Patents

Literature

47results about How to "Non-shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

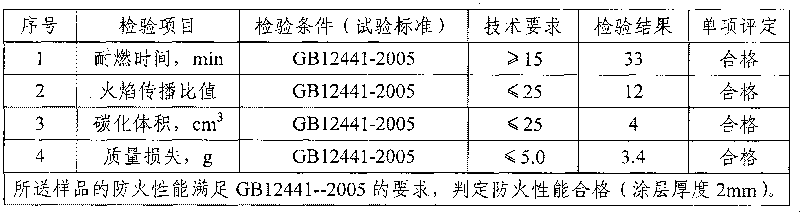

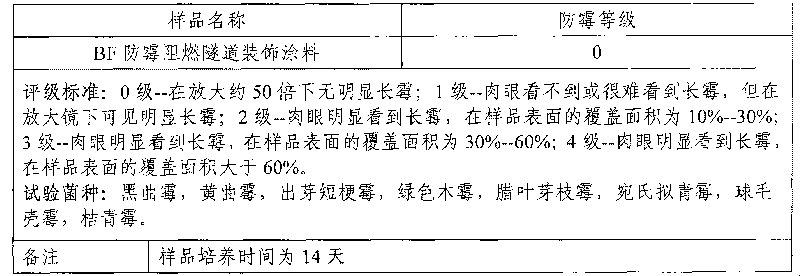

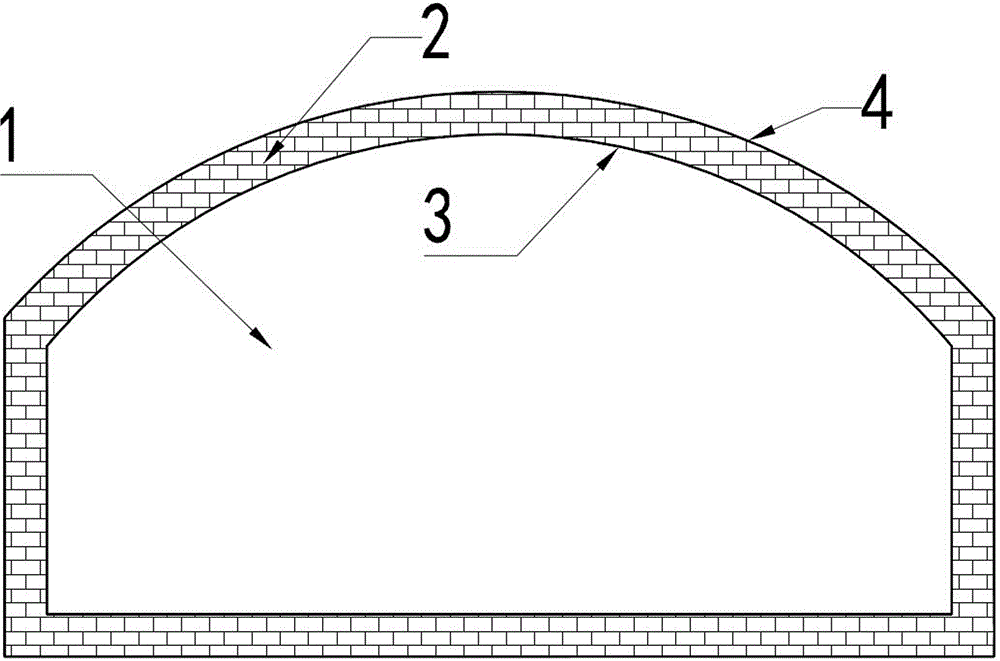

Mildewproof flame-retardant tunnel decoration paint, preparation method and application thereof

ActiveCN101712836AImprove water resistanceImprove stain resistanceFireproof paintsCovering/liningsHigh pressure waterFire retardant

The invention relates to mildewproof flame-retardant tunnel decoration paint, a preparation method and application thereof. The paint comprises the following components in parts by mass: 10 to 30 parts of water, 1.0 to 2.0 parts of dispersant, 1.0 to 2.0 parts of antimildew agent, 10 to 20 parts of titanium dioxide, 20 40 parts of flame retardant, 20 to 40 parts of acrylic ester polymer, 1.0 to 3.0 parts of nanometer modified coating reinforcing agent, 1.2 to 2.5 parts of film-forming additive, 0.2 to 0.6 parts of defoamer, 1.2 to 2.5 parts of polyurethane thickener, and 0.5 to 3.5 parts of inorganic nano-materials. The preparation method mainly comprises the steps of adding needed components under certain conditions, uniformly mixing or grinding the components, adding the needed component in turn, uniformly mixing all raw materials and then adjusting the mixture to have appropriate viscosity. The paint is applied to the decoration of tunnels, aboveground buildings and underground buildings, and has the characteristics of fire prevention, flame retardancy, mildewproof property, waterproof property, moisture-proof property, high adhesion, non-shedding property, strong resistance to high-pressure water impact, long lifespan and the like.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +1

Powder coating

The invention discloses a powder coating, which comprises the following components in parts by weight: 60 to 80 parts of magnesium carbonate, 4 to 5 parts of mica powder, 2 to 5 parts of cellulose, 3 to 5 parts of phosphor powder, 4 to 5 parts of porcelainized calcium, 5 to 10 parts of bentonite, 2 to 10 parts of rubber powder and 1 to 5 parts of adhesive. The powder coating has the advantages of high hardness, scrubbing resistance, firmness, low cost and the like, and a wall surface brushed with the powder coating serving as a raw material is as bright and clean as porcelain.

Owner:王鹏宇

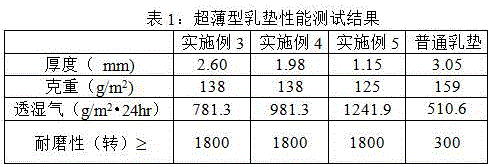

Ultra-thin breast pad and preparation method thereof

ActiveCN105970489AEliminates the defect of easy hair lossImprove wear resistanceLiquid surface applicatorsLayered productsPhysiologyHot melt

The invention discloses an ultra-thin breast pad and a preparation method thereof and relates to the field of female lactation products. The ultra-thin breast pad is composed of a surface layer hydrophilic non-woven fabric, an intermediate absorbing layer and an impermeable bottom film. The surface layer hydrophilic non-woven fabric is a soft type double-component filament non-woven fabric composed of core layer PP / skin layer PE; and the intermediate absorbing layer is a hot melting non-woven fabric formed by blending core layer PP / skin layer PE and superabsorbent fibers. According to the method for preparing the ultra-thin breast pad, the surface layer hydrophilic non-woven fabric for preparing the ultra-thin breast pad is selected through a PE / PP double-component filament non-woven fabric soft bulkiness processing method, the superabsorbent fibers and the PE / PP double-component fibers are blended, the intermediate absorbing layer is prepared through a plain net hot air reinforcing method, so that the prepared ultra-thin breast pad has the advantages of being not subjected to fiber slip, being ultra-thin and breathable, having moisture breathability and being safe and healthy, and the problems that a breast pad not subjected to fiber slip is poor in comfort, unsafe, high in moisture content and high in material cost are solved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

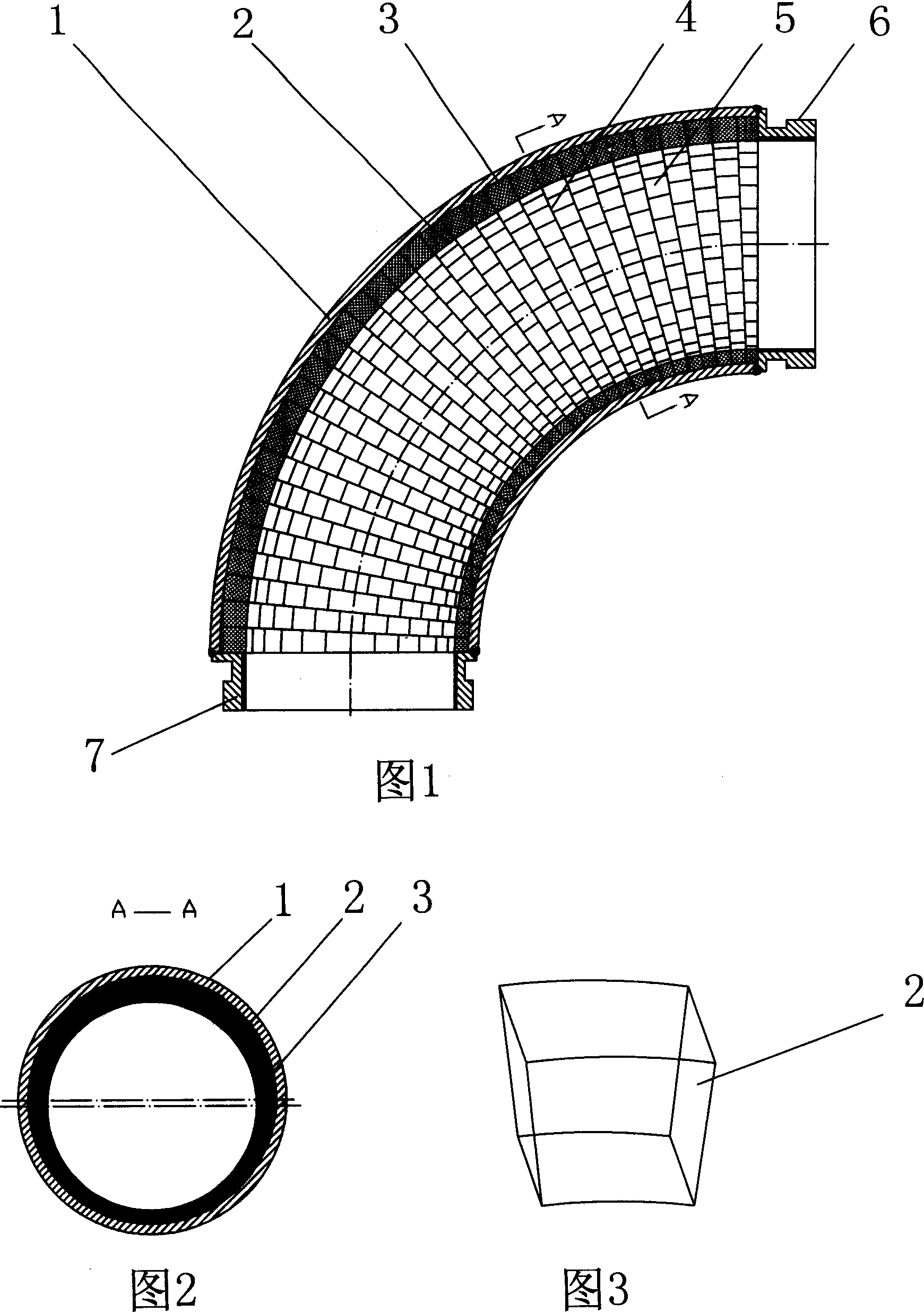

Split joint type ceramic wear-resisting bend

InactiveCN101008463AImprove wear resistanceExtended replacement cycleBulk conveyorsPipe protection against damage/wearAdhesiveJoints types

The invention discloses an assembly ceramic abrasion-resistance bend head, wherein, the inner wall of seamless bend head main body (1) is arranged with an abrasion-resistance ceramic liner (4) assembled from several abrasion-resistance ceramic plates (2) that assembles the abrasion-resistance ceramic plates in wedge shape into one abrasion-resistance ceramic liner ring (5) engaged with the inner wall of main body (1); several liner rings (5) are axially bended and connected to form the abrasion-resistance ceramic liner (4) engaged with the main body (1); two ends of main body (1) are respectively arranged with the baffle rings of abrasion-resistance ceramic liner (4); the high-temperature resistant inorganic adhesive (3) is filled between the inner wall and the abrasion-resistance ceramic liner (4). The invention can avoid reduction and deformation, with simple structure and low cost.

