Mask plate, mask device and preparation method of mask plate

A mask and mask technology, applied in the field of mask preparation, mask device, and mask, can solve the problems of evaporation shadow evaporation color mixing, wrinkles, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a mask plate, which is used for preparing a display substrate, and is especially suitable for vapor deposition of each layer structure of an OLED device in an OLED display substrate.

[0042] The mask plate includes: a rigid transparent base and a toughness enhancement layer; the rigid transparent base has a first opening, and the first opening corresponds to the pixel unit of the display substrate; the toughness enhancement layer is arranged on the rigid transparent base to enhance the strength of the mask plate Toughness: the toughness enhancing layer is provided with second openings, and the second openings correspond to the first openings one by one.

[0043] The mask plate of this embodiment is composed of a rigid transparent substrate and a toughness enhancing layer. Among them, the rigid transparent base makes the mask have sufficient skeleton support strength, and does not produce excessive sagging like the metal mask in the prior art, a...

Embodiment 2

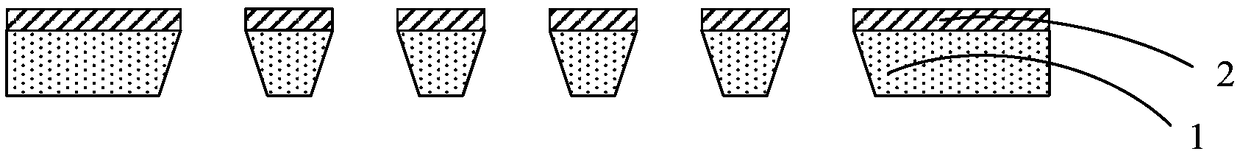

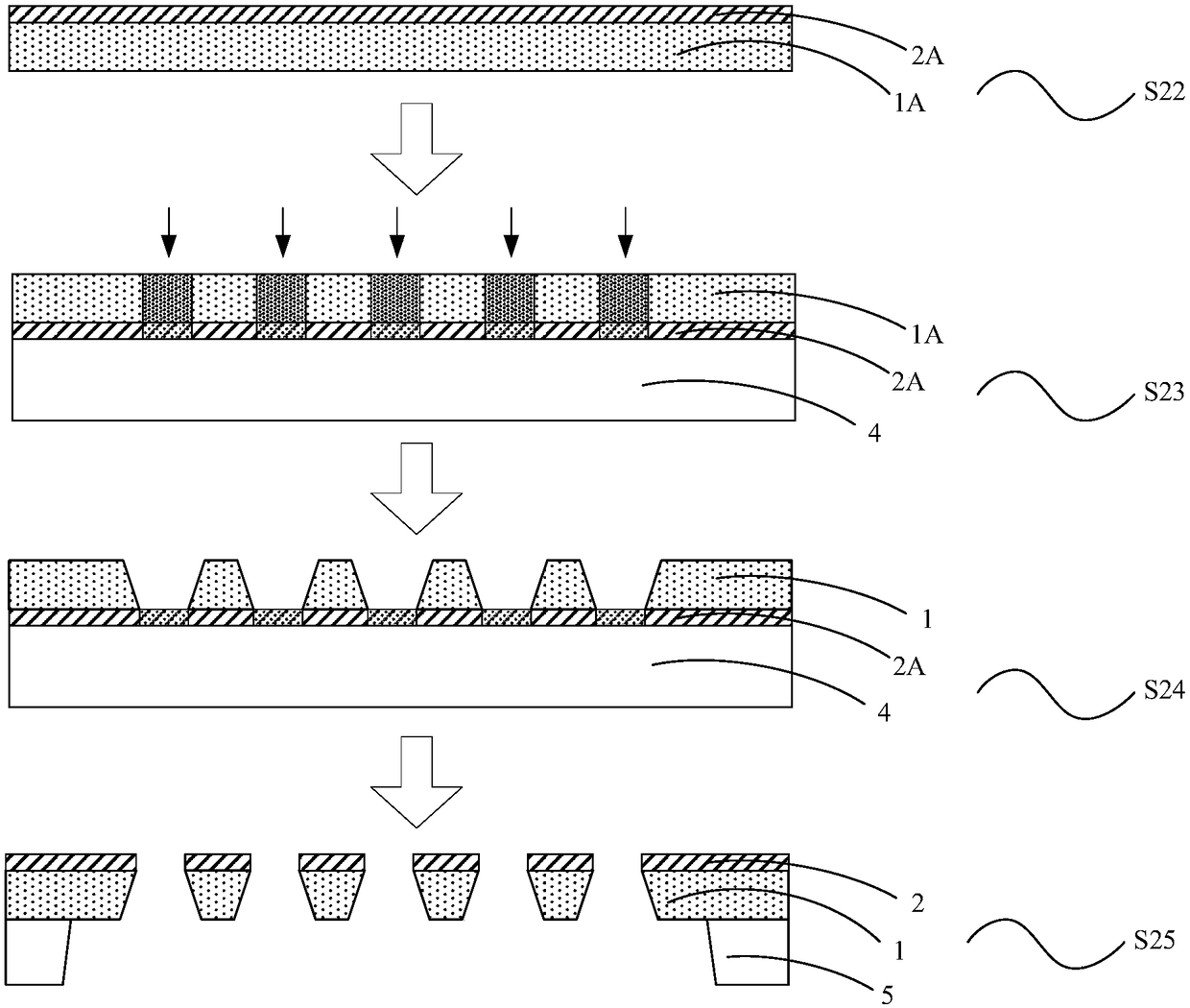

[0054] Such as figure 1 with 2 As shown, this embodiment provides a mask whose structure is similar to the mask provided in Embodiment 1, such as figure 1 As shown, the mask plate includes a rigid rigid transparent substrate and a flexible toughness enhancing layer 2 . In this embodiment, the material of the rigid transparent substrate is glass as an example for illustration.

