Energy-saving industrial furnace

An industrial furnace and energy-saving technology, applied in the chemical industry, furnaces, furnace components, etc., can solve the problems of low heat utilization efficiency of industrial furnaces, achieve the effect of improving heat utilization efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

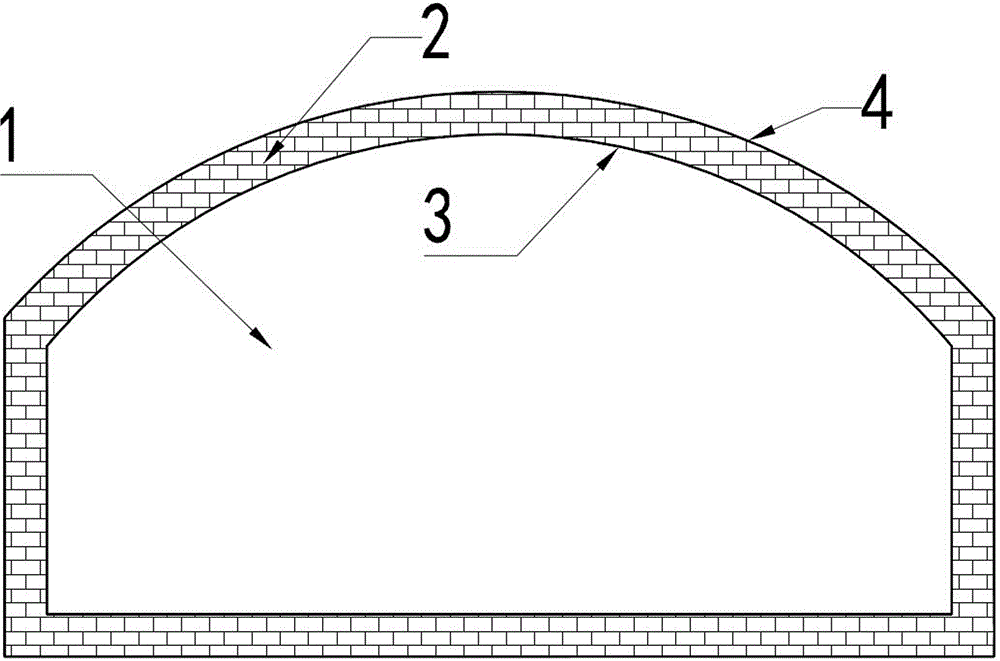

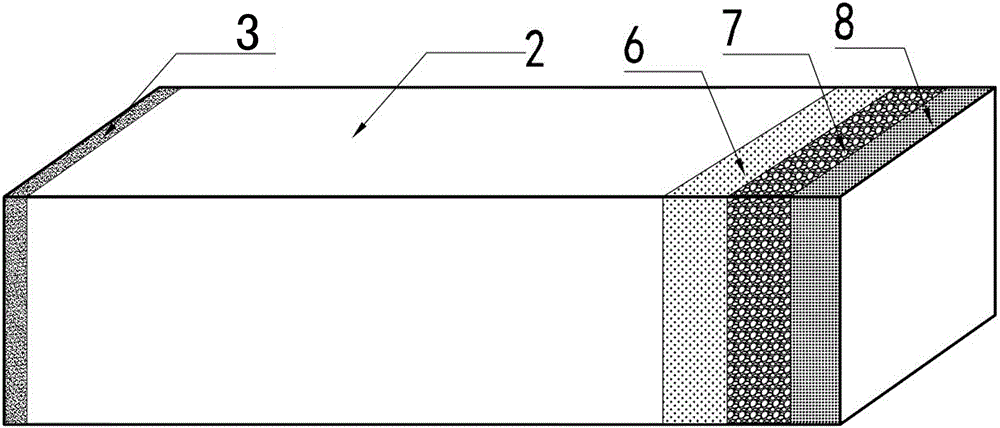

[0020] combine figure 1 and figure 2 As shown, the present invention provides a kind of energy-saving industrial furnace kiln, comprises furnace base body 2, and furnace base body 2 interior is furnace chamber 1, and furnace base body 2 adopts heat-resistant fiber, refractory brick or micronano material; The outer wall of described furnace base body 2 is coated with Covered with a combined thermal insulation coating 4, the inner wall of the furnace base 2 is coated with an infrared radiation energy-saving coating 3; the combined thermal insulation coating 4 includes an inner thermal insulation coating 6, a middle thermal insulation coating, and Layer 7 and outer thermal insulation coating 8;

[0021] The inner thermal insulation coating 6 is calculated by mass percentage, including the following components: 24% fly ash floating beads, 15% zirconia airgel, 16% kaolin, 9% bentonite, 8% sepiolite fiber, 11% zirconium Sol, 0.5% dispersant, 0.5% coalescent, 1% wetting agent, 1% ...

Embodiment 2

[0029] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0030] The inner thermal insulation coating 6 includes the following components in terms of mass percentage: 17% fly ash floating beads, 19% zirconia airgel, 17% kaolin, 5% bentonite, 5% sepiolite fiber, 18% zirconium Sol, 0.5% dispersant, 2% coalescent, 0.5% wetting agent, 0.5% thickener, 0.5% defoamer and 15% deionized water;

[0031] In terms of mass percentage, the middle insulation coating 7 includes the following components: 19% hollow ceramic microspheres, 16% alumina airgel, 13% mica powder, 10% bentonite, 10% ceramic fibers, 16% aluminum sol, 0.5% dispersant, 1% coalescent, 0.5% wetting agent, 2% thickener, 1% defoamer and 11% deionized water;

[0032] The outer thermal insulation coating 8 includes the following components in terms of mass percentage: 17% hollow glass microspheres, 16% silica airgel, 18% talcum powder, 3.4% bentonite, 9% quartz fiber, 8% silica so...

Embodiment 3

[0038] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0039] Inner thermal insulation coating 6 is calculated by mass percentage, including the following ingredients: 10% fly ash floating beads, 24% zirconia airgel, 23% kaolin, 5% bentonite, 6% sepiolite fiber, 20% zirconium Sol, 2% dispersant, 0.2% coalescent, 0.6% wetting agent, 0.2% thickener, 1% defoamer and 8% deionized water;

[0040] In terms of mass percentage, the middle insulation coating 7 includes the following components: 11% hollow ceramic microspheres, 14% alumina airgel, 19% mica powder, 10% bentonite, 14% ceramic fibers, 18% aluminum sol, 2% dispersant, 2% coalescent, 1% wetting agent, 0.5% thickener, 1.5% defoamer and 7% deionized water;

[0041] The outer thermal insulation coating 8 includes the following components in terms of mass percentage: 8% hollow glass microspheres, 18% silica airgel, 20% talcum powder, 8% bentonite, 3% quartz fiber, 15% silica sol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com