Owner:HUNAN JINGCHENG SPECIAL CERAMIC

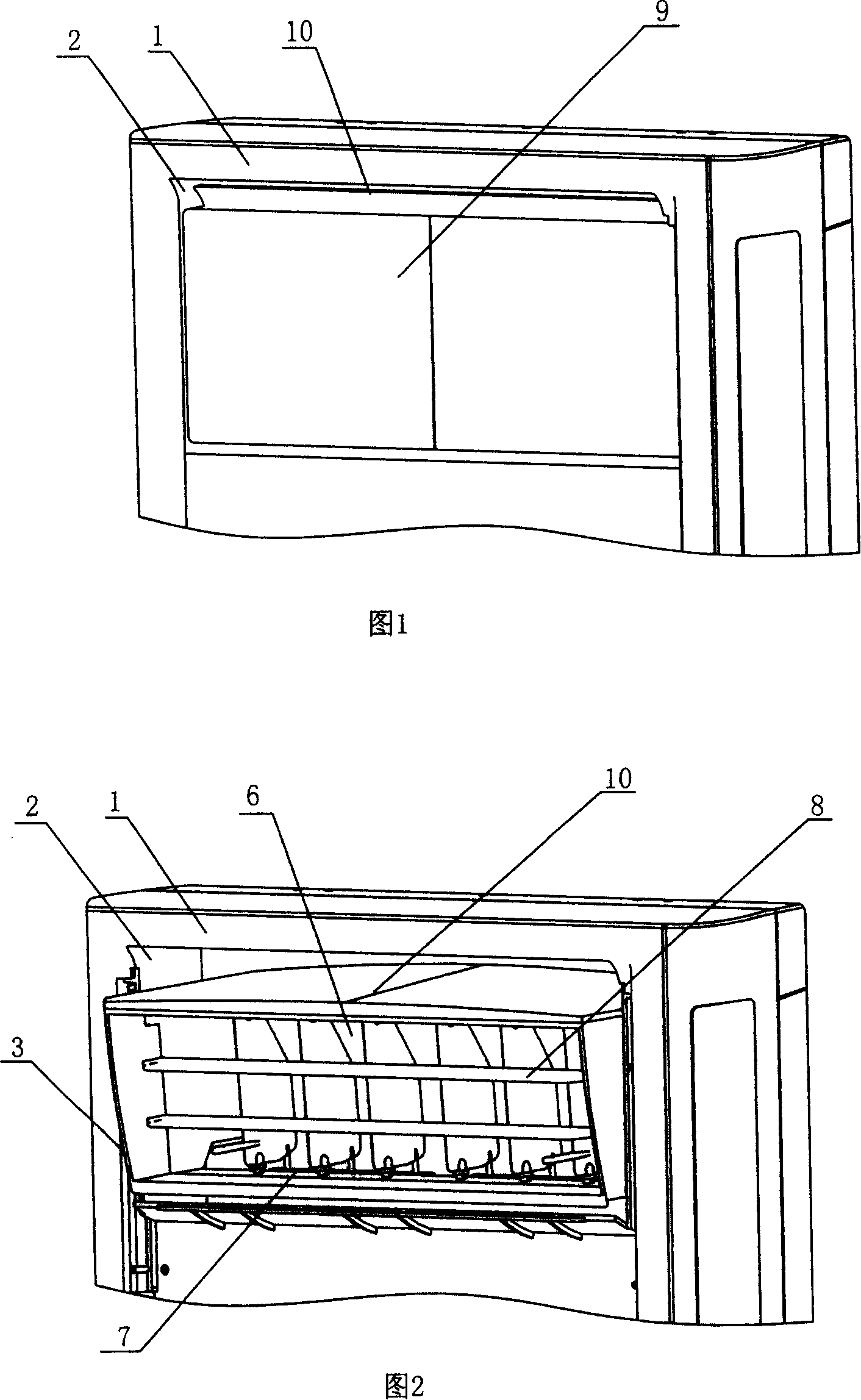

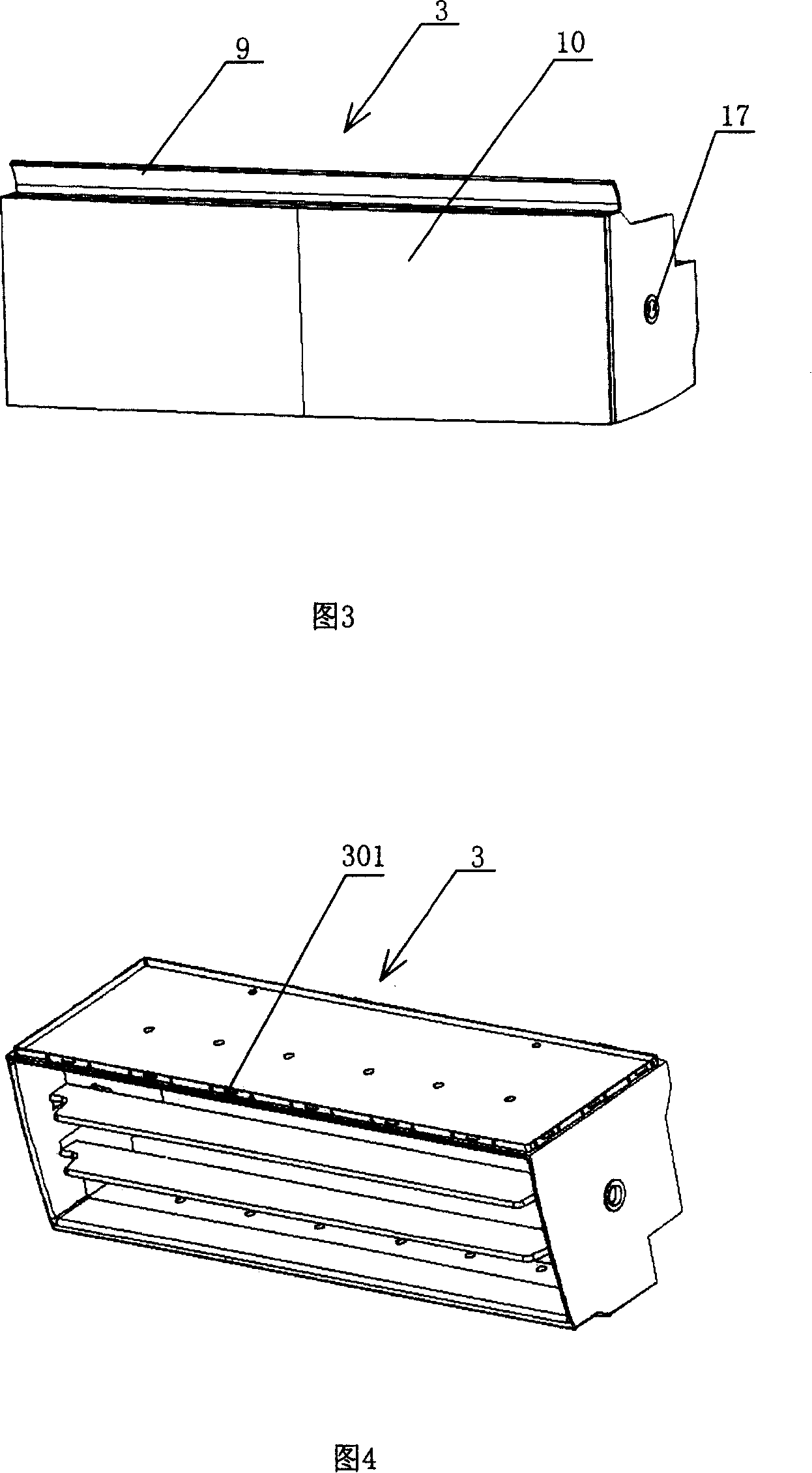

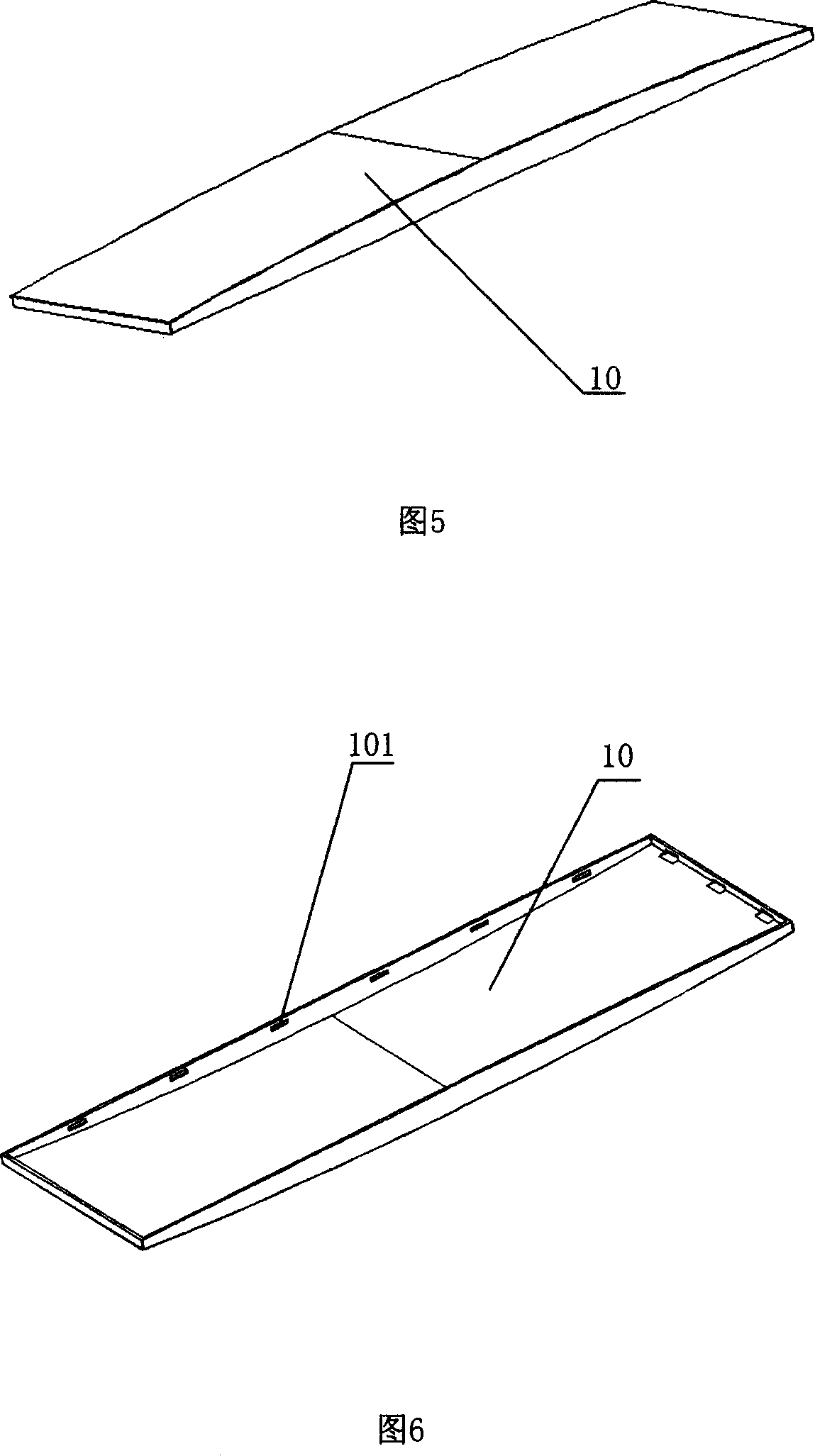

Air conditioner decorative sheet adopting novel technique of transcribing in model and its technique

ActiveCN101153737AAppearance coordinationFashionable and beautiful appearanceLighting and heating apparatusAir conditioning systemsCompression moldingWear resistant

The present invention discloses an air conditioner decorative plate adopting novel technique of transcribing in mold and the technologic method thereof, wherein, the decorative plate is arranged on an air outlet frame inside an air outlet frame of a front panel; the air outlet frame is pivoted inside the air outlet frame, can swing up and down around a shaft to supply air, and can also obstruct an air outlet to prevent dust from entering when an air conditioner is turned off. The decorative plate adopts a novel technique of transcribing in mold, and the technologic method comprises the following steps: firstly, membrane making, which comprises selection of materials for making membrane and printable materials, pattern printing in printed region and drying after making; secondly, positioning and membrane feeding, which comprise membrane feeding of a membrane feeding device, die positioning on the decorative plate and membrane fixing; thirdly, compression molding, which comprises heating for softening the membrane and molding; fourthly, injection molding, which comprises selection of castingresin corresponding to the membrane materials, corresponding to the resin temperature regulation and resin injection; fifthly, post treatment, which comprises taking-out, shearing and processing. The present invention executes silver luster treatment to the whole surface of the decorative plate; thereby the decorative plate is beautiful and stylish in exterior appearance, wear resistant and scratch resistant.

Owner:HAIER GRP CORP +1

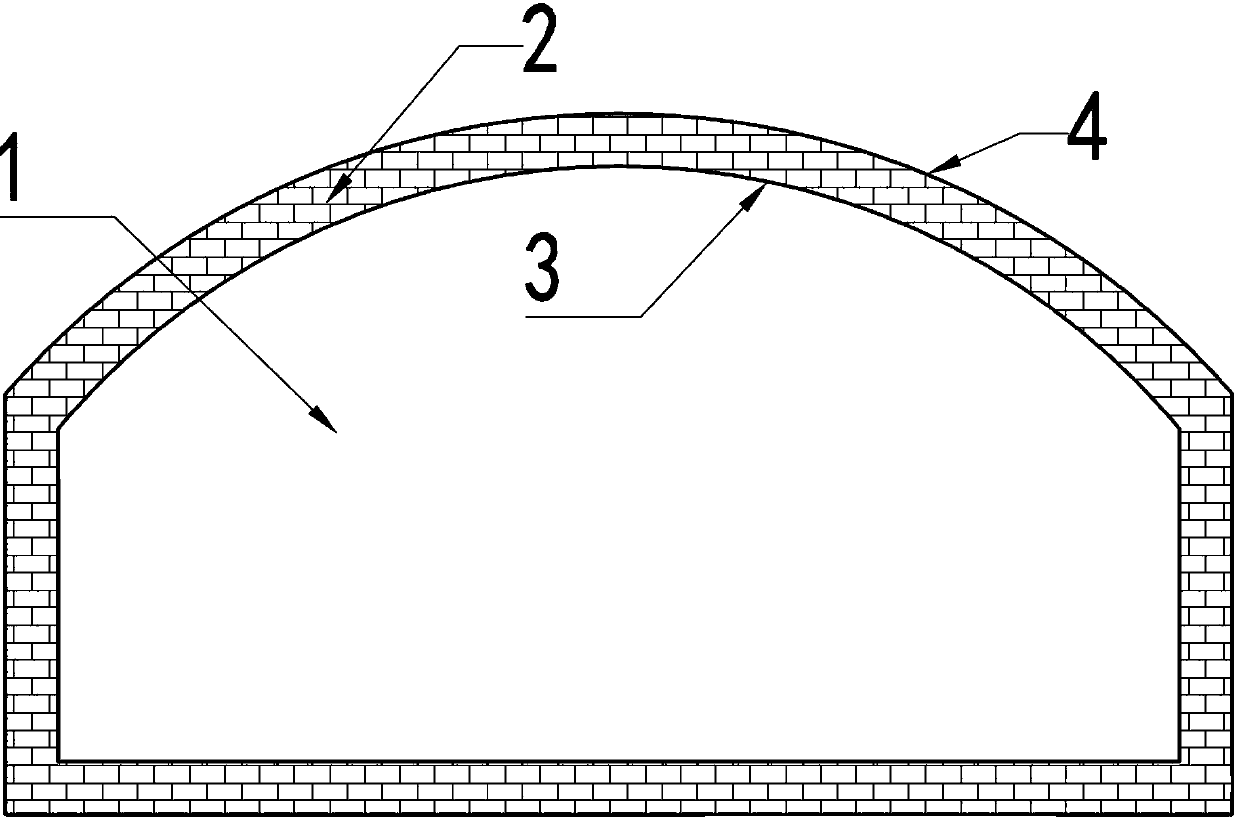

Energy-saving industrial furnace

