Hydrophobic corrosion-resistant ceramic paint and preparing method thereof

A ceramic coating, hydrophobic technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problem that the metal substrate cannot be effectively protected for a long time, the coating is prone to cracking and peeling, and is prone to cracking and Discoloration and other problems, to achieve the effect of low price of raw materials, excellent salt water resistance, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A kind of hydrophobic anticorrosion ceramic coating, adopts epoxy resin and modified organic silicon resin composite as film former, adds various fillers, auxiliary agent and solvent to prepare, and its each component and its mass percent are :

[0019] components

Mass percentage content

Mass ratio of 30% modified silicone resin and 70% epoxy resin E51 mixed

33%

Silica, ceramic powder and feldspar powder are compounded at a mass ratio of 4:3:1, all of which are micro / nano-scale particles

16%

Low surface energy material PTFE polytetrafluoroethylene

10%

T-31 Phenalkamine

14%

Titanium dioxide

3%

1.5%

Aliphatic Glycidyl Ether

10%

1.5%

Aminopropyltriethoxysilane

1%

10%

[0020] The preparation method of described a kind of hydrophobic anticorrosion ceramic coating, comprises the following steps:

[...

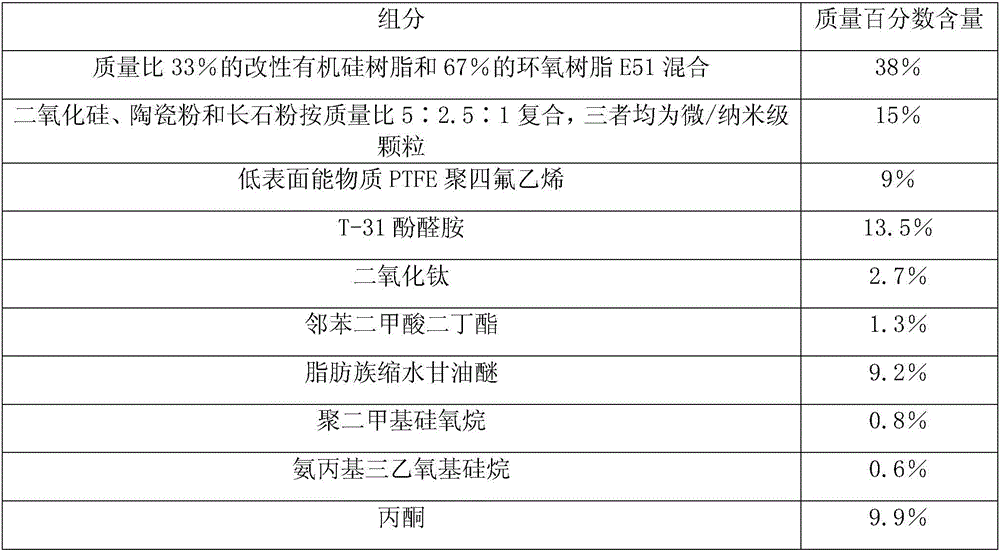

Embodiment 2

[0024] Embodiment 2: A kind of hydrophobic anti-corrosion ceramic coating, adopts epoxy resin and modified silicone resin composite as film former, adds various fillers, auxiliary agent and solvent to prepare, and its each component and its mass percentage are :

[0025]

[0026] The preparation method of described a kind of hydrophobic anticorrosion ceramic coating, comprises the following steps:

[0027] (1) Stir and mix the modified silicone resin and the diluent, the stirring speed is 90rpm, and the stirring time is 8min, so that the modified silicone resin is completely dissolved; then add 50% of the mass of the above-mentioned solvent, and then stir and mix. 350rpm, the reaction temperature is 130°C, and the reaction lasts for 1 hour. After the reaction stops, stop stirring; then add toughening agent, leveling agent, epoxy coupling agent, body filler and pigment filler in sequence, and stir and mix. The stirring speed is 30rpm, and the stirring time is 40min; finally...

