High-modulus automotive trim flame-retardant PP material and preparation method thereof

An automotive interior, high-modulus technology, which is applied to the preparation of automotive interior materials, can solve problems such as poor flame retardant effect, and achieve the effects of reducing production costs, high modulus performance, and excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

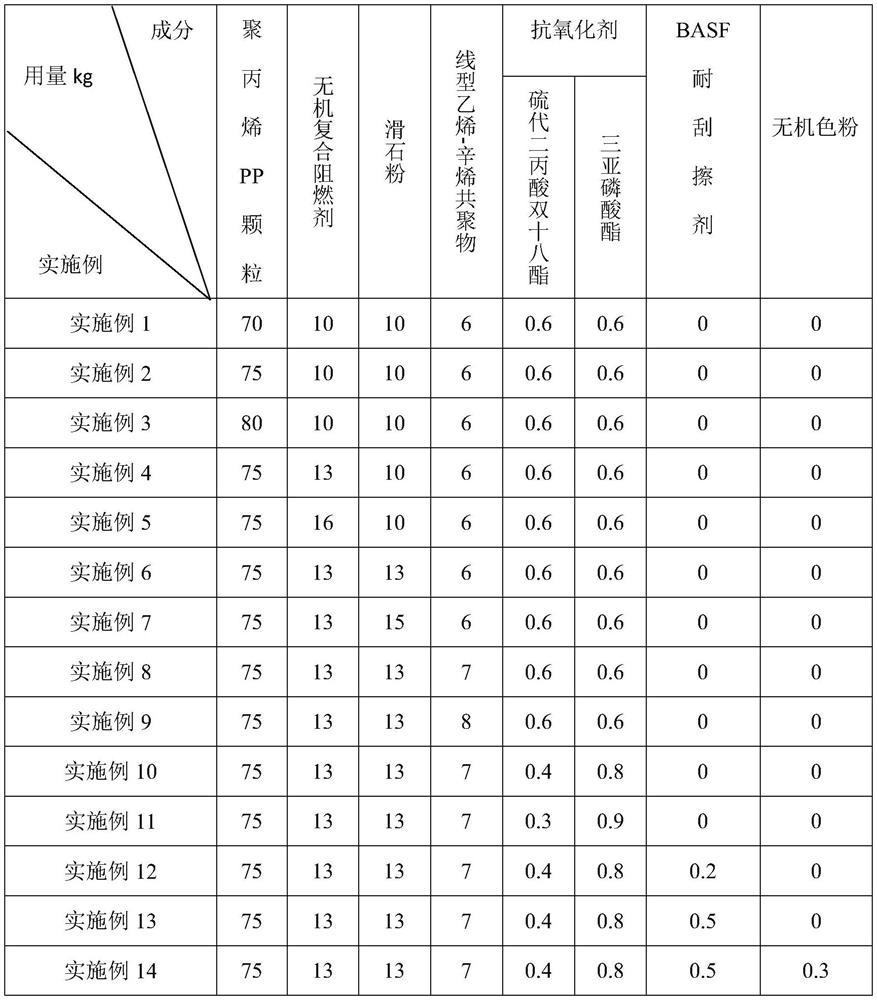

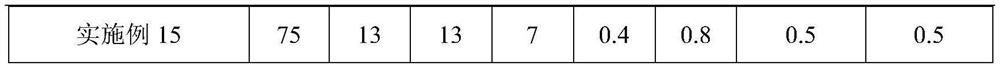

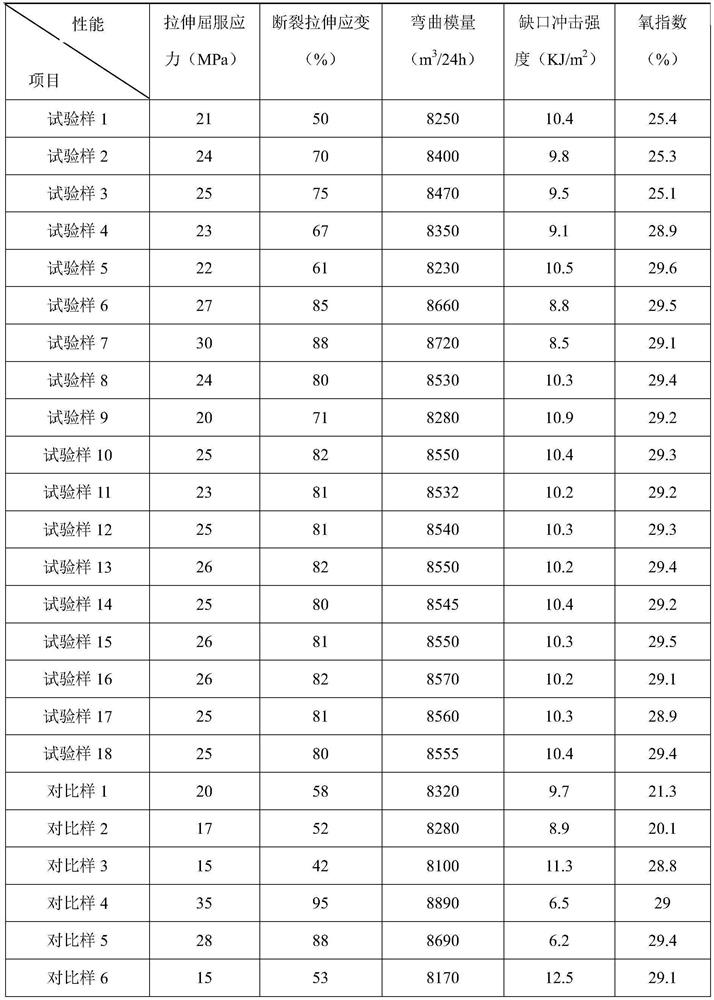

Examples

preparation example 1

[0042] This preparation example has prepared a kind of inorganic composite flame retardant, and concrete method is as follows:

[0043] Put 100kg of nano-aluminum hydroxide powder in a high-speed mixer, stir evenly and heat to 100°C, add 0.5kg of dimethyl silicone oil to the nano-aluminum hydroxide powder by spraying method, so that the nano-aluminum hydroxide is fully coupled and modified properties, made of modified nano-aluminum hydroxide;

[0044] Add 600kg of micron magnesium hydroxide and 100kg of zinc borate into the above-mentioned modified nano-aluminum hydroxide, and stir evenly to prepare an inorganic composite flame retardant.

preparation example 2

[0046] This preparation example has prepared a kind of inorganic composite flame retardant, and concrete method is as follows:

[0047] Put 300kg of nano-aluminum hydroxide powder in a high-speed mixer, stir evenly and heat to 115°C, add 4.5kg of linear polydimethylsiloxane to the nano-aluminum hydroxide powder by spraying method to make the nano-hydroxide Aluminum is fully coupled and modified to make modified nano aluminum hydroxide;

[0048] Add 700kg of micron magnesium hydroxide and 100kg of zinc borate into the above-mentioned modified nano-aluminum hydroxide, and stir evenly to prepare an inorganic composite flame retardant.

preparation example 3

[0050] Put 500kg of nano-aluminum hydroxide powder in a high-speed mixer, stir evenly and heat to 130°C, add 15kg of sodium oleate into the nano-aluminum hydroxide powder by spraying method, so that the nano-aluminum hydroxide is fully coupled and modified, Made into modified nano aluminum hydroxide;

[0051] Add 800 kg of micron magnesium hydroxide and 100 kg of zinc borate into the above-mentioned modified nano-aluminum hydroxide, and stir evenly to prepare an inorganic composite flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com