Throwing-filling structure system and working method thereof

A system and lifting system technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of large flatness tolerance of geobags, uncontrollable drop point, low construction efficiency, etc., to reduce downtime and refit time, improve throwing The effect of filling construction efficiency and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

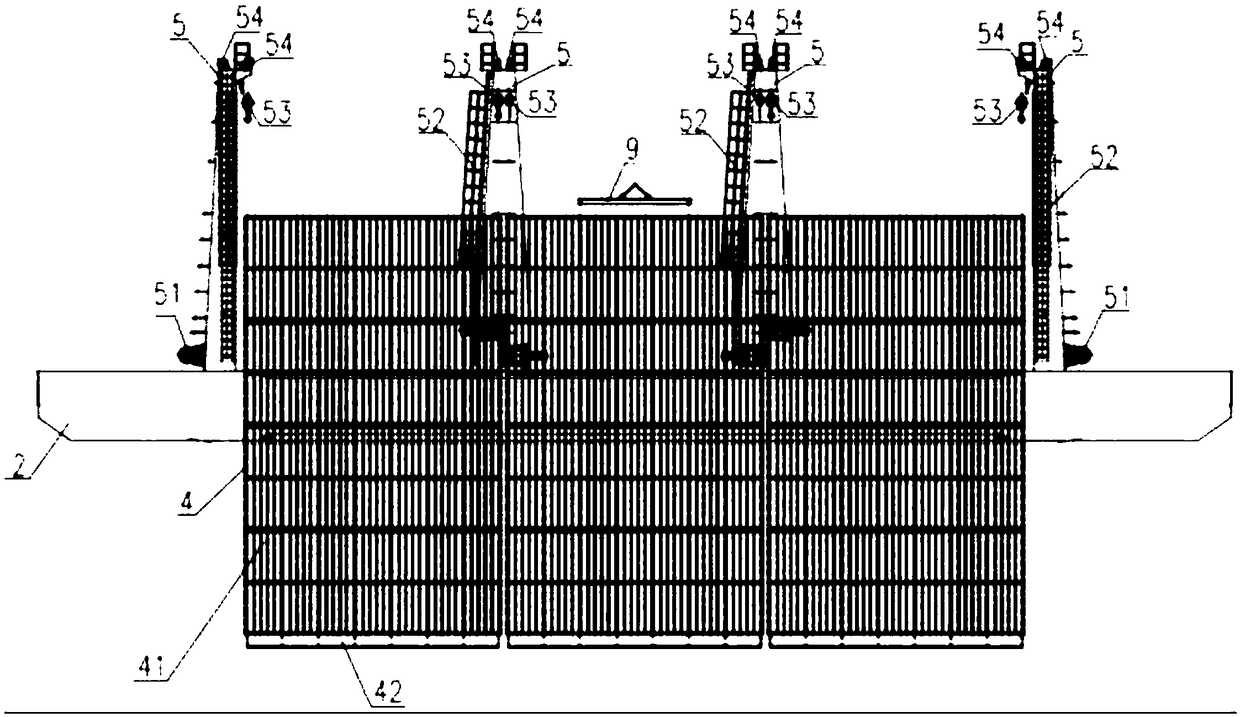

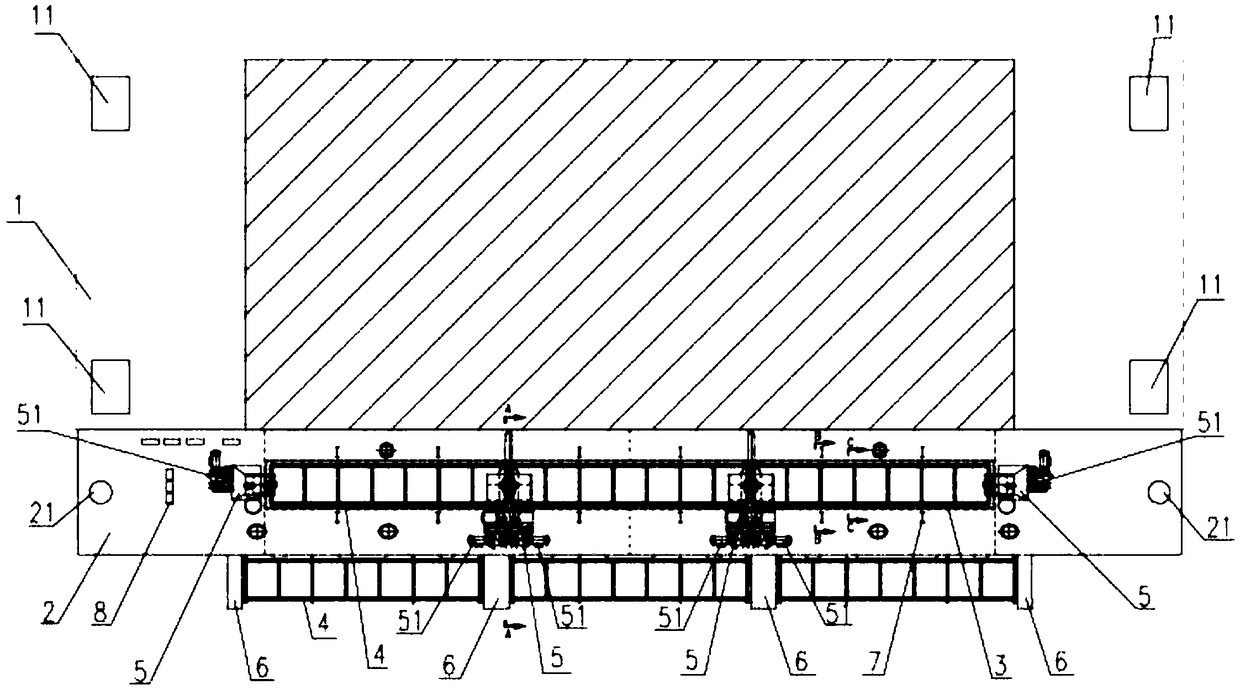

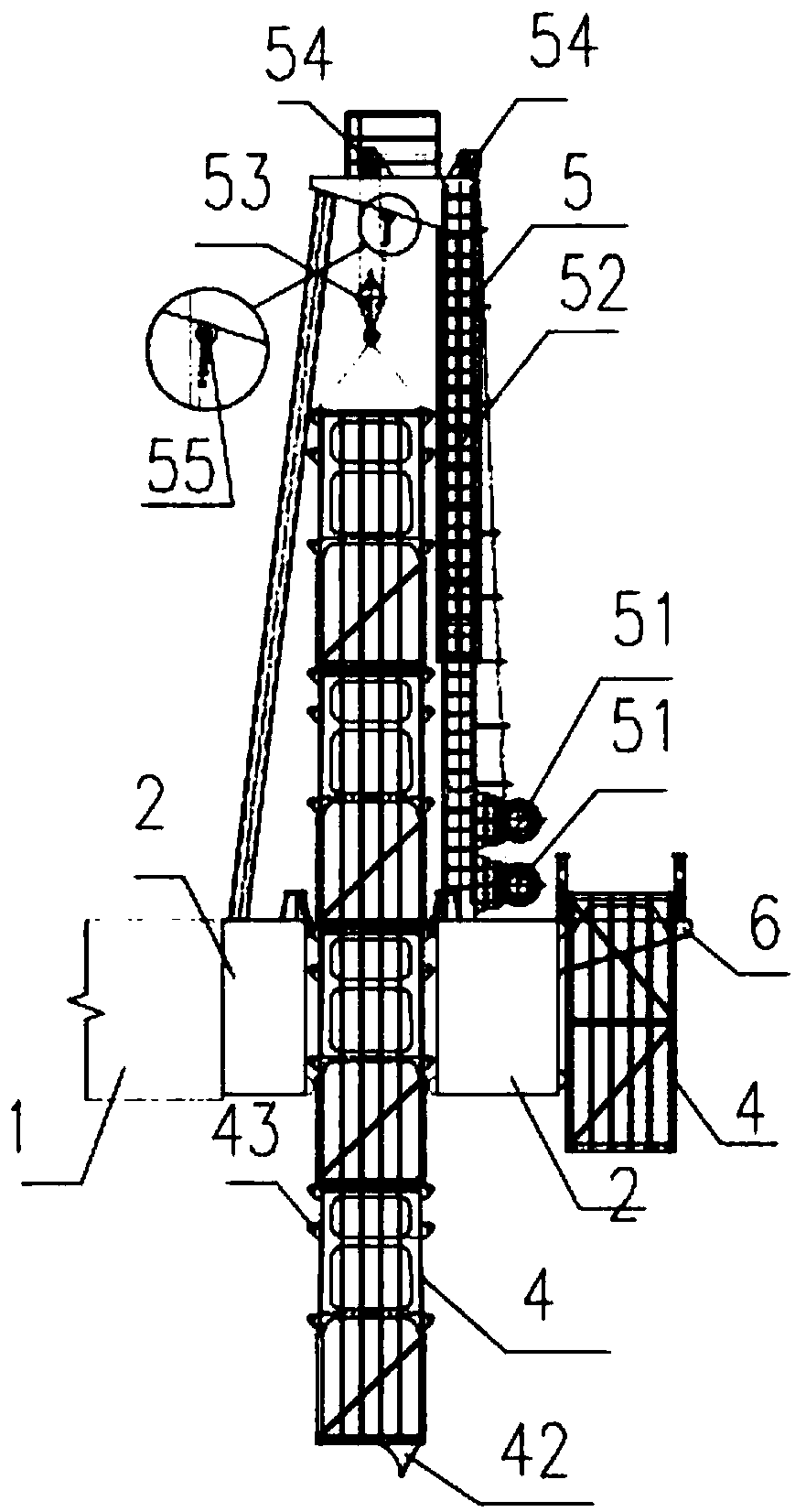

[0037] Such as figure 1 As shown, a dumping and filling structure system mainly includes dumping and filling ship 1, GPS 21, windlass 11, buoyancy tank 2, sandbag control guide frame 4, control frame fixing device 7, side control frame storage device, control frame lifting System and operation control box 8; GPS21 has two, is respectively positioned at the two ends of buoyancy tank 2, windlass 11 has four, is respectively positioned at the four corners of throwing and filling ship 1, and throwing and filling ship 1 moves to by GPS 21 and windlass 11 Designated drop-fill location;

[0038] Such as figure 2 As shown, the buoyant tank 2 is located on one side of the dumping and filling ship 1, and the buoyant tank 2 and the dumping and filling ship 1 are connected through the strong structure of the main deck, the bow and stern sealing plate and the side. The fixation between the buoyant tank 2 and the dumping and filling ship 1 can be ensured, and the position accuracy of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com