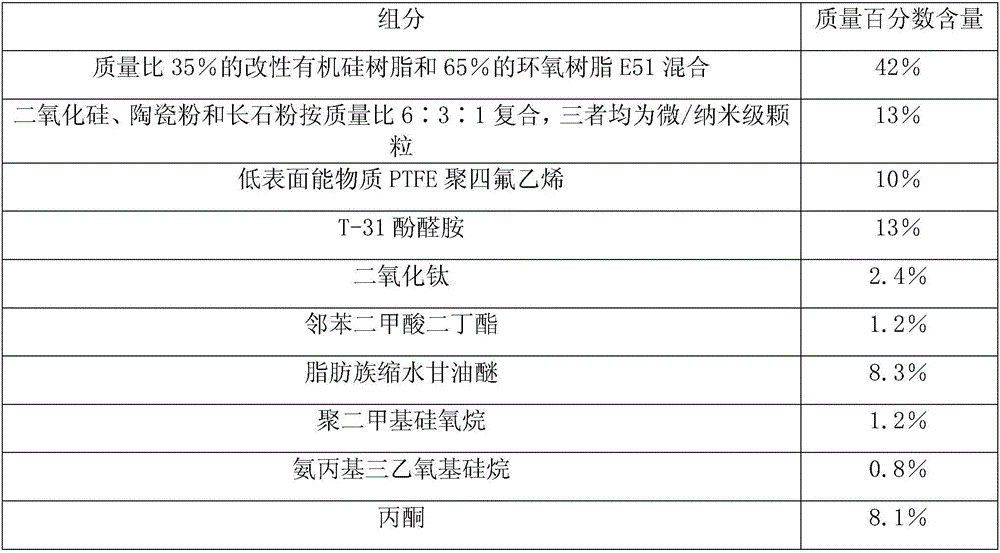

Embodiment 3

[0030] Embodiment 3: A kind of hydrophobic anticorrosion ceramic coating, adopts epoxy resin and modified organic silicon resin composite as film former, adds various fillers, auxiliary agent and solvent to prepare, and its each component and its mass percent are :

[0031]

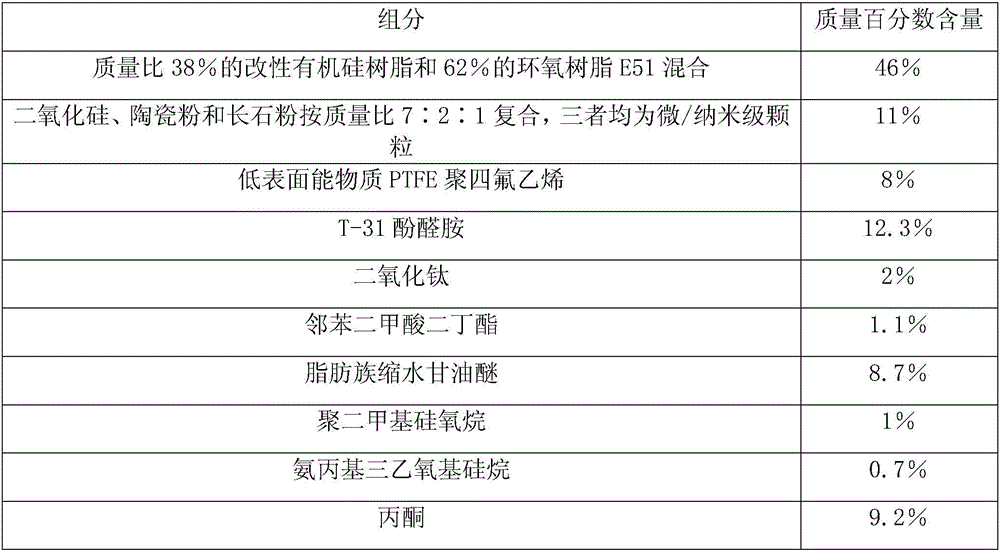

[0032] The preparation method of described a kind of hydrophobic anticorrosion ceramic coating, comprises the following steps:

[0033] (1) Stir and mix the modified silicone resin and the diluent, the stirring speed is 100rpm, and the stirring time is 5min, so that the modified silicone resin is completely dissolved; then add 50% of the mass of the above solvent, and then stir and mix, and the rotation speed is 400rpm, the reaction temperature is 150°C, and the reaction lasts for 0.5h. After the reaction stops, stop stirring; then add toughening agent, leveling agent, epoxy coupling agent, body filler and pigment filler in sequence, and stir and mix. The stirring time is 50rpm, and the stirring time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com