Ethylene furnace tube surface coating preparation method

A furnace tube and coating technology, which is applied in the field of coating preparation on the surface of ethylene furnace tubes, can solve the problems of large waste, strict requirements, high cost and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The chromium coating on the surface of the ethylene furnace tube prepared by the present invention is a thermal diffusion coating, which is formed by infiltrating metal and a series of elements into the matrix material such as nickel-based stainless steel in one step by adopting a variable temperature powder infiltration method.

[0023] In view of the considerable solubility of chromium in iron, during the powder embedding process, the surface is converted into a chromium alloy layer through the thermal diffusion of chromium to the steel substrate, and the thickness of the infiltrated layer and the content of chromium in the layer can be determined by Thermal diffusion temperature, processing time to control.

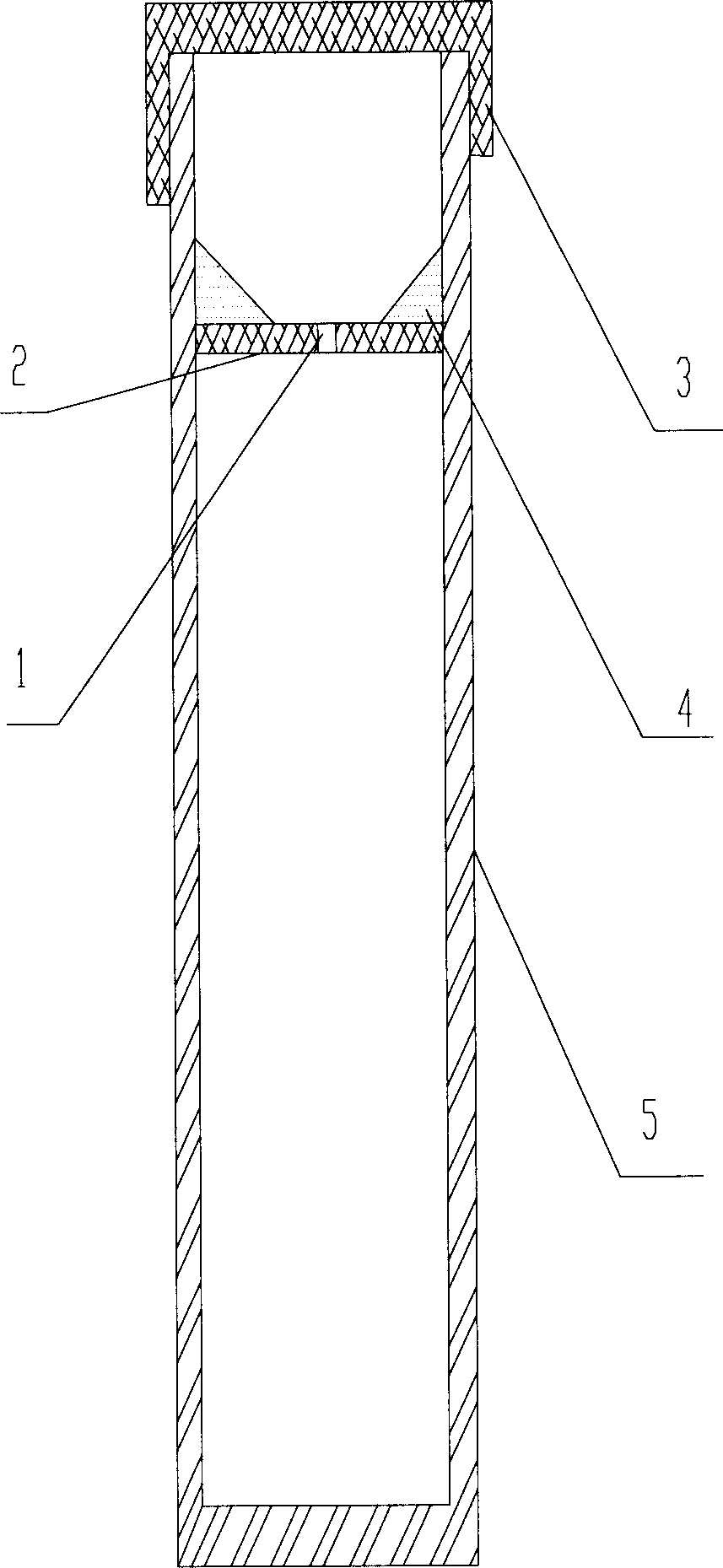

[0024] The chromizing is carried out in the co-drilling equipment, and the chromizing of the present invention is carried out in the co-drilling box. The accompanying drawing is a structural schematic diagram of the co-infiltration box provided by the present in...

Embodiment 1

[0048] The furnace tube material and raw material that present embodiment adopts are all identical with comparative example 1, 2, and this furnace tube prepares coating according to the method provided by the present invention, and used co-penetration agent consists of: 50% by weight of chromium powder (200 mesh) , 2% by weight of cerium dioxide, 1% by weight of sodium chloride, 2% by weight of ammonium chloride, 0.2% by weight of chromium dichloride, 10% by weight of graphite powder, and the rest being alumina powder. The heating temperature is 1060°C, the heating rate is 160°C / hour, and the constant temperature is 8 hours. The coking suppression experiment was carried out on a medium-sized ethylene cracking device. The coking experiment conditions and results are shown in Table 1. The coating was prepared according to the present invention. The coking rate of the furnace tube is only 0.3712×10 -7 kgcm 2 h, far lower than Comparative Examples 1 and 2.

[0049] Co...

Embodiment 2

[0055] The furnace tube material and raw material that present embodiment adopts are all identical with comparative example 3,4, and this furnace tube prepares coating according to the method provided by the present invention, and used co-penetration agent consists of: 45% by weight chromium powder (200 orders), 2% by weight of cerium oxide, 1% by weight of sodium chloride, 2% by weight of ammonium chloride, 0.1% by weight of chromium dichloride, 12% by weight of graphite powder, and the rest being alumina powder. The heating temperature is 1060°C, the heating rate is 160°C / hour, and the constant temperature is 8 hours. The coking inhibition experiment was carried out on the medium-sized ethylene cracking device. The coking experiment conditions and results are shown in Table 2. The coating was prepared according to the present invention. The coking rate of the furnace tube is only 0.6212×10 -7 kg / cm 2 h, far lower than Comparative Examples 3 and 4.

[0056] Compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com