Mask device and evaporation method

A mask and vapor deposition technology, applied in the field of mask device and vapor deposition, can solve the problems such as the inability to cope with the clamping of the netting equipment, the increase of wrinkles, and the decrease of the qualified rate of the netting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

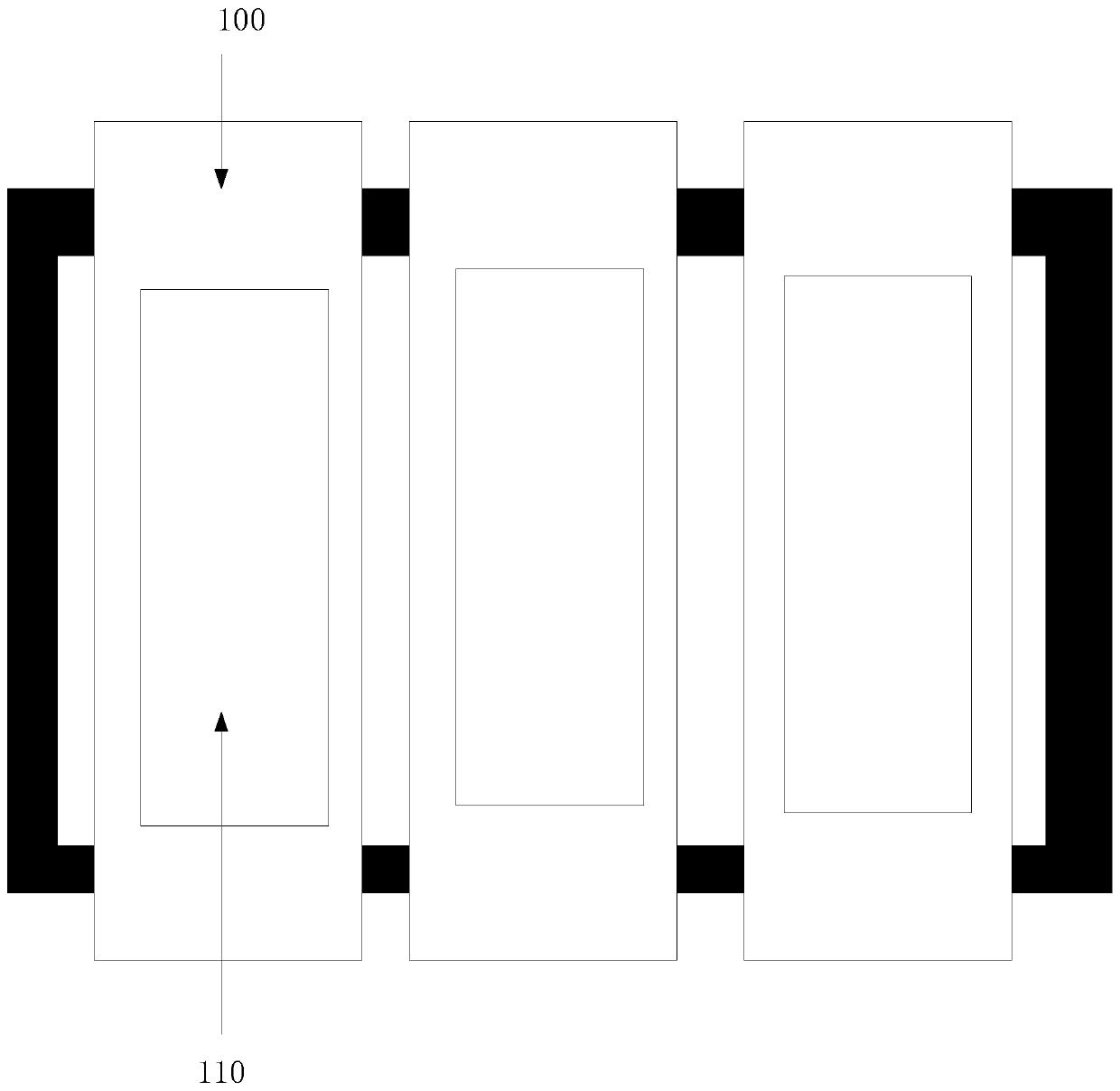

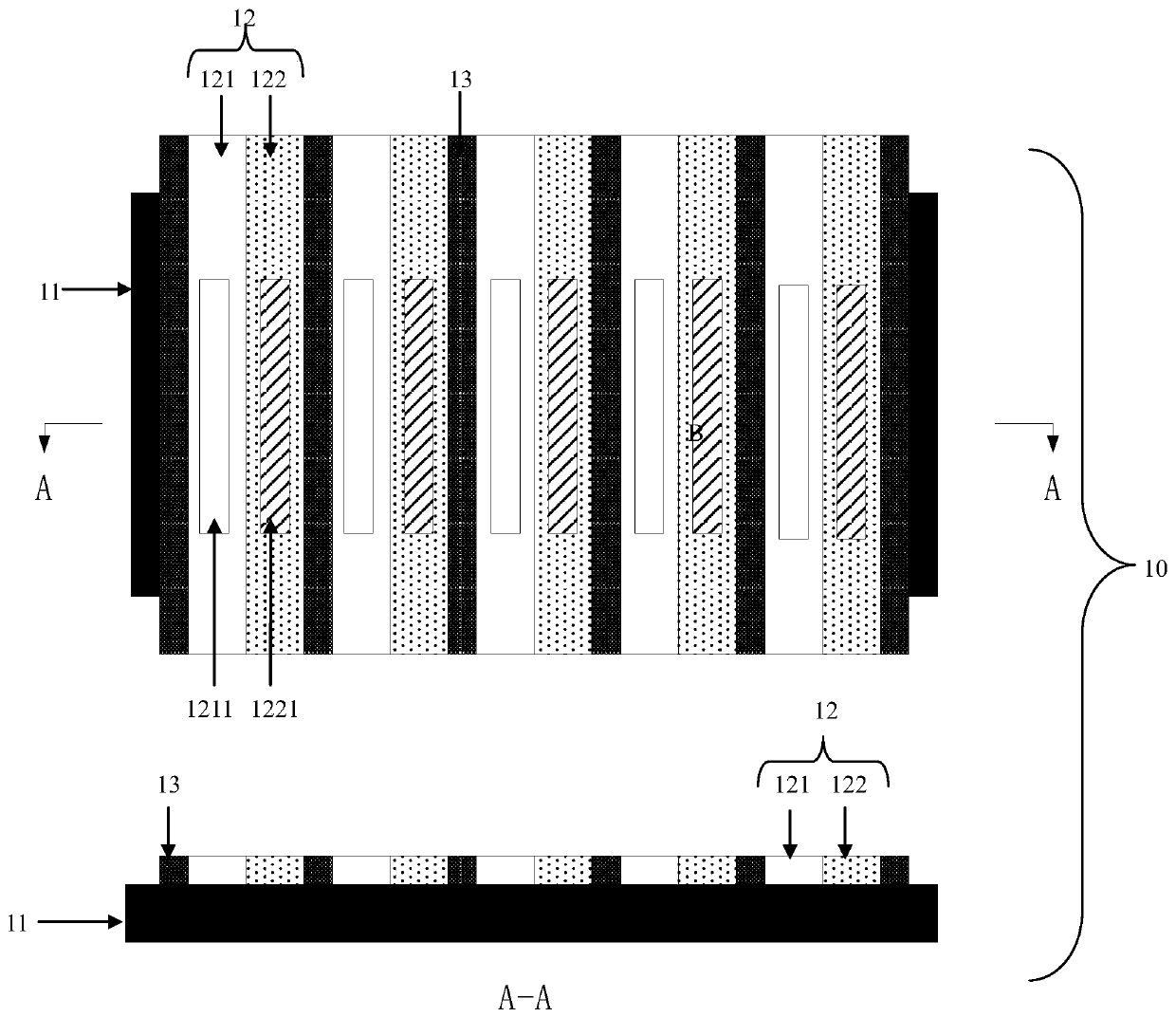

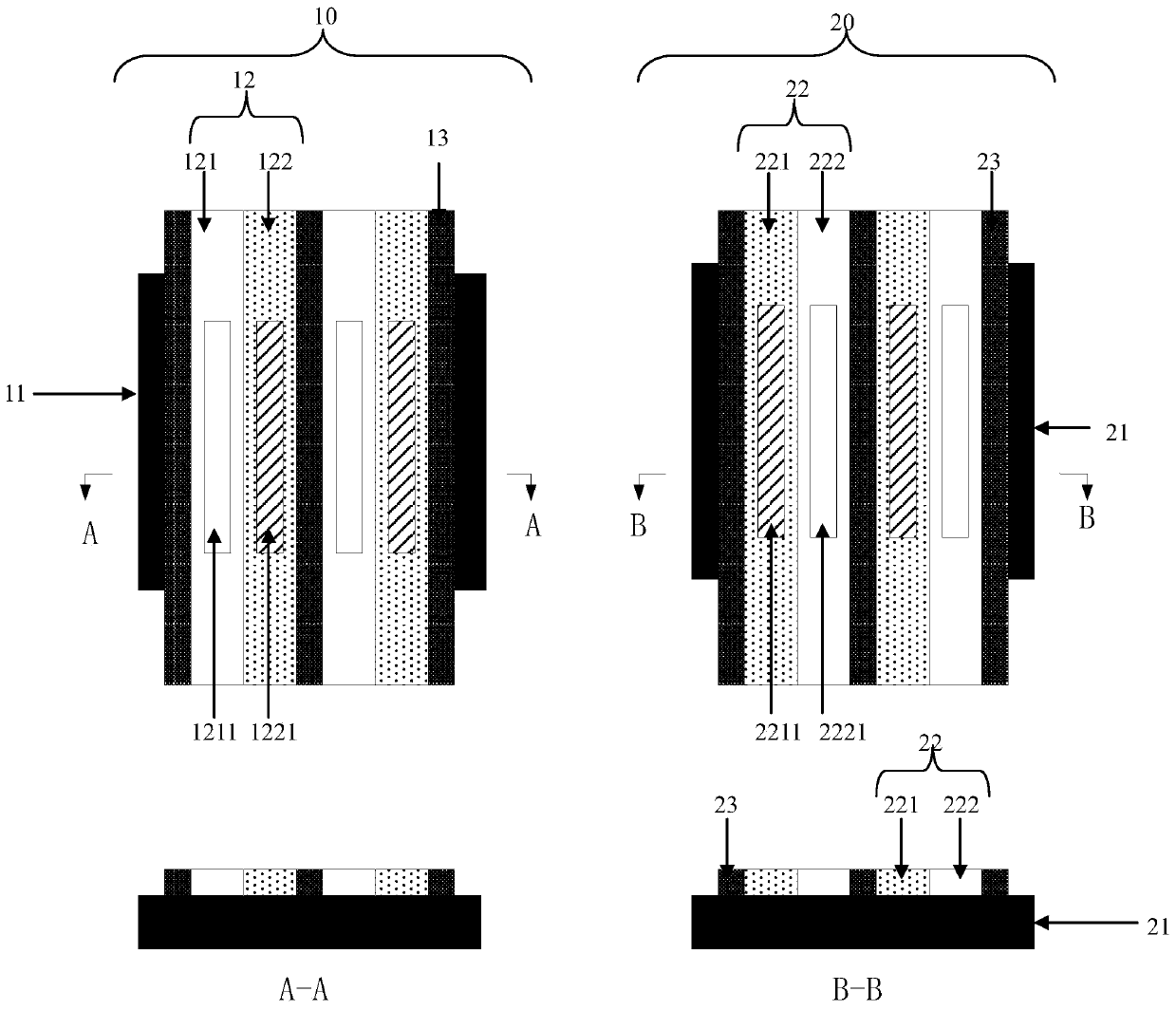

[0042] refer to figure 2 , to provide a mask device, comprising: a first mask 10; the first mask comprises a first frame 11, and a first mask strip 12 and a first mask strip 12 and a first mask are arranged side by side on the first frame 11 Blocking strips 13, the first masking strips 12 and the first blocking strips 13 are arranged at intervals;

