Method for achieving atomic force microscope (AFM) nano deposition by applying current

An atomic force microscope and current-applying technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as unguaranteed, uneven deposition points, and no fixation, etc., to achieve flexible control, good repeatability, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

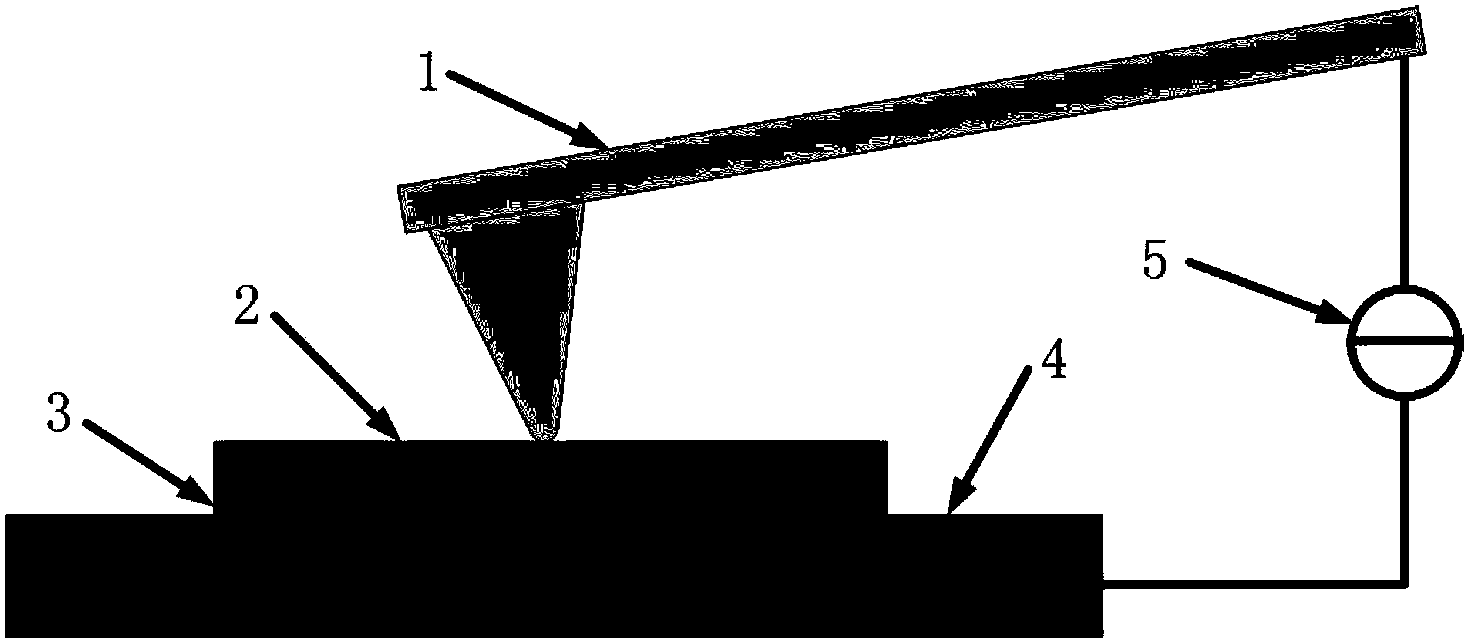

[0025] figure 1 It is a schematic diagram of the working state of the present invention. Among them, 1 is the AFM conductive probe, 2 is the substrate, 3 is the conductive glue, 4 is the metal sample stage, and 5 is the programmable current source.

[0026] The processing method is:

