Process for manufacturing Ti6Al4V powdered 3D printing additive material

A technology of additive manufacturing and 3D printing, which is applied in the field of Ti6Al4V powder 3D printing additive manufacturing technology, can solve the problems of no unified process method, etc., and achieve the effects of good surface quality, improved application, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

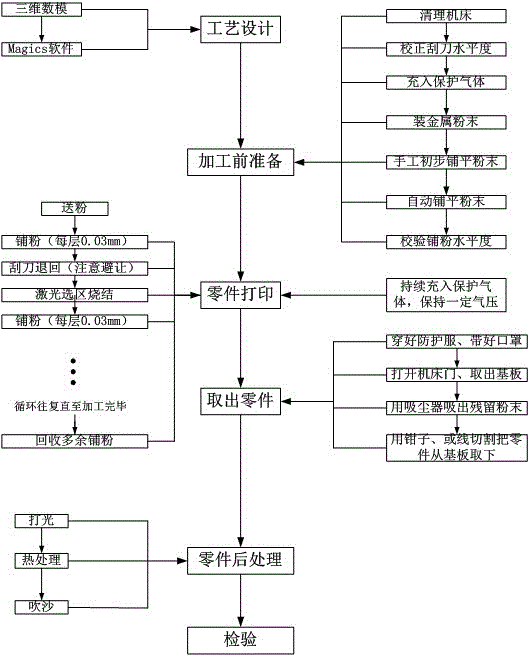

[0037] Attached below figure 1 The present invention is described in detail:

[0038] A Ti6Al4V powder 3D printing additive manufacturing process, the characteristics of its process flow are as follows:

[0039] 1) Process design: first import the 3D digital model, then layer the 3D digital model by 0.03mm per layer, and build process support;

[0040] 2) Preparation before processing:

[0041] (a) Clean the machine tool: clean the 3D printer bed to ensure that it does not contain impurities and other metal powders;

[0042] (b) Calibrate the levelness of the scraper: correct the levelness of the scraper;

[0043] (c) Rush into the protective gas: continuously rush into the working cavity of the 3D printing machine for argon protection;

[0044] (d) Loading metal powder: loading Ti6Al4V powder into the working cavity of the 3D printer bed;

[0045] (e) Preliminary paving of the powder manually: use a shovel to preliminarily pave the powder manually;

[0046] (f) Automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com