The invention discloses an energy-saving industrial furnace. The energy-saving industrial furnace comprises a furnace base body, and the furnace base body is made of heatproof fibers, firebricks or a micro-nano material; the outer wall of the furnace base body is coated with a combined heat insulation coating layer, and the inner wall of the furnace base body is coated with an infrared radiation energy-saving coating layer; and the combined heat insulation coating layer comprises an inner heat insulation coating layer, a medium heat insulation coating layer and an outer heat insulation coating layer which are sequentially coated from inside to outside. A reinforced radiation heat transfer combined thermodynamic heat insulation energy-saving technology, which combines the infrared high-radiation technology of the high temperature-resistant infrared-energy saving coating layer with the high-efficiency heat insulation technology of the combined heat insulation coating layer, is applied, so the industrial furnace disclosed in the invention has the characteristics of effective improvement of the heat utilization efficiency, good energy saving effect, long service time, prolonged service life, and generation of the environmental protection effect.

Owner:SHENZHEN TRIUMPH TECH ENG +1

Water-proof jade powder paint

A water-proof jade powder coating is characterized in that the coating is prepared by the following ingredients with the proportion by weight: 5-15 of polyvinyl alcohol, 50-100 of water, 1-2 of 4% (weight) sodium tetraborate solution, 5-10 of sodium bentonite, 25-40 of jade powder (400 mesh), 5-15 of white cement, 0.1-0.5 of SKANEM-8 mould inhibitor and 0.1-0.25 of NATROSOL250 thickener; polyvinyl alcohol is added into a reaction vessel and then water is added and heated to cause the polyvinyl alcohol to be completely dissolved; the sodium tetraborate solution is dropped into the reaction vessel and conduct cross linking reaction with the polyvinyl alcohol, and the polyvinyl alcohol is gelated; cooling water is used for cooling reaction to obtain colorless glue and then the sodium bentonite, jade powder, white cement, mould inhibitor and NATROSOL250 thickener are added; after being stirred evenly, the mixture is put into a grinder for grinding, thus preparing the water-proof jade powder coating.

