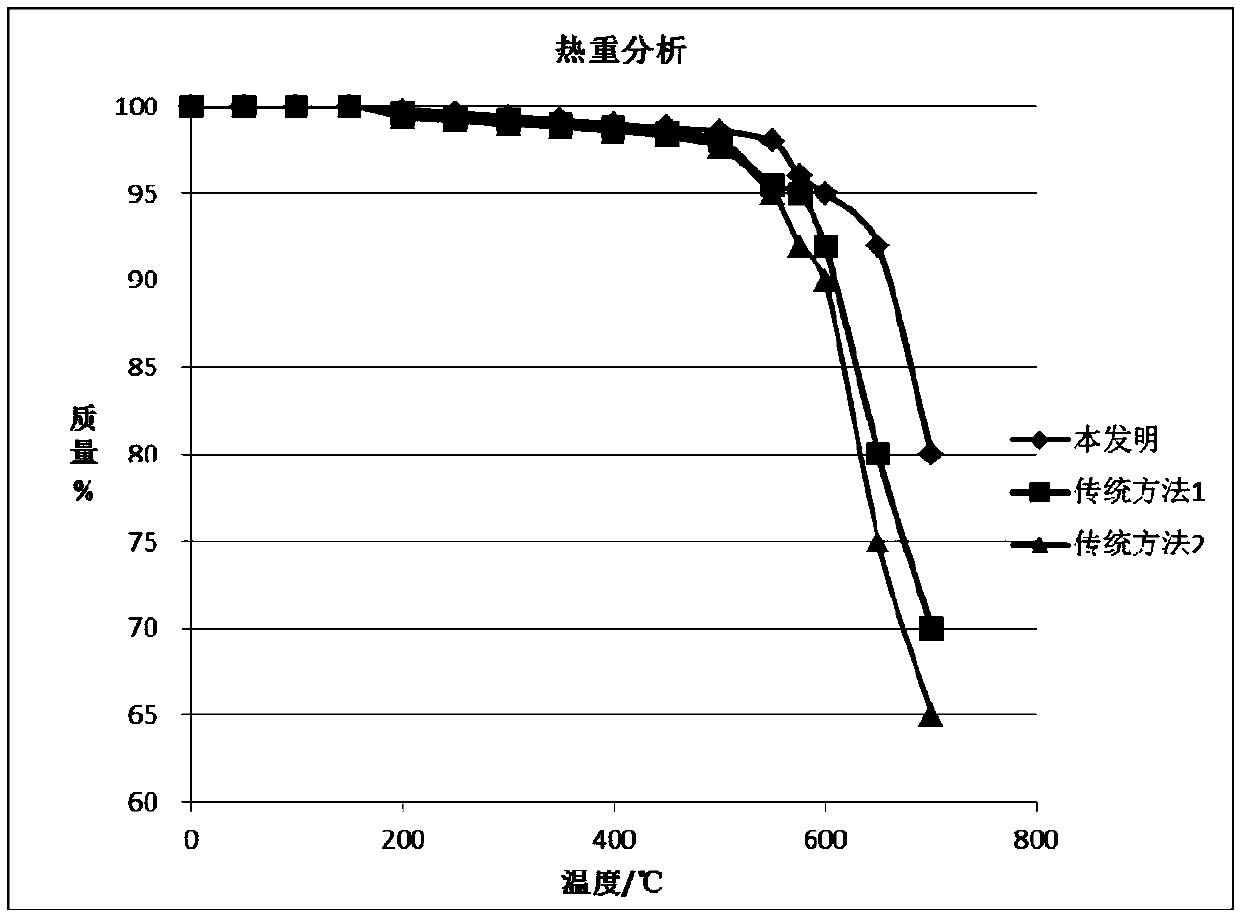

PBO fiber reinforced resin-based composite material and preparation method thereof

A fiber-reinforced resin and composite material technology, which is applied in the field of PBO fiber-reinforced resin-based composite materials and their preparation, can solve the problems of limited application of PBO fibers, poor adhesion of resin matrix, etc., so as to improve high temperature resistance and high temperature resistance. The effect of lifting, high modulus properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Heat-treat the PBO fiber at 350°C for 15s, modify the surface of the fiber after heat treatment, and pre-impregnate 30% of the PBO fiber in 70% polyimide pre-preg for 2 hours, and the pre-preg is completed Finally, the material is put into a mold and hot-pressed to form, and the hot-pressing pressure is 0.8MPa. The hot-pressing conditions are hot-pressing temperature 100° C., hot-pressing pressure 1.0 MPa, and hot-pressing time 2 hours. Prepared PBO fiber reinforced resin matrix composites.

Embodiment 2

[0021] Heat-treat the PBO fiber at 550°C for 18s, modify the surface of the fiber after heat treatment with a coupling agent, pre-impregnate 30% of the PBO fiber in 70% polyimide pre-preg for 3 hours, and the pre-preg is completed Finally, the material is put into a mold and hot-pressed, and the hot-pressing pressure is 1.0 MPa. The hot-pressing conditions are hot-pressing temperature 150° C., hot-pressing pressure 1.5 MPa, and hot-pressing time 3 hours. Prepared PBO fiber reinforced resin matrix composites.

Embodiment 3

[0023] Heat-treat the PBO fiber at 450°C for 20s, modify the surface of the fiber after heat treatment, and pre-impregnate 40% of the PBO fiber in 60% polyimide pre-preg for 4 hours, and the pre-preg is completed Finally, the material is put into a mold and hot-pressed, and the hot-pressing pressure is 2.0MPa. The hot-pressing conditions are hot-pressing temperature 200° C., hot-pressing pressure 2.0 MPa, and hot-pressing time 4 hours. Prepared PBO fiber reinforced resin matrix composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com