Iron-based putty powder and preparation method thereof

A putty powder and iron-based technology, which is applied in the field of building materials, can solve the problems of single performance and mildew, and achieve the effects of good viscosity, easy use, and good anti-corrosion and anti-mildew performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

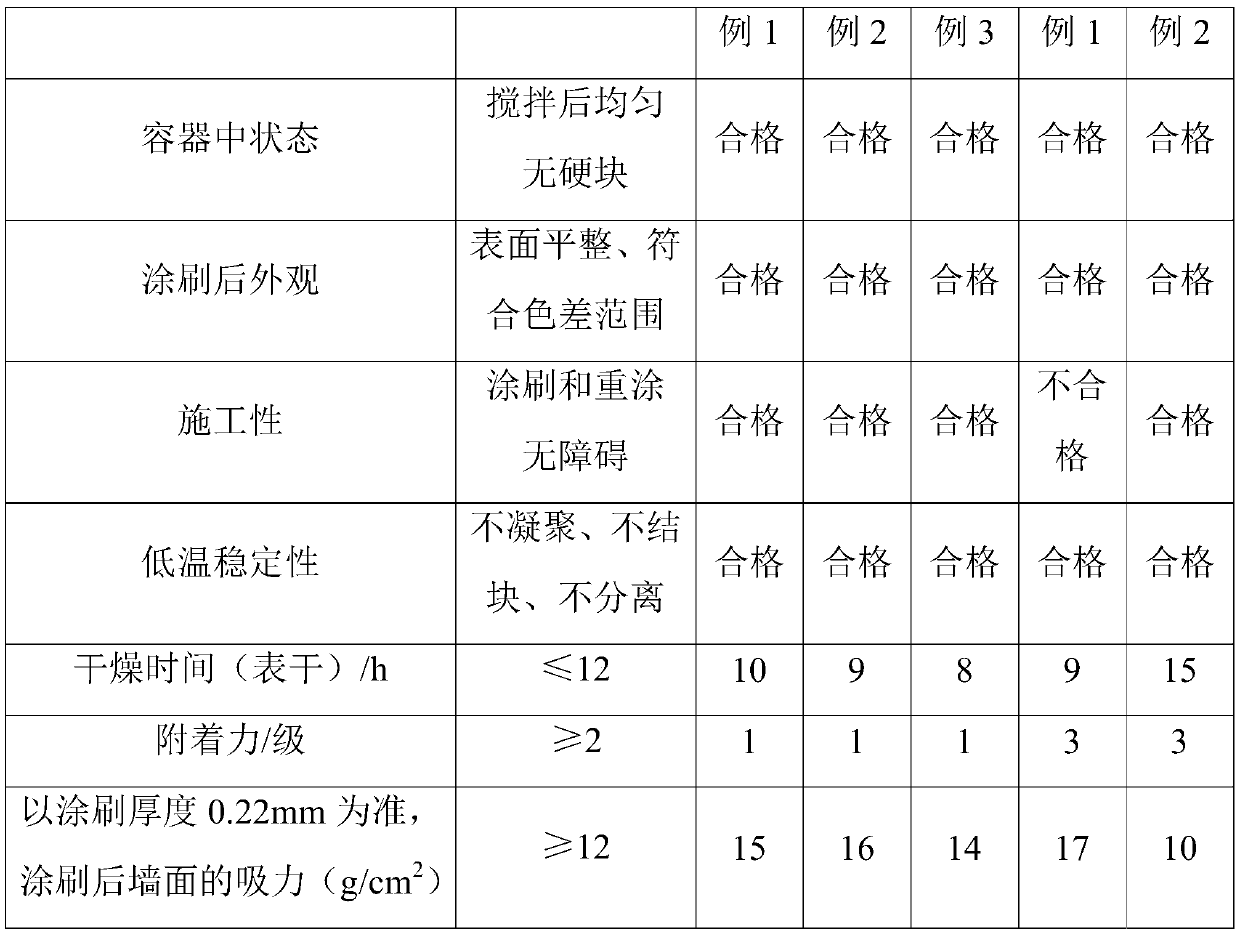

Embodiment 1

[0027] A ferrous putty powder, which is composed of the following components in weight percentage: 20% of ferric oxide powder, 30% of manganese-zinc ferrite powder, 25% of nickel-zinc ferrite powder, 4% of water-based adhesive, 0.5% of high-efficiency film-forming aids, 0.05% of anti-fungal agents, 0.05% of preservatives, 2% of water-based dispersants, 0.3% of silicone defoamers, 0.1% of thickeners, and 5% of curing agents , the cross-linking agent is 1%, the pearl powder is 8%, and the water is 4%.

[0028] Wherein, the water-based adhesive can use water-based acrylic emulsion or water-based polyurethane emulsion.

[0029]A preparation method for preparing the above-mentioned iron-based putty powder: mix ferric oxide powder, manganese-zinc ferrite powder, nickel-zinc ferrite powder, water-based adhesive, high-efficiency film-forming aid, anti-mildew Pour all the additives, preservatives, water-based dispersants, silicone defoamers, thickeners, curing agents, crosslinking age...

Embodiment 2

[0031] An iron-based putty powder, which consists of the following components in weight percentage: 70% of manganese-zinc ferrite powder, 5% of water-based adhesive, 1.5% of high-efficiency film-forming aid, 0.1% of anti-fungal agent, preservative 0.1%, water-based dispersant 1%, silicone defoamer 0.5%, thickener 0.3%, curing agent 6%, crosslinking agent 1.5%, pearl powder 9%, water 5% .

[0032] Wherein, the water-based adhesive can use water-based acrylic emulsion or water-based polyurethane emulsion.

[0033] A preparation method for preparing the above-mentioned iron-based putty powder: mix manganese-zinc ferrite powder, water-based adhesive, high-efficiency film-forming aid, anti-fungal agent, preservative, water-based dispersant, organic silicon defoaming agent in proportion by weight percentage Thickener, thickener, curing agent, cross-linking agent, pearl powder and water are all poured into the mixing container, and then the stirrer is stirred at a low speed of 200r / ...

Embodiment 3

[0035] An iron-based putty powder includes the following components in weight percentage: 28% of manganese-zinc ferrite powder, 32% of nickel-zinc ferrite powder, 8% of water-based adhesive, 1.5% of high-efficiency film-forming aid, anti Mold agent is 0.1%, preservative is 0.1%, water-based dispersant is 1%, silicone defoamer is 0.8%, thickener is 0.5%, curing agent is 10%, crosslinking agent is 2%, pearl powder 10% and 6% water.

[0036] Wherein, the water-based adhesive can use water-based acrylic emulsion or water-based polyurethane emulsion.

[0037] A preparation method for preparing the above-mentioned iron-based putty powder: mix manganese-zinc ferrite powder, nickel-zinc ferrite powder, water-based adhesive, high-efficiency film-forming aid, anti-mold agent, preservative, water-based Dispersant, silicone defoamer, thickener, curing agent, cross-linking agent, pearl powder and water are all poured into the stirring container, then use the stirrer to stir at a low speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com