A driving device for pressure-holding transfer of natural gas hydrate core samples

A driving device and core sample technology, which is applied in the preparation of test samples, sampling devices, etc., can solve the problems of unstable core, existence of swing, unable to meet the transfer requirements of long core samples, etc., to save the cost of the device and simplify the structure. , the effect of meeting the functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

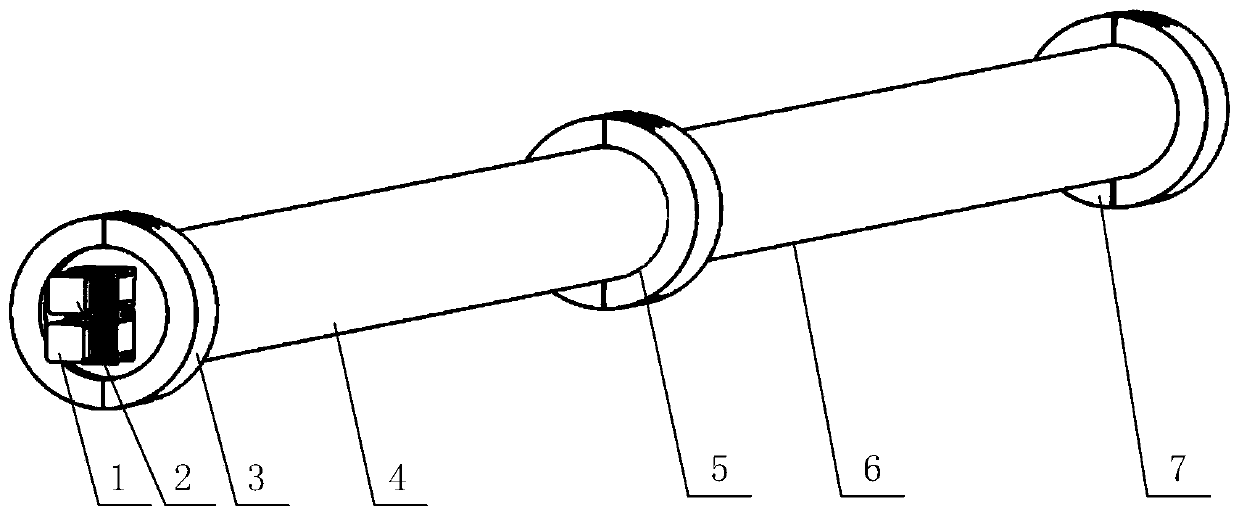

[0037] Such as figure 1 As shown, a driving device for pressure-holding and transfer of natural gas hydrate core samples, the external structure mainly includes a temporary storage tank 4 for transferring natural gas hydrate, and the temporary storage tank includes a front-stage temporary storage tank 4 connected by a hoop 5 and the rear section temporary storage tube 6, the front end and the rear end of the temporary storage tube are connected with a front end cover 9 and a rear end cover through hoops 3, 7; .

