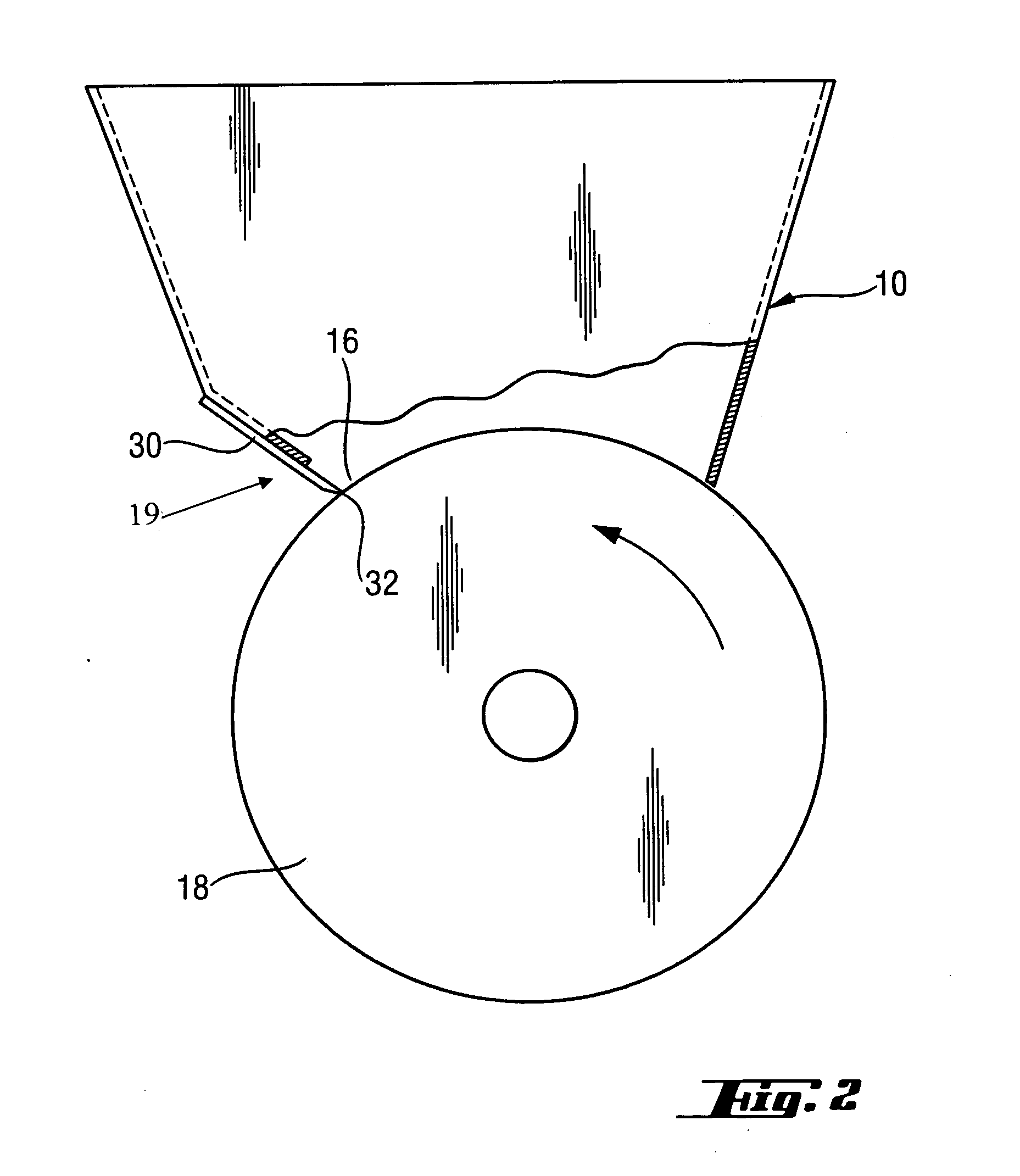

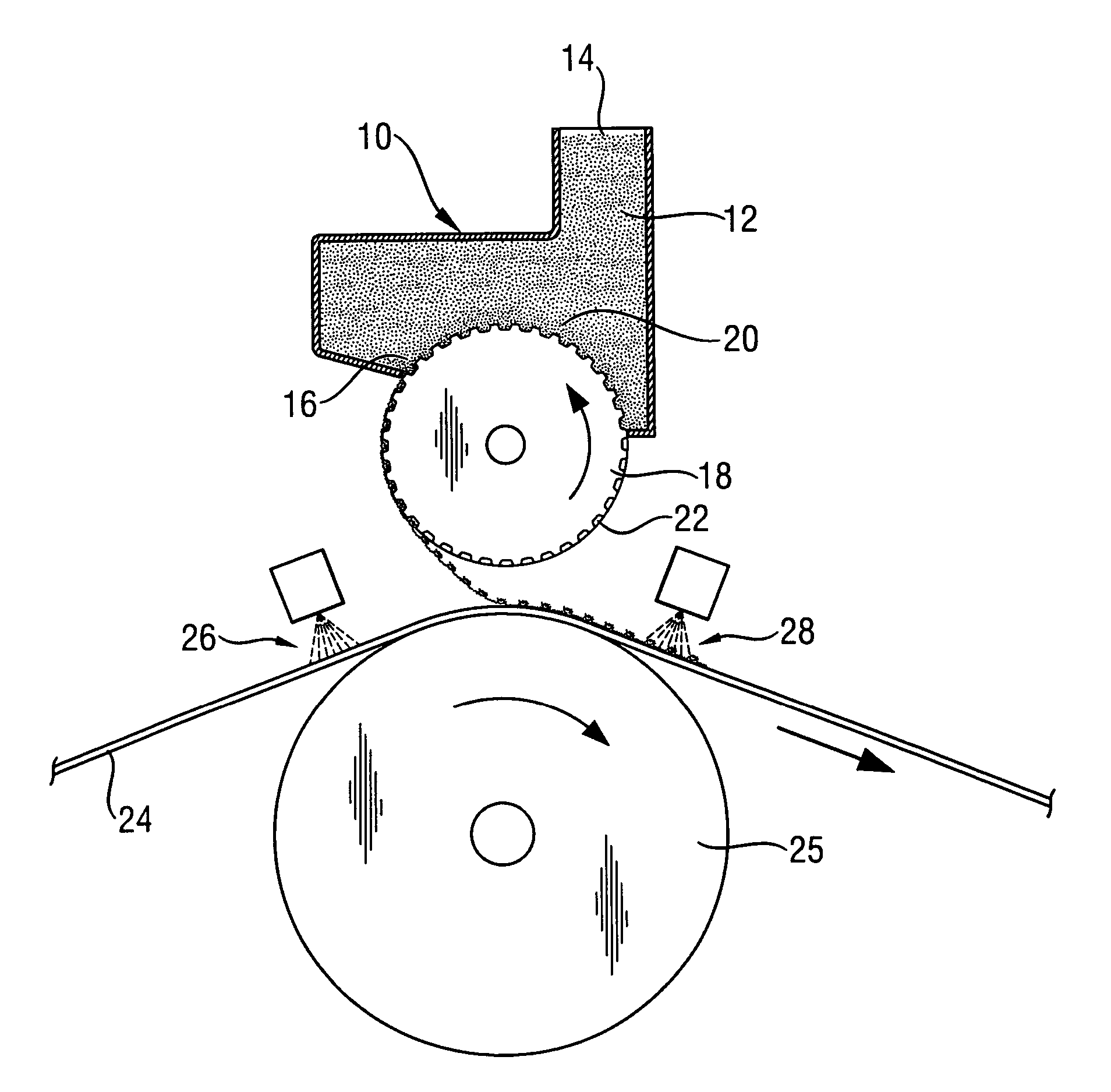

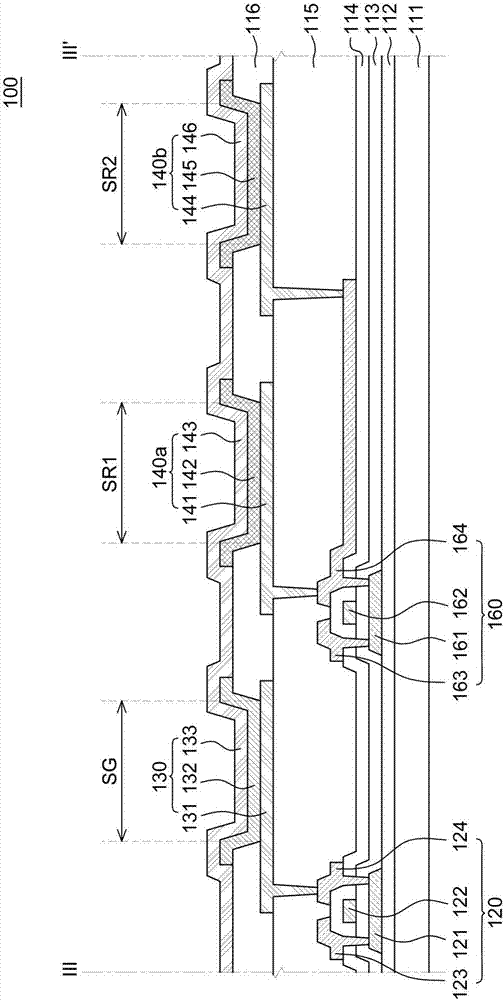

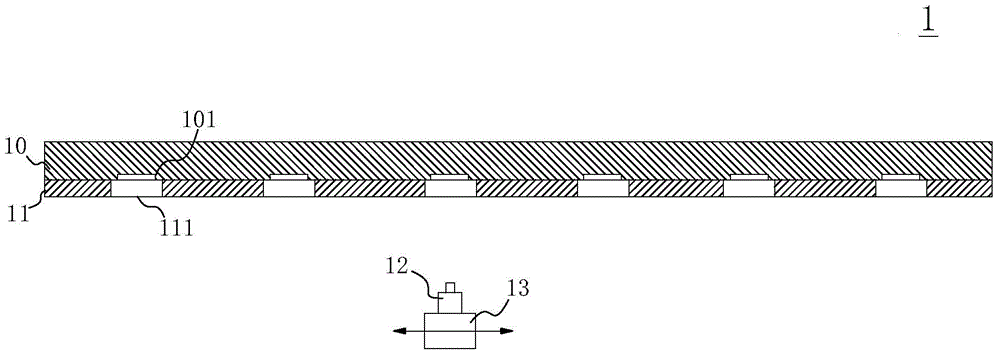

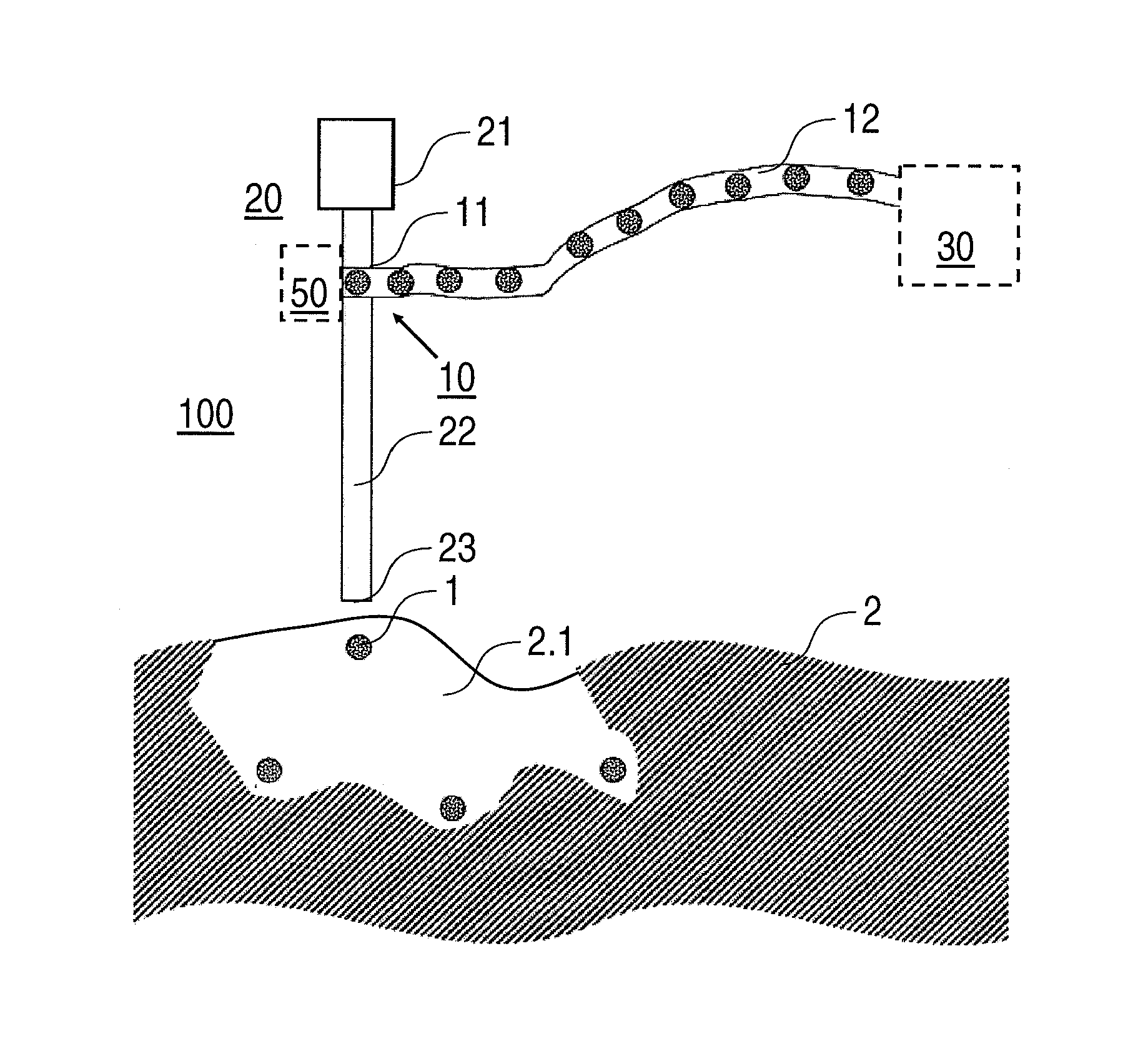

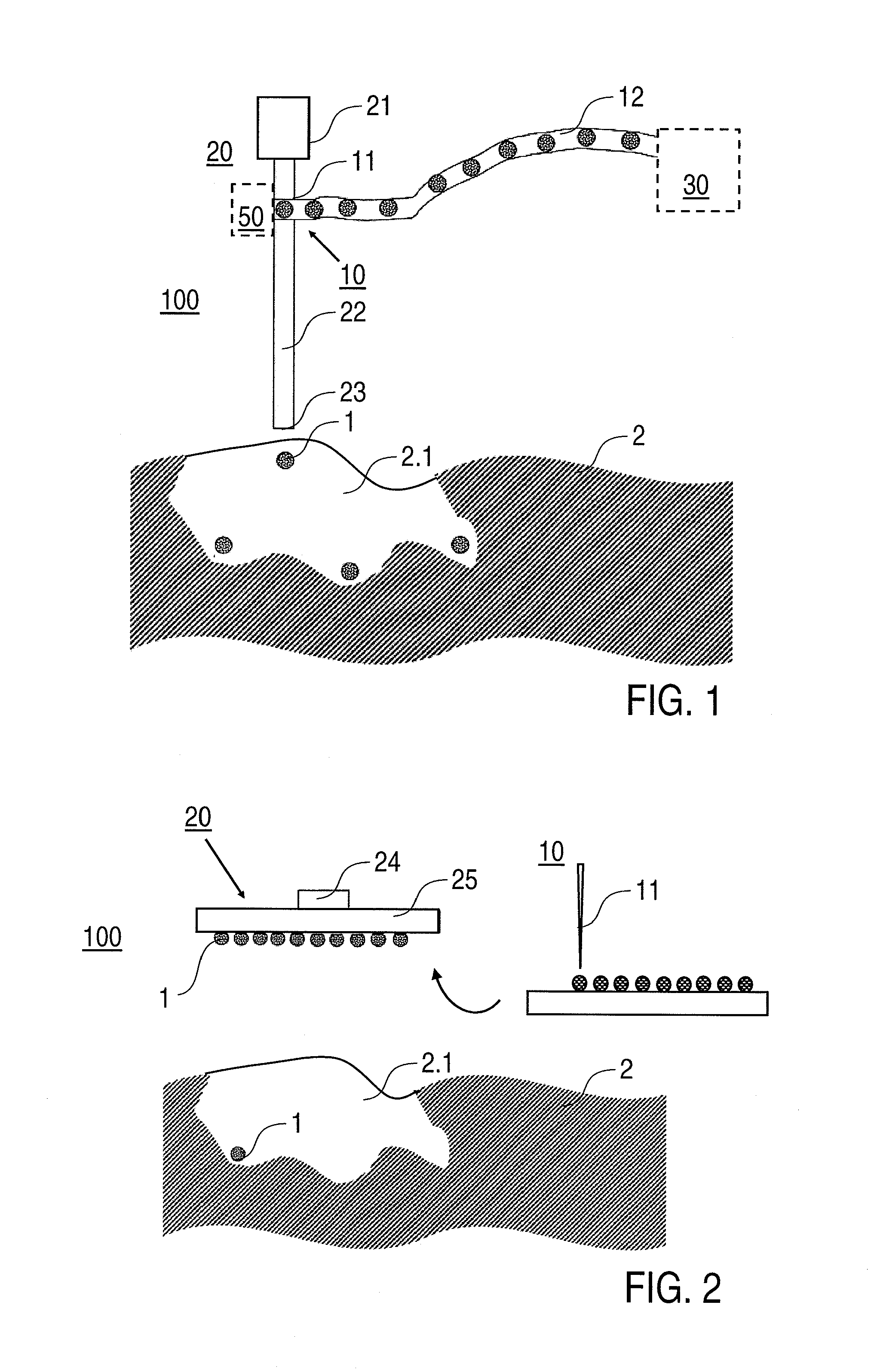

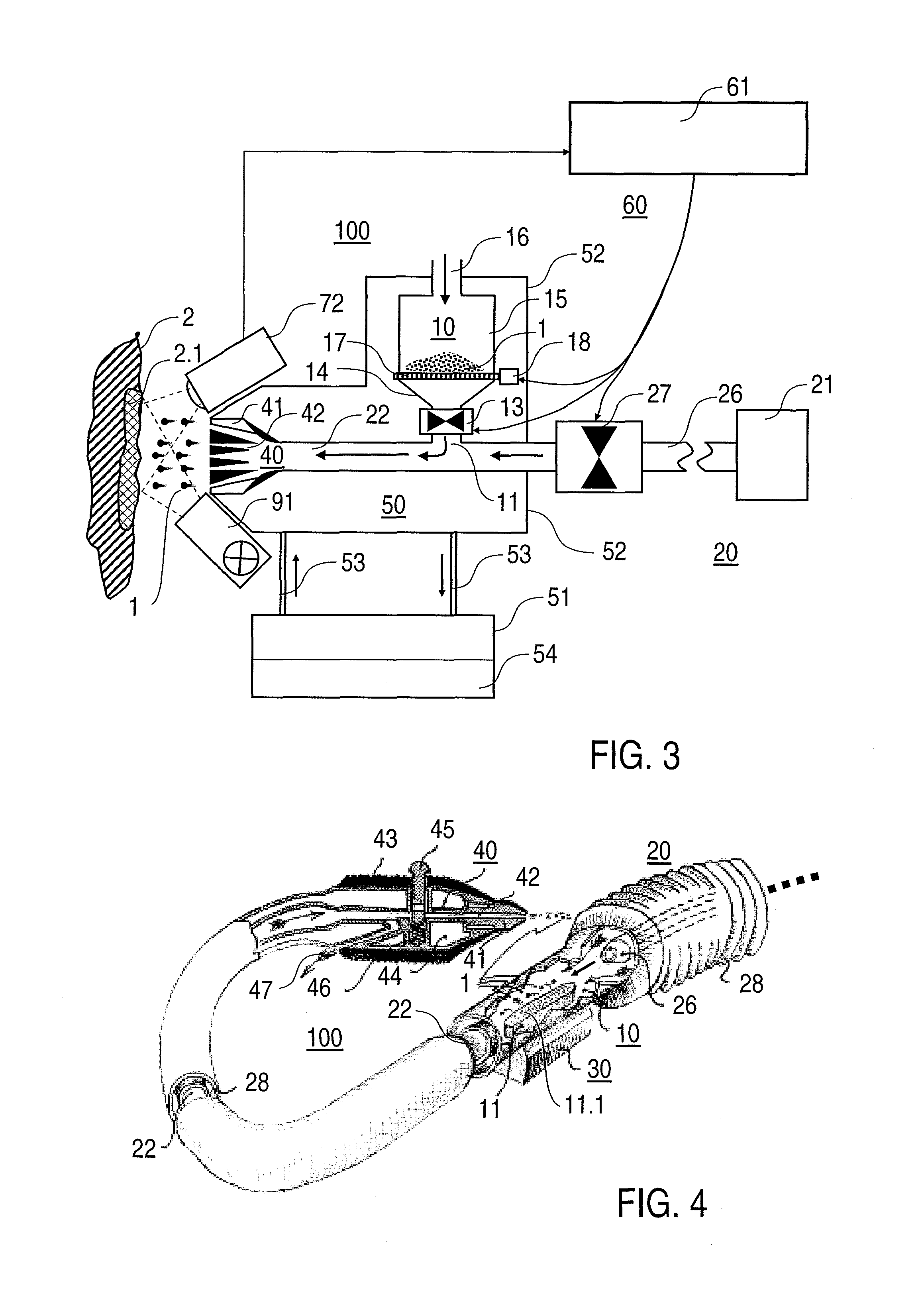

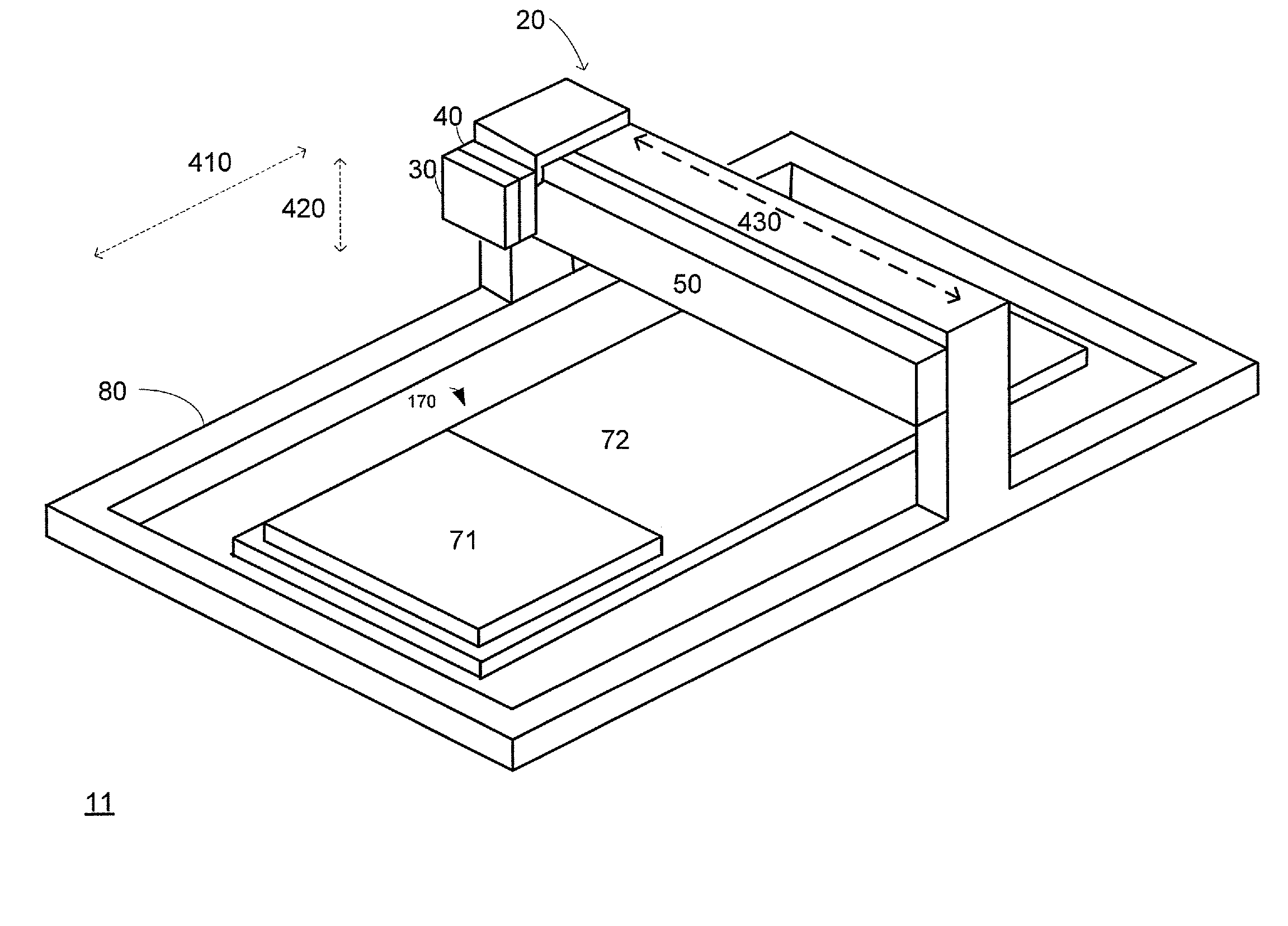

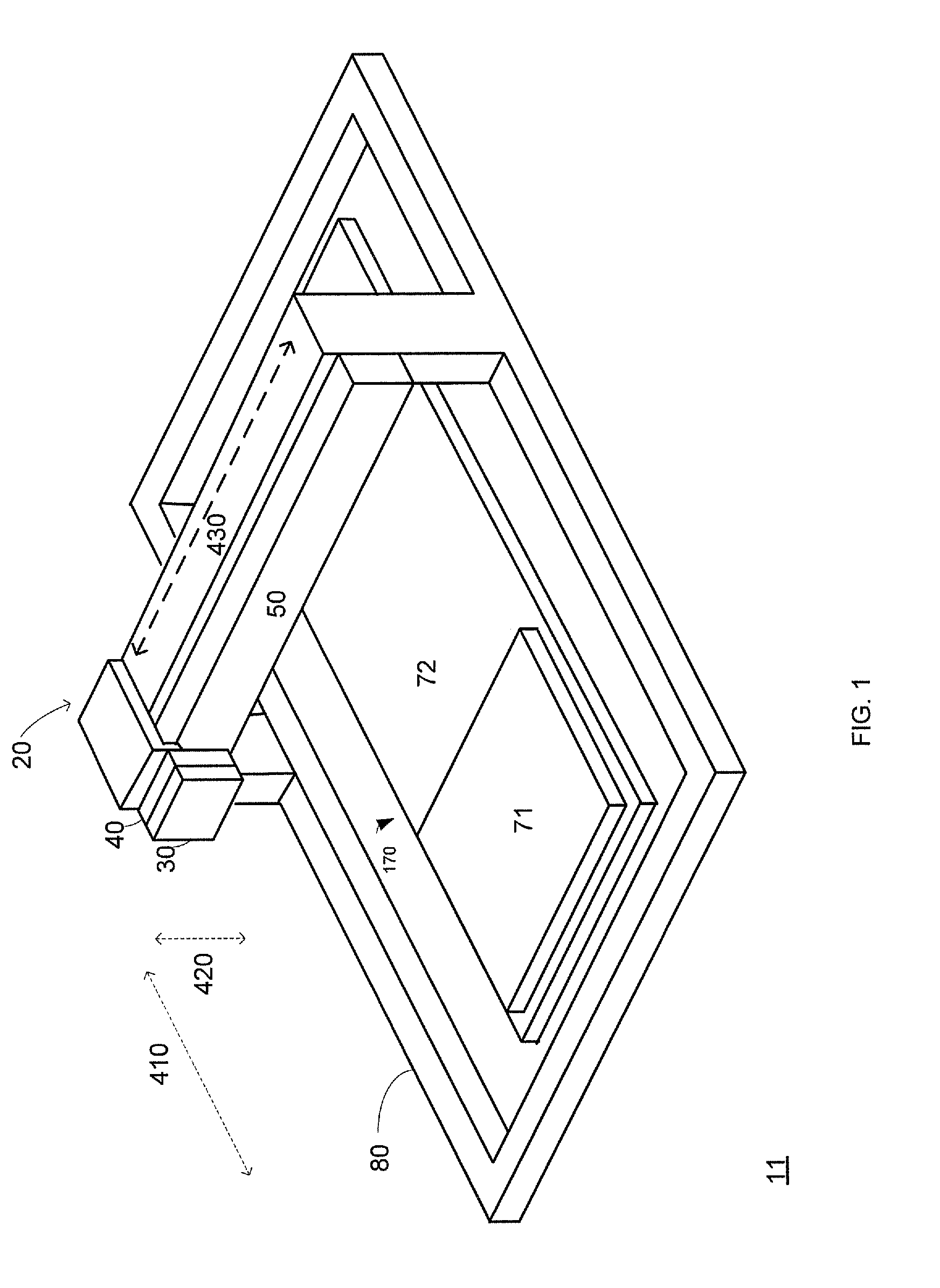

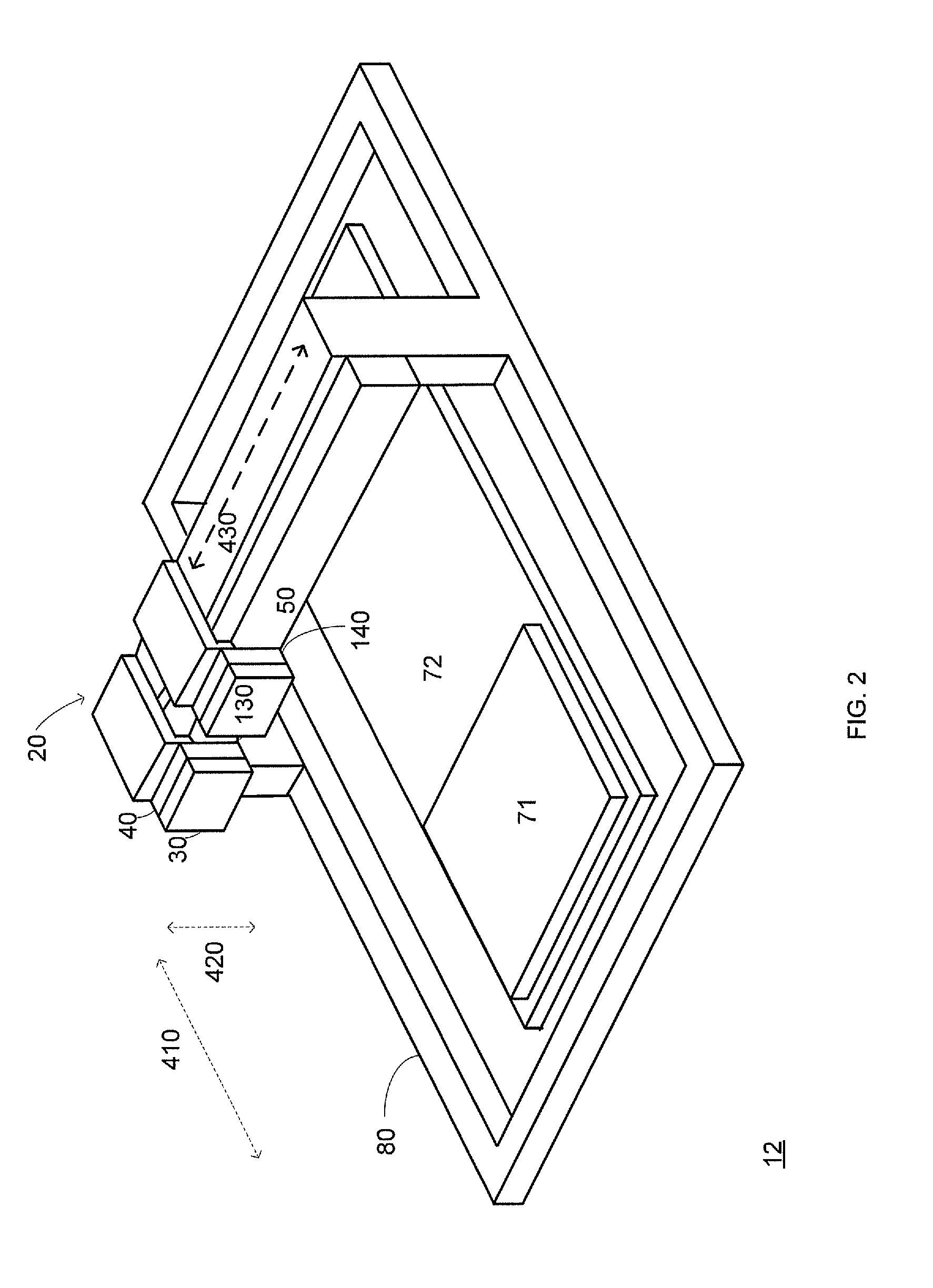

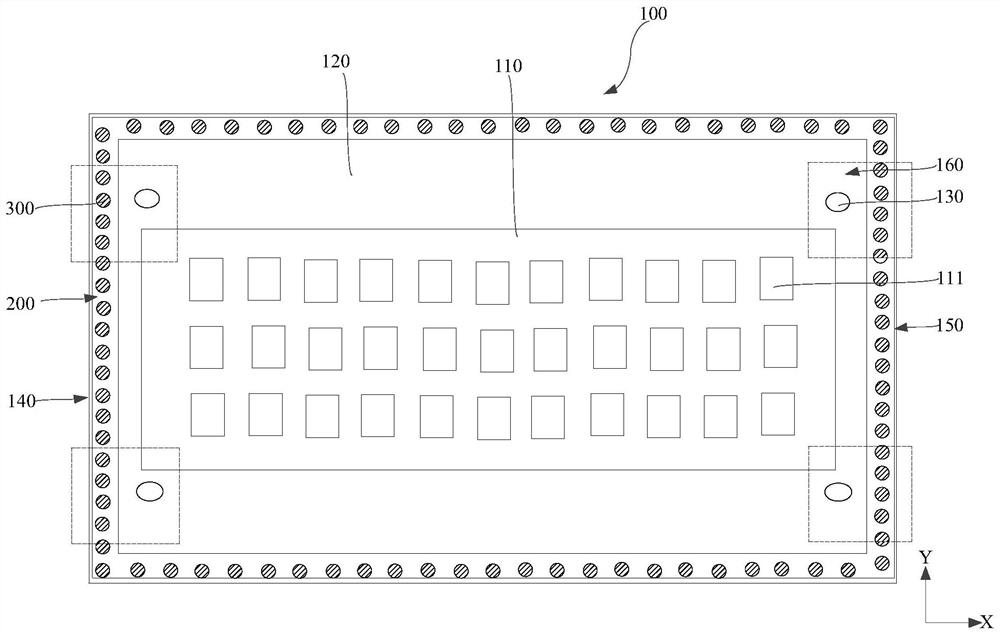

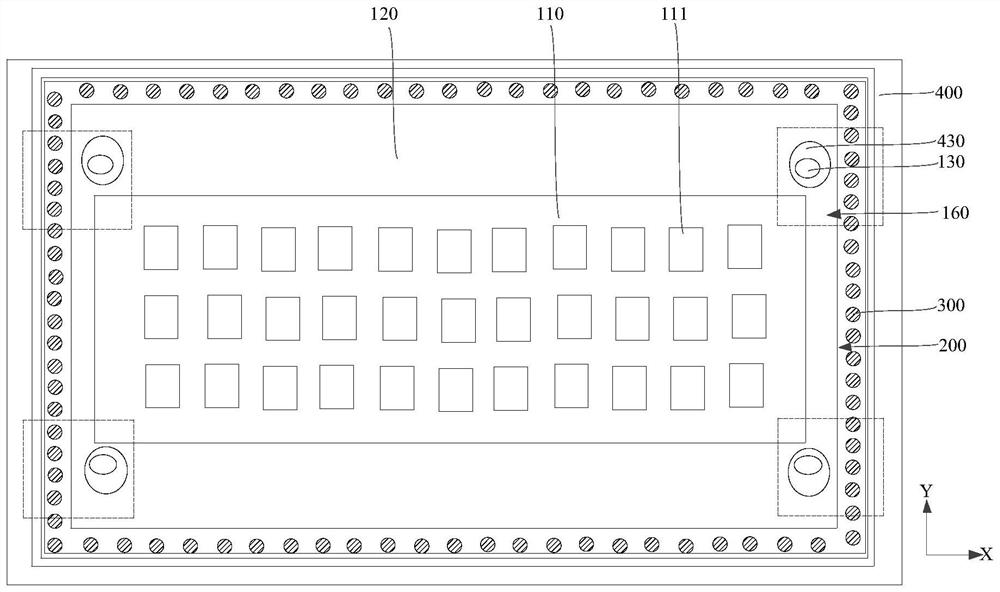

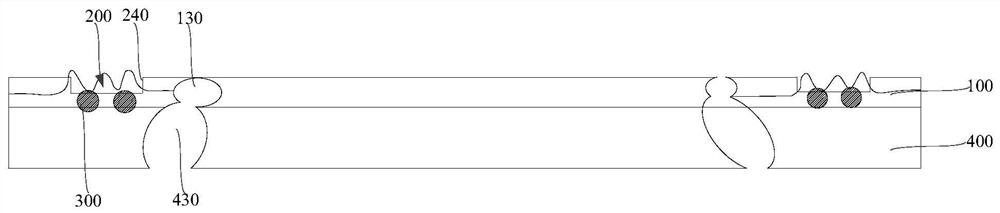

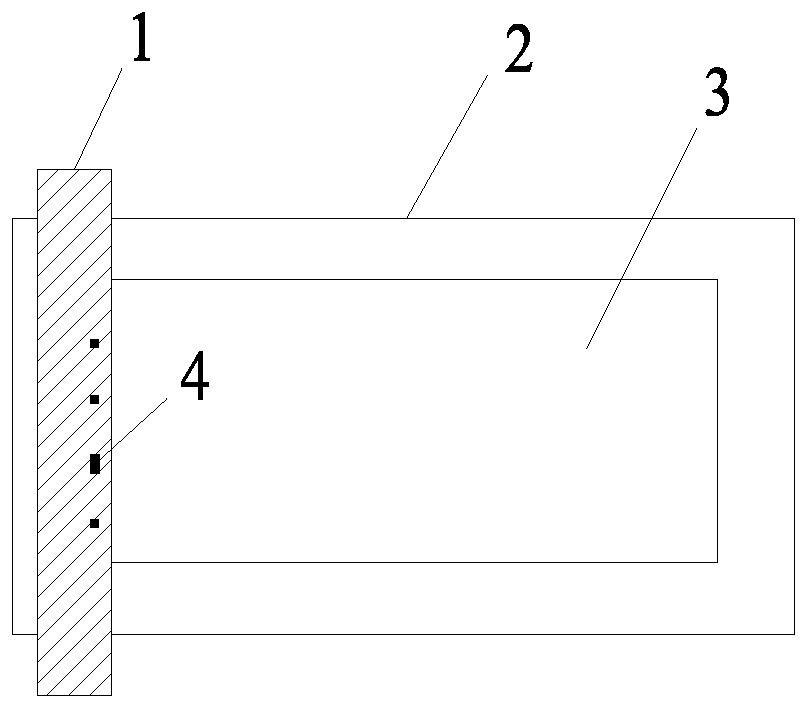

Apparatus and method for the deposition of biological material in a target substrate

ActiveUS9109195B2Increase deposition rateImprove deposition accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiological materials

Disclosed is a deposition apparatus (100) which is designed to deposit frozen biological material (1) in a target substrate (2) and includes a charging device (10) and a driving device (20). The charging device (10) is designed to supply the biological material (1) to the driving device (20) while the driving device (20) is designed to apply a driving force to the biological material (1). In order to apply the driving force, the driving device (20) is formed such that the biological material (1) can penetrate into the target substrate (2) under the effect of the driving force. Also disclosed are an injector cartridge which is designed to provide frozen biological material in a deposition apparatus as well as a method for depositing biological material (1) in a target substrate (2).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method and apparatus for depositing snow-ice treatment liquid on pavement

InactiveUS20050189432A1Minimizes air turbulenceAccurate storageLiquid surface applicatorsSelf-acting watering devicesLiquid stateEngineering

Method and apparatus for depositing liquid brine on roadway surface. Substantially horizontally disposed streamer nozzles are employed in conjunction with brine pumps which are operated in correspondence with the forward speed of the treatment vehicle. Substantially horizontally disposed streamer nozzles express the fluid at a rate corresponding with the vehicle forward velocity to effect a relative zero velocity relationship between the pavement and liquid. These streamer nozzles are mounted close to the pavement surface at a location effective to avoid truck induced air turbulence.