Owner:孟宁

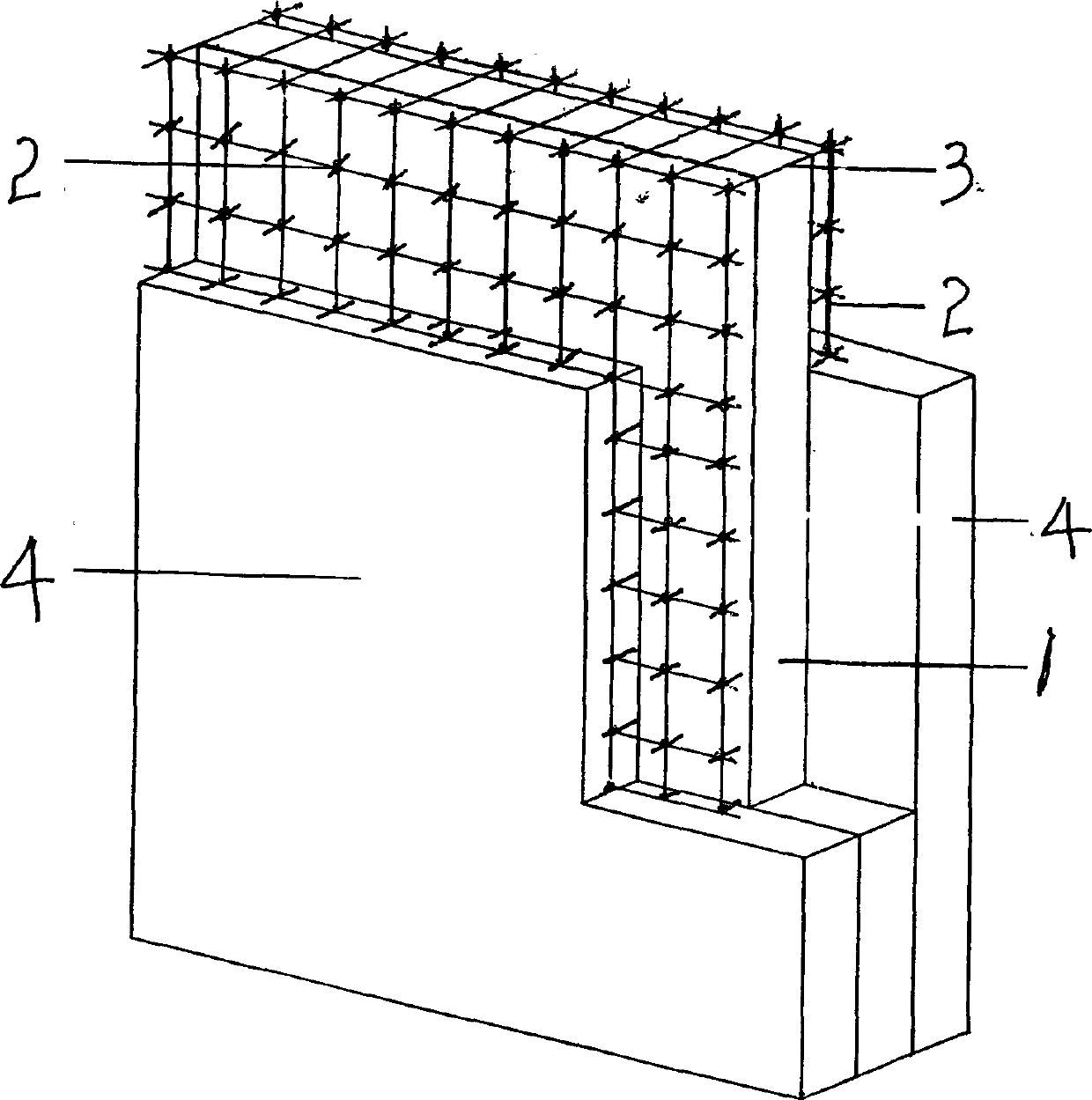

Technique for anti-seismic and energy-saving wall with built-in core net

InactiveCN103498519AImprove seismic performanceImprove energy efficiencyWallsHeat proofingButt jointEngineering

The invention discloses a technique for an anti-seismic and energy-saving wall with a built-in core net. According to the technique for the anti-seismic and energy-saving wall with the built-in core net, insulation boards are fixed at a position 0-30mm away from the outer side of a framework column, the boards are connected in a butt joint mode, board dovetail grooves and board dovetail joints are connected in a butt joint mode, connection seams are sealed by means of binding tape, board seams are fixed through clamping boards, and then a sandwich core of the wall is formed; metal nets are hung on the two sides of the sandwich core respectively, the inner metal net is hung at a position which is 30mm away from the inner side face of the sandwich core, the outer metal net is hung at a position which is 30mm away from the outer side face of the sandwich core, metal tie pieces penetrate through the sandwich core to enable the metal nets on the two sides to be connected, and the core net is formed by the sandwich core and the metal nets; wall molds are installed on the two sides of the core net respectively, the inner wall mold is installed at a position which is 50-60mm away from the inner side face of the sandwich core, the outer wall mold is installed at a position which is 50-60mm away from the outer side face of the sandwich core, a door-and-window hole wall mold is installed after enough space for installation of a door-and-window frame is reserved on the door-and-window hole wall mold, then lightweight concrete slurry is poured, and the anti-seismic and energy-saving wall with the built-in core net is formed after demolding.

Owner:张金法

Glitter powder sequin membrane and preparation method thereof

InactiveCN106010411AOvercome the disadvantages of not being environmentally friendlyBoilableNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhysical chemistryEngineering

The invention relates to a glitter powder sequin membrane and a preparation method thereof. The glitter powder sequin membrane comprises a PET base material layer, a first water glue layer and a glitter powder layer, wherein the water glue of the first water glue layer is obtained by processing the following raw materials in parts by weight: 20-28 parts of ethylene vinyl acetate, 30-45 parts of PU resin copolymer emulsion, 15-23 parts of isooctoate and 15-25 parts of water. The preparation method of the glitter powder sequin membrane comprises the following steps: (I) preparation of glitter powder: selecting a PET base material, aluminizing and coloring, and slitting and powdering to obtain the glitter powder; and (II) preparation of the glitter powder sequin membrane: selecting a PET base material, uniformly coating the PET base material with appropriate water glue, uniformly spreading appropriate glitter powder, and performing extrusion, powder absorption, drying, rolling and slitting processes to obtain the glitter powder sequin membrane. In the invention, oily glue is replaced by waterborne glue; the glitter powder sequin membrane is obtained by gluing, automatic powder spreading, extrusion, powder absorption, protection layer coating and drying; the defect that the oily glue is not environment-friendly is overcome; and the product has the advantages of brightness, beauty, easiness in powdering without tool penetration, boiling resistance, scratch resistance and no falling.

Owner:WENZHOU HONGDA LASER PICTURE

Solder resist for water-based aluminum alloy high-temperature treatment

ActiveCN108410336AGood suspension performanceGood temperature resistanceFireproof paintsPolyurea/polyurethane coatingsResistDefoaming Agents

The invention discloses a solder resist for water-based aluminum alloy high-temperature treatment. The solder resist comprises, in weight percent, 25-30wt% of modified concave soil / nano-zirconia composite powder, 20-25wt% of adhesives, 5%-10wt% of binding agents, 2%-5wt% of dispersing agents, 40%-60wt% of deionized water and 0.5-1wt% of silicone oil defoaming agents.

Owner:合肥九州龙腾科技成果转化有限公司

Interior wall coating and preparation method thereof

The present invention relates to an interior wall coat and its preparation method. Said interior cost is composed of ground coat, middle coat and external coat, and is characterized by that every layer of said coat contains its respective raw material composition and is made up by adopting a certain preparation process. Said coat is no-toxic, has no abnormal smell, has no radioactivity, contains no harmful substances of formaldehyde, etc. and has the features of resisting fungus, resisting damp, resisting corrosion, resisting smoke and steam, no scaling and seasily cleaning, and is suitable for brush-coating interior wall of color preparation workshop, Chinese medicine extraction workshop, Chinese medicinal material storehouse and color and oil-containing workshop of food industry.

Owner:刘晓刚 +2

Scrubbing-resistant shell powder paint for efficiently decomposing formaldehydes

ActiveCN107474598AAchieve adsorptionRealize decompositionAntifouling/underwater paintsPaints with biocidesEmulsionRare earth

The invention provides scrubbing-resistant shell powder paint for efficiently decomposing formaldehydes. The scrubbing-resistant shell powder paint is characterized by being prepared from the following ingredients in parts by weight: 100 parts of shell powder, 0.1 to 1 part of fired shell powder 0.1 to 1 part of nanometer titanium dioxide, 13 to 22 parts of emulsion powder, 0.01 to 0.1 part of zinc oxide, 0.5 to 2 parts of rare earth antibacterial agents and 0.1 to 1 part of silica sol.

