Metal molten drop deposition method implemented by using nonmetal sheets with trapezoidal grooves

A non-metallic sheet and trapezoidal groove technology, applied in the coating process and coating of metal materials, can solve problems such as difficulty, deformation effects of missing parts, and difficulty in grasping surface accuracy, so as to improve deposition accuracy and process Low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

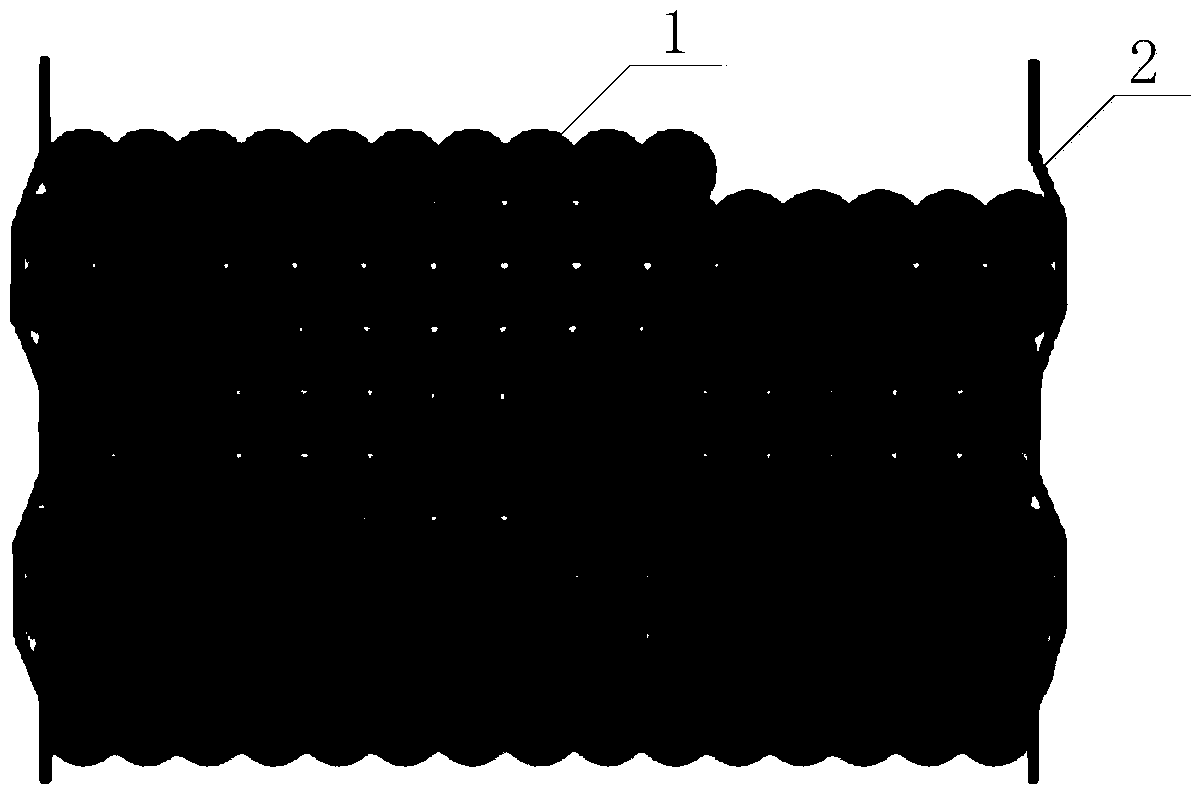

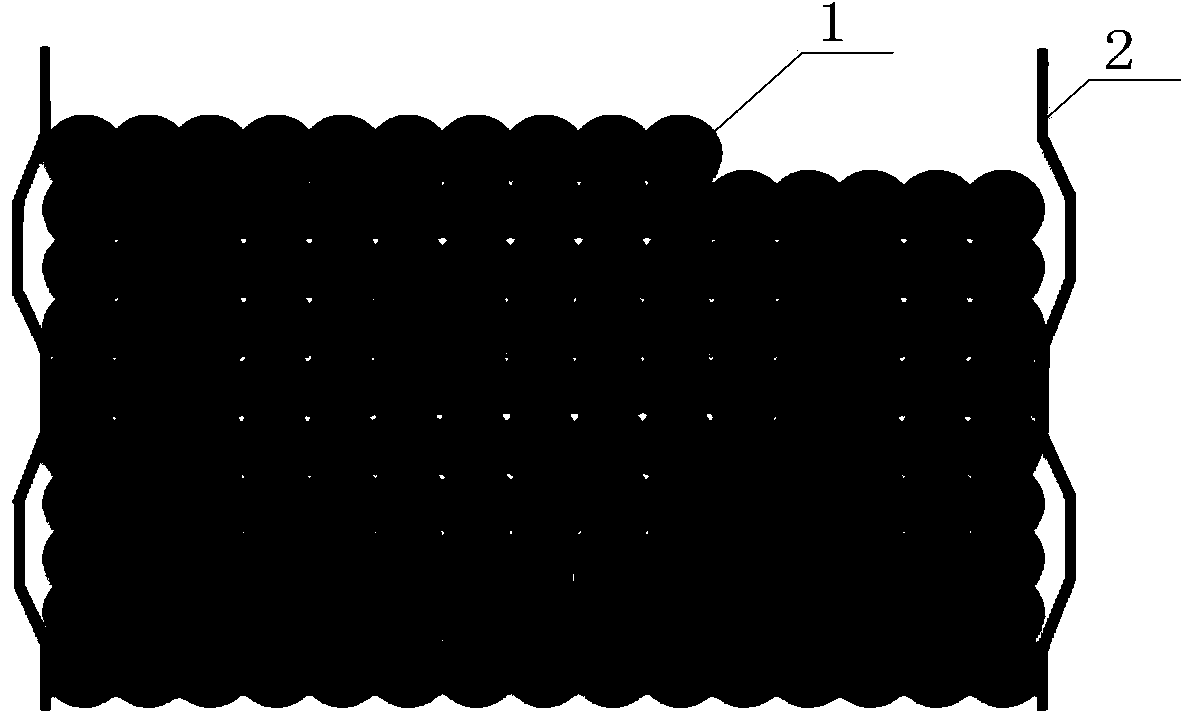

[0019] refer to figure 1 and figure 2 , the metal droplet deposition method utilizing the non-metal sheet with trapezoidal groove described in the present invention comprises the following steps:

[0020] First install the non-metallic sheet 2 with trapezoidal grooves on the four sides of the substrate, and preheat the substrate with the non-metallic sheet 2 with trapezoidal grooves, and then heat the metal material to a molten state, and the molten state The metal material is formed into a uniform metal droplet 1 through the nozzle, and then in an argon atmosphere, the metal droplet 1 is dropped drop by drop onto the surface of the substrate on which the non-metallic sheet 2 with trapezoidal grooves is installed, and at the same time according to The shape of the substrate surface moves the substrate on which the non-metallic sheet 2 with trapezoidal grooves is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com