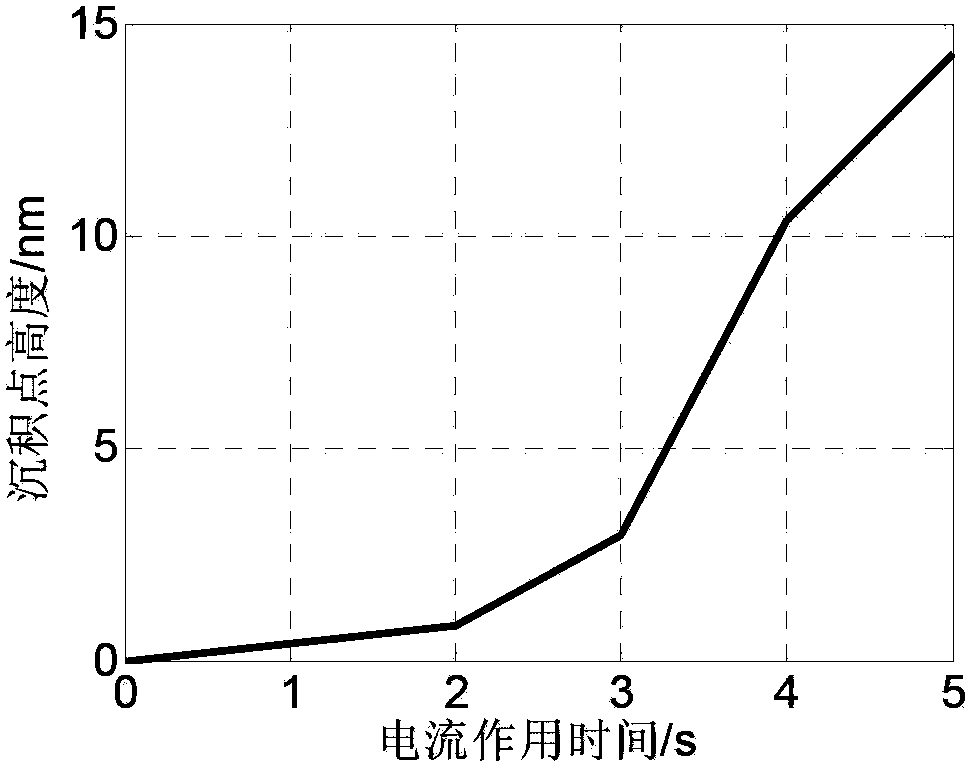

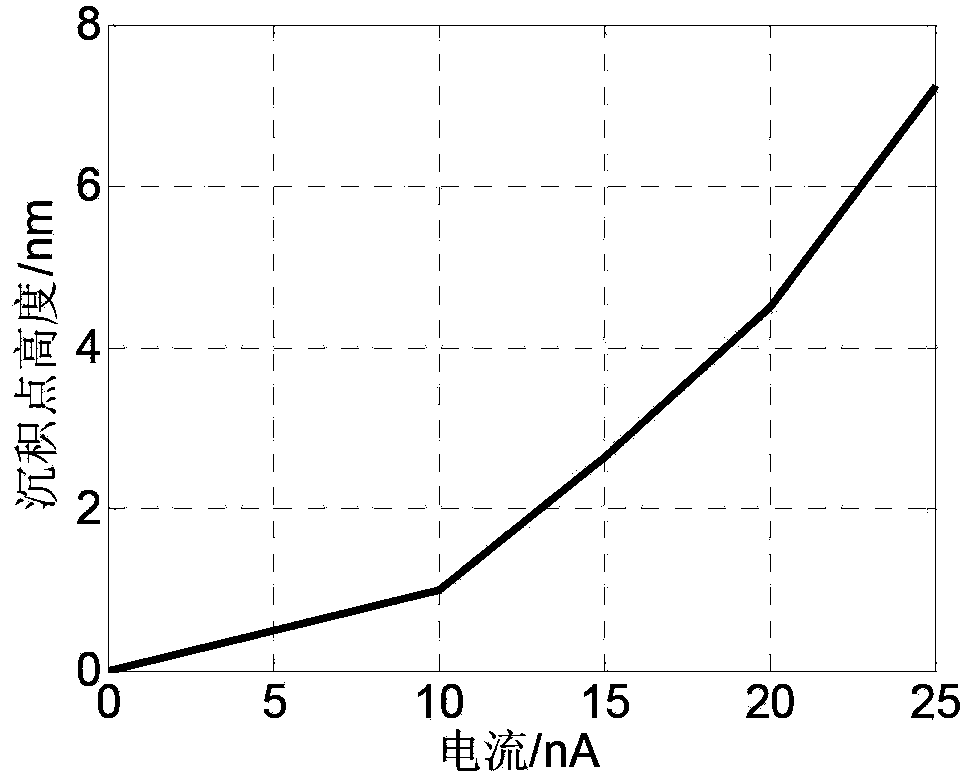

[0027] 1) Determine the parameters of the current applied during machining. The height of the deposition point is related to the size of the current and the time of the current. Figure 2 is the relationship curve of deposition point height, current magnitude and current action time calculated from the results of a large number of AFM nano-deposition experiments carried out in advance. This line can be used as the basis for current parameters when processing deposition points of different sizes. According to the height of the desired processing deposition poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com