High-wear-resistance tractor rubber track rubber material and manufacturing method thereof

A technology for rubber crawlers and tractors, which is applied in the field of high wear-resistant tractor rubber crawler rubber materials and manufacturing. It can solve the problems of rubber crawlers, such as easy wear and tear resistance, short service life, and short service life, and enhance the flatness of the contact area. , prolong the service life, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

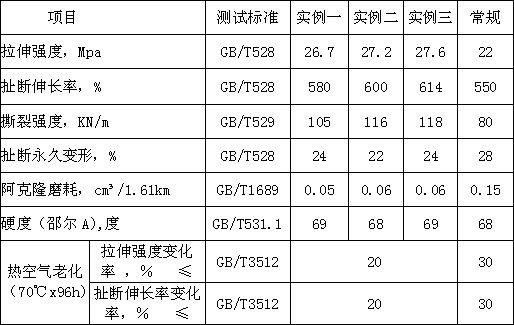

Examples

Embodiment 1

[0022] The high wear-resistant tractor rubber crawler rubber material and the manufacturing method of the present embodiment comprise the following steps:

[0023] Under the temperature condition of 130~155℃ and the pressure of 0.5~0.6MPa, 70 parts of polyisoprene, 30 parts of rare earth butadiene rubber, 4 parts of zinc oxide, 2 parts of stearic acid and 4 parts of anti-aging agent were mixed evenly 2.5 parts of agent R50, 2.2 parts of flow exhaust agent DC-P85 and mix evenly, then add 55 parts of N220 carbon black, 5 parts of nano silicon dioxide, 0.8 parts of coupling agent SI-69 and mix well; park for 12~24 hours Finally, add 3.5 parts of vulcanization accelerator under the condition of 85~95°C and mix evenly before forming; after vulcanization time of 30 minutes under the condition of 153°C and pressure of 3MPa, a film of high wear-resistant tractor rubber track compound is formed.

Embodiment 2

[0025] The high wear-resistant tractor rubber crawler rubber material and the manufacturing method of the present embodiment comprise the following steps:

[0026] Under the temperature condition of 130~155℃ and the pressure of 0.5~0.6MPa, 75 parts of polyisoprene, 25 parts of rare earth butadiene rubber, 3.5 parts of zinc oxide, 1.5 parts of stearic acid and 3.5 parts of anti-aging agent were mixed evenly 2.0 parts of agent R50, 1.7 parts of flow exhaust agent DC-P85 and mix well; then add 50 parts of N220 carbon black, 8 parts of nano silicon dioxide, 1.5 parts of coupling agent SI-69 and mix well; park for 12~24 hours Finally, add 3.1 parts of vulcanization accelerator under the condition of 85~95°C and mix evenly before forming; after vulcanization time of 30 minutes under the condition of 153°C and pressure 3MPa, a film of high wear-resistant tractor rubber track compound is formed.

Embodiment 3

[0028] The high wear-resistant tractor rubber crawler rubber material and the manufacturing method of the present embodiment comprise the following steps:

[0029] Under the temperature condition of 130~155℃ and the pressure of 0.5~0.6MPa, 85 parts of polyisoprene, 15 parts of rare earth butadiene rubber, 3 parts of zinc oxide, 1 part of stearic acid and 3 parts of anti-aging agent were mixed evenly 1.5 parts of agent R50, 1.2 parts of flow exhaust agent DC-P85 and mix well; then add 46 parts of N220 carbon black, 10 parts of nano silicon dioxide, 2 parts of coupling agent SI-69 and mix well; park for 12~24 hours Finally, add 2.7 parts of vulcanization accelerator under the condition of 85~95°C and mix evenly before forming; after vulcanization time of 30 minutes under the condition of 153°C and pressure 3MPa, a film of high wear-resistant tractor rubber track compound is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com