Strengthening method of pasting carbon fiber sheet on inner wall of large-diameter pipeline

A technology of carbon fiber sheet and large diameter, which is applied in the direction of chemical instruments and methods, tubular objects, lamination devices, etc., can solve the problem of damaging the pipe material, achieve the effect of solving the reinforcement problem without damaging the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

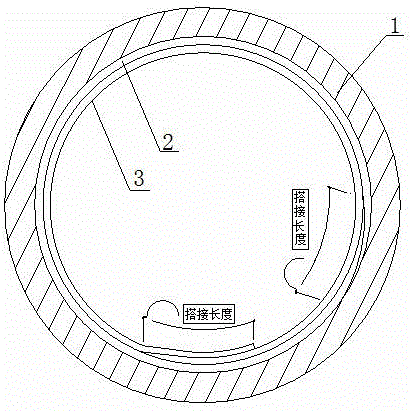

[0032] Embodiment 1, the reinforcement of carbon fiber cloth 2+carbon fiber plate 3 specifically includes the following steps:

[0033] Step 1: First, use an angle grinder to smooth the inner wall of the pipe 1, then use oil-free compressed air to blow off the dust in the pipe 1; dry.

[0034] Step 2: Prepare the bottom glue, and then apply the bottom glue evenly on the inner wall of the pipe 1 with a roller brush or a brush, so that the thickness of the bottom glue meets the design requirements. When preparing the bottom glue, the main agent and curing agent of the bottom glue should be placed in a clean container according to the formula ratio specified for the bottom glue, and stirred evenly; at the same time, depending on the actual situation on site, ensure that the bottom glue is used up once within the applicable period.

[0035] Step 3: After the surface of the bottom layer is dry to the touch, if the surface of the bottom layer is flat, proceed to step 4; if the surf...

Embodiment 2

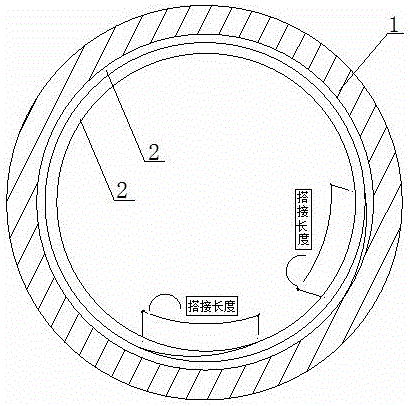

[0041] Embodiment two, two layers of carbon fiber cloth 2 reinforcement, then specifically include the following steps:

[0042] Step 1: First, use an angle grinder to smooth the inner wall of the pipe 1, then use oil-free compressed air to blow off the dust in the pipe 1; dry.

[0043] Step 2: Prepare the bottom glue, and then apply the bottom glue evenly on the inner wall of the pipe 1 with a roller brush or a brush, so that the thickness of the bottom glue meets the design requirements. When preparing the bottom glue, the main agent and curing agent of the bottom glue should be placed in a clean container according to the formula ratio specified for the bottom glue, and stirred evenly; at the same time, depending on the actual situation on site, ensure that the bottom glue is used up once within the applicable period.

[0044]Step 3: After the surface of the bottom layer is dry to the touch, if the surface of the bottom layer is flat, proceed to step 4; if the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com