Sealed and insulating vessel comprising a support foot

A technology of containers and feet, which is applied in the structural field of sealed and heat-insulated containers, and can solve problems such as the fragility of heat-insulating materials and the inability to support heavy equipment inevitably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

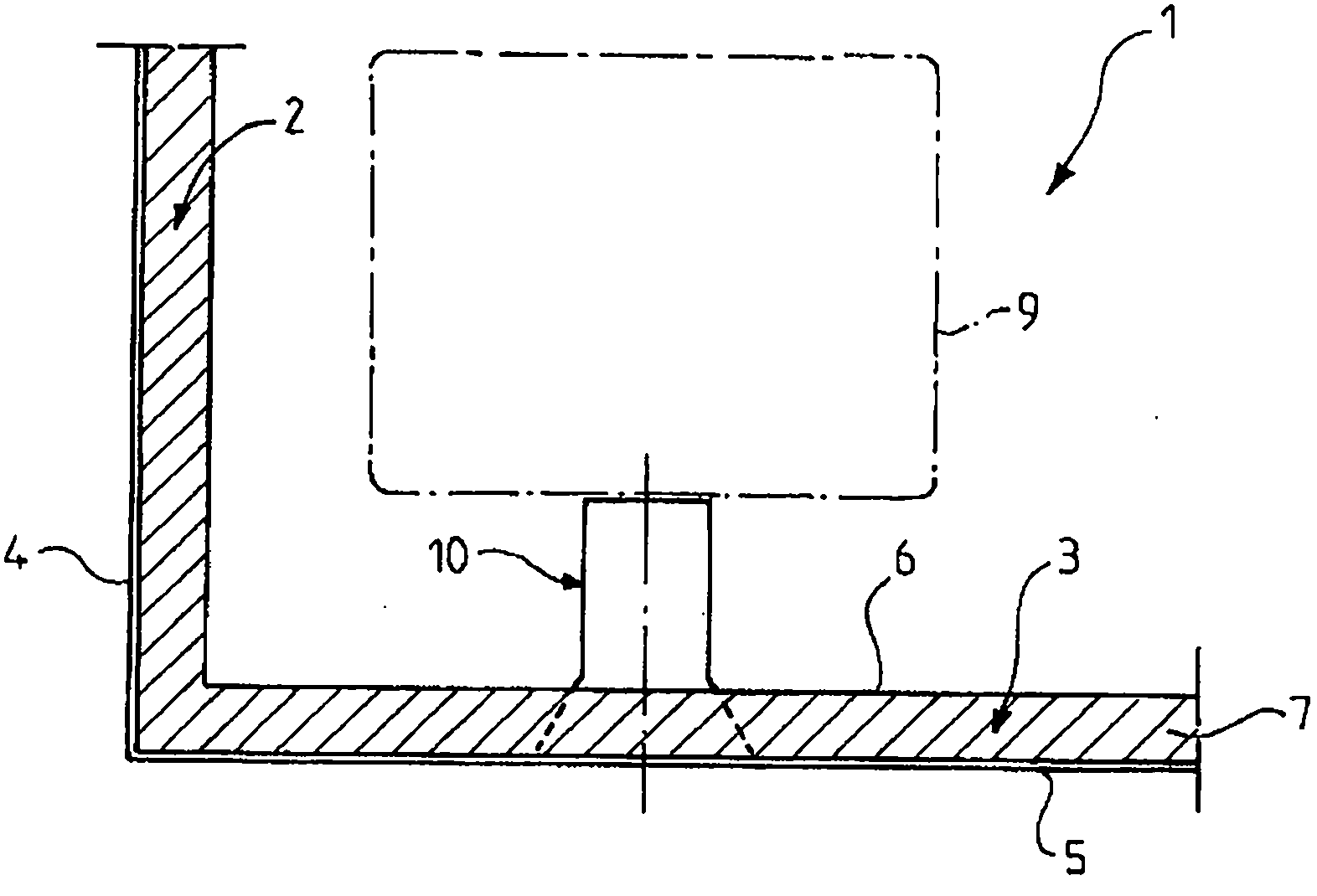

[0043] exist figure 1 Above, a sealed and thermally insulated container 1 can be partially seen, consisting of container walls 2 and 3 fastened to the inner surfaces of corresponding walls 4 and 5 of the load-bearing structure. The load-bearing structure is, for example, the inner hull of a double-hull ship or a building on the ground. To accommodate cold products such as GNL, the container wall comprises at least one sealing barrier 6 and at least one thermal insulating barrier 7 . For safety reasons, a secondary sealing barrier, not shown, can be provided between the load-bearing structure and the sealing barrier 6 , which in this case is called the primary sealing barrier.

