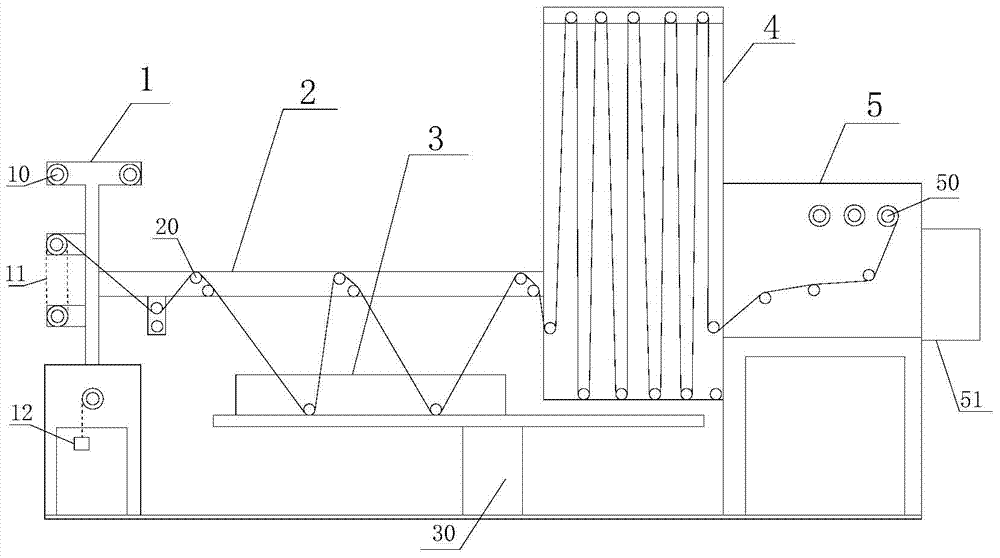

Surface modification processing device for poly(p-phenylene benzobisoxazole) fiber and use method of surface modification processing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

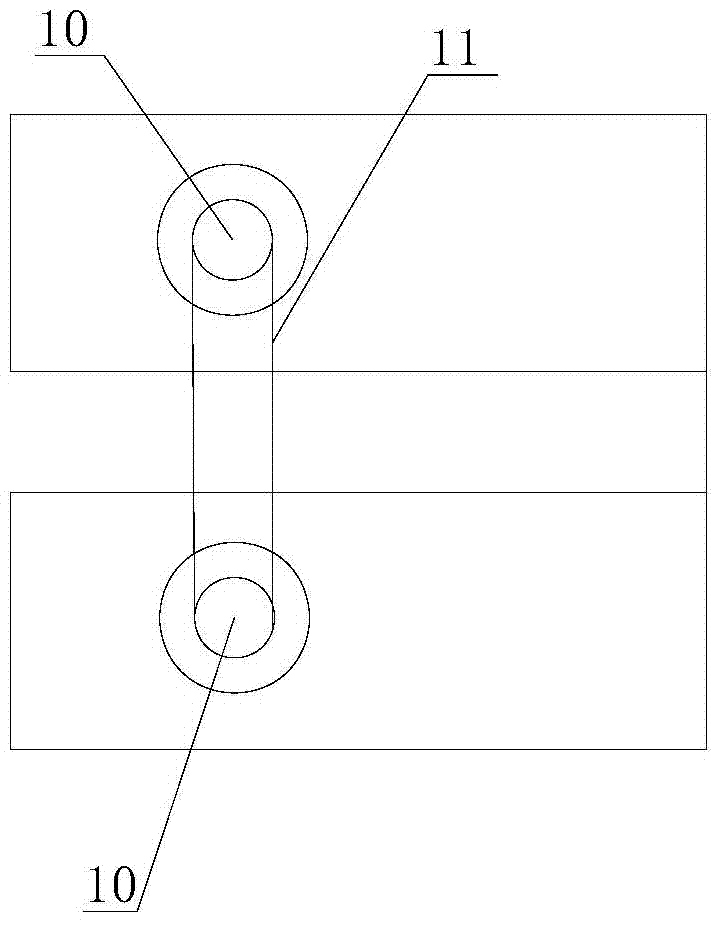

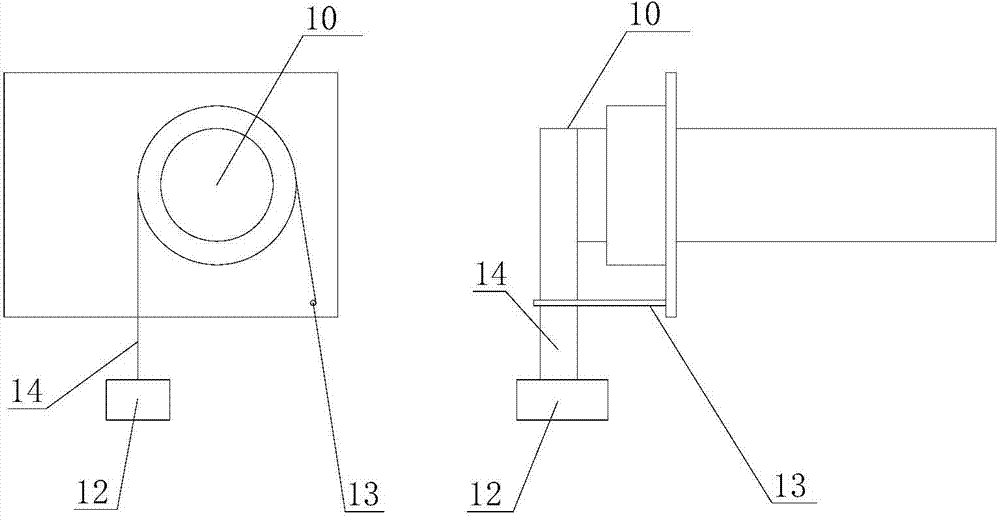

Method used

Image

Examples

Embodiment 1

[0035] Place the PBO fiber bundle on the yarn roll 10 on the device 1, place the prepared coupling agent modification solution (1-9% KH560 aqueous solution) in the surface modification tank 3, and manually draw the fiber bundle through the yarn guide The device 2, the surface modification treatment tank 3, and the drying device 4 are placed on the winding device 5 and fixed. Then turn on the drying device 4 and set the temperature at 100-110°C. After the temperature is reached, turn on the winding device 5 and set the roller speed at 1-5 r / min to wind the modified PBO fiber. The surface of PBO fiber modified by this device is obviously covered with a layer of uniform coating by scanning electron microscope observation, the surface roughness is increased, and the contact angle of single fiber to epoxy resin is reduced from 38.88° to 30.94°. The interfacial shear strength of the oxygen resin increased from 7.9MPa to 12.3MPa, an increase of 55.6%, and the wettability of the fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com