A sagging preventive mask framework and a sagging preventive mask assembly

A technology of mask components and frames, which is applied in the direction of photo-engraving process, optics, etc. for photomechanical processing of originals, patterned surfaces, etc. It can solve the problem of imprecise arrangement of material deposition on the substrate, different procedures cannot be produced at the same time, and batch production Large requirements and other issues, to achieve the effect of improving the evaporation precision, preventing pattern deformation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

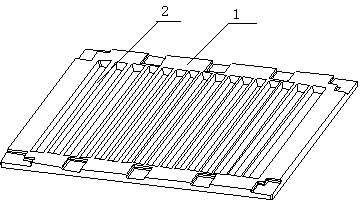

[0031] Such as figure 1 As shown, a mask frame for preventing sagging includes a frame 1 and a support bar 2, and the frame 1 and the support bar 2 are integrally formed and are on the same horizontal plane. The support bars 2 are parallel to each other and arranged longitudinally. There is a gap between the support bars 2, the size of which is greater than or equal to the size of the opening of the pattern area of the mask plate, and the width of the support bars is less than or equal to the gap between the openings of the pattern area of the mask plate. There are equal gaps between the support bars 2 .

[0032] Such as Figure 4 As shown, a sagging-preventing mask assembly includes the above-mentioned sagging-preventing mask frame and a mask plate, and the sagging-preventing mask frame is welded to the mask plate. The longitudinal support bar of the mask frame is aligned with the gap between the longitudinal pattern area of the mask plate, there is a welding point b...

Embodiment 2

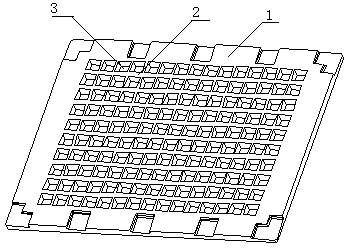

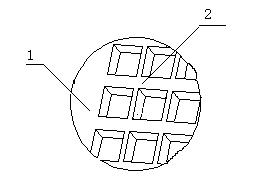

[0035] Such as figure 2 As shown, a mask frame for preventing sagging includes a frame 1 and a support bar 2, and the frame 1 and the support bar 2 are integrally formed and are on the same horizontal plane. The support bars vertically and horizontally intersect each other, the longitudinal support bars 2 are parallel to each other, and the horizontal support bars 2 are also parallel to each other, and the support bars intersect vertically and horizontally to form a grid 3 . The size of the grid 3 is greater than or equal to the size of the opening of the pattern area of the mask. The sizes of the grids 3 are consistent. Ensure that the support bar 2 cannot block the opening of the pattern area of the mask.

[0036] A sagging-preventing mask assembly includes the above-mentioned sagging-preventing mask frame and a mask plate, and the mask frame is welded to the mask plate. The vertical and horizontal support bars of the mask frame are aligned with the vertical and hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com