A kind of asphalt mixture modifier with high water damage resistance and its preparation and application in pavement laying method

A technology for asphalt mixture and water damage, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of weak water damage resistance of road surfaces, large amount of extruded PE, and reduce material costs. Improved water damage resistance, improved rutting resistance, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

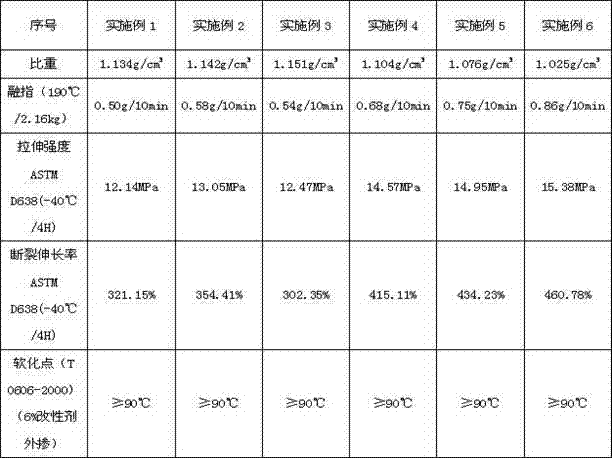

Examples

Embodiment 1

[0076] An asphalt mixture modifier with high resistance to water damage, which is composed of the following weight percentages of raw materials: polyethylene 60.5%, magnesium hydroxide 30%, lubricant 3.2%, antioxidant 0.8%, compatibilizer 4%, Toner 1.5%.

[0077] Among them, polyethylene is recyclable waste polyethylene, lubricant is 0.2% ethylene bis-stearamide and 3% waste engine oil, antioxidant is tetra[β-(3.5-di-tert-butyl-4-hydroxyl Phenyl) propionic acid] pentaerythritol ester, the compatibilizer is maleic anhydride grafted polyethylene, and the toner is carbon black.

[0078] The preparation method of the asphalt mixture modifier with high resistance to water damage in this embodiment includes the following steps: the first step: the polyethylene, magnesium hydroxide, lubricant, antioxidant, compatibilizer, and toner are sequentially Put it into the powder tank and stir evenly, the stirring time is 2min, the stirring speed is 1000r / min; the second step: the uniformly stirr...

Embodiment 2

[0082] An asphalt mixture modifier with high resistance to water damage, which is composed of the following weight percentages of raw materials: polyethylene 63.5%, magnesium hydroxide 25%, lubricant 7.4%, antioxidant 0.3%, compatibilizer 3%, Toner 0.8%.

[0083] Among them, polyethylene is recyclable waste polyethylene, lubricant is 0.4% ethylene bis-stearamide and 7% waste engine oil, antioxidant is 0.1% tris(2,4-di-tert-butyl phosphite) Benzene) ester and 0.2% tetra[β-(3.5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, the compatibilizer is maleic anhydride grafted polyethylene, and the toner is carbon black.

[0084] The preparation method of the asphalt mixture modifier with high water damage resistance of this embodiment includes the following steps: the first step: the polyethylene, magnesium hydroxide, lubricant, antioxidant, compatibilizer and toner are sequentially Put it into the powder tank and stir evenly, the stirring time is 4min, the stirring...

Embodiment 3

[0088] An asphalt mixture modifier with high resistance to water damage, which is composed of the following weight percentages of raw materials: 66.5% polyethylene, 25% magnesium hydroxide, 7.4% lubricant, 0.3% antioxidant, and 0.8% toner.

[0089] Among them, polyethylene is recyclable waste polyethylene, lubricant is 0.4% ethylene bis-stearamide and 7% waste engine oil, antioxidant is 0.1% tris(2,4-di-tert-butyl phosphite) Phenyl ester and 0.2% tetra[β-(3.5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester, the toner is carbon black.

[0090] The preparation method of the asphalt mixture modifier with high resistance to water damage in this embodiment includes the following steps: First step: Put polyethylene, magnesium hydroxide, lubricant, antioxidant, and toner into the powder tank in sequence Stir uniformly, the stirring time is 5min, the stirring speed is 800r / min; the second step: the uniformly stirred material is extruded and granulated with a twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com