Super-hydrophobic asphalt pavement anti-freezing coating and preparing method thereof

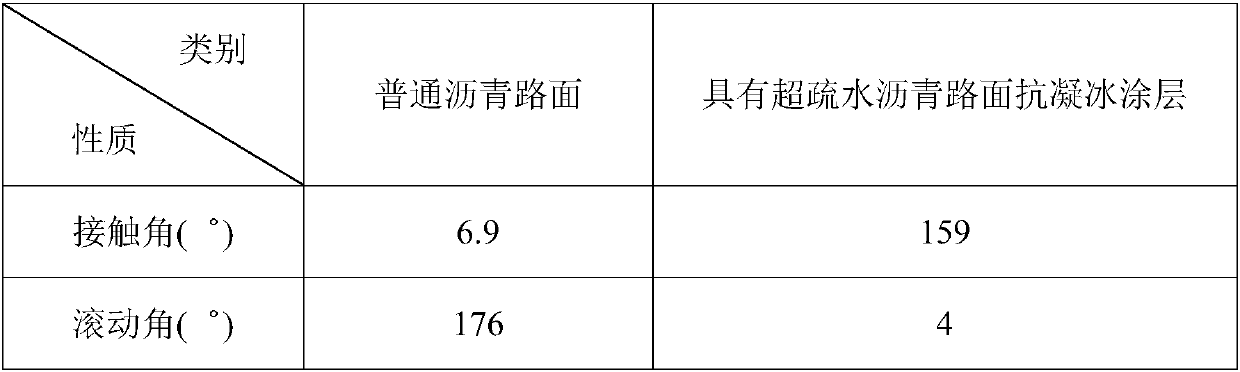

An asphalt pavement, anti-icing technology, applied to coatings, roads, roads, etc., can solve the problems of complex preparation process, pavement structure damage, high cost, etc., and achieve simple preparation process, low-carbon and energy-saving materials, and short curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