Owner:中科海洋生物再生资源(天津)有限公司

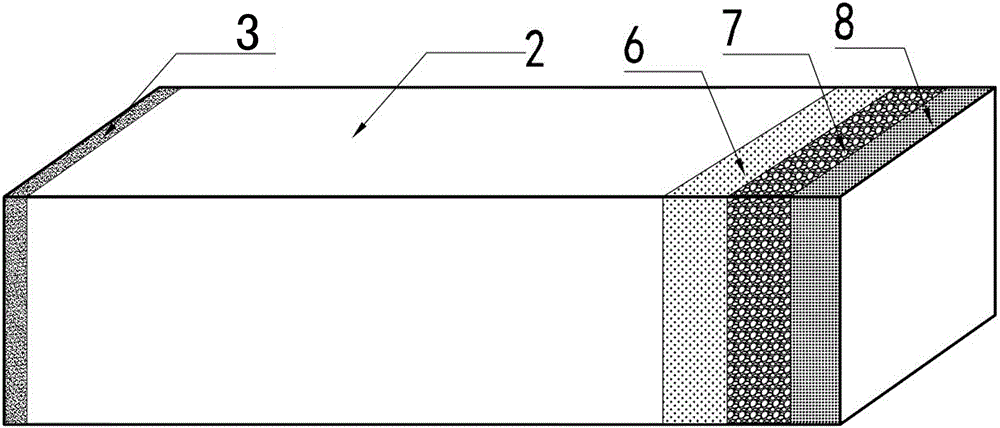

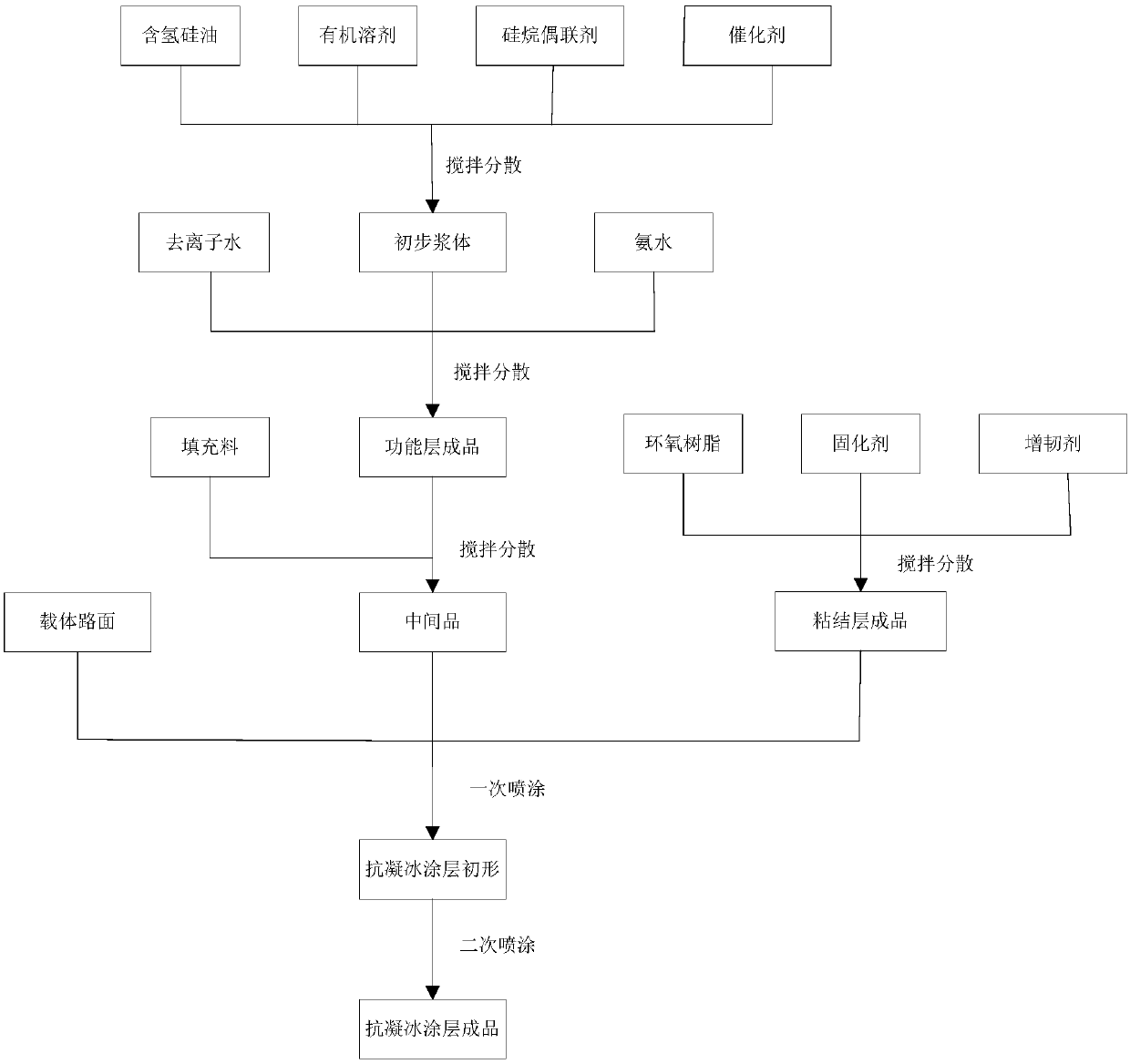

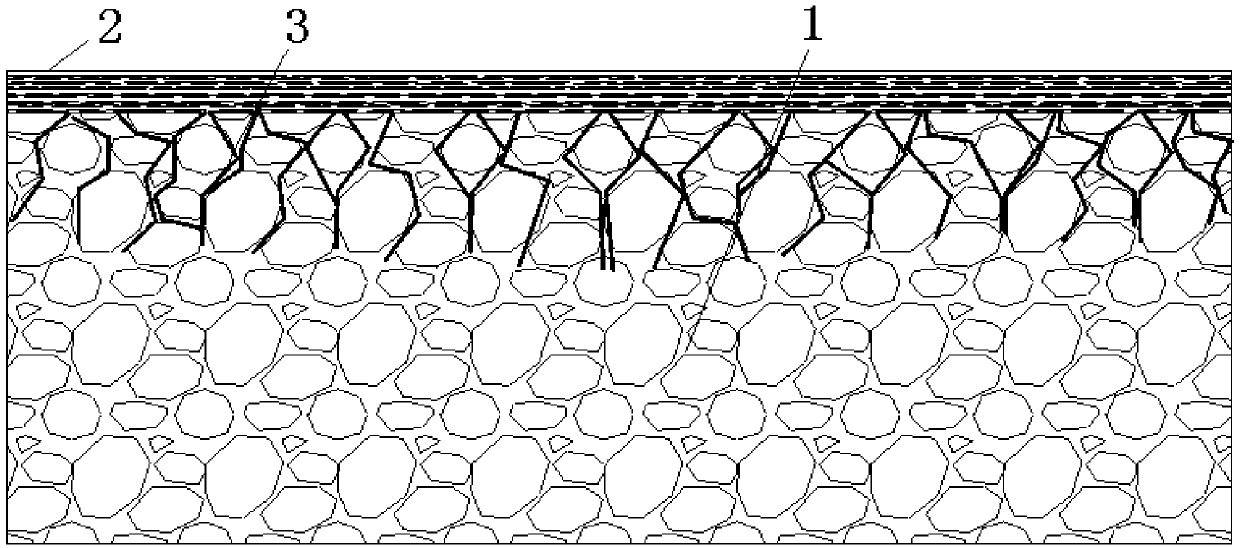

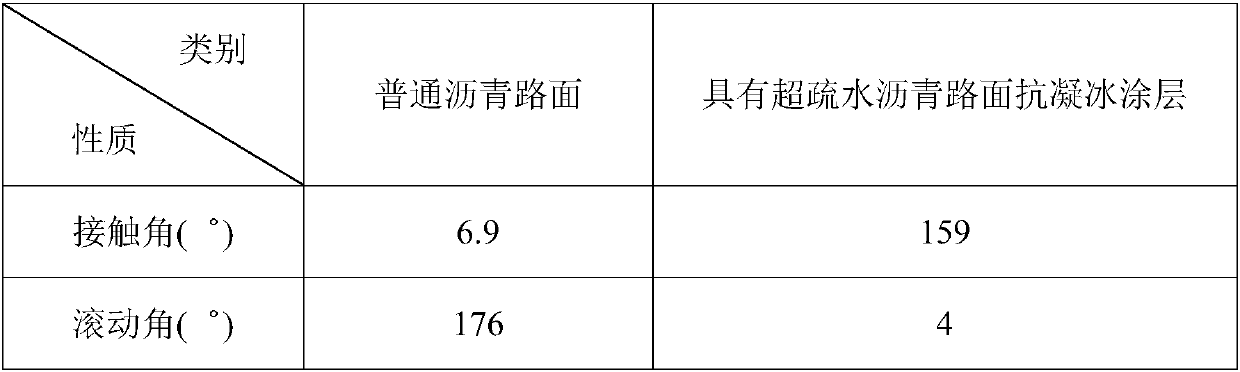

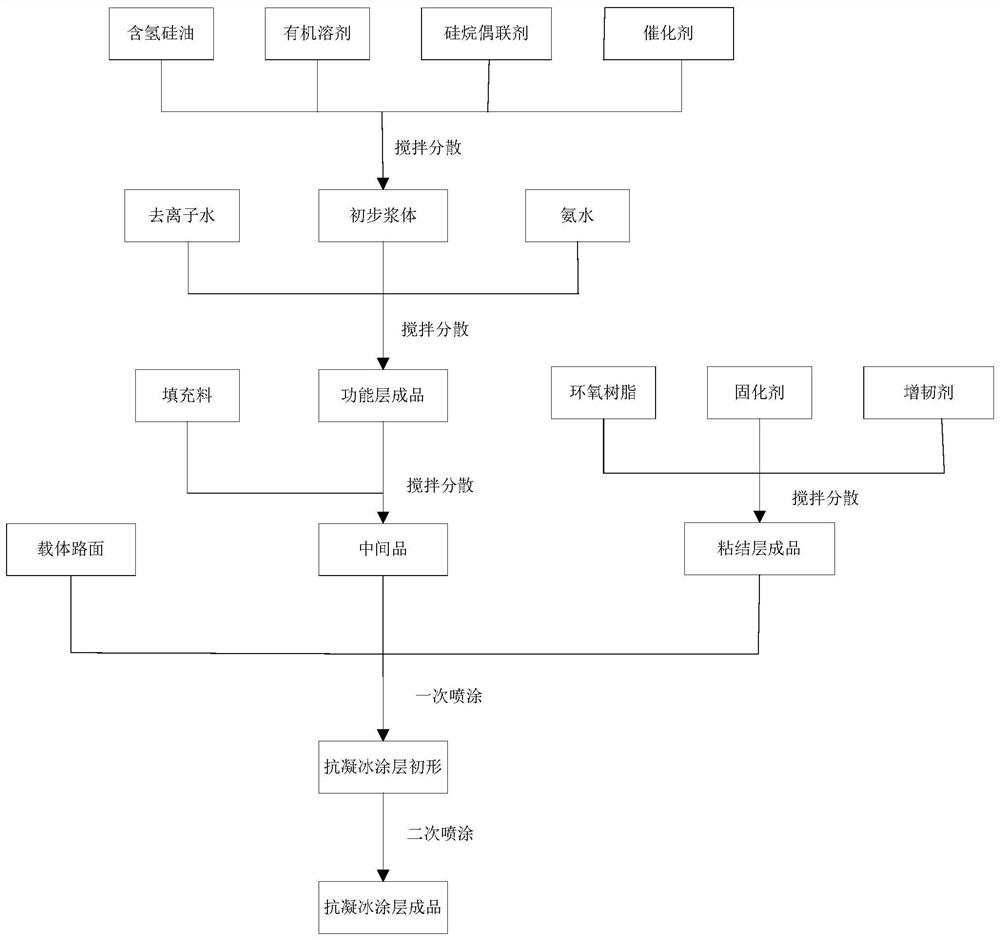

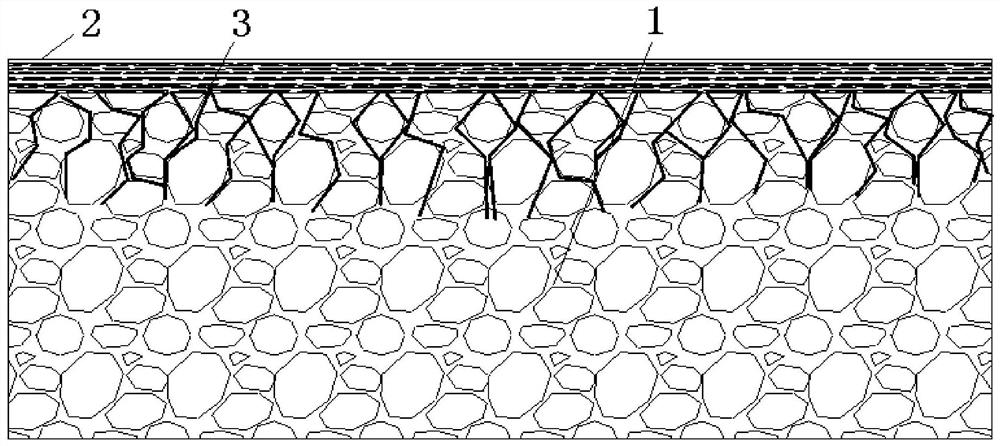

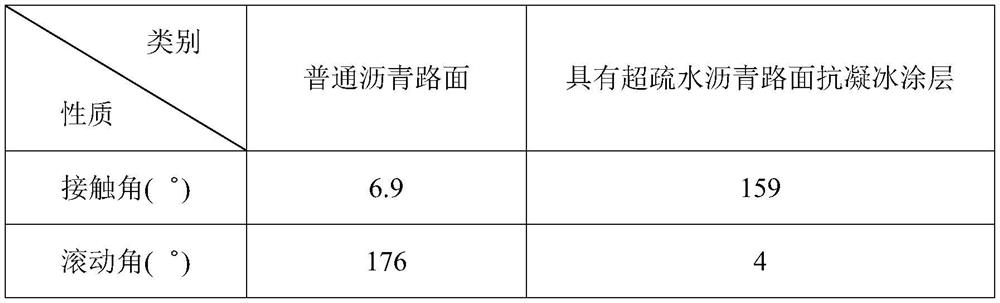

Super-hydrophobic asphalt pavement anti-freezing coating and preparing method thereof

