Rubber reforming styrene resin and molded product made by the rubber reforming styrene resin

A styrene-based resin and styrene-based technology, applied in the field of rubber-modified styrene-based resin, can solve problems such as mold contamination, melt fracture of molded products, and poor fluidity, so as to reduce mold pollution and improve processing properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

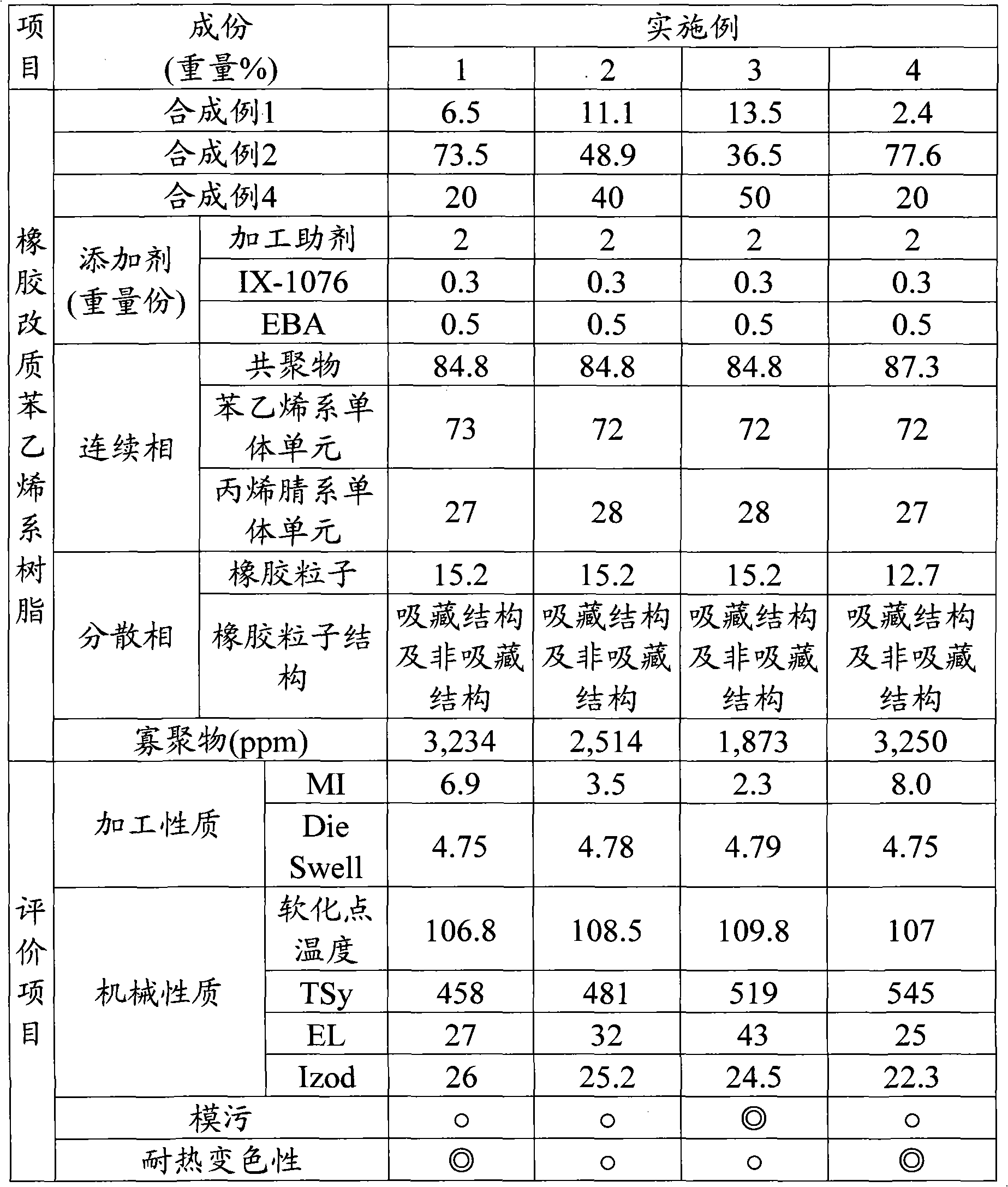

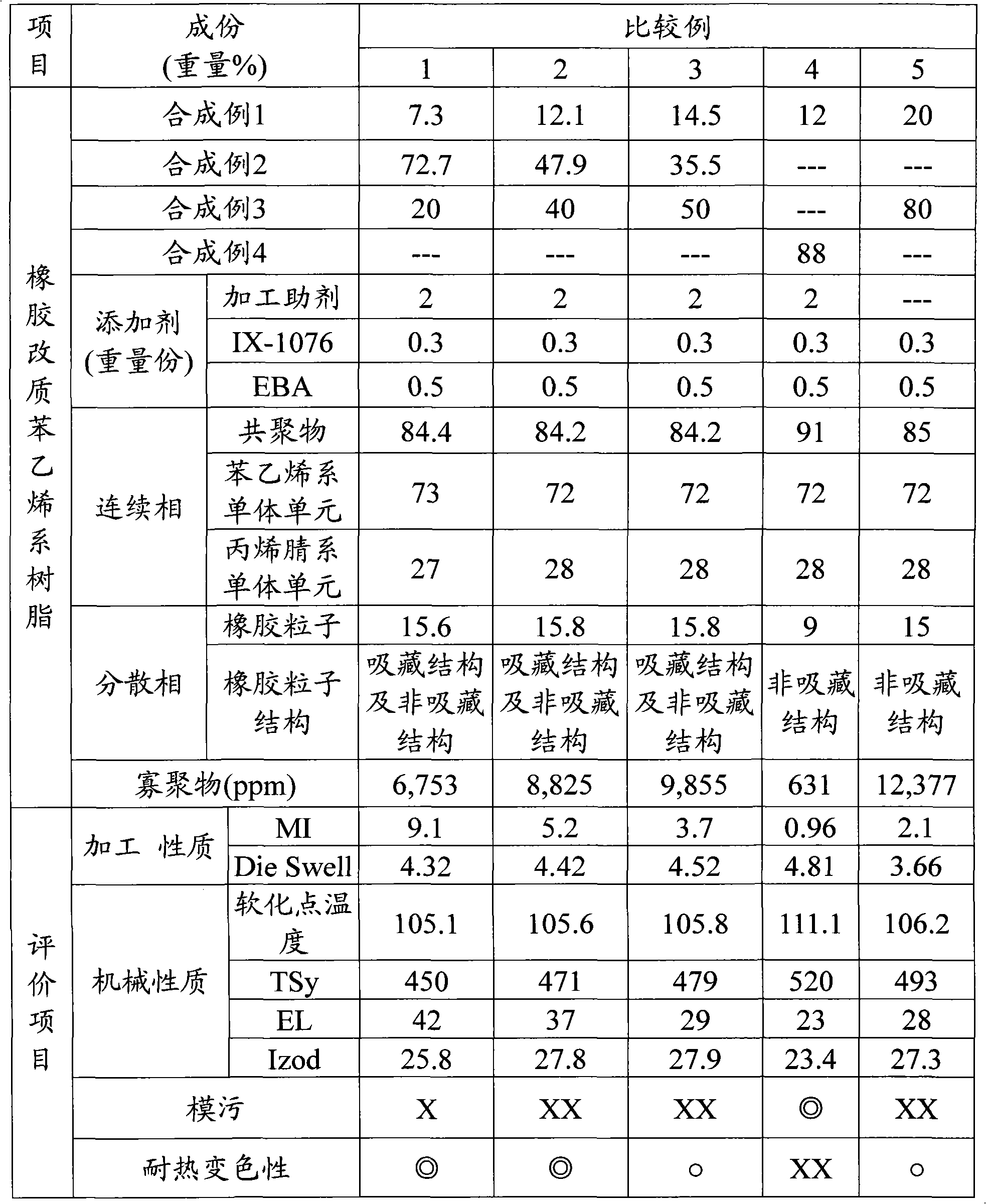

Examples

preparation example Construction

[0069] The preparation method of the rubber-modified styrene-based resin can adopt a general mixing method, place it in a stirrer and stir to make it evenly mixed, and if necessary, add additives or polymers to obtain the rubber-modified styrene-based resin of the present application. Vinyl resin.

[0070]The molded article of the rubber-modified styrenic resin of the present invention is obtained by mixing and molding the above-mentioned rubber-modified styrenic resin. The kneading, processing and molding process can be performed in a conventional manner, so details are not repeated here.

Synthetic example 1

[0073] [Synthesis Example 1] Emulsion Polymerized Rubber Graft Copolymer (I)

[0074] 95.0 parts by weight of 1,3-butadiene, 5.0 parts by weight of acrylonitrile, 15.0 parts by weight of potassium persulfate solution, 3.0 parts by weight of sodium pyrophosphate, 1.5 parts by weight of potassium oleate, 140.0 parts by weight of distilled water and 0.2 parts by weight of tertiary-dodecyl mercaptan were reacted at a reaction temperature of 65°C for 12 hours to obtain a rubber emulsion with a conversion rate of 94%, a solid content of about 40%, and a weight average particle size of 0.1 μm.