[0043] The first mask strip 12 includes: a first sub-mask strip 121 and a second sub-mask strip 122 spliced with each other; a first hollow area 1211 is provided on the first sub-mask strip 121 .

[0044] Wherein, the thickness of the middle region 1221 of the second sub-mask strip 122 is smaller than the thickness of the edge region.

[0045] In a specific implementation, the thickness of the middle region 1221 of the second sub-mask strip 122 is 0.4-0.6 times the thickness of the edge region.

[0046] In the embodiment of the present invention, the middle area is set relatively thin, which can prevent the middle area of th...

Embodiment 2

[0064] refer to Figure 4 , an embodiment of the present invention provides an evaporation method, including:

[0065] Step 201, aligning the evaporation object with the first mask; defining a region to be evaporated on the evaporation object, and aligning the first hollowed out region with the first part of the region to be evaporated .

[0066] In the embodiment of the present invention, the first mask plate and the vapor deposition object are aligned through the alignment marks on the first shielding layer.

[0067] In the embodiment of the present invention, the evaporation target includes a display panel, and the area to be evaporated is the pixel defining layer on the glass substrate in the display panel.

[0068] Wherein, the first mask plate is placed on the evaporation object, the first hollow area corresponds to a part of the area to be evaporated, and the second sub-mask bars block the rest of the area to be evaporated.

[0069] In a specific implementation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com