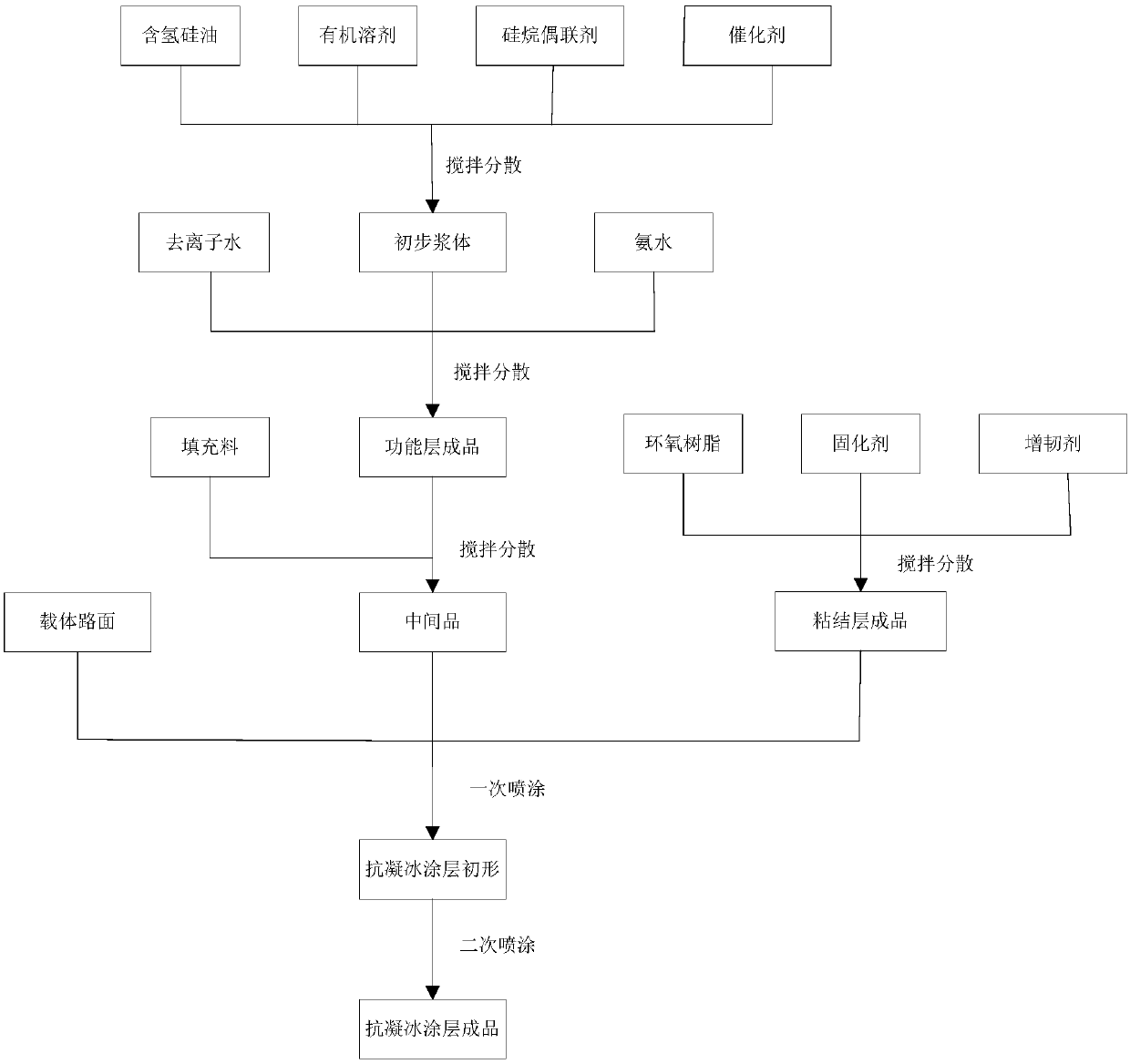

[0030] The simple and convenient superhydrophobic asphalt pavement anti-icing coating of the present embodiment, its preparation process is as follows:

[0031] Add 90 parts of PMHS, 20 parts of KH550, 20 parts of dibutyltin dilaurate and 930 parts of absolute ethanol into the beaker, stir at room temperature at a stirring rate of 2000rpm for 2 hours to fully react between them, and prepare Go out preliminary slurry; Then, add 130 parts of deionized water and 30 parts of ammoniacal liquor respectively in the preliminary slurry with glue tip dropper, the solute mass percentage of ammoniacal liquor is 25%, stirs 18 hours, reacts completely between reactant, At this time, the finished slurry of the functional layer is prepared; finally, the hydrophobic meteorological silica particles are added to the finished slurry of the functional layer and stirred to prepare the finished slurry, wherein the quality of the hydrophobic meteorological silica particles is the final product of the ...

Embodiment 2

[0043] The simple and convenient superhydrophobic asphalt pavement anti-icing coating of the present embodiment, its preparation process is as follows:

[0044] Add 95 parts of PMHS, 25 parts of KH550, 25 parts of dibutyltin dilaurate and 960 parts of absolute ethanol into the beaker, and stir at room temperature at a stirring rate of 2300rpm for 2.1h to fully react between them. Prepare a preliminary slurry; then, add 150 parts of deionized water and 35 parts of ammonia water to the preliminary slurry with a rubber dropper, the solute mass percentage of ammonia water is 25%, stir for 19 hours, and react completely between the reactants , the functional layer finished slurry is prepared at this time; finally, the hydrophobic meteorological silica particles are added into the functional layer finished slurry and stirred to prepare the finished slurry, wherein the mass of the hydrophobic meteorological silica particles is the functional layer 0.8% of the mass of the finished slu...

Embodiment 3

[0058] The simple and convenient superhydrophobic asphalt pavement anti-icing coating of the present embodiment, its preparation process is as follows:

[0059] Add 100 parts of PMHS, 30 parts of KH550, 30 parts of dibutyltin dilaurate and 990 parts of absolute ethanol into the beaker, and stir at room temperature at a stirring rate of 2500rpm for 2.2 hours to make them fully react, Prepare a preliminary slurry; then, add 180 parts of deionized water and 40 parts of ammonia water to the preliminary slurry with a rubber dropper, the solute mass percentage of ammonia water is 25%, stir for 20 hours, and react completely between the reactants , the functional layer finished slurry is prepared at this time; finally, the hydrophobic meteorological silica particles are added into the functional layer finished slurry and stirred to prepare the finished slurry, wherein the mass of the hydrophobic meteorological silica particles is the functional layer 1% of the mass of the finished sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com