Owner:KIME JAMES A

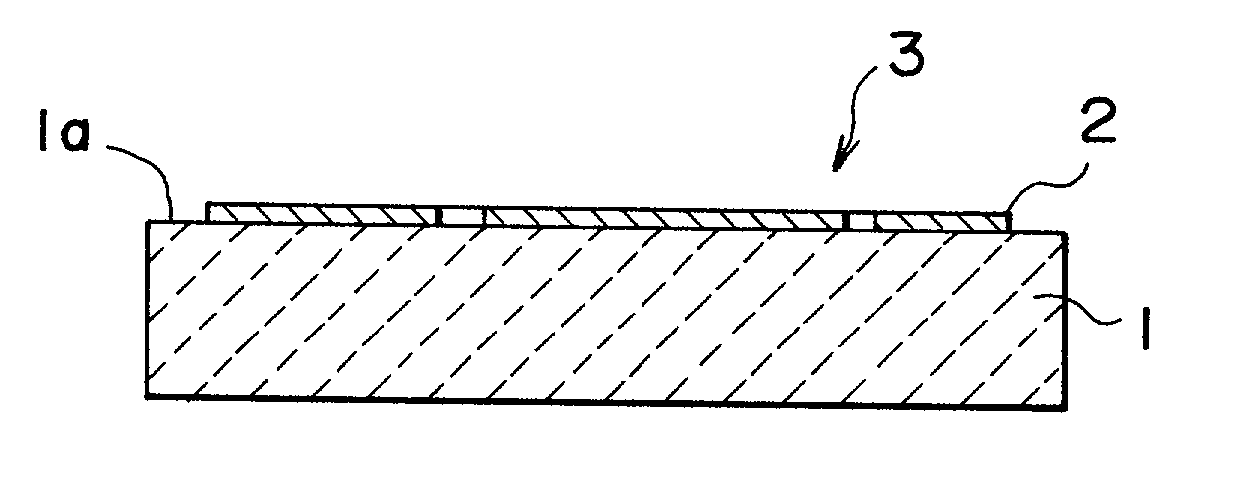

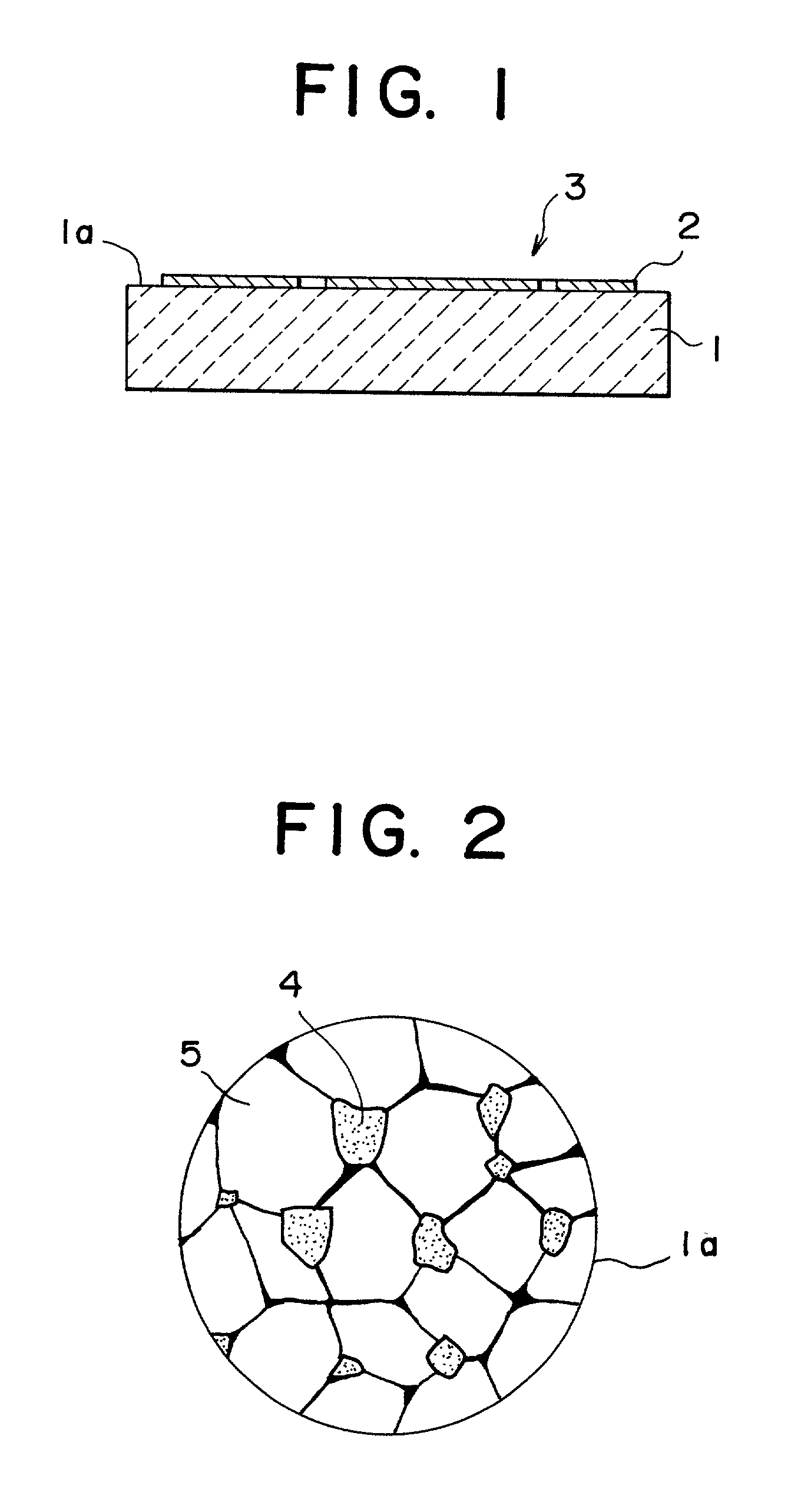

Aluminum nitride substrate and thin film substrate therewith, and manufacturing method thereof

InactiveUS20020102441A1Improve deposition accuracyReduce areaPretreated surfacesRecord information storageMachined surfaceRare earth

An aluminum nitride substrate includes an aluminum nitride sintered body containing a rare earth oxide as a sintering additive component. In the aluminum nitride substrate, a surface thereof is machined so that arithmetic average roughness Ra is 0.5 mum or less; an aggregate size of the sintering additive component present on the machined surface is 20 mum or less; and a total aggregate area in a unit area of the machined surface is 5% or less. A metal thin film is deposited on such machined surface with good intimate contact properties, and furthermore deposition accuracy or the like is improved.

Owner:KK TOSHIBA

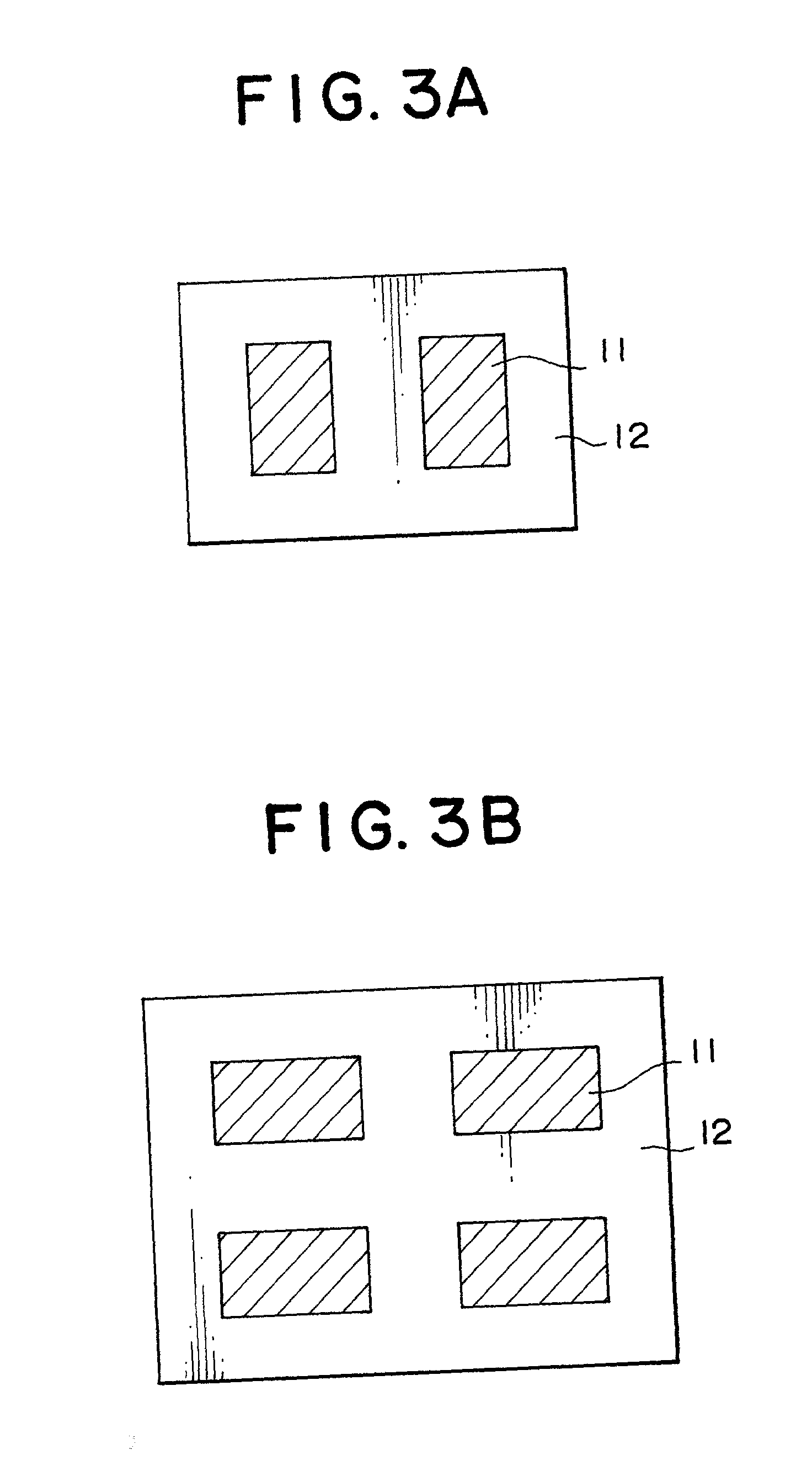

Method and system for printing on a printed circuit board

InactiveUS20100066786A1Reduces board handlingImprove deposition accuracyTypewritersInspection/indentification of circuitsSolder maskEngineering

A method, a printing system and a printing bridge. The printing bridge is configured to accommodate in a precise manner a jet print head. The jet print head includes first jet nozzles for injecting a first type jettable substance to form a first pattern onto the surface of a object, and a second jet nozzles for injecting a second type of jettable substance to form a first pattern onto the surface of a object. The first type jettable substance is utilized for printing a solder mask pattern and the second type jettable substance is utilized for printing a legend pattern.

Owner:CAMTEK LTD

Mask device and evaporation method

ActiveCN109913809AAchieve preparationImprove deposition accuracyVacuum evaporation coatingSputtering coatingEngineeringElectrical and Electronics engineering

The invention provides a mask device and an evaporation method. The mask device comprises a first mask plate, and the first mask plate comprises a first frame, and a first mask strip and a first blocking strip which are arranged on the first frame side by side; the first mask strip and the first blocking strip are arranged at intervals; the first mask strip comprises a first sub mask strip and a second sub mask strip which are spliced; and a first hollowed-out region is arranged on the first sub mask strip. According to the mask device, the mask strip is divided into the two sub mask strips, netting difficulty is reduced, and preparation of a variable-amplitude mask plate is achieved; and besides, when the size of the mask plate is increased, the situation that the droop amount of the middle region of the mask strip is increased as the mask strip is too wide is avoided, and evaporation precision of the variable-amplitude mask plate is improved.

Owner:BOE TECH GRP CO LTD +1

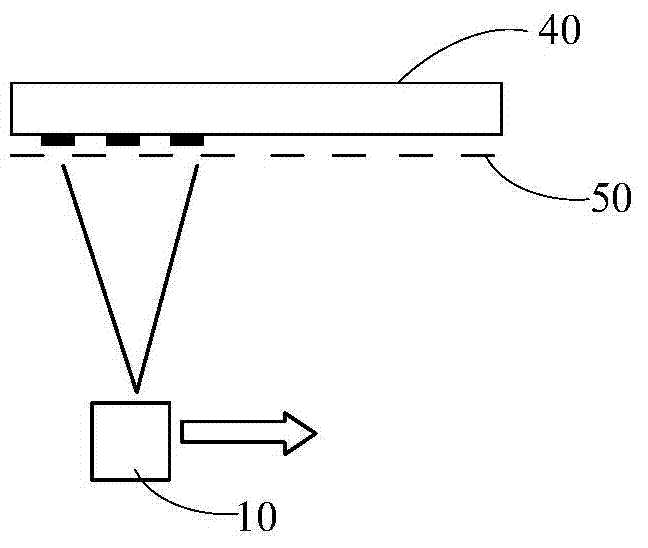

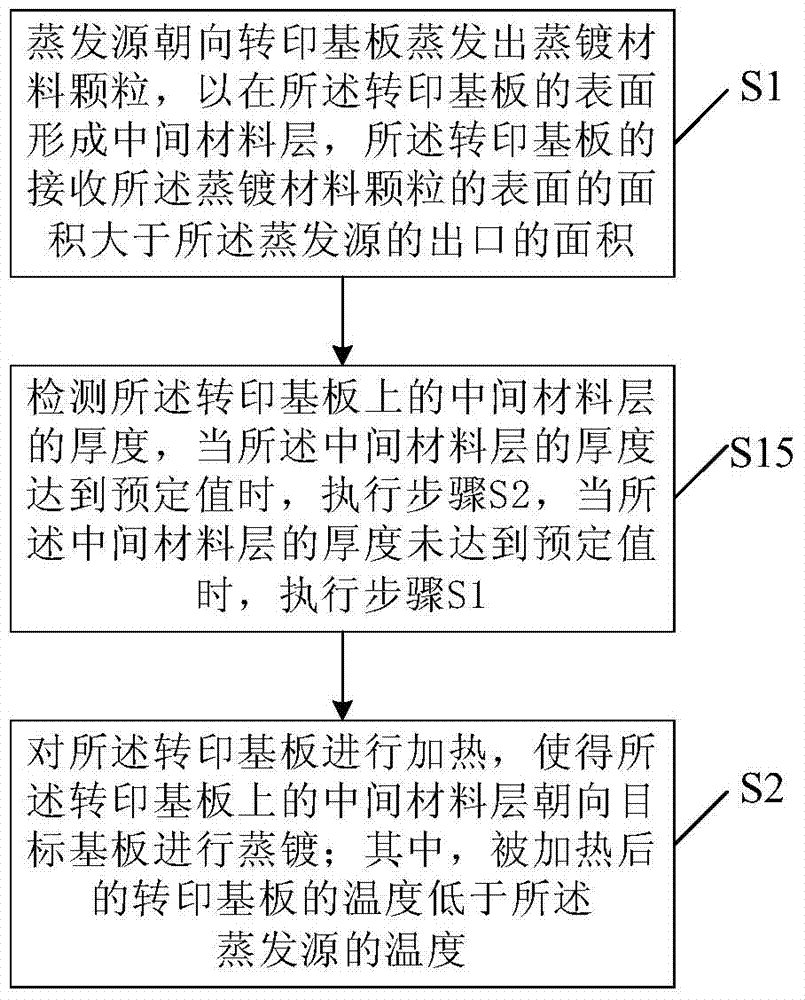

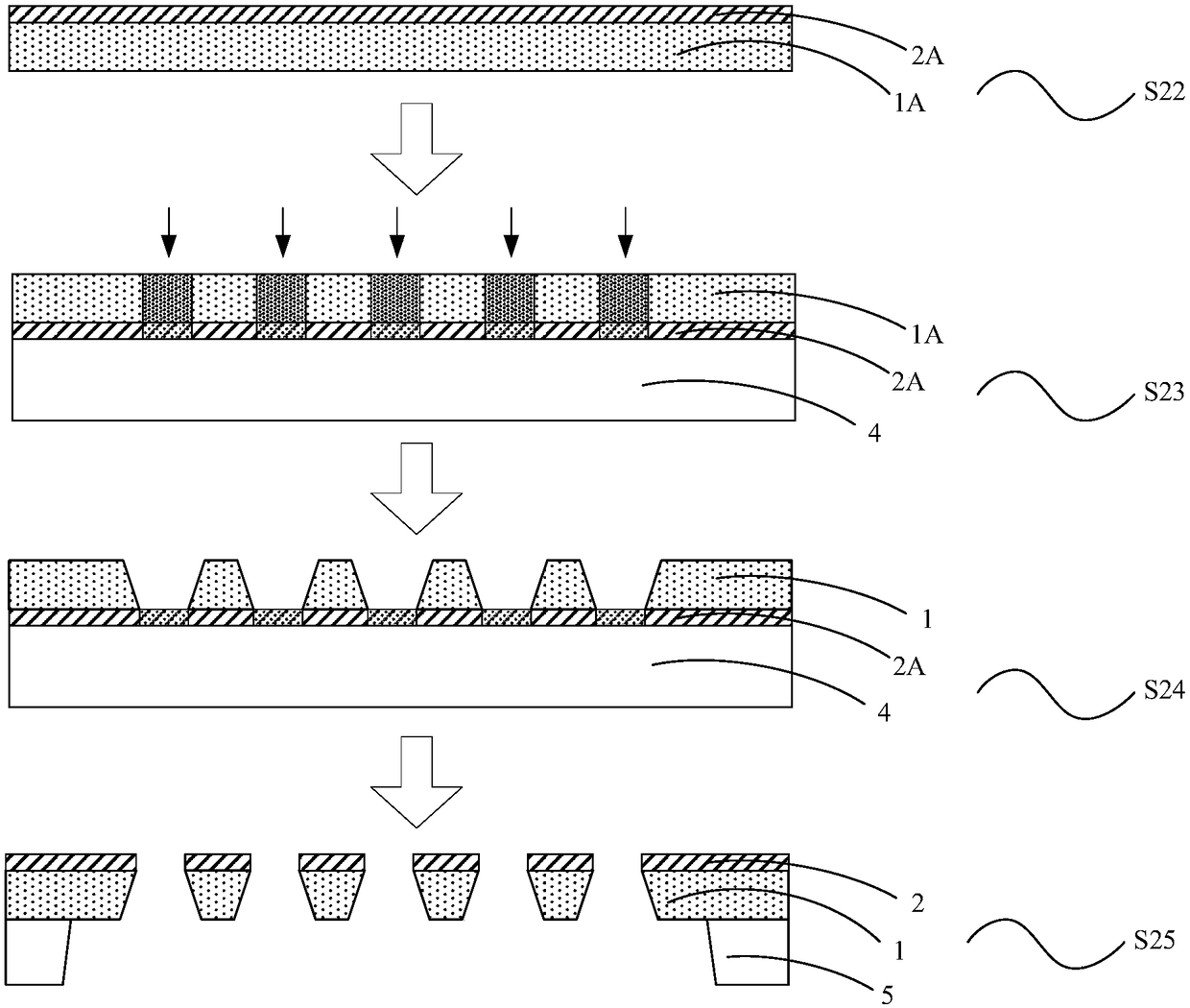

Vapor deposition method and vapor deposition device

InactiveCN104762599AIncrease profitImprove deposition accuracyVacuum evaporation coatingSputtering coatingEvaporation (deposition)Physical chemistry

The invention provides a vapor deposition method which comprises the following steps: an evaporation source evaporates vapor deposition material granules toward a transfer printing substrate to form an intermediate material layer on the surface of the transfer printing substrate, wherein the surface area of the vapor deposition material granules received by the transfer printing substrate is greater than the area of the outlet of the evaporation source; and the transfer printing substrate is heated to perform vapor deposition on the intermediate material layer on the transfer printing substrate toward the target substrate, wherein the temperature of the heated transfer printing substrate is lower than that of the evaporation source. Correspondingly, the invention also provides a vapor deposition device. The vapor deposition method can reduce the influence of high temperature on the target substrate, and enhances the vapor deposition precision.