[0055] In particular, in the mask plate provided in this embodiment, the toughness enhancing layer 2 is doped with magnetic nanoparticles, that is, when preparing the toughness enhancing layer 2, magnetic nanoparticles can be added to the toughness enhancing layer material 2A to form Flexible, magnetic toughness enhancing layer 2. Among them, the flexible material can include at least one of polyimide, polyethylene terephthalate, polyethylene naphthalate, polystyrene, and polypropylene; the material of magnetic nanoparticles includes magnetic metals or magnetic metal oxides.

[0056] In this embodi...

Embodiment 3

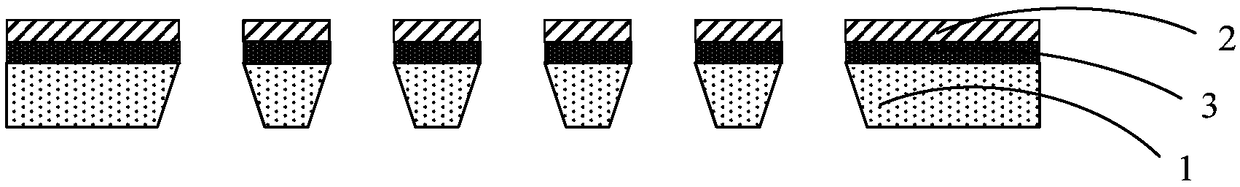

[0076] Such as image 3 with 4 As shown, this embodiment provides a mask whose structure is similar to that provided in Embodiment 1 and Embodiment 2, including a rigid rigid transparent substrate and a flexible toughness enhancing layer 2 .

[0077] In particular, in the mask plate of this embodiment, in addition to the toughness enhancing layer 2 , it also includes a magnetic layer 3 having third openings, and the third openings correspond to the first openings one by one. That is to say, in the mask plate of this embodiment, the mask plate has a certain magnetic property through another magnetic layer 3, and it is possible to ensure that the mask plate is compatible with the film to be evaporated while enhancing the toughness of the rigid transparent substrate. The high-quality display substrate can be closely attached under the action of a magnetic field, thereby avoiding evaporation shadows and improving the product yield of the display substrate.

[0078] Specifically,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com