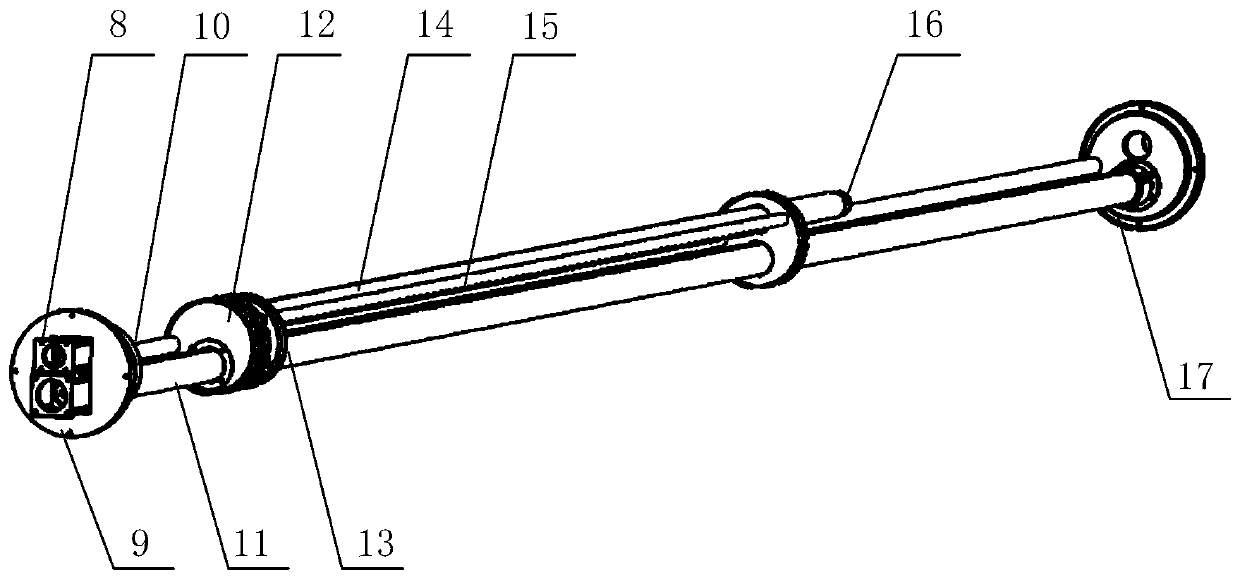

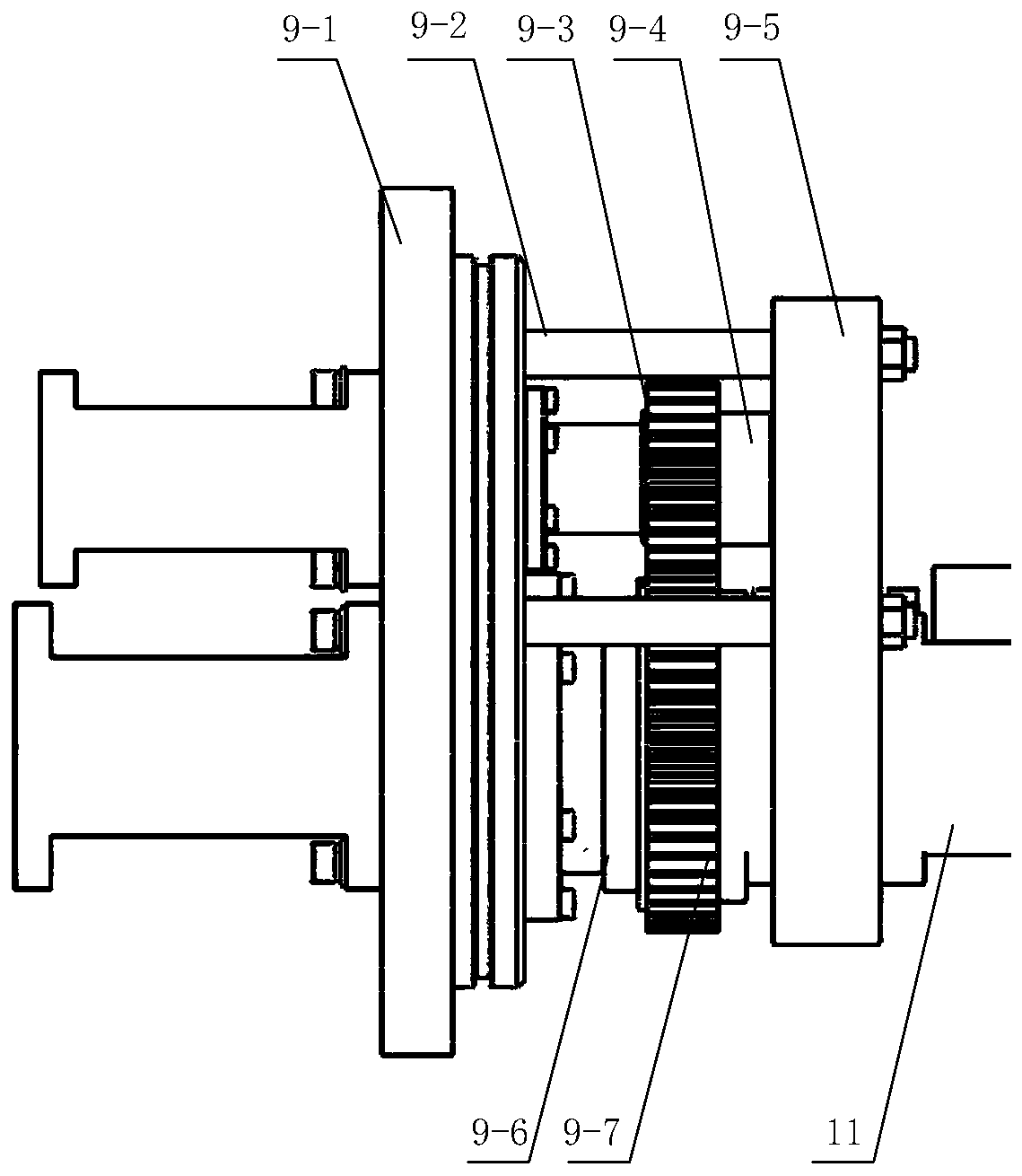

[0038] Such as figure 2 As shown, the internal structure of the driving device used for pressure-holding and transferring of natural gas hydrate core samples mainly includes a front end cover 9, a circular guide rail 10, a guide groove sleeve 11, an auxiliary support structure 12, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com