Owner:BOE TECH GRP CO LTD

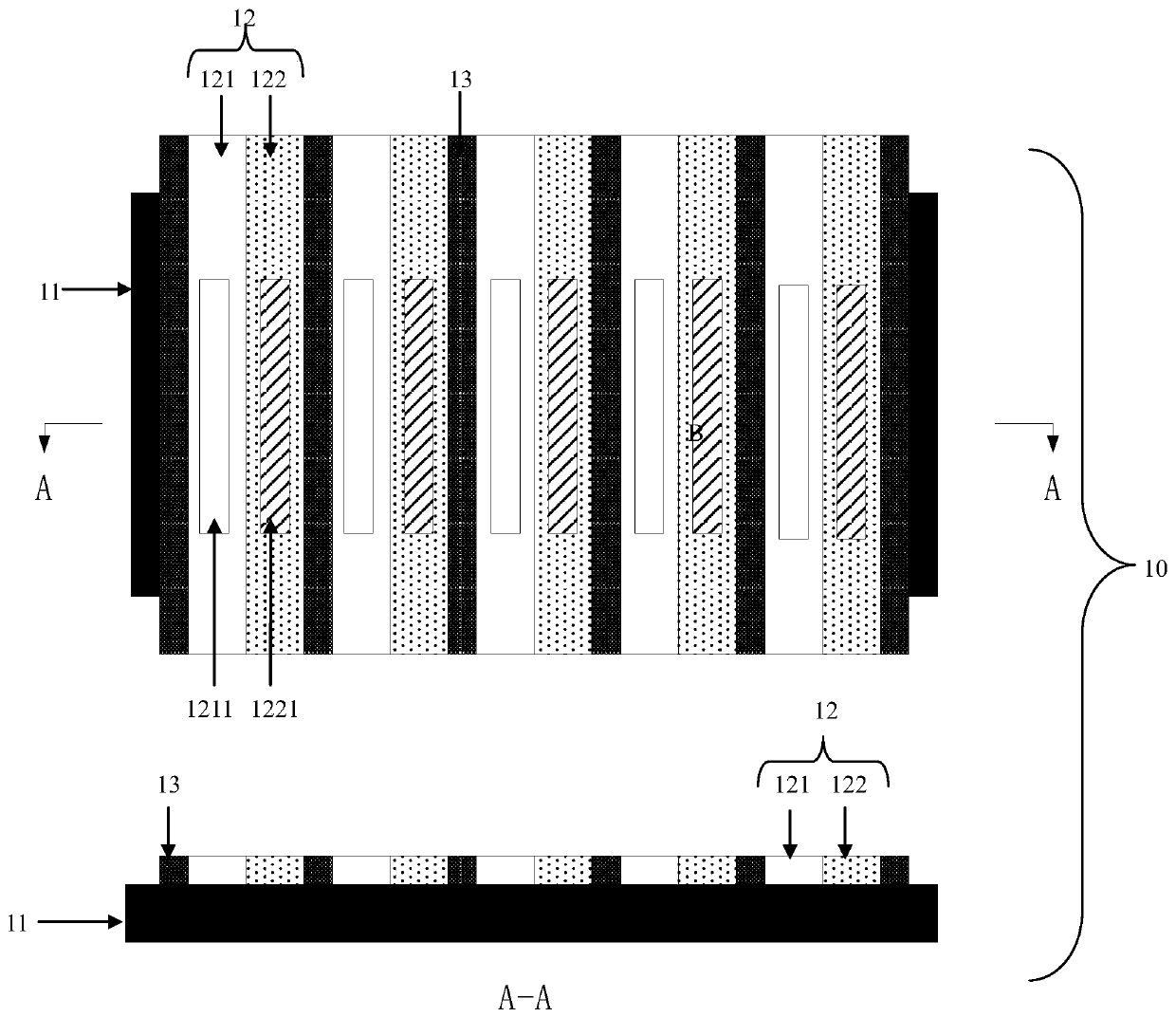

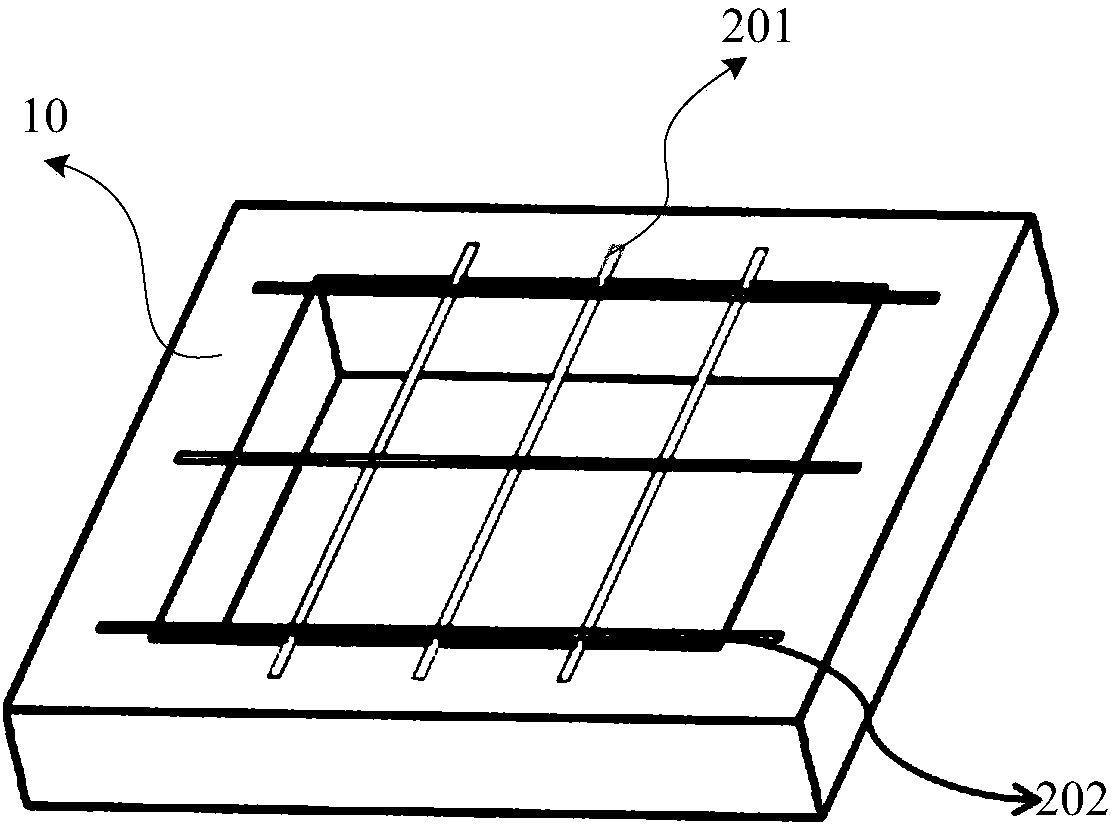

Mask frame assembly and manufacturing method thereof

ActiveCN108251792AAny matchReduce manufacturing costSolid-state devicesVacuum evaporation coatingEvaporationEngineering

The embodiment of the invention provides a mask frame assembly and a manufacturing method thereof, and relates to the technical field of evaporation. The problems that in the prior art, mask sheets are wrinkled and warped, howling strips and cover strips are replaced or repaired, consequently, cost is increased, the relative positions of the howling strips, the cover strips and the mask sheets cannot be adjusted, and a mask frame assembly cannot be cleaned up can be solved. The mask frame assembly comprises a first frame, a second frame, multiple mask sheets and cover strips and / or howling strips. The first frame and the second frame are each provided with a hollow area and are fixedly connected in a sleeved manner. The multiple mask sheets are sequentially arranged on the hollow area of the first frame in a crossing manner, and the two opposite ends of each mask sheet are fixed to the first frame. The cover strips and / or howling strips are arranged on the hollow area of the second frame in a crossing manner, and the two opposite ends of each cover strip and / or howling strip are fixed to the second frame. The cover strips are located at the clearance positions between the adjacentmask sheets, and the howling strips cross over invalid mask areas of the multiple mask sheets so as to support the multiple mask sheets.