[0075] 85.0 parts by weight of ethyl acrylate, 15.0 parts by weight of acrylic acid, 0.3 parts by weight of tert-dodecyl mercaptan, 2.0 parts by weight of potassium oleate, 1.0 parts by weight of dioctyl sodium sulfosuccinate, 0.4 parts by weight Parts of cumene hydroperoxide, 0.3 parts by weight of sodium formaldehyde sulfoxylate and distilled water of 200.0 parts by weight were reacted for ...

Synthetic example 2

[0078] [Synthesis Example 2] Bulk or solution polymerization rubber graft copolymer (II)

[0079] 103.2 parts by weight of styrene, 15 parts by weight of styrene / butadiene rubber (styrene / butadiene content=25% by weight / 75% by weight, Mw=130,000), 45.4 parts by weight of ethylbenzene, 31.4 parts by weight Parts by weight of acrylonitrile, 3.9 parts by weight of butyl acrylate, 0.08 parts by weight of n-dodecyl mercaptan, 0.063 parts by weight of 3,5-bis(1,1-dimethylethyl)-4- Octadecyl hydroxyphenylpropionate and 0.063 parts by weight of ethylene distearamide were mixed to form a mixture.

[0080] 100 parts by weight of styrene, 3.0 parts by weight of 1,1-bis-tert-butylcyclohexane peroxide, and 1.8 parts by weight of dibenzoyl peroxide were used to form a polymerization initiator solution.

[0081] Use a pump to continuously supply the above-mentioned mixture with a flow rate of 61kg / hour, and the above-mentioned polymerization initiator solution with a flow rate of 1.3kg / hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com