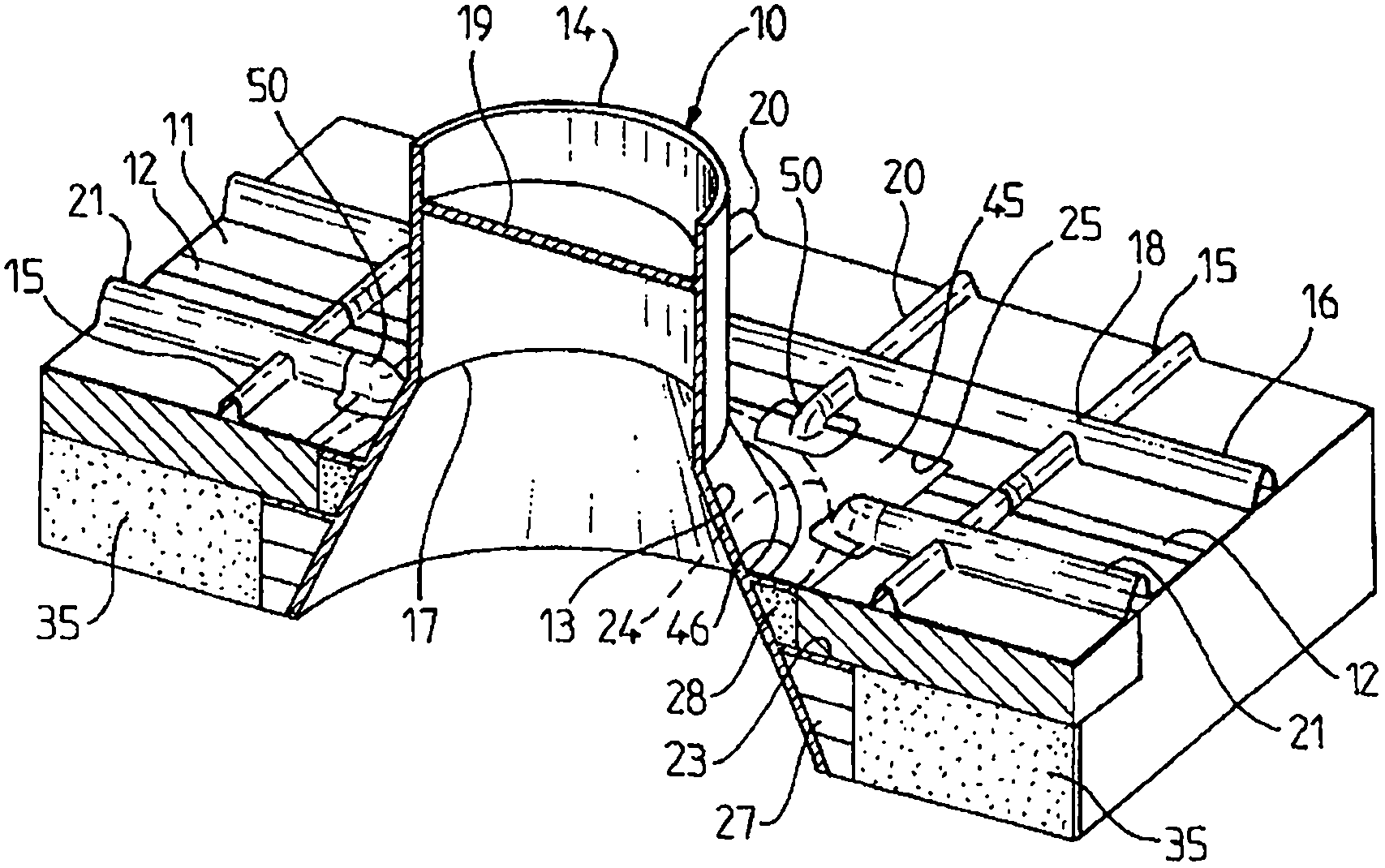

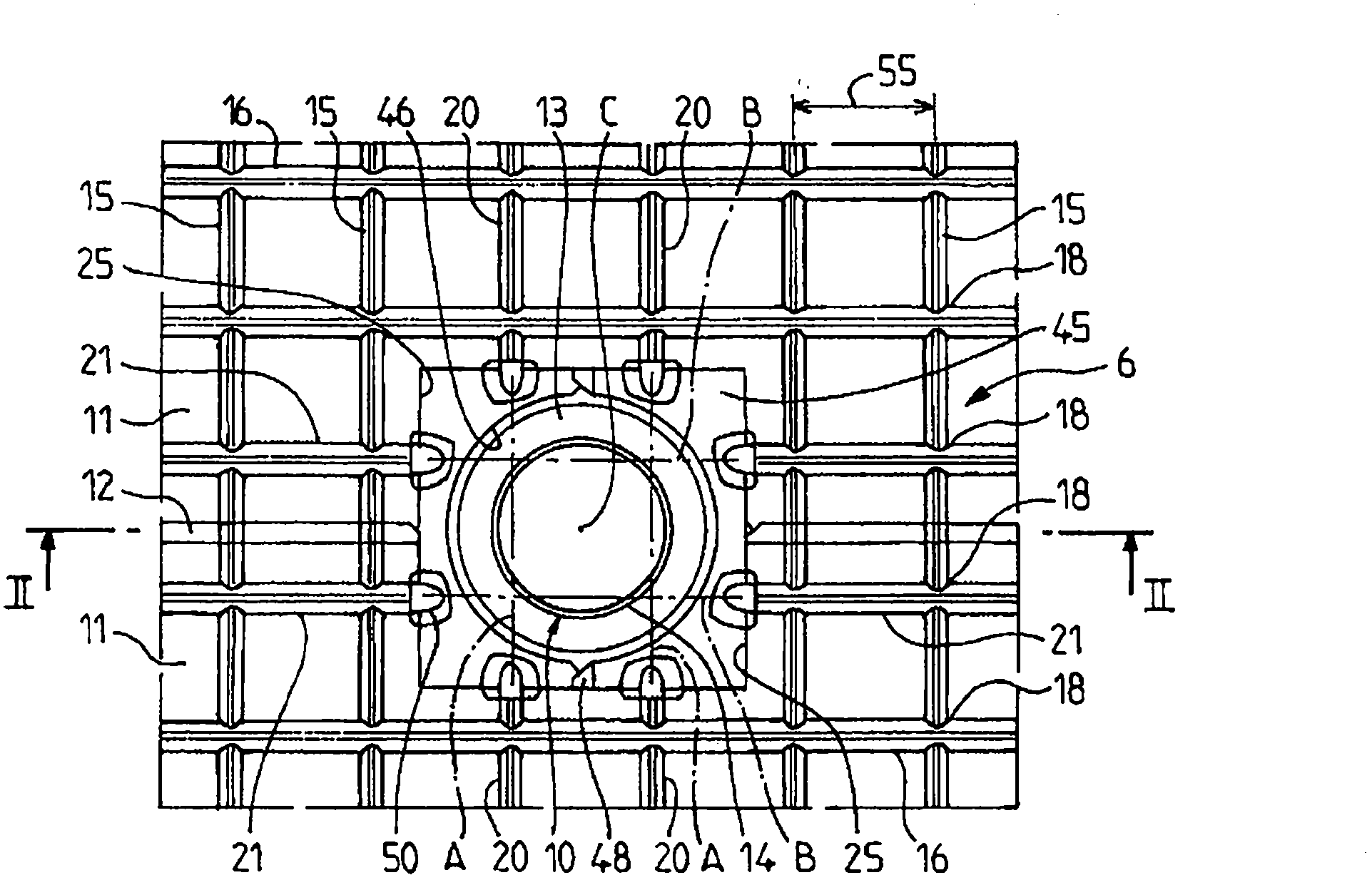

[0044]The container 1 can be implemented according to known different geometries, for example prismatic geometries in ship hulls or above-ground cylindrical geometries or others. Furthermore, many methods are available for implementing the thermal and sealing barriers, for example using prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com