Owner:BOE TECH GRP CO LTD +1

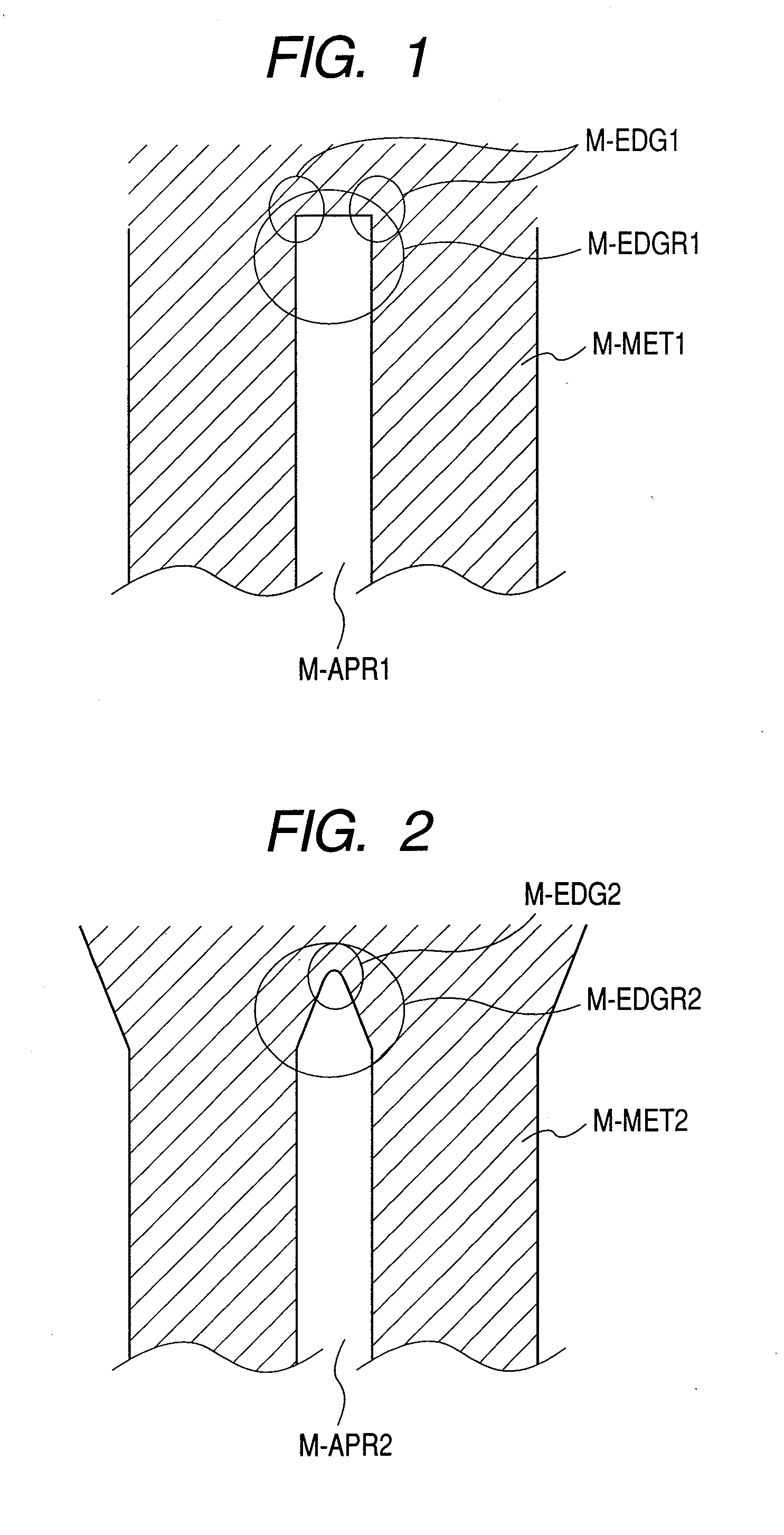

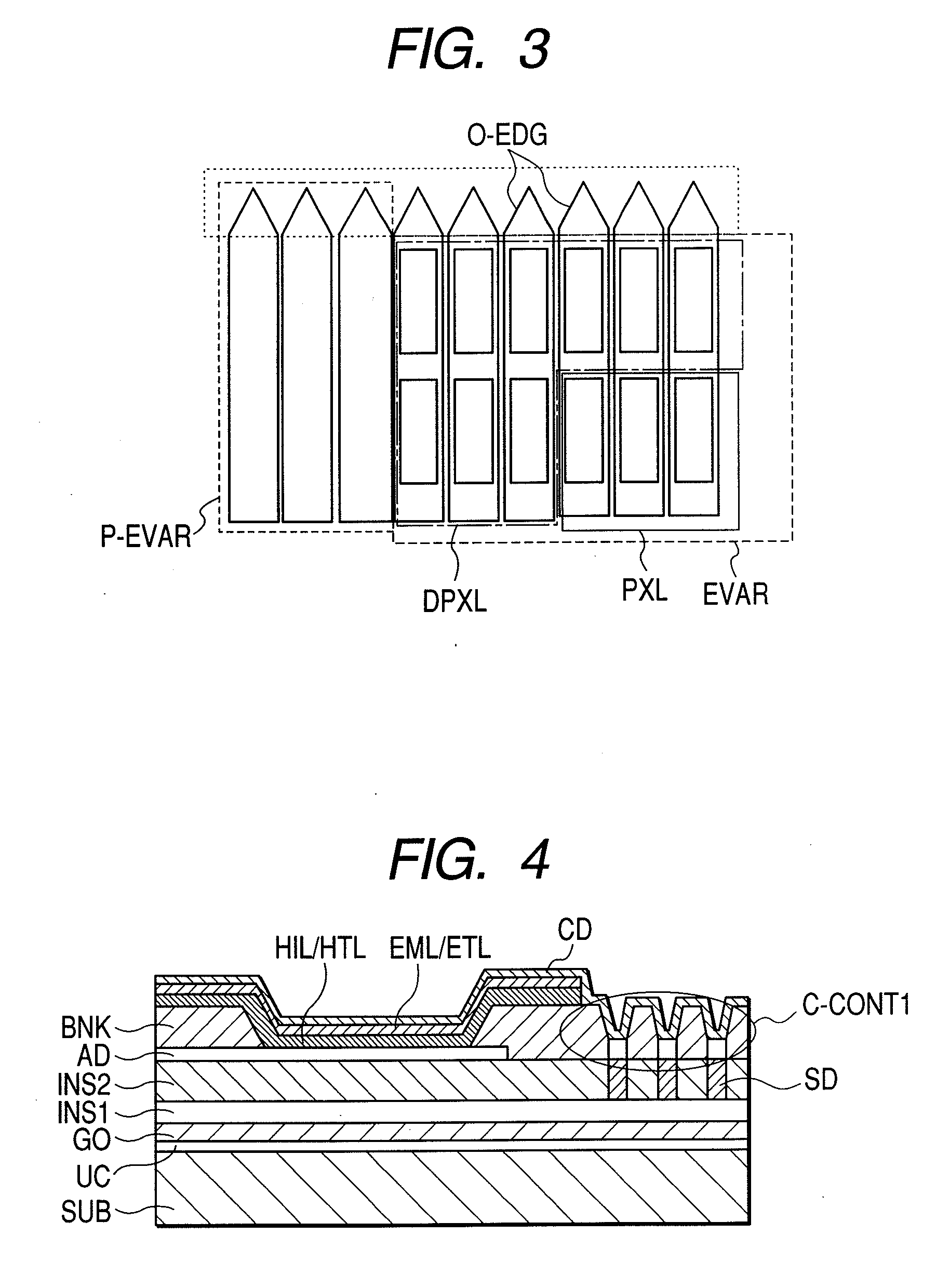

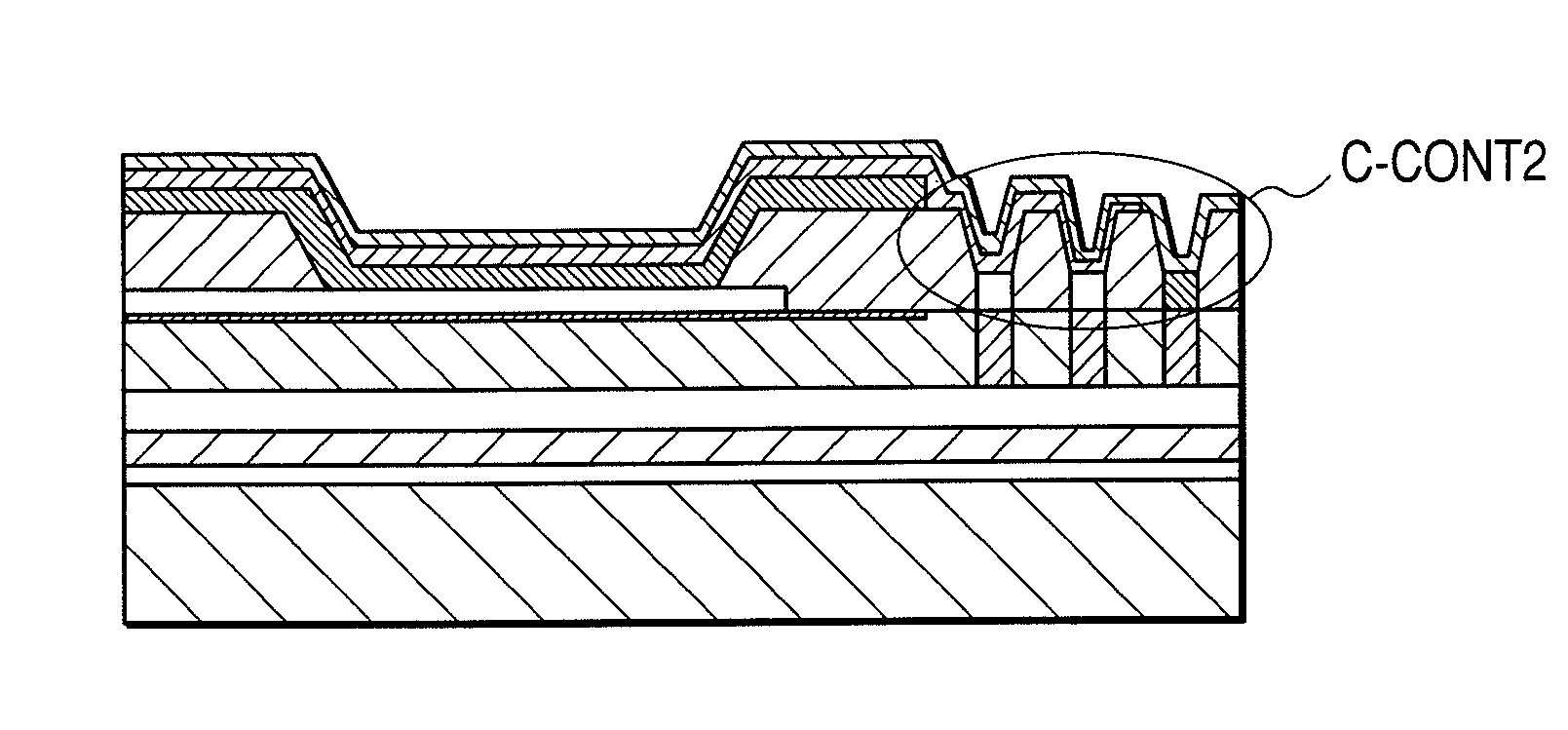

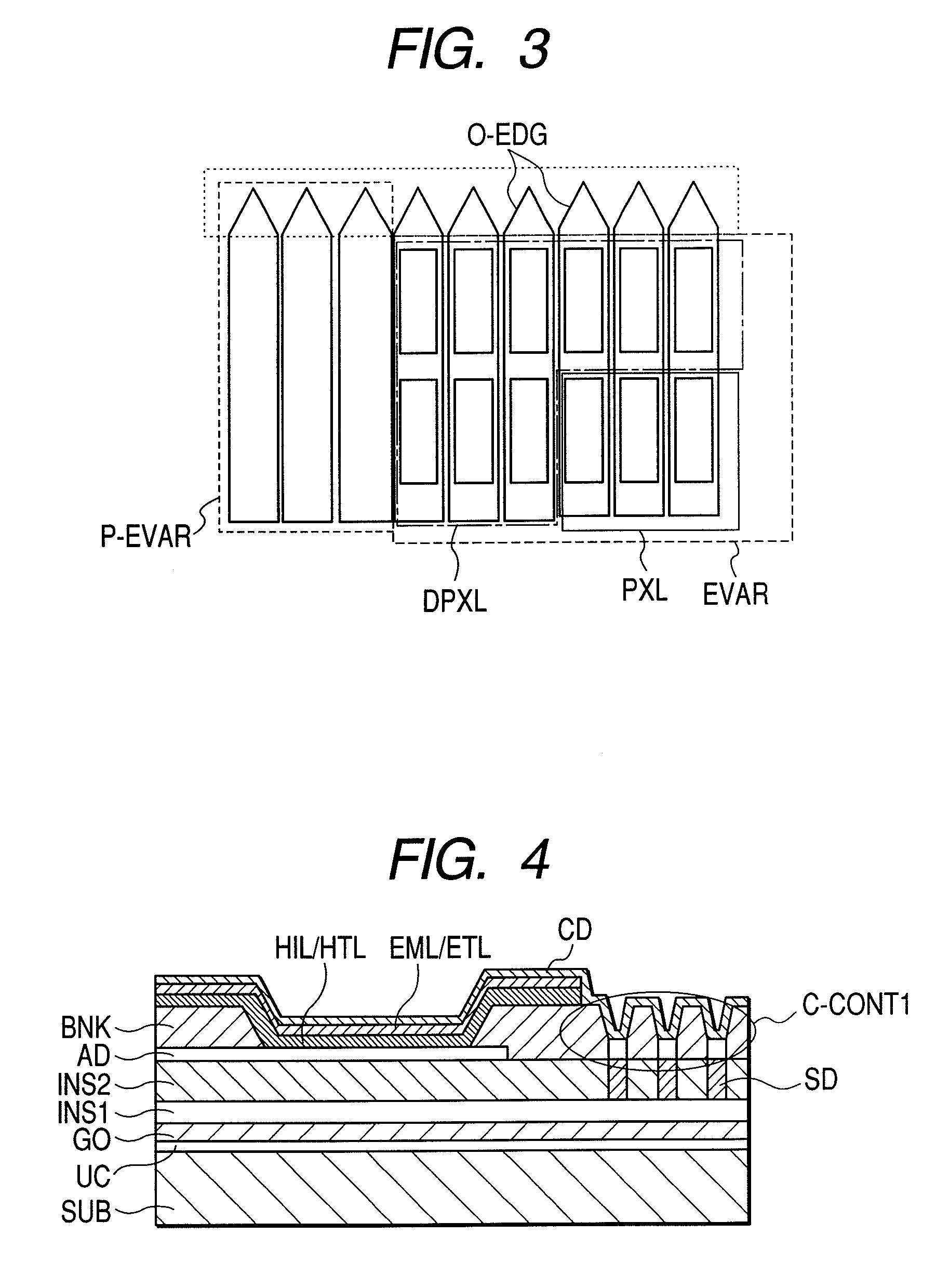

Organic electroluminescence display device

ActiveUS20070200494A1Improve deposition accuracySimple designDischarge tube luminescnet screensElectroluminescent light sourcesGas phaseOrganic layer

An organic electroluminescence display device is disclosed wherein plural organic electroluminescence elements each having an anode, a cathode and an organic layer sandwiched in between the anode and the cathode, the plural organic electroluminescence elements including organic electroluminescence elements developing different colors in a row direction, and at least one of the organic layers having an outer edge of a conic section at an end portion in a column direction thereof, the outer edge of the conic section becoming narrower gradually in its width in a row direction of vapor deposition thereof toward an extreme end at an end portion in a column direction thereof. The organic electroluminescence display device can improve the vapor deposition accuracy and the degree of design freedom.

Owner:SAMSUNG DISPLAY CO LTD +1

Evaporation system, and preparation method for OLED device

InactiveCN109023236AHigh strengthImprove uniformityVacuum evaporation coatingSolid-state devicesEvaporationUltimate tensile strength

The application provides an evaporation system, and a preparation method for an OLED device. The evaporation system comprises a mask plate, and the mask plate comprises at least one evaporation area corresponding to an OLED baseplate, and evaporation holes formed in the evaporation area and used for forming sub-pixels of a sub-pixel pattern; the evaporation holes are arranged in a matrix, and thenumber of the sub-pixels is N times the number of the evaporation holes (N is an integer but no less than 2); and the evaporation holes are used for preparing a complete sub-pixel pattern through cooperation with offset of an evaporation machine. According to the evaporation system, through decrease of the number of the evaporation holes in the mask plate, the strength of the mask plate is improved, and the risk that wrinkles are generated during net laying is reduced; meanwhile, the phenomenon that the color of the OLED device is uneven during evaporation is avoided in the preparation methodfor the OLED device; and in addition, by adopting the OLED baseplate or the mask plate offset mode, the overall evaporation accuracy of the light-emitting sub-pixels is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

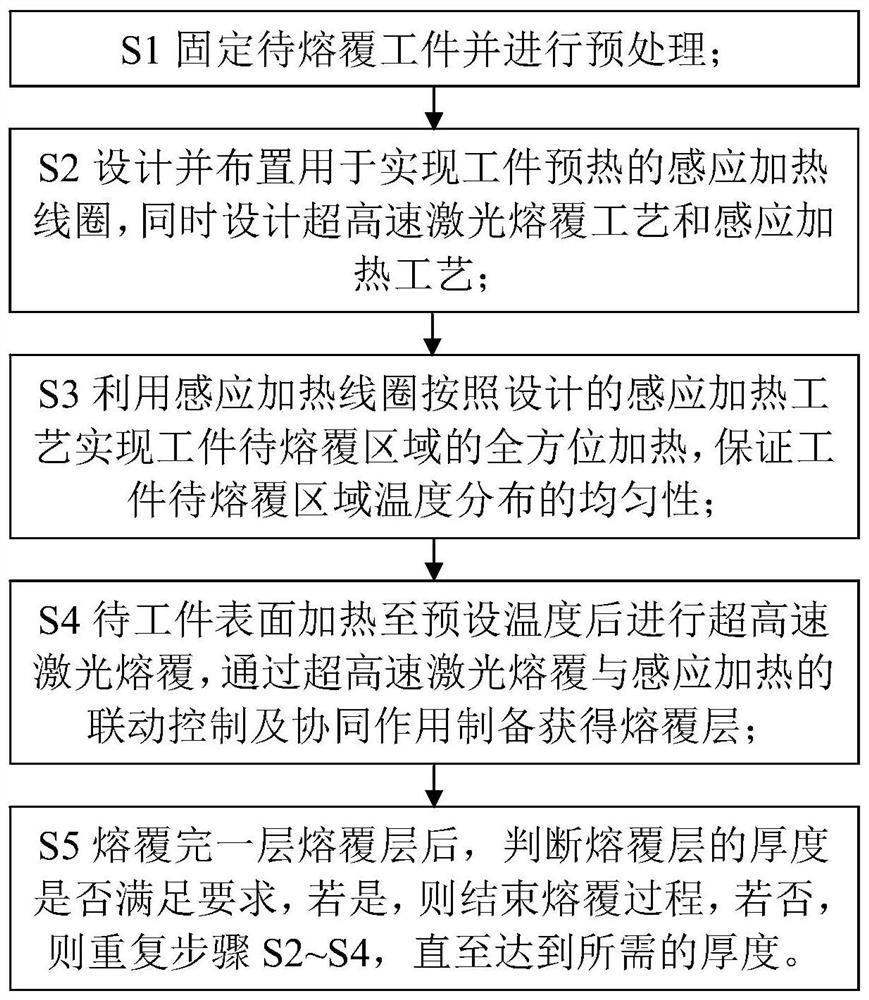

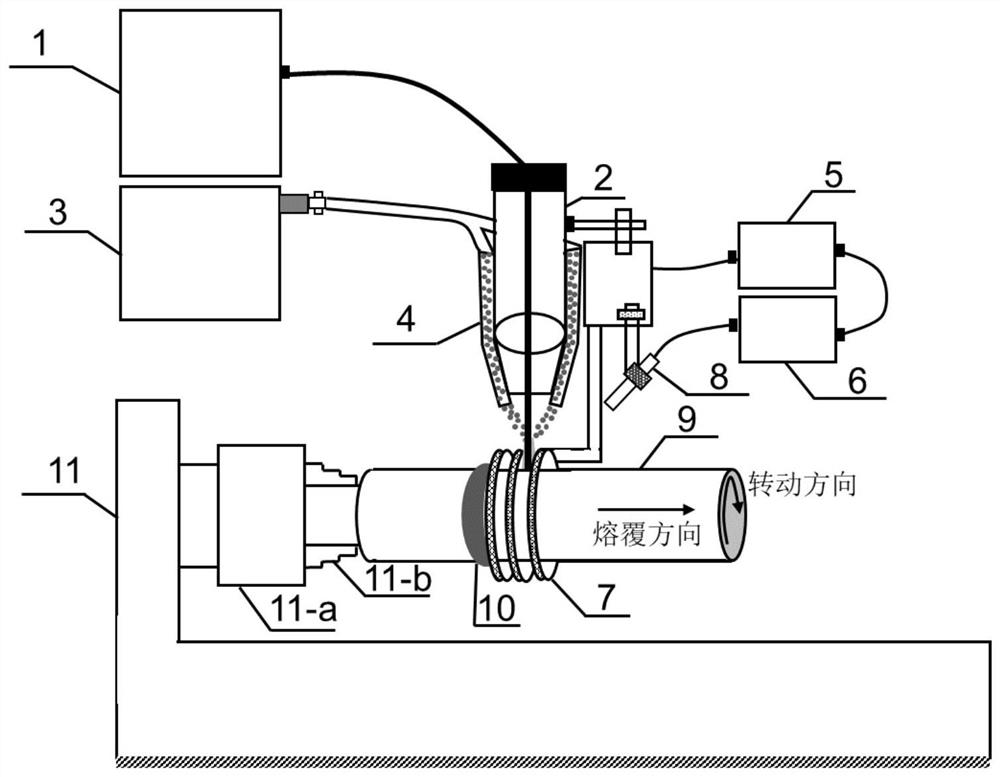

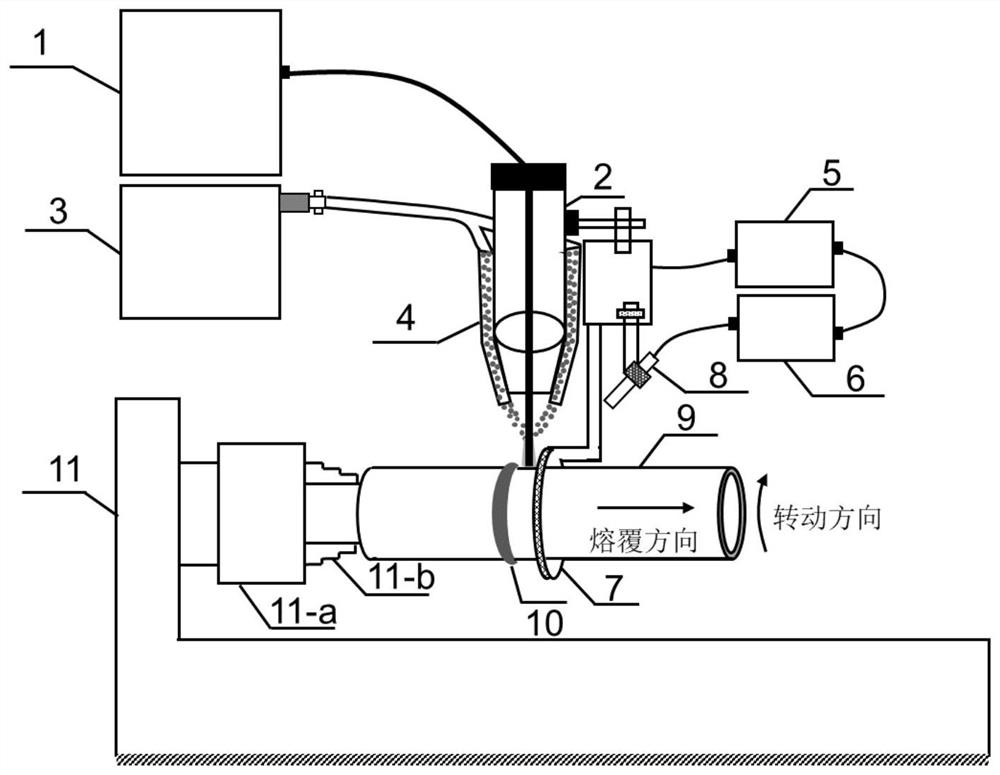

Ultrahigh-speed laser-induction composite cladding method and device

ActiveCN111676477AHigh precisionQuality improvementIncreasing energy efficiencyMetallic material coating processesUltra high speedAlloy

The invention belongs to the field of surface coating processing, and particularly discloses an ultrahigh-speed laser-induction composite cladding method and device. Aiming at a workpiece to be cladded as a processing object, the ultrahigh-speed laser-induction composite cladding device is provided with an induction heating coil used for realizing the fact of preheating the workpiece, the induction heating coil is arranged nearby the workpiece to be cladded, a area to be cladded of the workpiece is heated to a set temperature through the shape of the induction heating coil and the spatial arrangement of the induction heating coil relative to the workpiece to be cladded; and carrying out ultrahigh-speed laser-induction composite cladding above the area to be cladded of the workpiece by adopting ultrahigh-speed laser cladding and induction heating modes, so that interaction effect between a laser beam spot and a powder beam flow is carried out at a target position of a cladding area to heat a alloy powder to a molten drop or semi-molten drop state, and the alloy powder is sprayed to a micro molten pool on the preheated surface of the workpiece in a liquid or semi-solid form so as toprepare a required cladding layer. By means of the ultrahigh-speed laser-induction composite cladding method and device, high-precision, high-performance and metallurgical-defect-free ultra-efficientdeposition of the metal cladding layers of various materials can be achieved on the surface of a metal component.

