75Cr hot-rolled plate coil produced from thin sheet billets through continuous casting and continuous rolling and production method thereof

A thin slab continuous casting and hot-rolled coil technology, which is applied in the field of high-grade saw blade steel production, can solve problems such as center segregation and center porosity, aggravated decarburization on the surface of 75Cr slab, and bonding accidents, etc., to achieve uniform structure and performance. good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

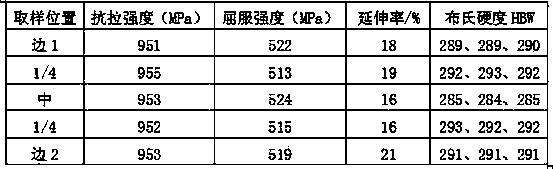

Embodiment 1

[0017] Embodiment 1: The 75Cr hot-rolled coil produced by continuous casting and rolling of thin slab adopts the following steps.

[0018] (1) It is smelted in a converter and alloyed by refining outside the furnace. Its chemical composition and weight percentage are: C 0.74%, Si 0.27%, Mn 0.68%, P≤0.015%, S≤0.005%, Cr 0.34% , Als 0.023%, the rest is Fe and unavoidable impurities.

[0019] (2) Carry out continuous casting with a superheat of 28°C, using 75Cr special mold powder, controlling the thickness of the slab to 65mm, and controlling the casting speed to 4.5m / min; the composition ratio of the mold powder is: CaO 22% 、Al 2 o 3 3.2%, SiO 2 27%, MgO 6.0%, F 11.5%, Na 2 O 13%, Fe 2 o 3 1.01%, MnO 2 0.1%, Li 2 0 3.46%, the balance of carbon and uncontrollable impurities; the temperature of the hemispherical point is 730-780°C, and the viscosity is 0.7-0.8Pa·s.

[0020] (3) Perform uniform heating in the heating furnace, reduce the heating time of the heating fur...

Embodiment 2

[0026] Embodiment 2: The 75Cr hot-rolled coils produced by continuous casting and rolling of thin slabs adopt the following steps.

[0027] (1) It is smelted in a converter and alloyed by refining outside the furnace. Its chemical composition and weight percentage are: C 0.75%, Si 0.26%, Mn 0.69%, P≤0.013%, S≤0.004%, Cr 0.36% , Als 0.022%, the rest is Fe and unavoidable impurities.

[0028] (2) Carry out continuous casting with a superheat of 25°C, using 75Cr special mold powder, controlling the thickness of the slab to 70mm, and controlling the casting speed to 4.4m / min; the composition ratio of the mold powder is: CaO 20% 、Al 2 o 3 3.3%, SiO 2 28%, MgO 6.5%, F 11%, Na 2 O 12.5%, Fe 2 o 3 1.58%, MnO 2 0.18%, Li 2 0 3.47%, the balance of carbon and uncontrollable impurities; the temperature of the hemispherical point is 730-780°C, and the viscosity is 0.7-0.8Pa·s.

[0029] (3) Perform uniform heating in the heating furnace, reduce the heating time of the heating f...

Embodiment 3

[0035] Embodiment 3: 75Cr hot-rolled coils produced by continuous casting and rolling of thin slabs adopt the following steps.

[0036] (1) It is smelted in a converter and alloyed by refining outside the furnace. Its chemical composition and weight percentage are: C 0.78%, Si 0.25%, Mn 0.65%, P≤0.020%, S≤0.006%, Cr 0.60% , Als 0.03%, the rest is Fe and unavoidable impurities.

[0037] (2) Carry out continuous casting with a superheat of 15°C, using 75Cr special mold powder, controlling the thickness of the slab to 80mm, and controlling the casting speed to 4.3m / min; the composition ratio of the mold powder is: CaO 24% 、Al 2 o 3 3.0%, SiO 2 26%, MgO 7.0%, F 11.5%, Na 2 O 14%, Fe 2 o 3 1.48%, MnO 2 0.07%, Li 2 0 3.0%, the balance of carbon and uncontrollable impurities; the temperature of the hemispherical point is 730-780°C, and the viscosity is 0.7-0.8Pa·s.

[0038] (3) Perform uniform heating in the heating furnace, reduce the heating time of the heating furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com