Split joint type ceramic wear-resisting bend

A splicing, elbow technology, applied in elbows, pipes/pipe joints/fittings, pipes to prevent damage/wear, etc. problems, to achieve the effect of extending the replacement cycle, reliable performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

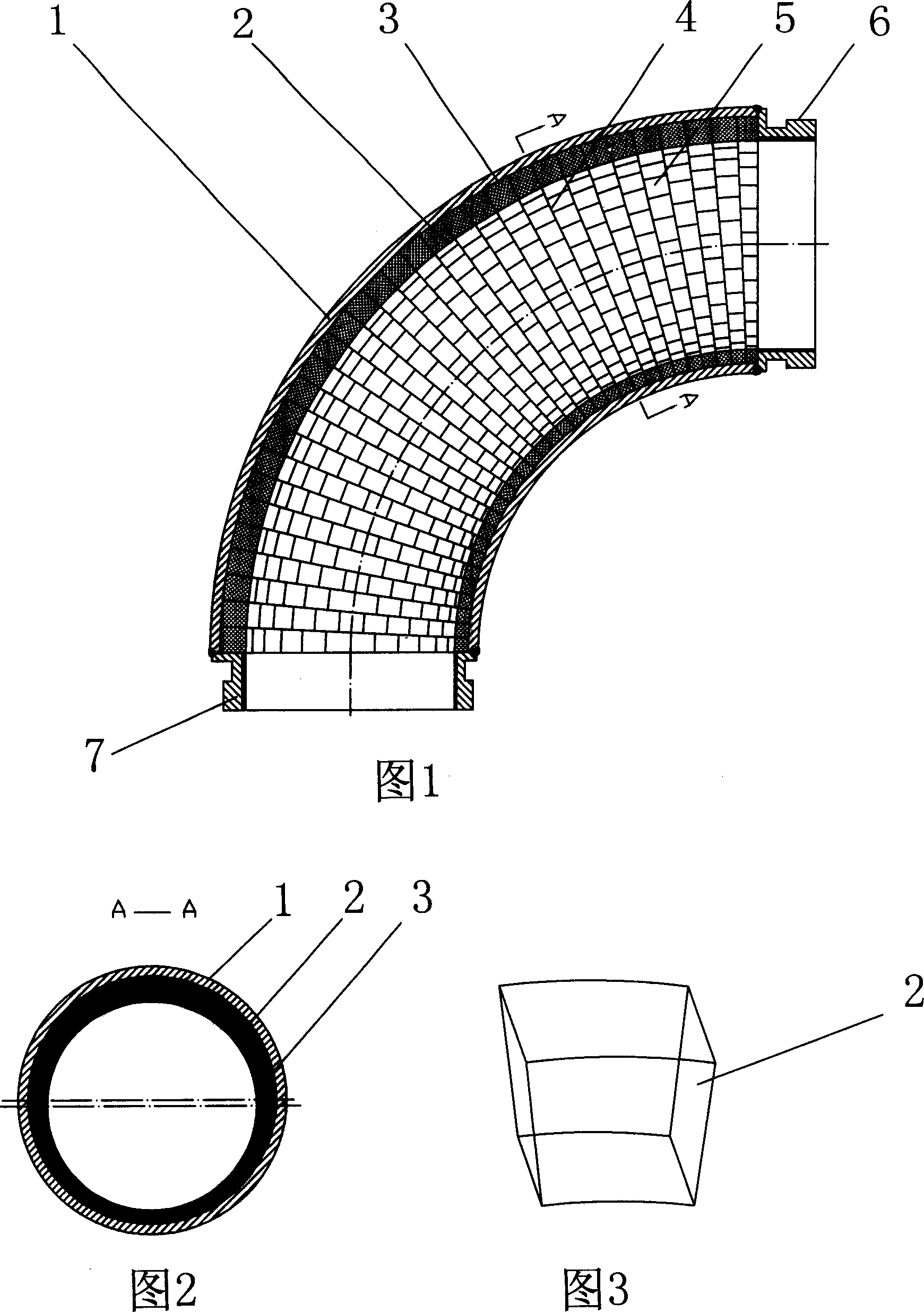

[0017] Referring to Fig. 1, Fig. 2 and Fig. 3, a wear-resistant ceramic lining 4 is provided on the inner wall of the seamless elbow body 1, and the wear-resistant ceramic lining 4 is spliced by a plurality of wear-resistant ceramic sheets 2, that is, wear-resistant ceramic sheets 2. Wedge splicing in the circumferential direction to form a wear-resistant ceramic lining ring 5 adapted to the inner wall of the seamless elbow body 1, and multiple groups of wear-resistant ceramic lining rings 5 are axially connected and bent to form a wear-resistant ceramic lining adapted to the seamless elbow body 1 The lining 4 is provided with a first retaining ring 6 and a second retaining ring 7 at the two ports of the seamless elbow body 1 to block the wear-resistant ceramic lining 4 respectively.

[0018] Referring to Fig. 1, Fig. 2 and Fig. 3, the present invention greatly improves the wear resistance of the iron and steel delivery pipeline. The wear-resistant ceramic lining 4 has goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com