Owner:武汉飞能达激光技术有限公司

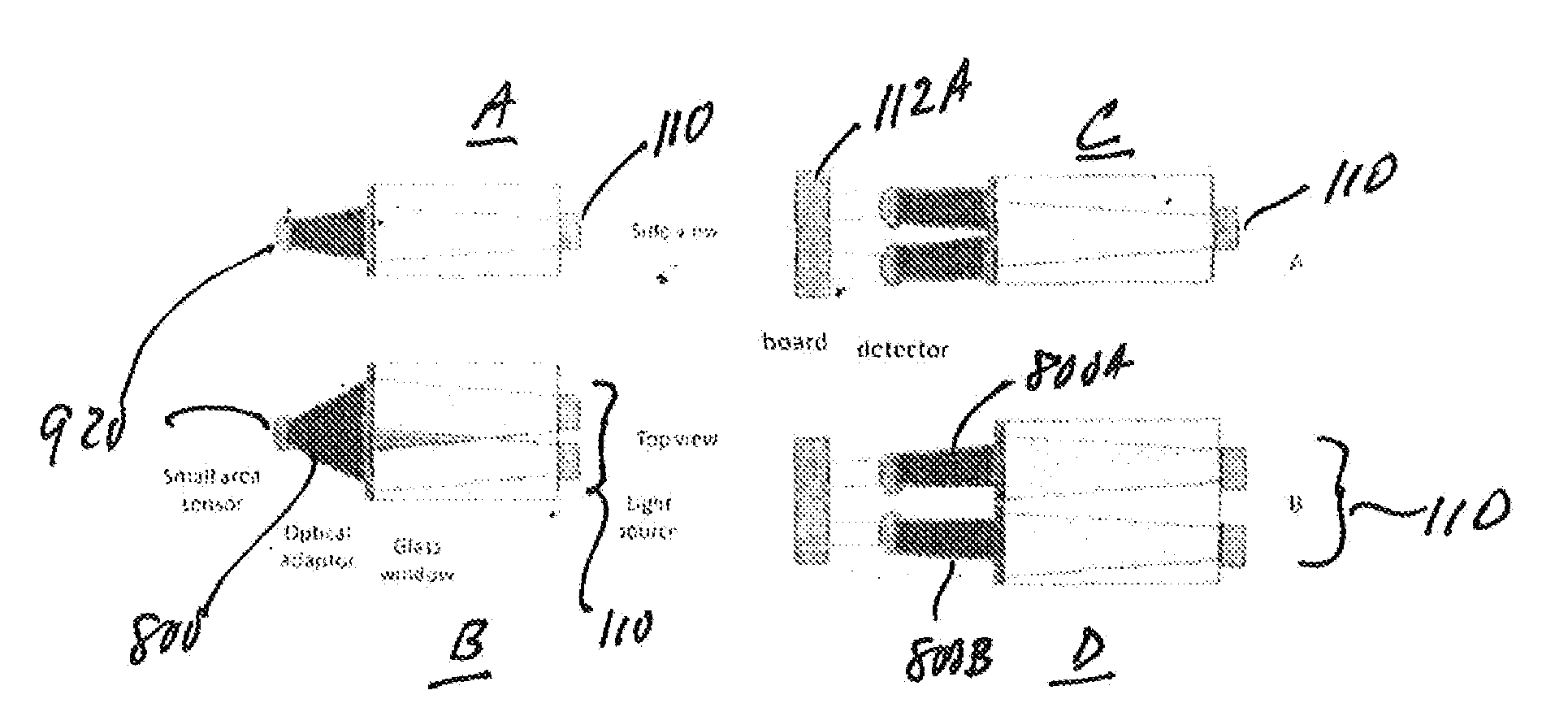

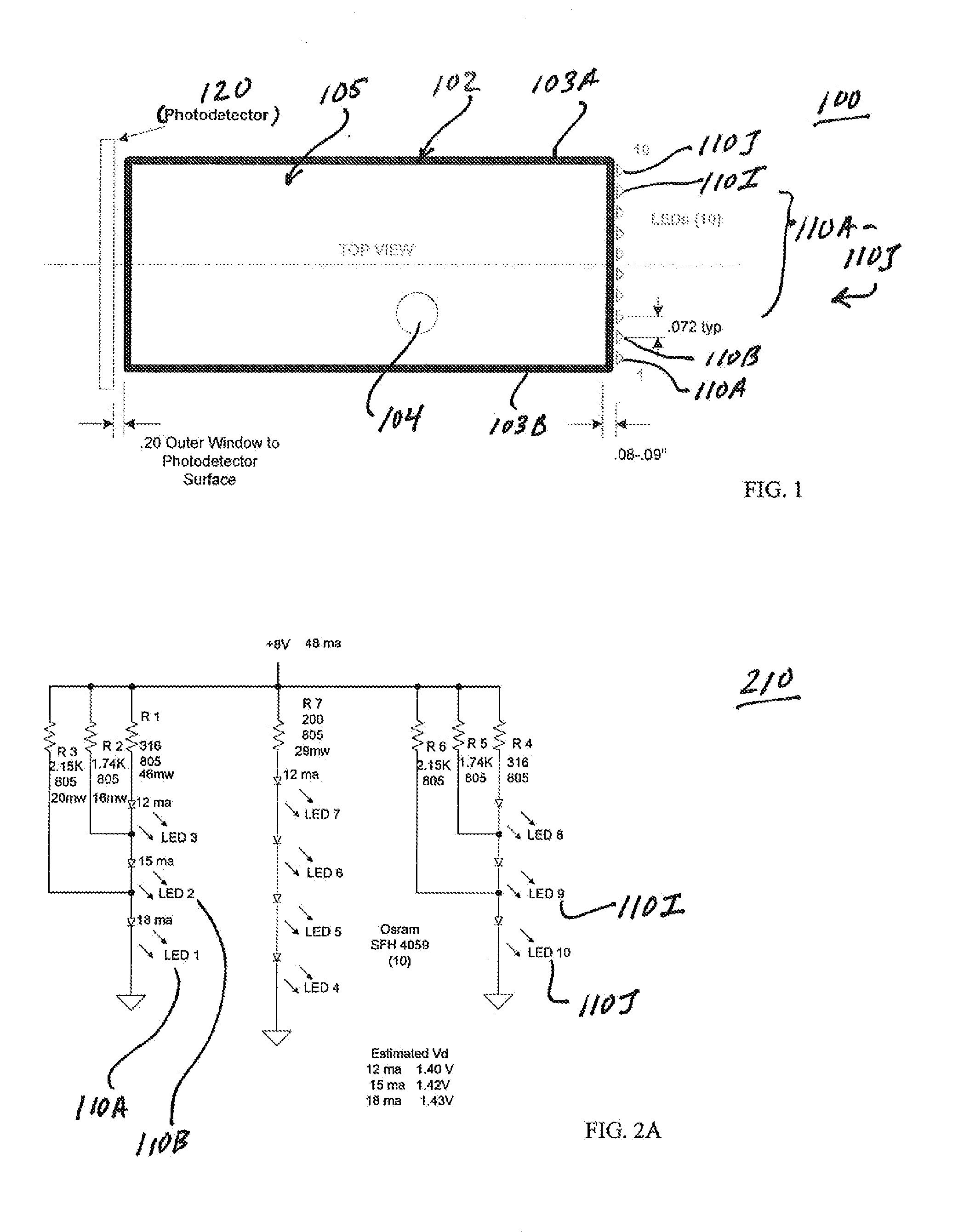

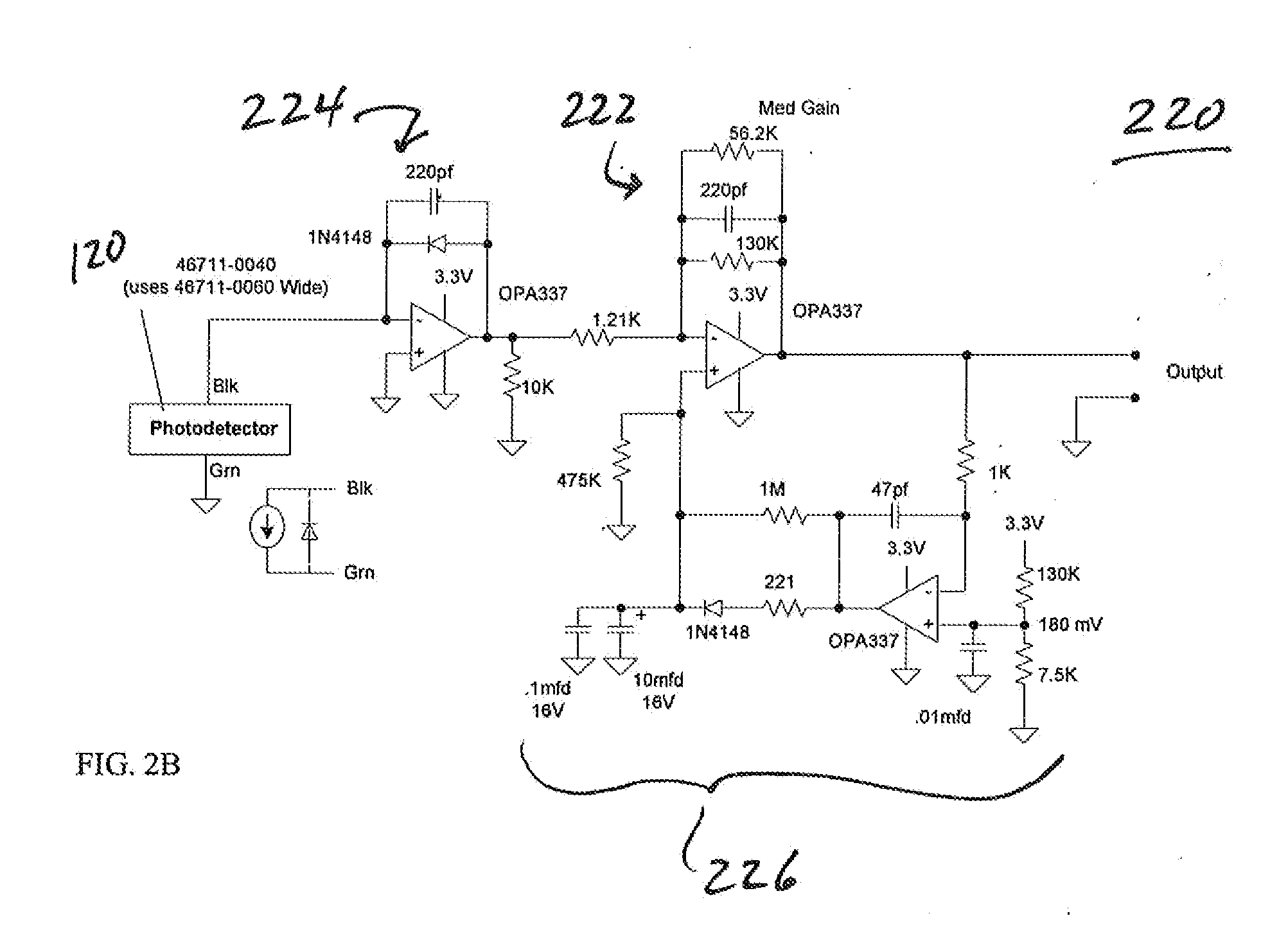

Seed sensor with lightpipe photodetect assembly

ActiveUS20160374263A1Improve performanceReduce spatial variabilityUsing optical meansSeed depositing seeder partsPhotovoltaic detectorsPhotodetector

In one example embodiment, a seed sensor is disclosed adapted to fit a conventional mounting location in existing seed tubes that provides improved performance by providing a wide light source (more LEDS), a wide photodetector and a current profiling scheme for the LEDs that provides more light at the opposite ends of the LED array. A result of such an arrangement is to improve seed resolution and to reduce seed spatial variability within the seed tube.

Owner:TSI INC

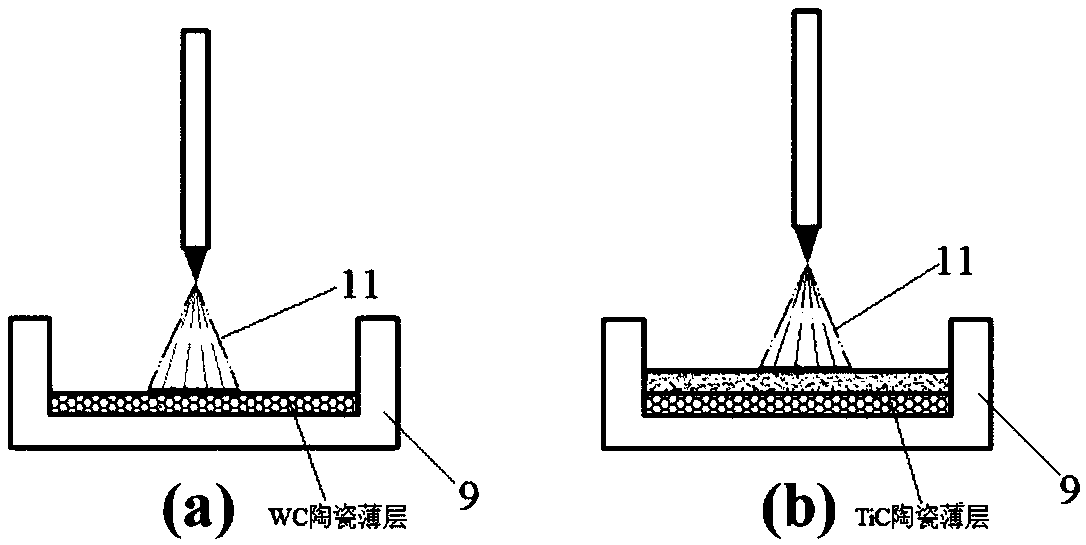

Method for preparing laminar composite ceramic cutter material blanks by using electrojet deposition technology

InactiveCN108608555AWide adaptabilitySimple manufacturing processCeramic shaping apparatusManufacturing technologyComposite ceramic

The invention relates to a method for preparing laminar composite ceramic cutter material blanks by using an electrojet deposition technology, and belongs to the technical field of mechanical cutter manufacturing. The method comprises the following steps: (1) firstly, ceramic powder is uniformly mixed with a solvent and a binding agent to prepare suspension; and then, the suspension is positionedin an injector of an electrojet deposition device; (2) a mold is positioned on a motion platform of a substrate of the electrojet deposition device; the motion distance and speed and the grid gap of the substrate of the motion platform are set; the flow of the suspension, the voltage of a high-voltage power supply and the distance between a metal nozzle and a graphite mold are set; and the suspension is deposited in the mold to form a ceramic thin layer; and (3) the step (2) is repeated to obtain the laminar composite ceramic cutter material blanks. The electrojet deposition technology is usedfor depositing the ceramic cutter pulp thin layer on micro-nanoscale to realize ordered arrangement of materials in the laminar composite ceramic cutter material blanks.

Owner:SHANDONG UNIV

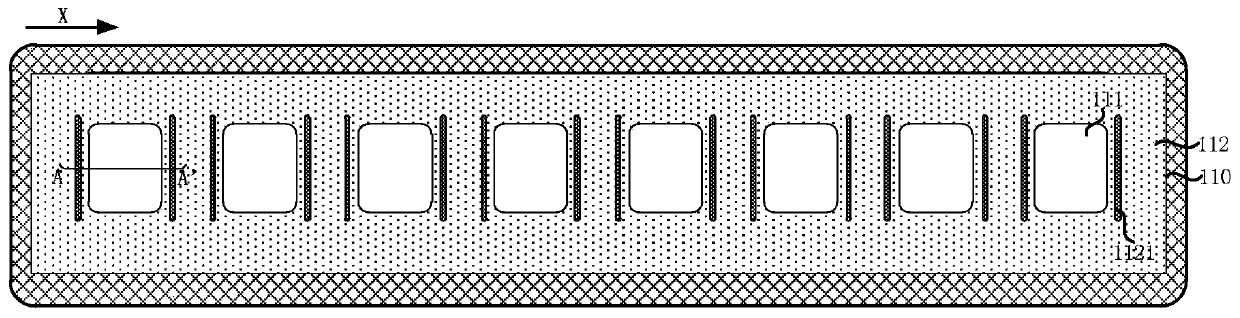

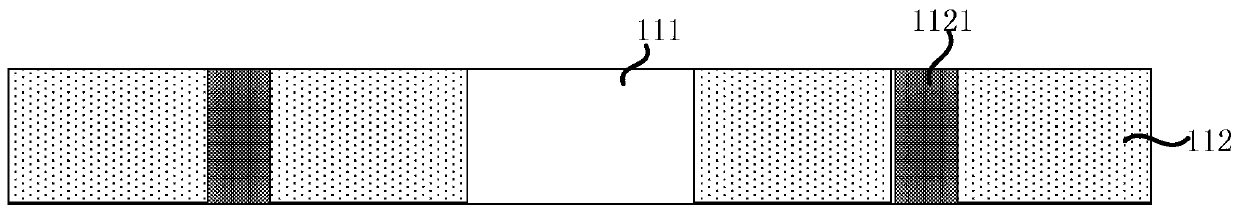

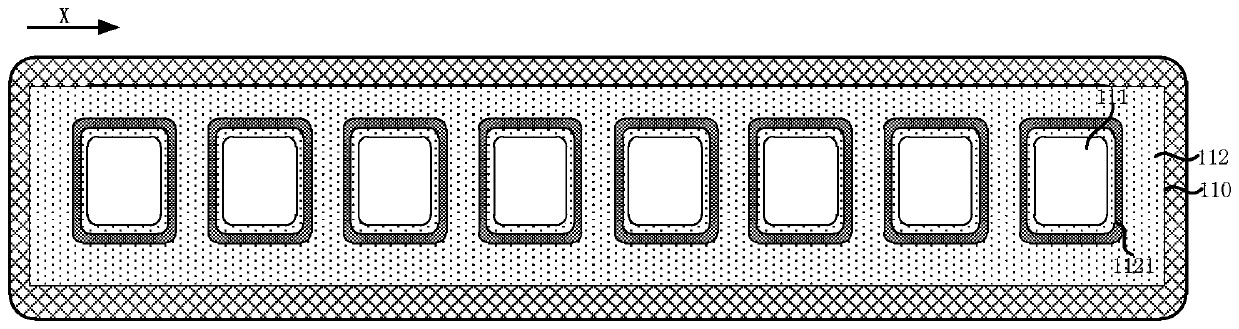

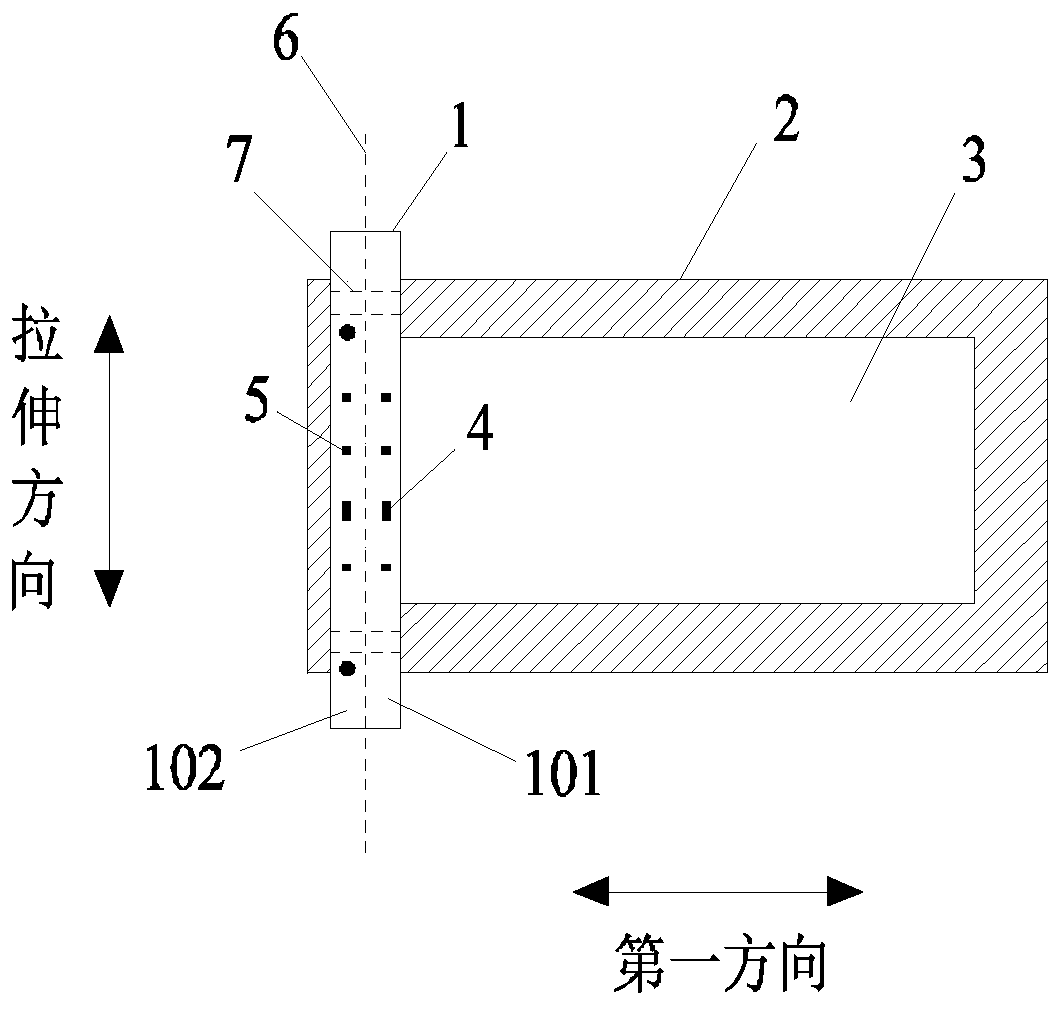

Mask plate and mask plate assembly

PendingCN111926291APrevent driftImprove deposition accuracyVacuum evaporation coatingSputtering coatingPhysicsEngineering

The invention provides a mask plate and a mask plate assembly, and relates to the technical field of display. The mask plate comprises an open area and a welding area arranged around the open area, and a stop groove is arranged outside the open area. When the mask plate is welded to a framework, wrinkles can be formed on the mask plate. The stop groove is arranged on the mask plate and can stop transmission of wrinkles, wrinkles are prevented from being transmitted into the open area of the mask plate, then the position of the open area is prevented from deviating, and evaporation precision isimproved.

