Mask plate and mask plate assembly

A mask plate and component technology, which is applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems affecting the evaporation accuracy and the position deviation of the opening, so as to improve the evaporation accuracy and prevent The effect of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

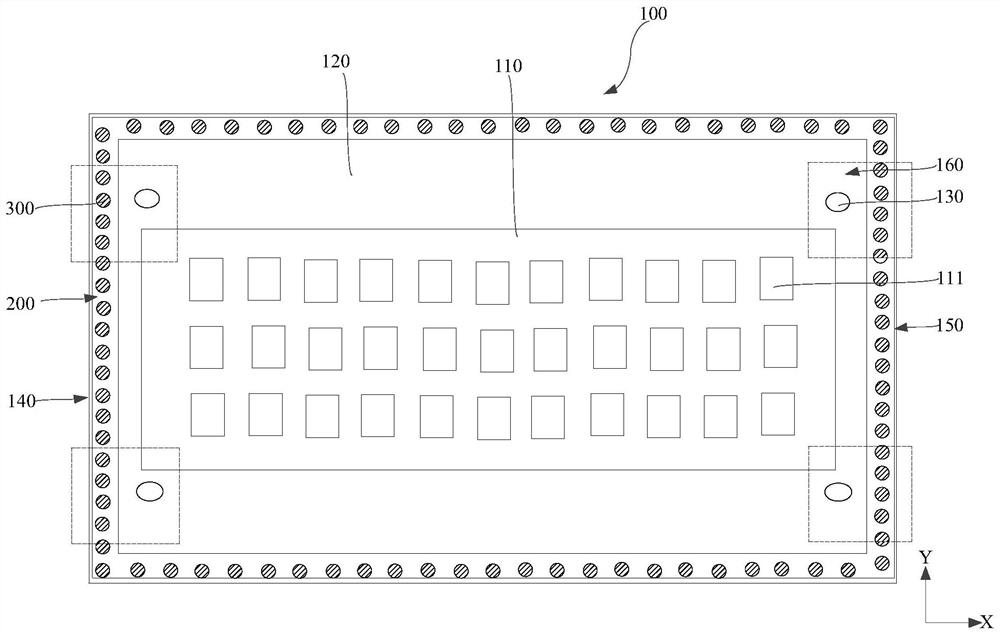

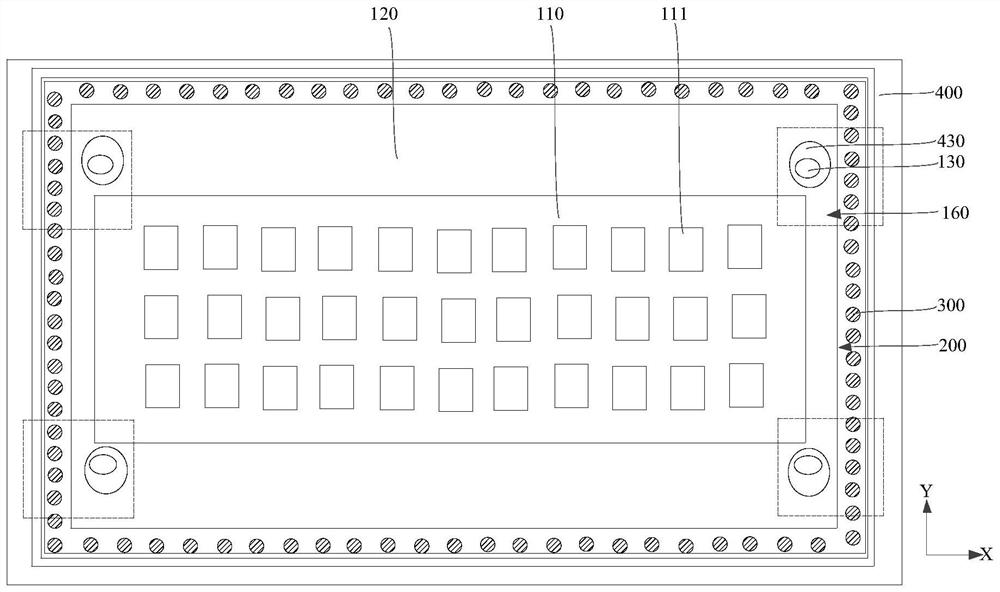

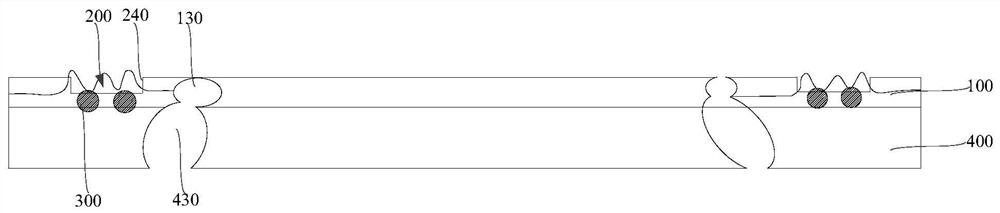

[0059] The inventor of the present application found in the actual work process that when the mask plate is placed on the frame with the jaws and the mask plate is welded to the frame by laser welding, stress will be formed inside the mask plate. When the stress is concentrated in some areas of the mask plate, for example, the area where the alignment holes are located, wrinkles will occur in these areas. During the subsequent evaporation alignment process, the magnetic adsorption will expand the above-mentioned wrinkles and make the above-mentioned wrinkles Extending into the opening area of the mask plate causes the position of the opening area to shift, reducing the positional accuracy (PAA) of the evaporation pattern, which in turn causes the pixel of the evaporated OLED device to shift, affecting the normal display of the OLED device.

[0060] In view of the above-mentioned technical problems, embodiments of the present invention provide a mask and a mask assembly. By pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com