ActiveCN109627974ASuperhydrophobicTo achieve the effect of anti-icingPaving detailsCoatingsEpoxySlurry

The invention belongs to the technical field of the design of asphalt concrete pavement coatings, and relates to a super-hydrophobic asphalt pavement anti-freezing coating and a preparing method thereof. The coating comprises an adhesive layer arranged on the surface of a carrier pavement, a functional layer arranged on the surface of the adhesive layer, and anti-wear filler dispersed in the functional layer. The functional layer is a low-surface-energy material. Slurry of the adhesive layer is formed by mixing epoxy resin 128, an amine curing agent and an epoxy toughening agent 277. Slurry ofthe functional layer is formed by mixing MHX-1107 hydrogen-containing silicone oil, gamma-aminopropyl triethoxysilane, dibutyltin dilaurate, absolute ethyl alcohol, ammonium hydroxide and deionized water. The anti-wear filler is evenly dispersed in the slurry of the functional layer. The performance of the super-hydrophobic asphalt pavement anti-freezing coating can completely meet the requirements for super hydrophobicity, freezing resistance, wear resistance, high friction coefficient and the like.

Owner:CHANGAN UNIV

Hydrophobicity-enhanced powder coating for corrosion protection of pump valves

InactiveCN105440902AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPowdery paintsSilanesSesquioxide

The invention discloses hydrophobicity-enhanced powder coating for corrosion protection of pump valves. The hydrophobicity-enhanced powder coating is prepared from the following raw materials by weight: 52 to 54 parts of hydroxyl polyester resin, 7 to 8 parts of fluorine-carbon resin, 4 to 5 parts of triglycidyl isocyanurate, 13 to 15 parts of nano aluminum sesquioxide, 0.8 to 0.9 part of perfluoro octyl triethoxy silane, 25 to 30 parts of an ethanol solution of which the concentration is 75%, 0.5 to 0.6 part of a silane coupling agent kh560, 14 to 16 parts of calcium carbonate, 2.5 to 3.5 parts of stearic acid, 6 to 7 parts of nano-silicon sol, 2 to 3 parts of polyvinyl pyrrolidone, 1 to 1.2 parts of dibutyltin dilaurate, 0.9 to 1.1 parts of polydimethyl siloxane, and a proper amount of water. The prepared powder coating is high in leveling property, smooth in a formed coating layer, and high in corrosion resistance, is sprayed on the surface of a pump valve material via static electricity, and has the effects of resisting wiping, preventing shedding, and being long in service life.

Owner:TONGLING SIDE TECH

Durable antibacterial ivory board and production method thereof

InactiveCN110886131ANo harmHigh antibacterial efficacyFlexible coversCoatings with pigmentsBiotechnologySilica gel

The invention relates to the technical field of durable ivory board processing, and concretely relates to a durable ivory board. The durable ivory board comprises raw paper and a coating layer, and the coating layer comprises, by weight, 50-80 parts of nanometer calcium carbonate, 1-5 parts of microcrystalline cellulose, 1-5 parts of silica gel powder, 25-45 parts of modified starch, 0.5-2 parts of grapefruit seed extract, 0.1-0.5 part of a dispersing agent and 1-3 parts of a defoaming agent. The invention also provides a production method of the durable ivory board. Pure natural plants are used as antibacterial components and are compounded to obtain the coating layer, and the surfaces of a surface layer and a bottom layer are coated with the coating layers, so the durable ivory board hasan antibacterial effect, is natural and pollution-free, and has no potential harm to human bodies; and the modified starch added into the coating layer has no corrosivity, improves the durability ofthe ivory board, and also improves the adhesiveness of the coating layer and the paper base.

Owner:友元办公联盟(天津)股份有限公司

Lightweight composite building energy-saving heat-insulation material

ActiveCN104773985AEasy to processReduce processing costsCeramicwareThermal insulationSuperplasticizer

A fire-proof non-combustible composite heat-insulation material with good energy saving effect, good water proofing effect and better mechanical spraying construction effect is prepared by mixing and stirring ordinary Portland 42.5R cement with different weights, fiber brucite, magnesium silicate long fiber, wood fiber, light weight magnesium oxide, polypropylene fiber, an organic active waterproof agent, ultra light nano expansion beads, urea formaldehyde particles or polystyrene particles, adhesives, a foaming agent, a procoagulant regulating agent, silicon micropowder and a poly carboxylic acid superplasticizer, and has the appearance of dry and powdery fiber. The material can be directly spared on external walls, interior walls, roofs and staircase rooms of buildings according to a certain thickness after addition of water for mixing and stirring, has the characteristics of being thermal-insulation, energy-saving, non-combustible, environmentally-friendly, waterproof, and simple and quick in construction, is applicable to heat insulation of a variety of houses and buildings, and can achieve high efficiency and energy saving effect.

