Method for preparing laminar composite ceramic cutter material blanks by using electrojet deposition technology

A ceramic tool and layered composite technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of complex electrophoretic deposition molding equipment, affecting the quality of film formation, and easy cracking of green bodies, so as to achieve mass production and controllability Good, low processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

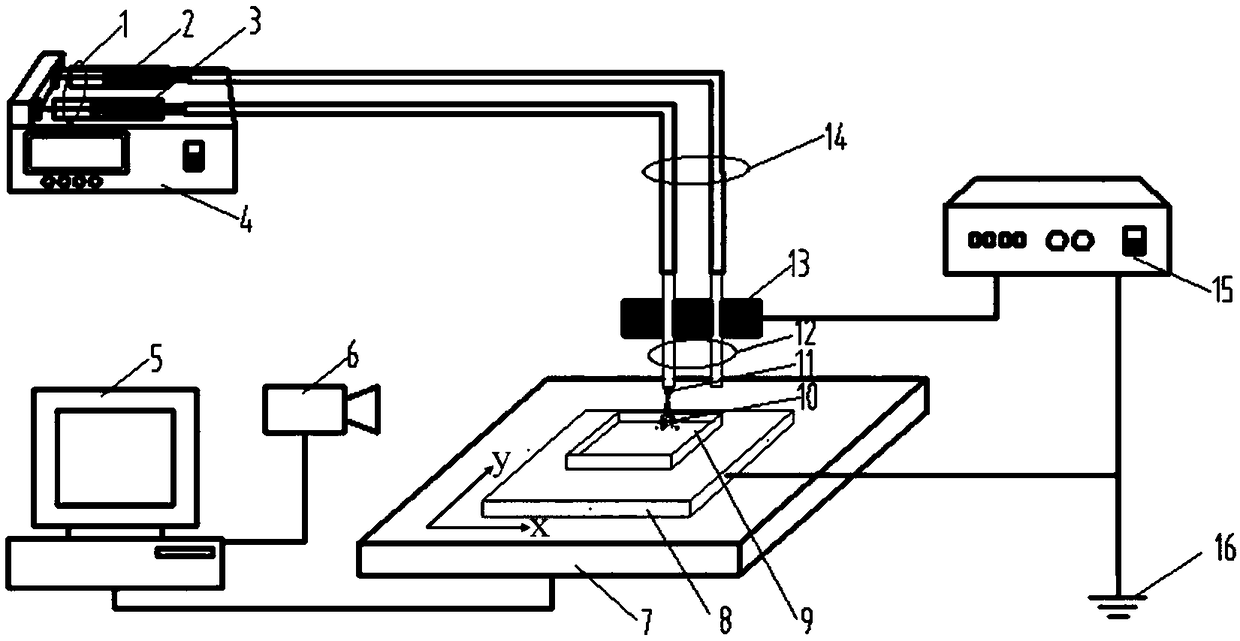

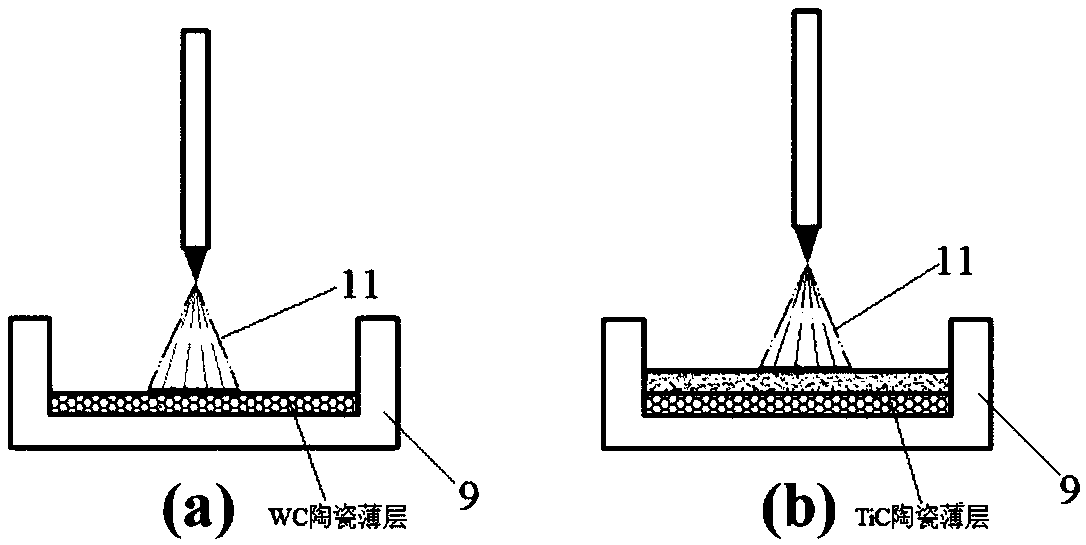

[0043] like Figure 1-2 Shown, a kind of method that utilizes electric jet deposition technology to prepare layered composite ceramic cutter material green body, comprises the steps:

[0044] 1) Mix WC+Ni mixed powder and TiC+Ni mixed powder with anhydrous ethanol and binder to make WC+Ni suspension and TiC+Ni suspension for later use; wherein WC and TiC are matrix phases, Ni is a metal phase, and the WC, TiC, Al 2 o 3 , Ni powder particle size is less than 100nm.

[0045] 2) The graphite mold 9 is placed on the substrate 8 of the XY motion platform 7 of the electrojet deposition device, and then the WC+Ni suspension and the TiC+Ni suspension in step (1) are respectively placed on the two sides of the electrojet deposition device. A syringe 1, ready for use;

[0046] 3) Set the moving distance of the XY motion platform 7 in the X and Y directions to 40 mm, the speed in the X and Y directions to 2 mm / s, and the grid spacing to 0.2 mm, and adjust the WC+Ni suspension 3 throu...

Embodiment 2

[0050] With embodiment 1, difference is: in step 1), with Al 2 o 3 +Ni mixed powder instead of TiC+Ni mixed powder.

Embodiment 3

[0052] With embodiment 2, difference is: in step 3) and 4), the flow of suspension is 1 * 10 -12 m 3 ·s -1 1. The output voltage of the high-voltage power supply is 0.1Kv, and the deposition height is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com