Polymer Electrolyte Fuel Cell Stack

一种高分子电解质、燃料电池组的技术,应用在固体电解质燃料电池、燃料电池分组、燃料电池等方向,能够解决联接载荷过大、联接载荷过大或过小、电池组体积增大等问题,达到联接容易、装配性优异、发电性能及耐久性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

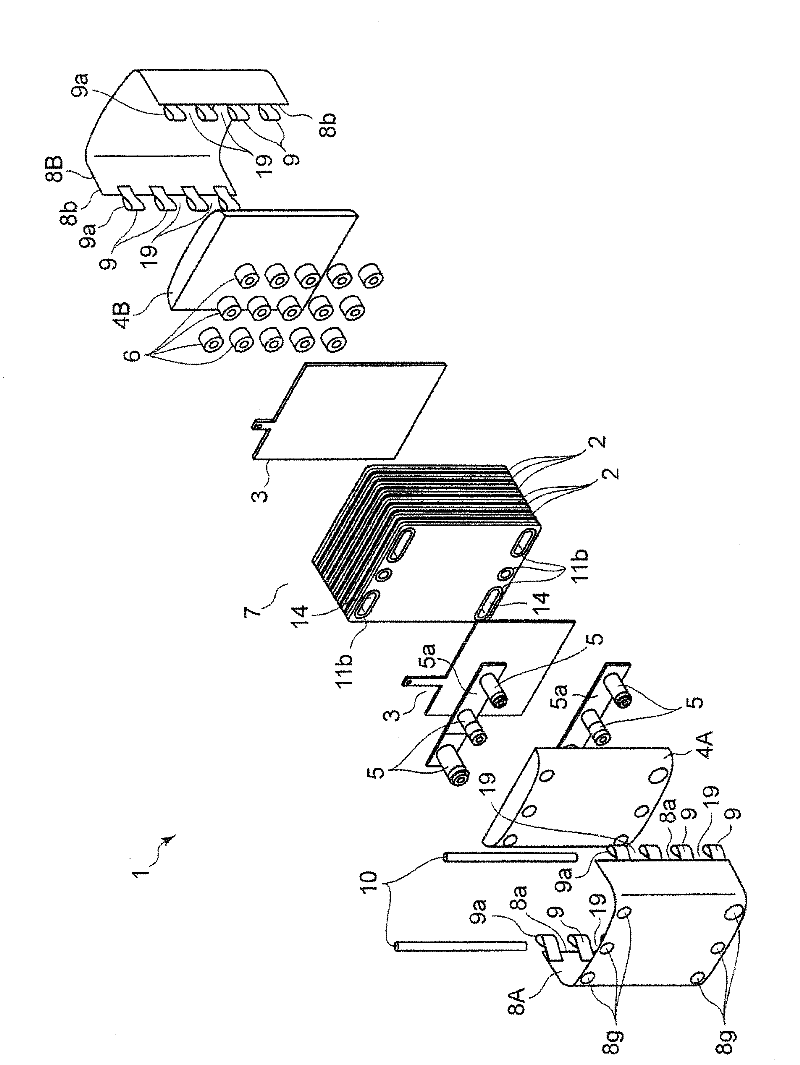

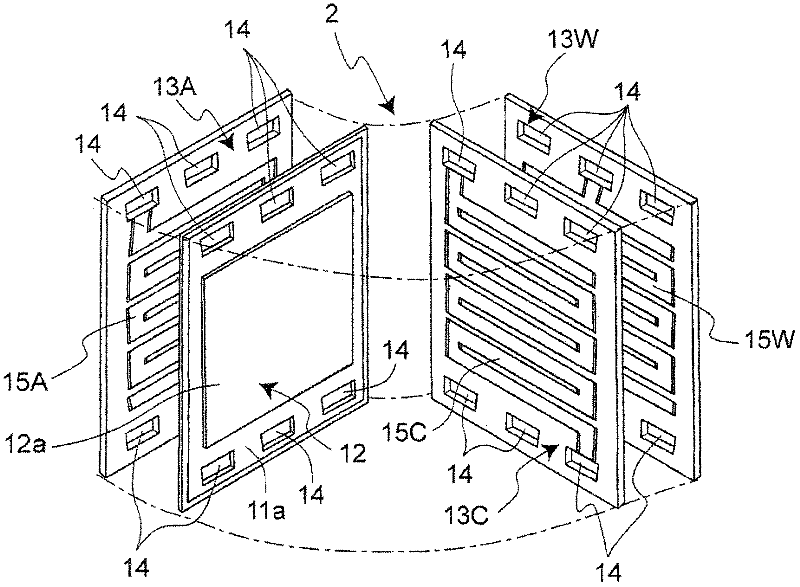

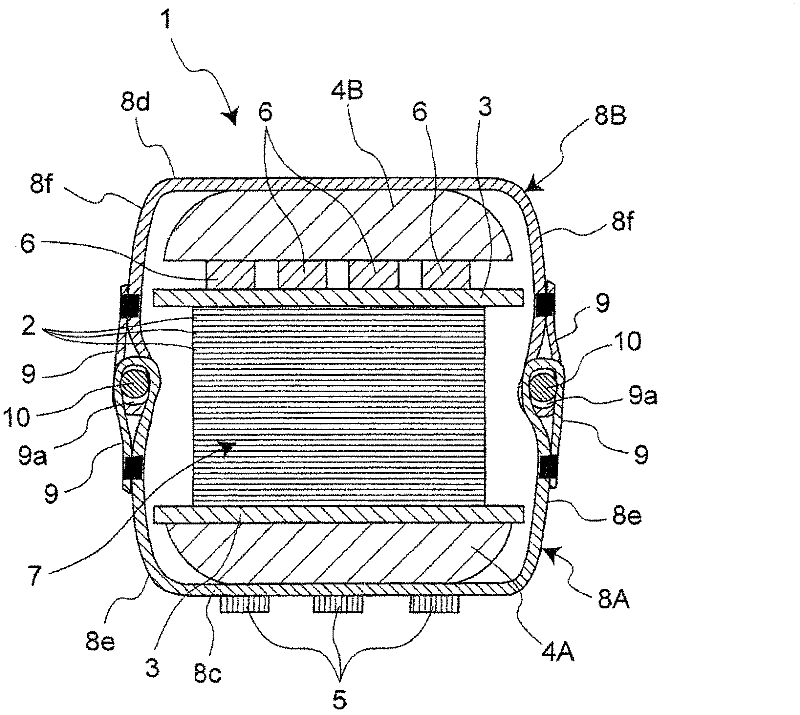

[0075] Figure 3A and Figure 3B A cross-sectional plan view of the fuel cell stack 1 in the first example of the present embodiment and its modifications is shown in . Collector plates 3 are arranged on the upper and lower sides of the battery cell stack 7, and pipes 5 are placed near one collector plate 3 on the lower side of the battery cell stack 7, pressed against by the end plate 4A, and the other collector plate on the upper side is pressed. A plurality of inner springs 6 are arranged on the plate 3, and are clamped by the upper and lower end plates 4A, 4B. The whole member to be connected is covered with two straps 8A, 8B having strap main parts 8c, 8d having the same width as the battery unit 2. As an example, the straps 8A, 8B are connected by two pins 10 to connect them. When the assembly is completed with the strips 8A, 8B and the pins 10, the plurality of inner springs 6 on the collector plate 3 are compressed between the battery cell stack 7 and the end plate 4...

no. 2 example

[0105] The cross-sectional shape of the pin 10 is not limited to the circular shape of the first embodiment, but may be of any shape, and examples of shapes other than the circular shape will be described below. For example, Figure 8 (1) is for comparison with Figure 6 (1) is the same, and is a cross-sectional plan view of a state in which the connecting portion 9 is connected using the pin 10A having a circular cross-sectional shape in the first embodiment.

[0106] in comparison, Figure 8 (2) shows an enlarged sectional plan view of the joint portion 9 and the pin 10E of the strap 8 in the second embodiment. As the pin 10E to be used, a rod having an oblong cross-sectional shape perpendicular to its longitudinal direction is used. In this second embodiment, a pin 10E having an oblong cross-sectional shape whose length in the major axis direction is a multiple (double) of the length in the minor axis direction is used as the coupling load, which is similar to that of th...

no. 3 example

[0109] Figure 8 (4) shows an enlarged cross-sectional plan view of the vicinity of the coupling portion 9 of the strap 8 in the third example of the above-described embodiment. For the coupling of the link 9 of the strap 8, several pins 10G of the same kind are used, whereby the coupling load can be adjusted. In the third embodiment, when the thickness of the battery cell stack 7 is thin, both pins 10G are inserted into the connection portion 9 and one connection portion of the connection portion 9, that is, both pins are inserted into the connection portion 9. In one through hole 9a, the connection load can be adjusted according to the thickness deviation of the battery cell stack 7 corresponding to the diameter and length of the pin 10G. There is no need to increase the volume of the battery pack 3, and there is no need to prepare different types of pins 10 having different diameters and cross-sectional shapes, and the assembly of the battery pack can be completed, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com