Owner:HEFEI VISIONOX TECH CO LTD

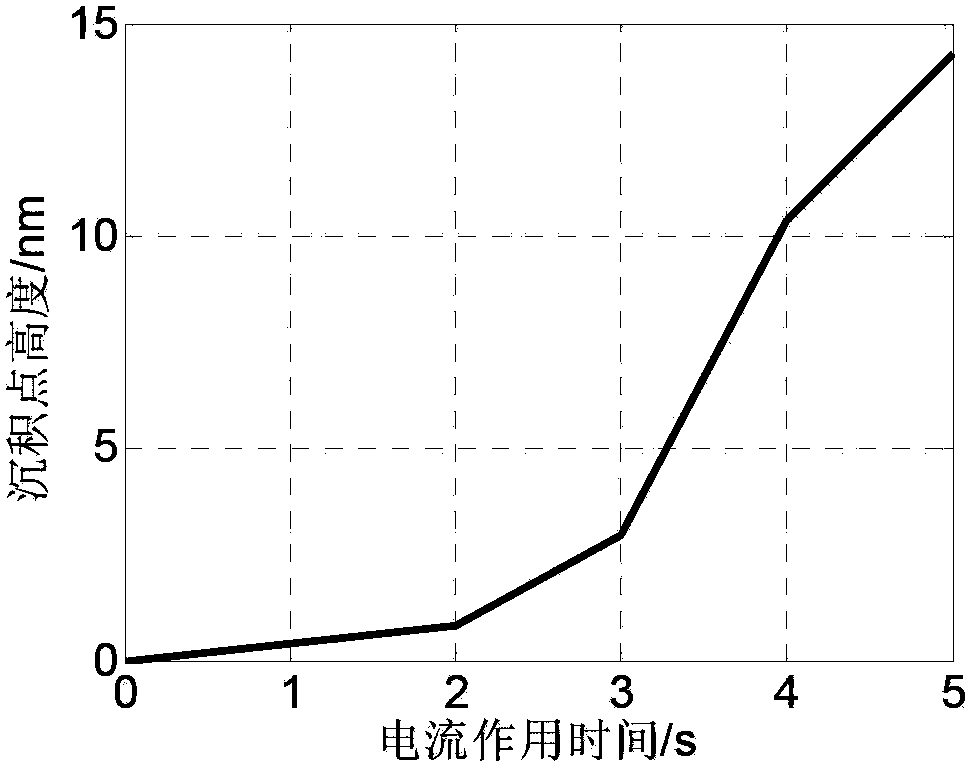

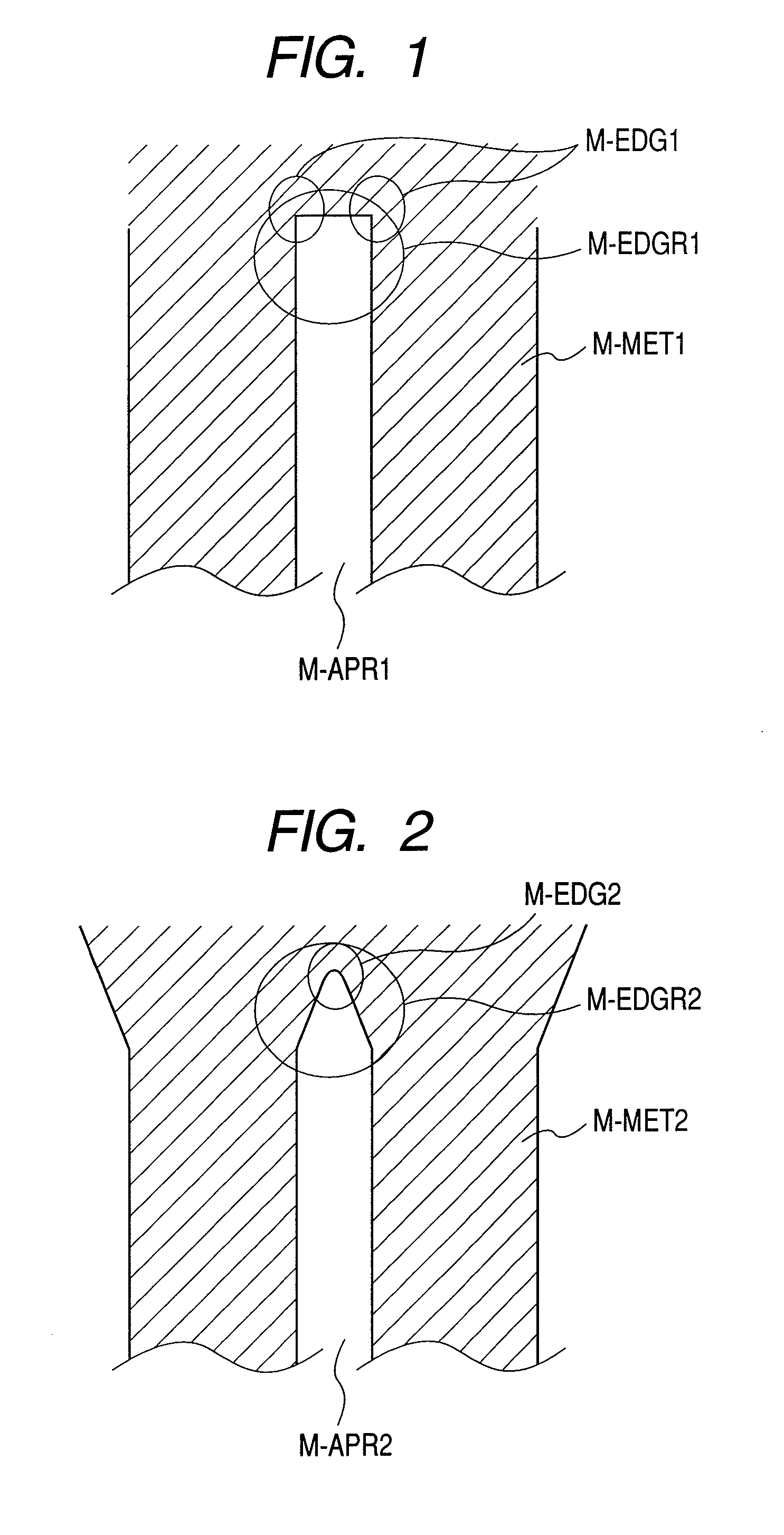

Method for achieving atomic force microscope (AFM) nano deposition by applying current

InactiveCN103879955AGood repeatabilityHigh precisionNanostructure manufactureAtomic force microscopyMagnetic force microscope

The invention discloses a method for achieving atomic force microscope (AFM) nano deposition by applying a current. According to the method, by means of application of the certain current onto an AFM pinpoint and substrate and control of the magnitude of the current, atoms on an AFM conducting probe are deposited on the substrate to form a conductor deposition point, and the conductor deposition point can be used for processing a nano lattice structure and welding nano materials in a nano device. By means of the method for achieving AFM nano deposition by applying the current, the deposition point with good repeatability and high precision can be processed, and meanwhile, the size of the deposition point can be flexibly controlled; the method can be used for processing nanowires.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

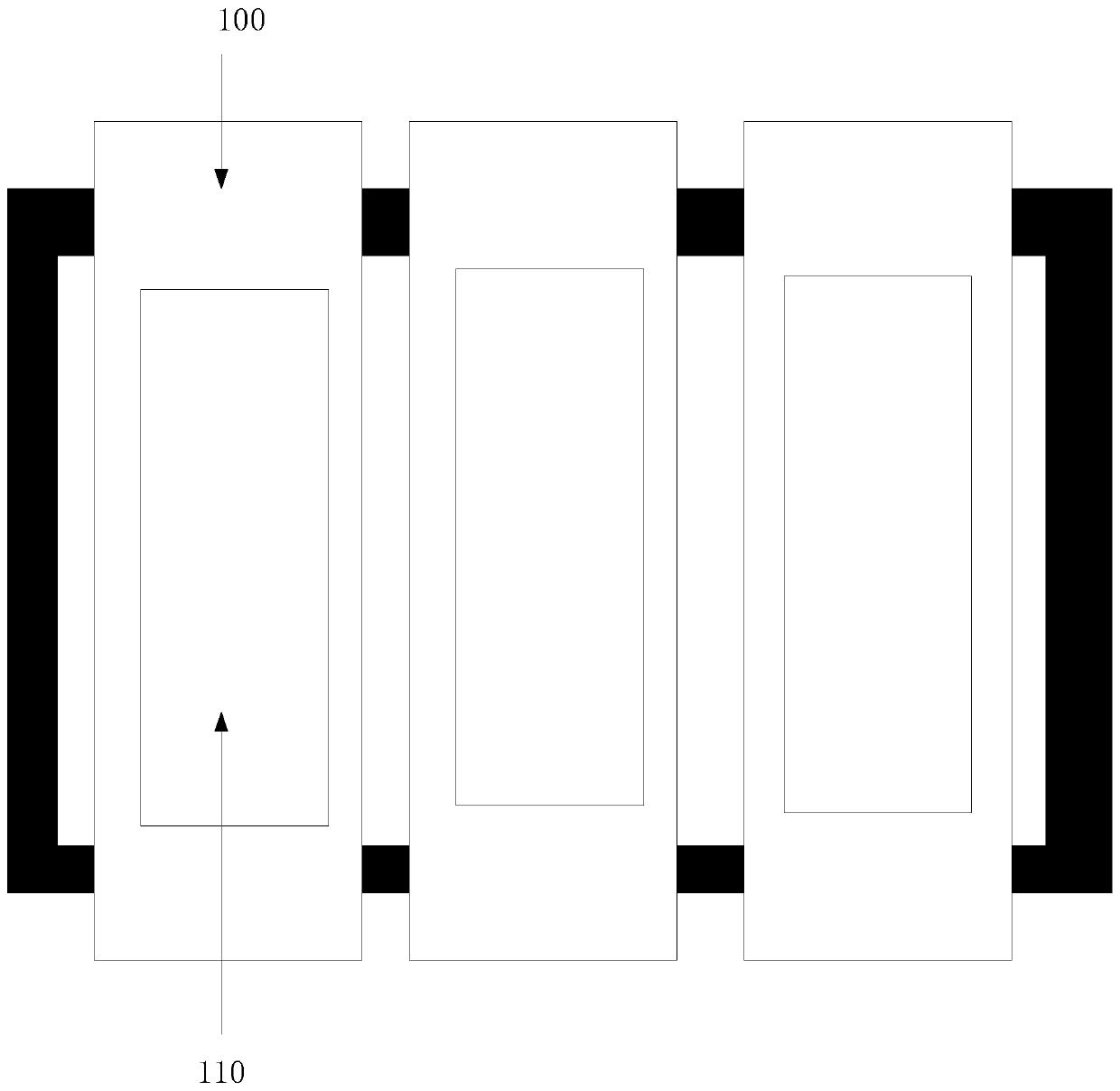

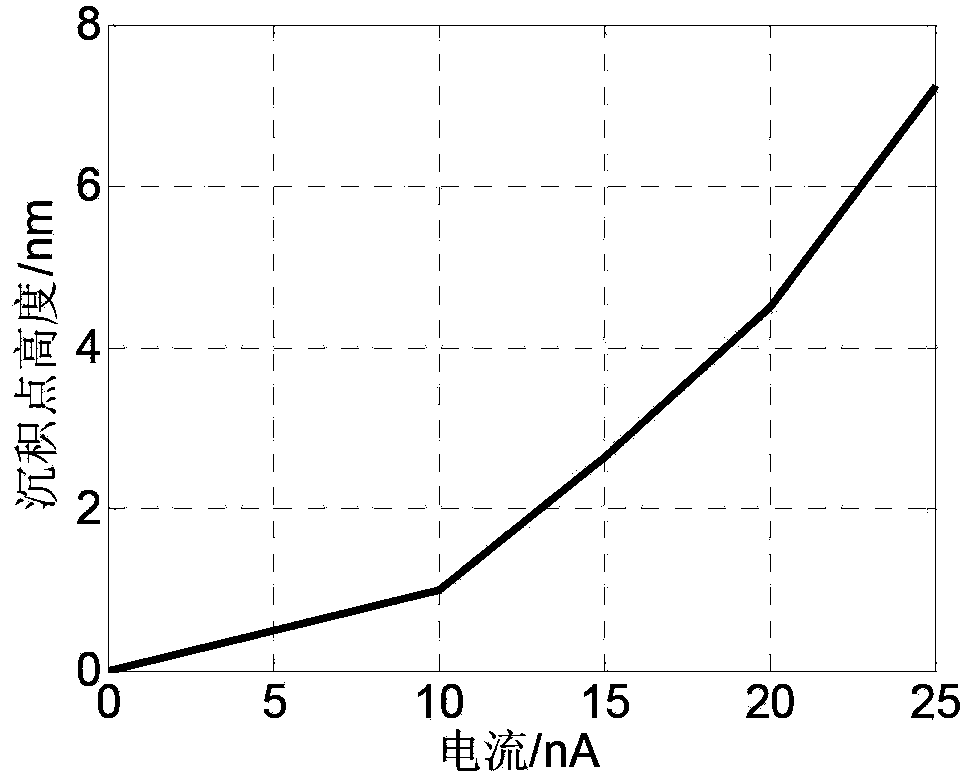

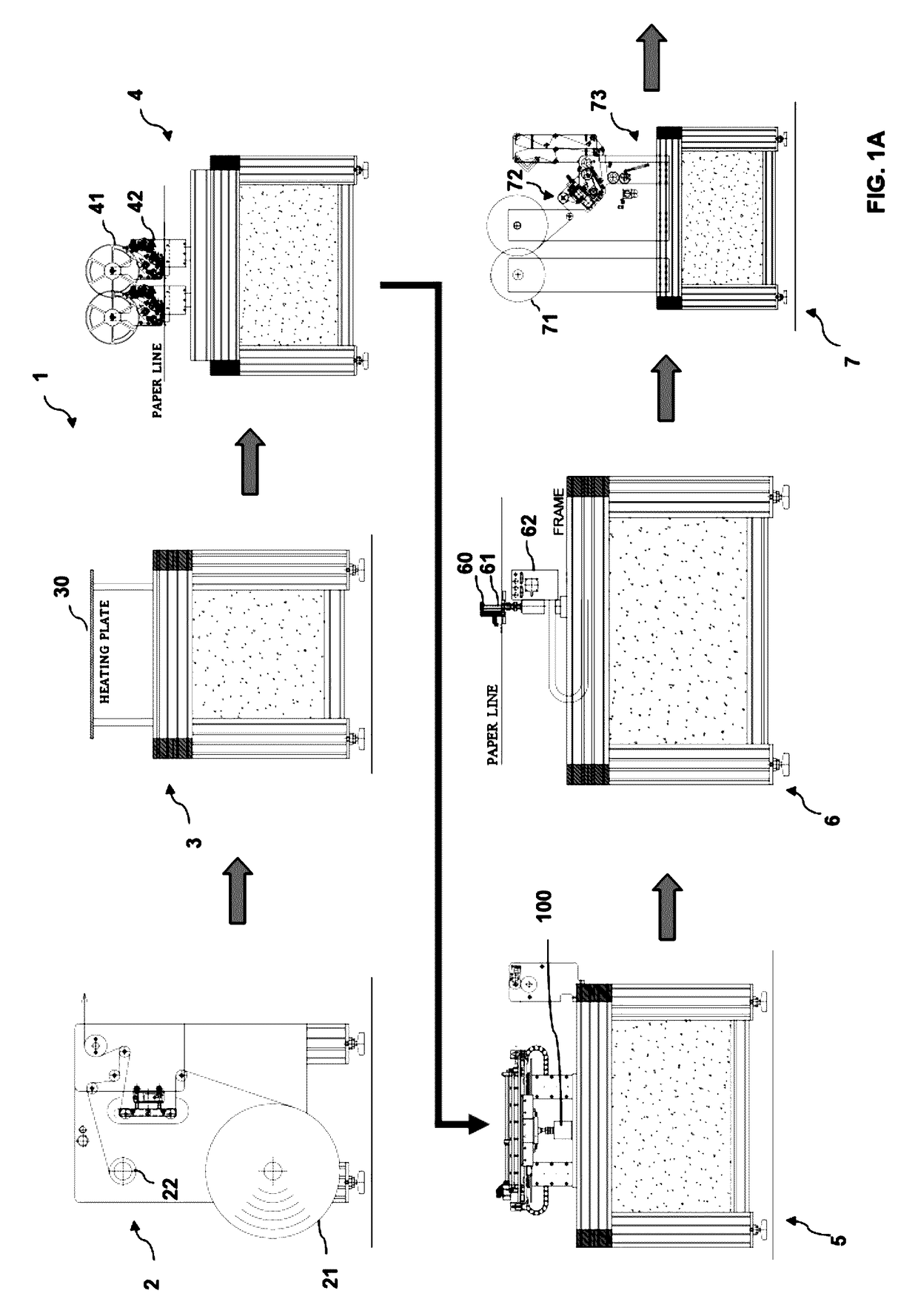

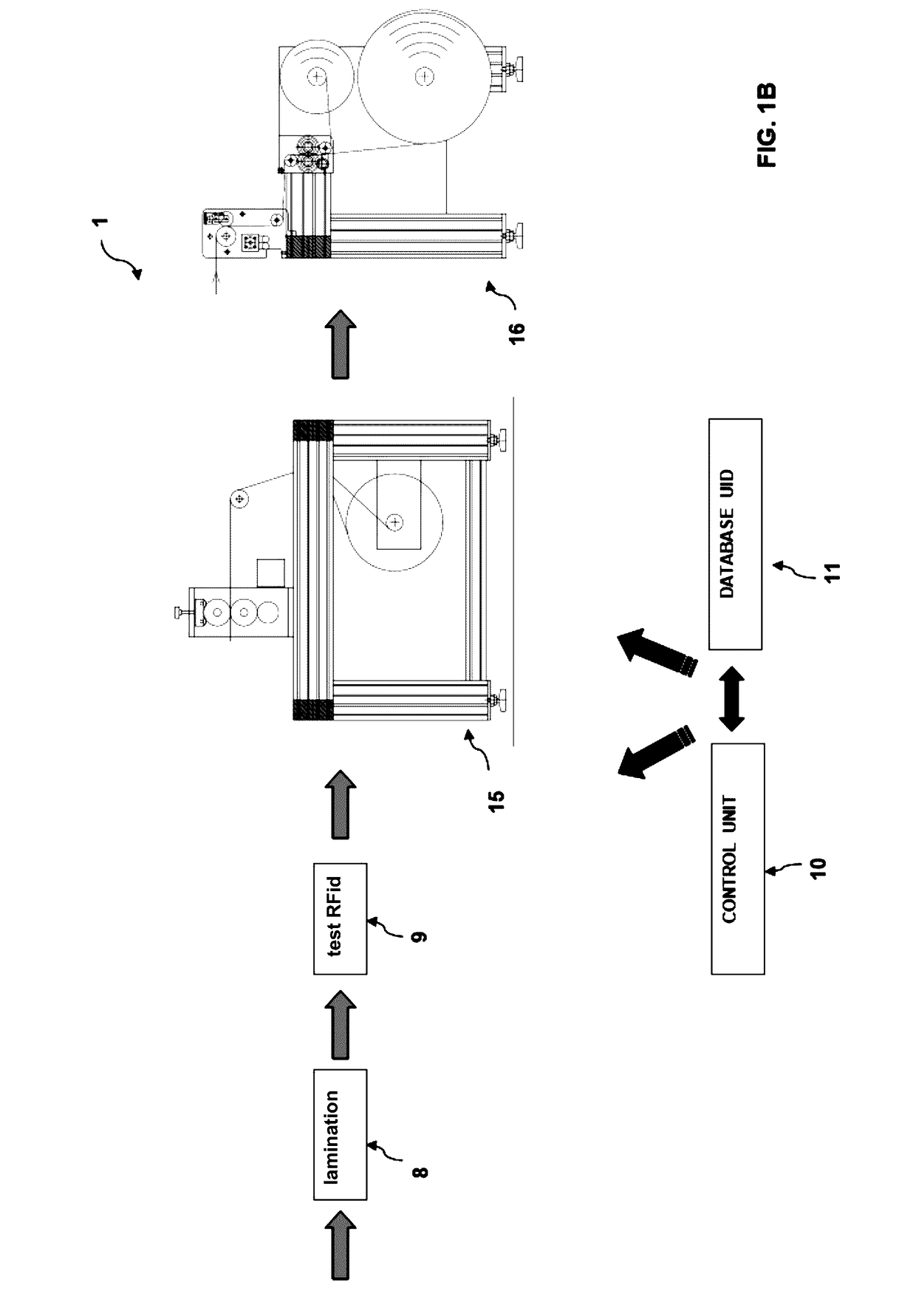

APPARATUS, METHOD AND DEVICE FOR MAKING PRODUCTS INCORPORATING AN RFid

ActiveUS20170103291A1High precisionImprove efficiencyRecord carriers used with machinesElectrical componentsBeakCoupling

