Preparation method of Haynes 214 alloy strip foil

A technology of alloy strips and foils, which is applied in the field of preparation of Haynes214 alloy strips and foils, can solve the problems of unsystematic research on strip and foil forming methods, poor structure uniformity, and inability to prepare parts, so as to avoid uneven deformation and the method is simple , Good uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The Haynes214 alloy ingot was prepared by vacuum induction plus electroslag melting, and forged into a 60mm thick slab at a temperature of 1050 ° C ~ 1120 ° C, and the deformation amount is about 45%. The obtained slab is as follows: figure 1 as shown; heated to 1150°C and hot rolled into a 5.0mm strip with a deformation of about 91%; then subjected to solution treatment at 1160°C for 60 minutes, water-cooled, pickled and sandblasted, and then the strip was cold-rolled, The annealing was repeated 4 times and rolled into a 0.6mm×210mm strip. The rolling process parameters are shown in Table 1.

[0036] Table 1 Rolling process parameters of Example 1

[0037]

Embodiment 2

[0039] The Haynes214 alloy ingot is smelted by vacuum induction and electroslag, and is forged into a 60mm thick slab at 1050℃~1120℃ with a deformation of about 45%; heated to 1200℃ and hot rolled into a 5.0mm strip with a deformation of about 91% ; After solution treatment at 1160 ℃ × 60 minutes, pickling and sand blasting after water cooling, then cold rolling and annealing are repeated for 6 times, and the strip is rolled into a 0.2mm × 210mm strip. The rolling process parameters are shown in Table 2.

[0040] Table 2 Rolling process parameters of Example 2

[0041]

Embodiment 3

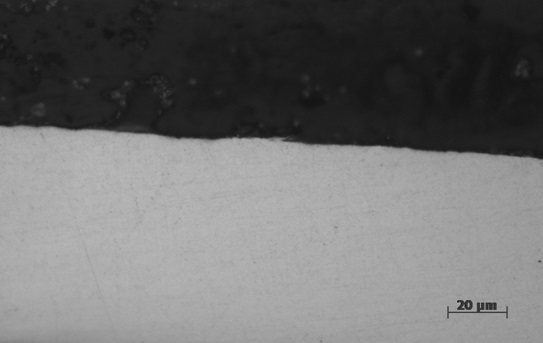

[0043] The Haynes214 alloy ingot is smelted by vacuum induction and electroslag, and forged into a 60mm thick slab at 1050℃~1120℃, with a deformation of about 45%; heated to 1250℃ and hot rolled into a 5.0mm strip, with a deformation of about 91% ; After solution treatment at 1120 ℃ × 60 minutes, pickling and sand blasting after water cooling, then cold rolling and annealing are repeated 8 times, and rolled into 0.076mm × 210mm foil, and the obtained foil is prepared as follows: figure 2 shown, image 3 For the foil texture after polishing, Figure 4 is the grain structure of the foil. The rolling process parameters are shown in Table 3.

[0044] Table 3 Rolling process parameter table of Example 3

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com