A natural stone imitation layer, photovoltaic building material and preparation method thereof

A technology imitating natural stone and building materials, applied in the field of photovoltaic building integration, can solve the problems of reduced battery life, low transparency, shedding, etc., and achieve good power generation effect, good stability, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

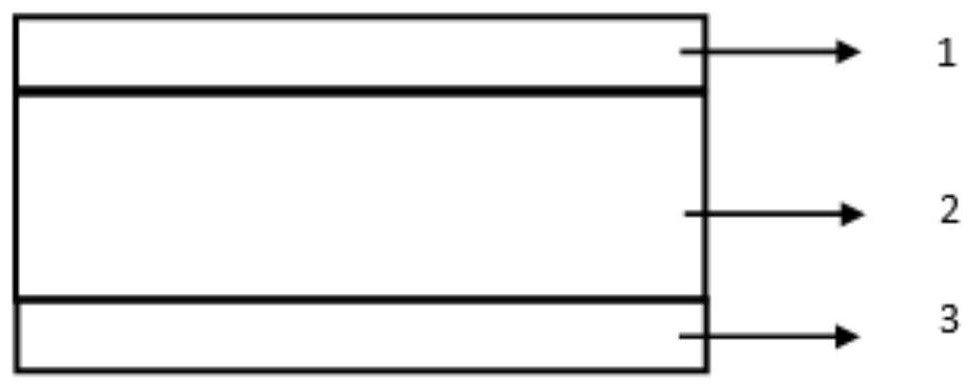

[0035] Prepare an imitation marble layer on the surface of the solar cell obtained, comprising the steps of:

[0036] Preparation of imitation marble slurry, its components and weight ratio include: 35 parts of acrylic resin, 50 parts of natural fine sand, 25 parts of filler, 5 parts of film-forming aids, 3 parts of nano-alumina, 4 parts of nano-zinc oxide, 95 parts of water, 6 parts of cellulose, 1 part of leveling agent, 0.5 part of defoamer, 0.5 part of water-based thickener, 0.5 part of inorganic pigment.

[0037] The selected natural fine sand is a mixture of marble, calcite and white marble.

[0038] The selected filler is a mixture of lime and titanium dioxide.

[0039] The selected film-forming aid is dodecyl alcohol ester.

[0040] The selected leveling agent is diacetone alcohol.

[0041] The selected defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether.

[0042] The selected thickener is a mixture of silica gel and methyl cellulose.

[0043] The s...

Embodiment 2

[0050] Prepare an imitation granite layer on the surface of the obtained solar cell, comprising the following steps:

[0051] Preparation of imitation granite slurry, its components and weight ratio include: 25 parts of acrylic resin, 65 parts of natural fine sand, 40 parts of filler, 3 parts of film-forming aids, 5 parts of nano-alumina, 6 parts of nano-zinc oxide, 130 parts of water, 8 parts of cellulose, 0.5 parts of leveling agent, 2 parts of defoamer, 1.0 part of water-based thickener, 0.1 part of inorganic pigment.

[0052] The selected fine sand is a mixture of quartz stone, granite and calcite.

[0053] The selected filler is a mixture of kaolin, talcum powder and titanium dioxide.

[0054] The selected film-forming aid is dodecyl alcohol ester.

[0055] The chosen leveling agent is acrylic acid.

[0056] The selected defoamer is a mixture of emulsified silicone oil and polyoxyethylene polyoxypropylene pentaerythritol ether.

[0057] The thickener of choice is hydrox...

Embodiment 3

[0065] Prepare the imitation natural stone layer on the obtained solar cell surface, comprising the following steps:

[0066] Preparation of natural stone layer slurry, its components and weight ratio include: 40 parts of acrylic resin, 50 parts of natural fine sand, 35 parts of filler, 8 parts of film-forming aids, 4 parts of nano-alumina, 5 parts of nano-zinc oxide 90 parts of water, 6 parts of cellulose, 1 part of leveling agent, 0.5 part of defoamer, 1.0 part of water-based thickener, 0.6 part of inorganic pigment.

[0067] The selected fine sand is a mixture of white marble, granite and calcite.

[0068] The selected filler is a mixture of kaolin, talcum powder and titanium dioxide.

[0069] The selected film-forming aid is dodecyl alcohol ester.

[0070] The chosen leveling agent is acrylic acid.

[0071] The selected defoamer is a mixture of emulsified silicone oil and polyoxyethylene polyoxypropylene pentaerythritol ether.

[0072] The thickener of choice is hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com