An apparatus (1) for the creation of products incorporating devices for radio frequency identification (RFID), said apparatus (1) being configured to operate according to a continuous processing line which includes, in sequence:a supply unit (2) of a substrate material;an add-chip unit (4), having means for the application of chips on the substrate material (41);an aerial-making assembly comprising:an aerial posing unit (5), configured to deposit a metal wire at each chip;an electrical connection unit, configured for electrically connecting the metal wire and a respective chip therebetween;a coupling unit (7), adapted to place a coating material on the substrate material; anda plurality of reading means (42, 62, 9) of each chip, arranged along said processing line,wherein said unit of aerial posing (5) comprises a plurality of devices (100) for realizing an aerial,wherein each device (100) is provided with a putting wire head (150) arranged at one end of a main body (101) and having a translational degree of freedom in a longitudinal direction (L),said putting wire head (150) comprising a guide element (102) rotatable according said longitudinal direction (L) and adapted to engage and guide the wire to deposit it on a substrate and a beak-like element (103) adapted to selectively abut in abutment on said rotatable element

Owner:MECSTAR

Mask

ActiveCN111304585AReduce saggingReduce wrinklesVacuum evaporation coatingSolid-state devicesEngineeringDislocation

The invention discloses a mask. The mask comprises at least one mask strip, the mask strip comprises an evaporation area and a shielding area, the evaporation area is provided with a plurality of openings, the shielding area is arranged on the two sides of all the openings in the first direction, wherein the first direction is the length direction of the mask strip, the shielding area comprises atleast one thermal shrinkage area, and the thermal shrinkage areas comprise thermal shrinkage materials. According to the mask, when the mask strip is welded to a mask frame, the thermal shrinkage materials in the thermal shrinkage areas are heated, and crystal lattices are shrunk, so that the thermal shrinkage phenomenon is generated; the thermal shrinkage phenomenon of the thermal shrinkage areas applies thermal shrinkage tension to the shielding area of the mask strip to drive the shielding area to be tensioned, so that the mask strip is further tensioned, and then the drooping phenomenon of the mask strip due to gravity can be reduced; and meanwhile, wrinkles on the mask strip can be reduced, the laminating effect between the mask and a substrate to be evaporated during evaporation isimproved, the evaporation precision of the mask is improved, and the risks of pixel dislocation, color mixing and the like after evaporation of the substrate to be evaporated are reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

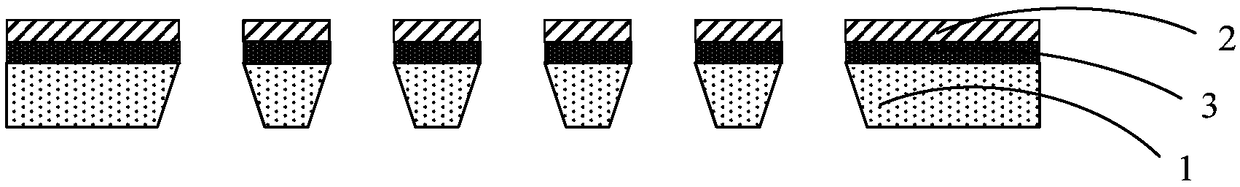

Mask plate, mask device and preparation method of mask plate

ActiveCN109440061AImprove deposition accuracyIncrease opening ratioVacuum evaporation coatingSputtering coatingToughnessMaterials science

The invention provides a mask plate, a mash device and a preparation method of the mask plate, and belongs to the technical field of preparation of a display substrate. The mask plate is used for preparing the display substrate. The mask plate comprises a rigid transparent base with first openings, and a tough reinforcing layer arranged on the rigid transparent base and used for reinforcing the toughness of the mask plate. The first openings correspond to pixel units of the display substrate. The tough reinforcing layer is provided with second openings, and the second openings correspond to the first openings one to one.

Owner:BOE TECH GRP CO LTD

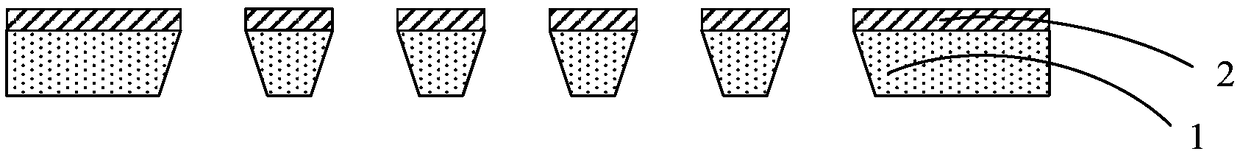

Metal molten drop deposition method implemented by using nonmetal sheets with trapezoidal grooves

InactiveCN104032302AImprove deposition accuracyEasy to operateMetallic material coating processesMolten stateMolten salt

The invention discloses a metal molten drop deposition method implemented by using nonmetal sheets with trapezoidal grooves. The metal molten drop deposition method comprises the following steps: firstly, arranging nonmetal sheets with trapezoidal grooves on the four side faces of a baseplate, and preheating the baseplate on which the nonmetal sheets with trapezoidal grooves are arranged; then, heating a metal material until the metal material is in a molten state, enabling the molten-state metal material to pass through a nozzle so as to form uniform metal molten drops; and in an argon gas environment, dropwise adding the metal molten drops on the surface of the baseplate on which the nonmetal sheets with trapezoidal grooves are arranged, and moving the baseplate on which the nonmetal sheets with trapezoidal grooves are arranged according to the shape of the surface of the baseplate, so that the metal molten drops are deposited layer by layer and point and point, and meanwhile, blocking the edge of each layer of metal molten drops through the nonmetal sheets with trapezoidal grooves until the metal molten drops are deposited completely, and after the obtained product is subjected to curing shrinkage, completing the metal molten drop deposition of the surface of the baseplate. According to the metal molten drop deposition method disclosed by the invention, the precision of metal molten drop deposition on the surface of the baseplate can be realized.

Owner:XI AN JIAOTONG UNIV +1

Organic electroluminescence display device

ActiveUS7714506B2Improve deposition accuracySimple designDischarge tube luminescnet screensLamp detailsGas phaseDisplay device

An organic electroluminescence display device is disclosed wherein plural organic electroluminescence elements each having an anode, a cathode and an organic layer sandwiched in between the anode and the cathode, the plural organic electroluminescence elements including organic electroluminescence elements developing different colors in a row direction, and at least one of the organic layers having an outer edge of a conic section at an end portion in a column direction thereof, the outer edge of the conic section becoming narrower gradually in its width in a row direction of vapor deposition thereof toward an extreme end at an end portion in a column direction thereof. The organic electroluminescence display device can improve the vapor deposition accuracy and the degree of design freedom.

Owner:SAMSUNG DISPLAY CO LTD +1

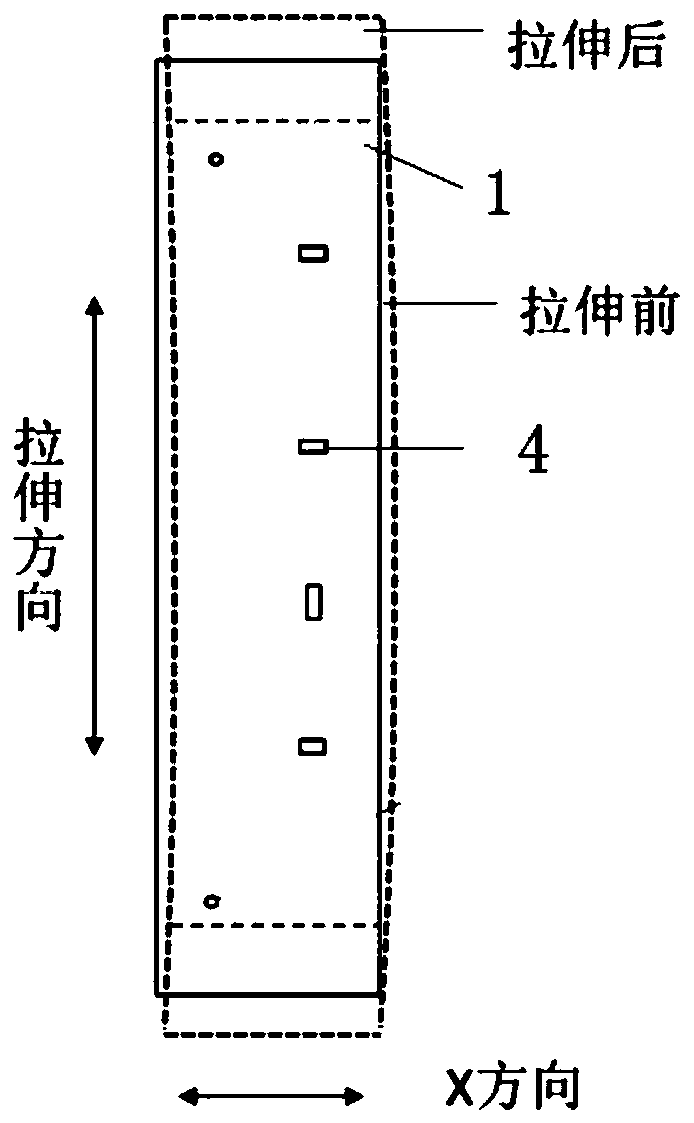

Mask and preparation method thereof

ActiveCN110629159AImprove stabilityImprove deposition accuracyVacuum evaporation coatingSputtering coatingEngineeringEvaporation

The embodiment of the invention provides a mask and a preparation method thereof. The mask comprises a mask body, wherein the mask body is provided with a detection opening, and a balance pattern usedfor balancing stretching stress born by the detection opening, the balance pattern and the detection opening are located on two sides of a center line of the mask body in the first direction length correspondingly, and the first direction is perpendicular to the stretching direction of the mask body. After the mask is stretched, the deformation is uniform, the alignment precision stability of themask can be improved, and the evaporation deviation caused by the poor alignment precision of the mask in the evaporation process is avoided.

Owner:BOE TECH GRP CO LTD +1

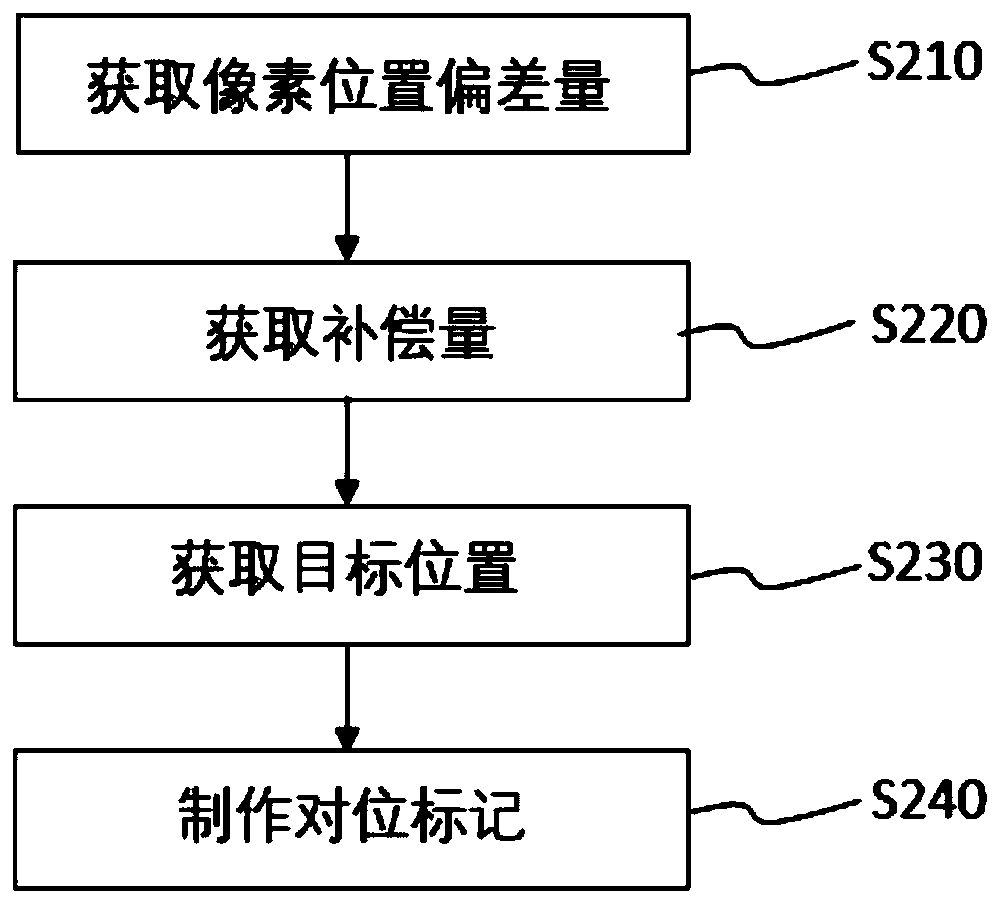

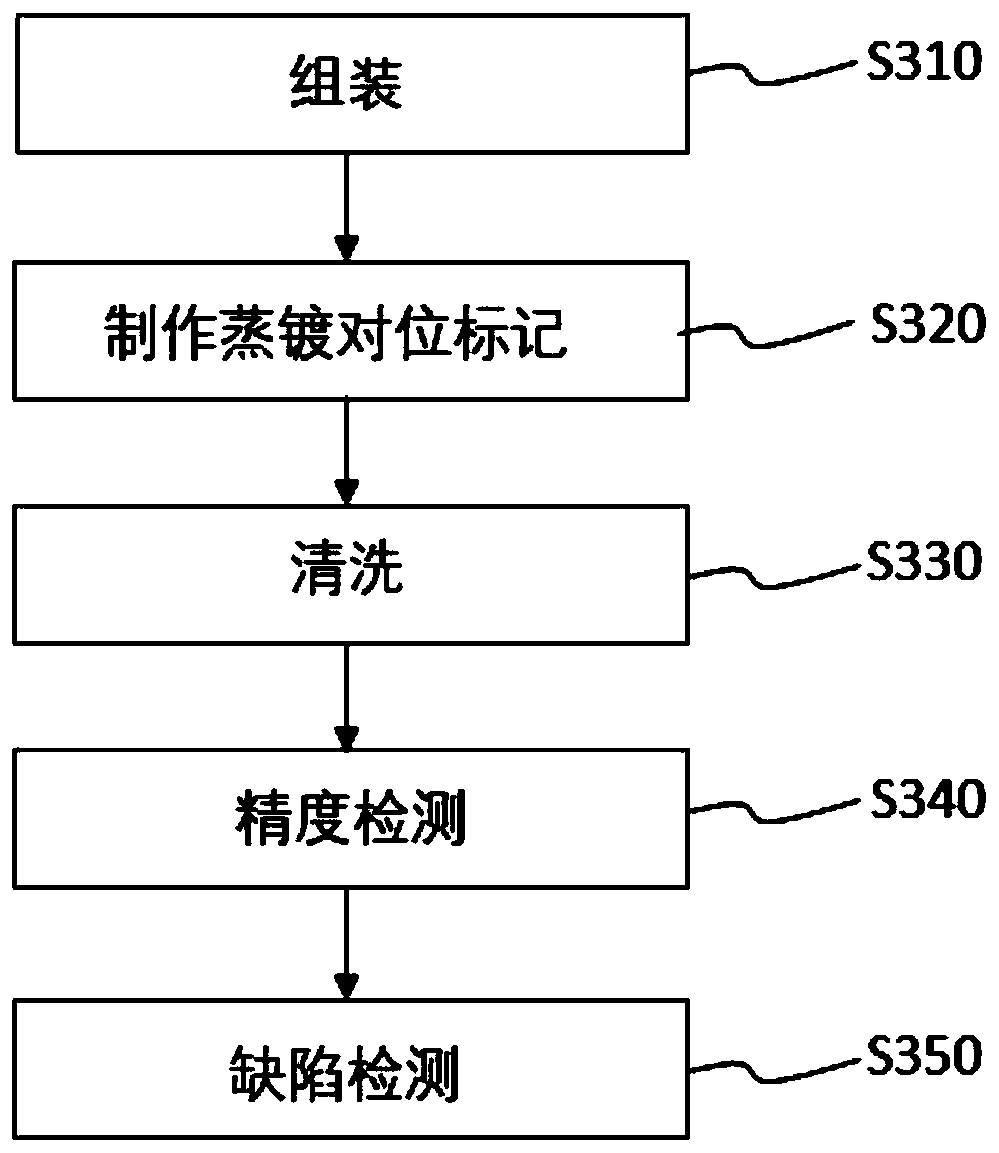

Alignment marking method and manufacturing method of mask plate

InactiveCN111471959AReduce wasteImprove alignment accuracyVacuum evaporation coatingSolid-state devicesEngineeringMechanical engineering

The invention discloses an alignment marking method and a manufacturing method of a mask plate. The alignment marking method comprises the steps that (1) the deviation value of pixel positions is acquired; (2) the compensation dosage is acquired; and (3) offset compensation is carried out. By means of the alignment marking manufacturing method, compensation to offset of the pixel positions of themask plate can be completed; and by means of the manufacturing method of the mask plate, the alignment marking method is adopted for completing compensation to offset of the pixel positions in the production process of manufacturing the mask plate, and then the offset compensation step in the evaporation technological process can be omitted.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com