Owner:营口天瑞新型建筑材料有限公司

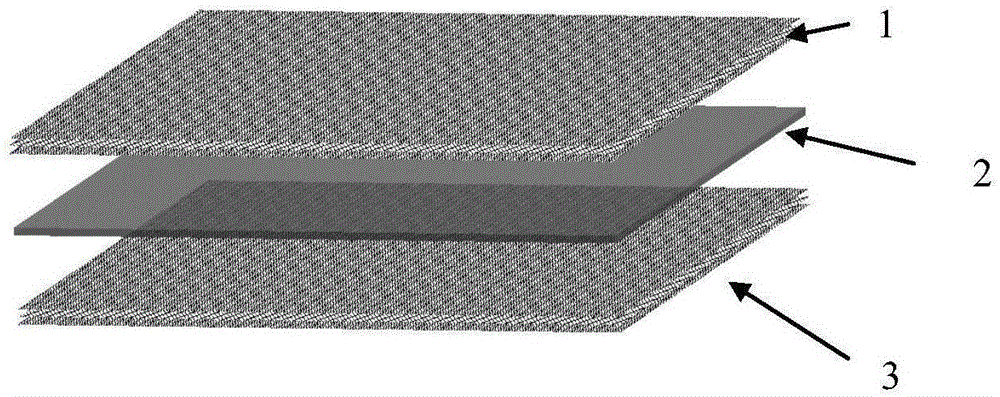

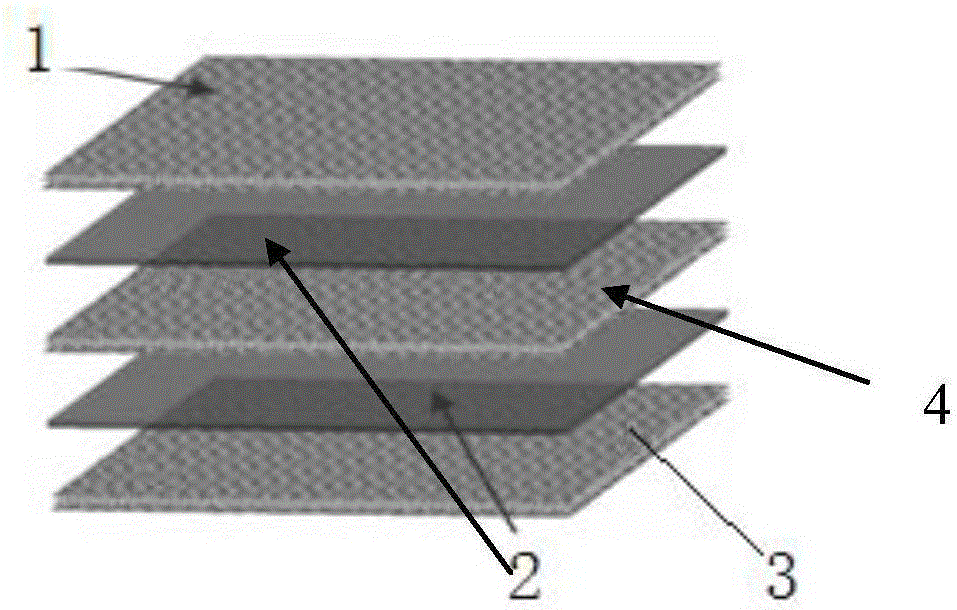

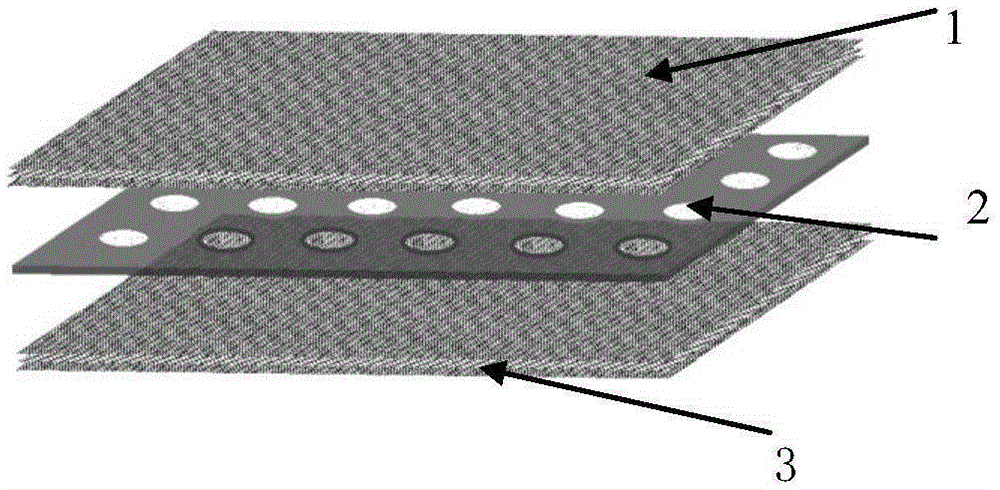

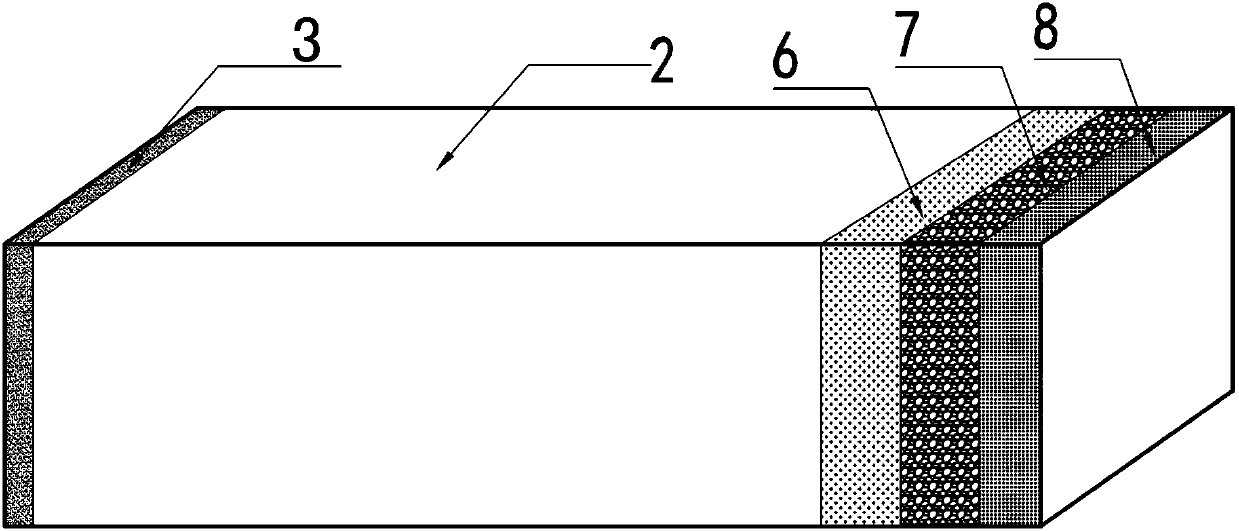

Manufacturing technology of metal interlayer plate in which damping film is embedded

InactiveCN105109146AImproved damping, vibration and noise reduction performanceNon-sheddingTransportation and packagingLaminationManufacturing technologyLayer interface

The invention discloses a manufacturing technology of a metal interlayer plate in which a damping film is embedded. The manufacturing technology includes the steps that firstly, a metal interlayer plate structure in which the damping film is embedded is designed; secondly, the damping film is manufactured; thirdly, metal plates and the damping film are laid according to the design requirement; fourthly, technological parameters of a spot welder are adjusted, a proper spot welding technology mold is designed and manufactured, a damping film layer between the metal plates becomes thin through pressure of welding points, the thinned position of the damping film layer is punctured under the action of an external electric field, a discharging channel is generated, local high temperature is formed, the thinned damping film portion will be firstly combusted and gasified, a gap between metal layers at the thinned position of the damping layer becomes small, a local discharging channel is formed, and local metal between layer interfaces is melted together under the action of pressure and high temperature; fifthly, the damping metal interlayer plate is formed after spot welding machining and cooling. A foundation is laid for research of the design theory of an orthotropic damping structure and wide application of the metal interlayer plate structure in which the damping film is embedded.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Polylactic acid medical water-spraying non-woven material and its production process

InactiveCN1710161AHas no lintNon-sheddingMonocomponent polyesters artificial filamentWater sprayPolymer chemistry

The non-woven material is prepared from poly lactic acid fiber. The process includes: opening and mixing under the environment temperature of 80% + / - 5% and the fiber density is not more than 10kg / m3; carding step to make the opened fiber diffuse and uniformly mixed to form fiber net; net-laying step; water pricking solidifying step under the pre-wetting water pressure of 30 bar, the water pressure of the first water-pricking is 100bar, the water pressure of the second water-pricking is 110bar and the water pressure of the third water-pricking is 120bar; drying step under the temperature of 120-150 degree C. The said non-woven material is mainly used in medical material.

Owner:河南新飘安高科股份有限公司

Manufacture technology of inlaying injection circuit in mold

ActiveCN103158228AOvercome the disadvantages of bondingSimple processCoatingsSolvent moleculeMolten state

The invention relates to the technical field of circuit printing technology, in particular to manufacture technology of a printing circuit. The manufacture technology of inlaying an injection circuit in a mold comprises the manufacture technology of a printing circuit film and further comprises film molding integration technology. The printing circuit film is embedded into a mold cavity of an injection mold and formed together with plastics in a molten state in an injection mode, and an integration injection part is manufactured. By the adoption of the technical scheme, the film and plastic gluing technology is once completed in an injection mold. The printed circuit film and a main molding part body are firmly integrated, and the manufacture technology of inlaying the injection circuit in the mold has the advantages that the printed circuit film does not desquamate and not to be oxidated without escaping of small solvent molecules and the like.

Owner:上海志承新材料有限公司 +1

Reflection heat insulation and preservation veneer integrated external wall panel sectional material

InactiveCN104594586ASuppresses radiant heatGood energy saving effectCovering/liningsWater-setting substance layered productFiberEmulsion

The invention relates to a reflection heat insulation and preservation veneer integrated external wall panel sectional material which is composed of a heat preservation layer and a veneer layer, wherein the heat preservation layer and the veneer layer are pressed to form a whole. The heat preservation layer is an existing external wall external heat preservation sectional material product made of inorganic mineral materials in the market. The veneer layer is formed by preparing ten raw materials of waste stone detrital materials, hollow glass micro-beads, vitrified micro-beads, rare-earth oxides, rutile, waterborne emulsion, inorganic adhesives, wood fiber, polypropylene short fiber and film formation auxiliaries and water. An overall composed, pressed and formed structure of the heat preservation layer and the veneer layer is adopted for the sectional material, the structure is used for an external wall body, safety is high, solar radiant heat absorbed by a building can be reduced, temperature rising caused by solar radiation absorbed by the surface of the building is prevented, heat transmitted into a room is reduced, the heat preservation and insulation requirement of the building outer wall body is met, and the purposes of providing comfortable indoor and outdoor environments, saving energy and lowering consumption are achieved.

Owner:信阳天意节能技术股份有限公司

Waterproof wall lining indoor coating

The invention discloses a waterproof wall lining indoor coating which is composed of the following components in parts by weight: 20-30 parts of putty paste, 10-20 parts of diatomite, 10-25 parts of carbon, 5-15 parts of Eva emulsion, 3-10 parts of quartz sand, 3.5-7.5 parts of methyl acetate, 2.3-4.5 parts of marigold essential oil, 6.5-12.7 parts of hydroxymethyl propyl cellulose, 10-15 parts of titanium dioxide, 20-28 parts of white latex, 1.2-3.5 parts of perillaldehyde, 5.7-8.6 parts of calcined kaolin, 2.7-6.2 parts of citronellal, 3.5-6.5 parts of 0.4%wt sodium tetraborate solution, 3.5-7 parts of 2,4-imidazolidinone, 1-3 parts of rosin air entraining agent, 1-3 parts of color paste, 25-30 parts of polyacrylamide solution, 10-13 parts of zinc oxide, 2-6 parts of tributyl phosphate, and 30-50 parts of water. Compared with the existing various porcelain-like rigid coatings, the waterproof wall lining coating has the characteristics of being waterproof, damp-proof, mould-proof, free from leakage of water immersion, strong in bonding adhesion, free from dusting and falling, non-toxic and odorless, long in service life and convenient for construction, is suitable for indoor decoration of high-standard hotels, office buildings and houses and apartments, and can be used as a waterproof coating for walls of basements and underground warehouses.

Owner:章麒

Outdoor heavy-duty anticorrosive self-cleaning water paint and use method thereof

InactiveCN111548716AAchieve waterproof effectAchieve high weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsFirming agentWater repellent

The invention relates to the technical field of interior wall surface paint, in particular to outdoor heavy-duty anti-corrosion self-cleaning water paint and a using method thereof. The water paint includes a component A and a component B, wherein the component A includes: 15-75 parts of aqueous polyurethane, 0.5-10 parts of a defoamer, 0.5-10 parts of a leveling agent, 1-20 parts of a coupling agent, 5-40 parts of color paste, an anti-ultraviolet agent and a water repellent, and the component B includes an aqueous curing agent. The outdoor heavy-duty anticorrosive self-cleaning water paint isprepared by the following steps: sequentially adding the components into a high-speed stirrer, adding water, stirring the components, mixing the components with the water-based curing agent, and curing the mixture.

Owner:惠州市漆优化工股份有限公司

A kind of facing layer material, photovoltaic building material and preparation method thereof

ActiveCN111138155BImprove power generation effectImprove the decorative effectPhotovoltaic supportsPhotovoltaic energy generationBuilding integrationKaolin clay

The invention belongs to the technical field of photovoltaic building integration, and relates to a decorative surface layer material, a photovoltaic building material and a preparation method thereof. Said a facing layer material, in terms of weight ratio, the raw materials of said facing layer material include 1-6 parts of inorganic pigment, 20-40 parts of silica sol, 10-25 parts of spinel powder, 12-20 parts of kaolin powder 20-30 parts of red garnet powder, 3-8 parts of talcum powder, 2-8 parts of lime powder and 15-40 parts of water. The slurry prepared by the invention is all inorganic matter, has good weather resistance, strong adhesion to the solar cell layer, has the advantages of no falling off, no cracking, etc., and can be used outdoors for many years.

Owner:PHOTON TECH BEIJING INC

Interior wall coating, and preparation method thereof

InactiveCN108912872ANo radioactivityCorrosion resistanceAntifouling/underwater paintsPaints with biocidesFood industryHazardous substance

The invention discloses an interior wall coating, and a preparation method thereof. The interior wall coating is composed of a bottom layer coating, a middle layer coating, and an external layer coating at a certain ratio through specific technology, and is used for colored preparation chambers. The beneficial effects are that: the preparation method is simple; the obtained interior wall coating is nontoxic; no special smell is detected; no radioactivity is caused; no toxic substance such as formaldehyde is contained; mildew resistance, moisture resistance, corrosion resistance, fumigating resistance, and anti-shedding performance are achieved; cleaning is convenient; and the interior wall coating is especially suitable for coating of interior walls of colored preparation workshops, traditional Chinese medicine extraction workshops, and traditional Chinese medicinal material warehouses in pharmacy industry, and colored preparation, oil-containing workshops in food industry.

