Ultra-thin breast pad and preparation method thereof

An ultra-thin, breast pad technology, applied in brassiere, melt spinning, filament/thread forming, etc., can solve the problems of high water content, high material cost, and easy breeding of bacteria in the surface layer of breast pads, and achieve instant suction speed Fast, short processing flow, the effect of protecting safety and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

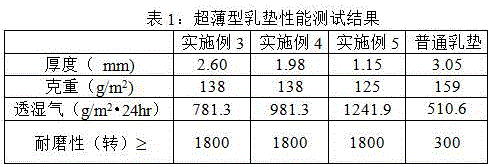

Examples

Embodiment 1

[0034] (1) Select PP slices with a melt index of 25-35g / 10min as the core layer material, and transport them to the first screw extruder through negative pressure, and select LDPE slices with a melt index of 10-17g / 10min as the skin layer material. Pressure delivery to the second screw extruder;

[0035] (2) The PP chips are melted by the first screw extruder to obtain a PP melt, and the PP melt is fed into the spinning compound assembly, and the temperature settings of the first screw extruder are respectively : Zone 1 180-190℃, Zone 2 195-205℃, Zone 3 210-220℃, Zone 4 225-235℃;

[0036] (3) melting the LDPE slices through the second screw extruder to obtain an LDPE melt, and feeding the LDPE melt into the spinning compound assembly through an equal-length melt distribution pipe, the first The temperature settings of the two-screw extruder are: 200-210°C for the first zone, 215-225°C for the second zone, 230-240°C for the third zone, and 245-255°C for the fourth zone;

[00...

Embodiment 2

[0041] (1) Select PP slices with a melt index of 25-35g / 10min as the core layer material, and transport them to the first screw extruder through negative pressure, and select LDPE slices with a melt index of 10-17g / 10min as the skin layer material. Pressure delivery to the second screw extruder;

[0042] (2) The PP chips are melted by the first screw extruder to obtain a PP melt, and the PP melt is fed into the spinning compound assembly, and the temperature settings of the first screw extruder are respectively : Zone 1 180-190℃, Zone 2 195-205℃, Zone 3 210-220℃, Zone 4 225-235℃;

[0043] (3) melting the LDPE slices through the second screw extruder to obtain an LDPE melt, and feeding the LDPE melt into the spinning compound assembly through an equal-length melt distribution pipe, the first The temperature settings of the two-screw extruder are: 200-210°C for the first zone, 215-225°C for the second zone, 230-240°C for the third zone, and 245-255°C for the fourth zone;

[00...

Embodiment 3

[0054] 1. Preparation of surface hydrophilic non-woven fabric

[0055] (1) Select PP slices with a melting index of 35g / 10min as the core layer material, and transport them to the first screw extruder through negative pressure, and select LDPE slices with a melting index of 17g / 10min as the cortical material, and transport them to the first screw extruder through negative pressure Two-screw extruder;

[0056] (2) The PP chips are melted by the first screw extruder to obtain a PP melt, and the PP melt is fed into the spinning compound assembly, and the temperature settings of the first screw extruder are respectively : Zone 1 180°C, Zone 2 195°C, Zone 3 210°C, Zone 4 225°C;

[0057] (3) melting the LDPE slices through the second screw extruder to obtain an LDPE melt, and feeding the LDPE melt into the spinning compound assembly through an equal-length melt distribution pipe, the first The temperature settings of the two-screw extruder are: 200°C in the first zone, 215°C in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com