Owner:刘小蕾

A superhydrophobic asphalt pavement anti-icing coating and preparation method thereof

ActiveCN109627974BSuperhydrophobicTo achieve the effect of anti-icingPaving detailsCoatingsPolymer scienceFirming agent

The invention belongs to the technical field of asphalt concrete pavement coating design, and relates to a super-hydrophobic asphalt pavement anti-icing coating and a preparation method thereof. layer and anti-wear filler dispersed in the functional layer; the functional layer is a low surface energy material; the slurry of the adhesive layer is formulated from epoxy resin 128, amine curing agent and epoxy toughener 277, the functional layer The slurry is prepared from MHX-1107 hydrogen-containing silicone oil, γ-aminopropyltriethoxysilane, dibutyltin dilaurate, absolute ethanol, ammonia water and deionized water; the anti-wear filler is evenly dispersed in the slurry of the functional layer In the body; the performance of the superhydrophobic asphalt pavement anti-icing coating of the present invention can fully meet the requirements of superhydrophobic, anti-icing, wear resistance and high friction coefficient.

Owner:CHANGAN UNIV

Lightweight composite building energy-saving thermal insulation material

ActiveCN104773985BEasy to processReduce processing costsCeramicwareThermal insulationSuperplasticizer

A fire-proof non-combustible composite heat-insulation material with good energy saving effect, good water proofing effect and better mechanical spraying construction effect is prepared by mixing and stirring ordinary Portland 42.5R cement with different weights, fiber brucite, magnesium silicate long fiber, wood fiber, light weight magnesium oxide, polypropylene fiber, an organic active waterproof agent, ultra light nano expansion beads, urea formaldehyde particles or polystyrene particles, adhesives, a foaming agent, a procoagulant regulating agent, silicon micropowder and a poly carboxylic acid superplasticizer, and has the appearance of dry and powdery fiber. The material can be directly spared on external walls, interior walls, roofs and staircase rooms of buildings according to a certain thickness after addition of water for mixing and stirring, has the characteristics of being thermal-insulation, energy-saving, non-combustible, environmentally-friendly, waterproof, and simple and quick in construction, is applicable to heat insulation of a variety of houses and buildings, and can achieve high efficiency and energy saving effect.

Owner:营口天瑞新型建筑材料有限公司

A natural stone imitation layer, photovoltaic building material and preparation method thereof

ActiveCN111138112BImprove power generation effectImprove the decorative effectPhotovoltaic supportsFinal product manufactureCelluloseBuilding integration

The invention belongs to the technical field of photovoltaic building integration, and relates to an imitation natural stone layer, a photovoltaic building material and a preparation method thereof. An imitation natural stone layer, the raw material of the imitation natural stone layer includes imitation natural stone slurry, wherein, by weight ratio, the imitation natural stone slurry includes 20-40 parts of acrylic resin, 50-65 parts of natural fine sand, 20-40 parts of filler, 3-10 parts of film-forming aid, 3-5 parts of nano-alumina, 4-6 parts of nano-zinc oxide, 80-130 parts of water, 3-8 parts of cellulose, 0.3-2 parts of leveling agent 0.5-2 parts of defoamer, 0.5-1.2 parts of water-based thickener, 0.1-1 part of inorganic pigment. The imitation natural stone layer prepared by the present invention has strong compactness and corrosion resistance, so it can well isolate the protected material from external corrosive substances; the hardness of this imitation natural stone layer is not low At 5H, it reached the hardness required by conventional building materials.

Owner:PHOTON TECH BEIJING INC

An energy-saving industrial furnace

The invention discloses an energy-saving industrial furnace. The energy-saving industrial furnace comprises a furnace base body, and the furnace base body is made of heatproof fibers, firebricks or a micro-nano material; the outer wall of the furnace base body is coated with a combined heat insulation coating layer, and the inner wall of the furnace base body is coated with an infrared radiation energy-saving coating layer; and the combined heat insulation coating layer comprises an inner heat insulation coating layer, a medium heat insulation coating layer and an outer heat insulation coating layer which are sequentially coated from inside to outside. A reinforced radiation heat transfer combined thermodynamic heat insulation energy-saving technology, which combines the infrared high-radiation technology of the high temperature-resistant infrared-energy saving coating layer with the high-efficiency heat insulation technology of the combined heat insulation coating layer, is applied, so the industrial furnace disclosed in the invention has the characteristics of effective improvement of the heat utilization efficiency, good energy saving effect, long service time, prolonged service life, and generation of the environmental protection effect.

Owner:SHENZHEN TRIUMPH TECH ENG +1

Interior wall coating and preparation method thereof

The present invention relates to a coating. The invention discloses an interior wall paint and a preparation method thereof. The technical scheme adopted in the present invention is: a kind of interior wall coating, is made up of primer coating, middle coating, and outer coating, is characterized in that: described primer coating, middle coating, outer coating each contain the raw material of certain ratio Components; and prepared according to the prescribed process; the interior wall paint is used for the interior wall paint of the colored preparation room. The beneficial effect of the invention is that the preparation process is simple, and the prepared interior wall paint is non-toxic, odorless, radioactive, and harmful substances such as formaldehyde. And it has the characteristics of mildew resistance, moisture resistance, corrosion resistance, fumigation resistance, non-shedding and easy cleaning. It is especially suitable for interior wall painting of colored preparation workshops in the pharmaceutical industry, traditional Chinese medicine extraction workshops, Chinese herbal medicine warehouses, and colored and oily workshops in the food industry.

Owner:刘晓刚 +2

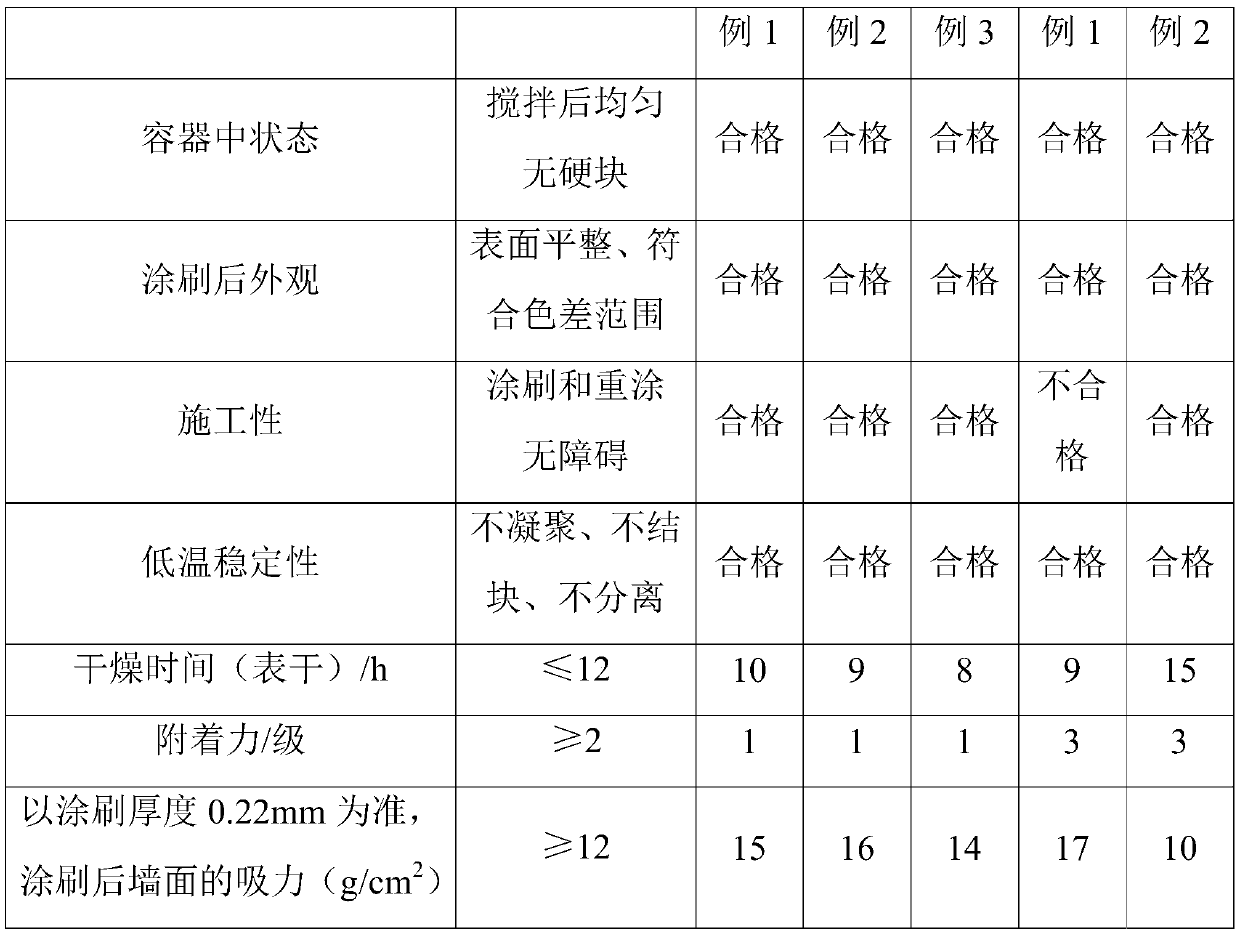

Iron-based putty powder and preparation method thereof

InactiveCN111019428AColorfulIncrease stickinessAntifouling/underwater paintsPaints with biocidesAdhesiveNickel-zinc ferrite

The invention discloses iron-based putty powder and a preparation method thereof. The iron-based putty powder comprises the following components in percentage by weight: 60-75% of soft magnetic ferrite powder, 3-8% of a water-based adhesive, 0.5-2% of an efficient film forming agent, 0.5-3% of a water-based dispersing agent, 0.2-0.8% of an organic silicon defoaming agent, 0.1-0.8% of a thickeningagent, 5-12% of a curing agent, 1-2% of a cross-linking agent, 8-10% of pearl powder and 3-8% of water, wherein the soft magnetic ferrite powder is at least one selected from ferroferric oxide powder,manganese zinc ferrite powder and nickel zinc ferrite powder. According to the invention, the soft magnetic ferrite powder is used as the main material for preparing the putty powder, so that the prepared iron-based putty powder can achieve the wall brushing effect of general putty powder, and enables the painted wall surface to have magnetism.

Owner:杨振龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com