Manufacture technology of inlaying injection circuit in mold

A technology of inlaid injection molding and manufacturing technology, applied in the direction of coating, etc., can solve the problems of small operation possibility, pollution, high scrap rate, etc., and achieve the effect of reducing production cost and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

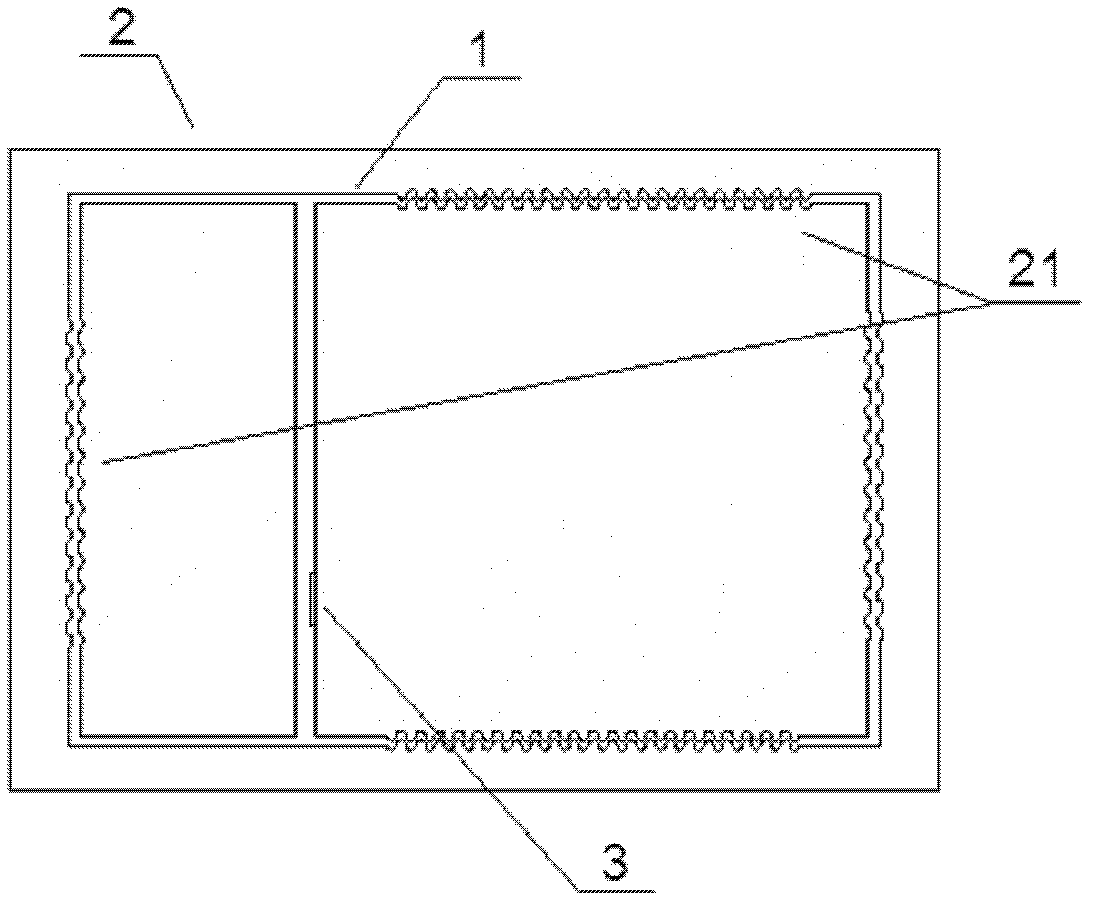

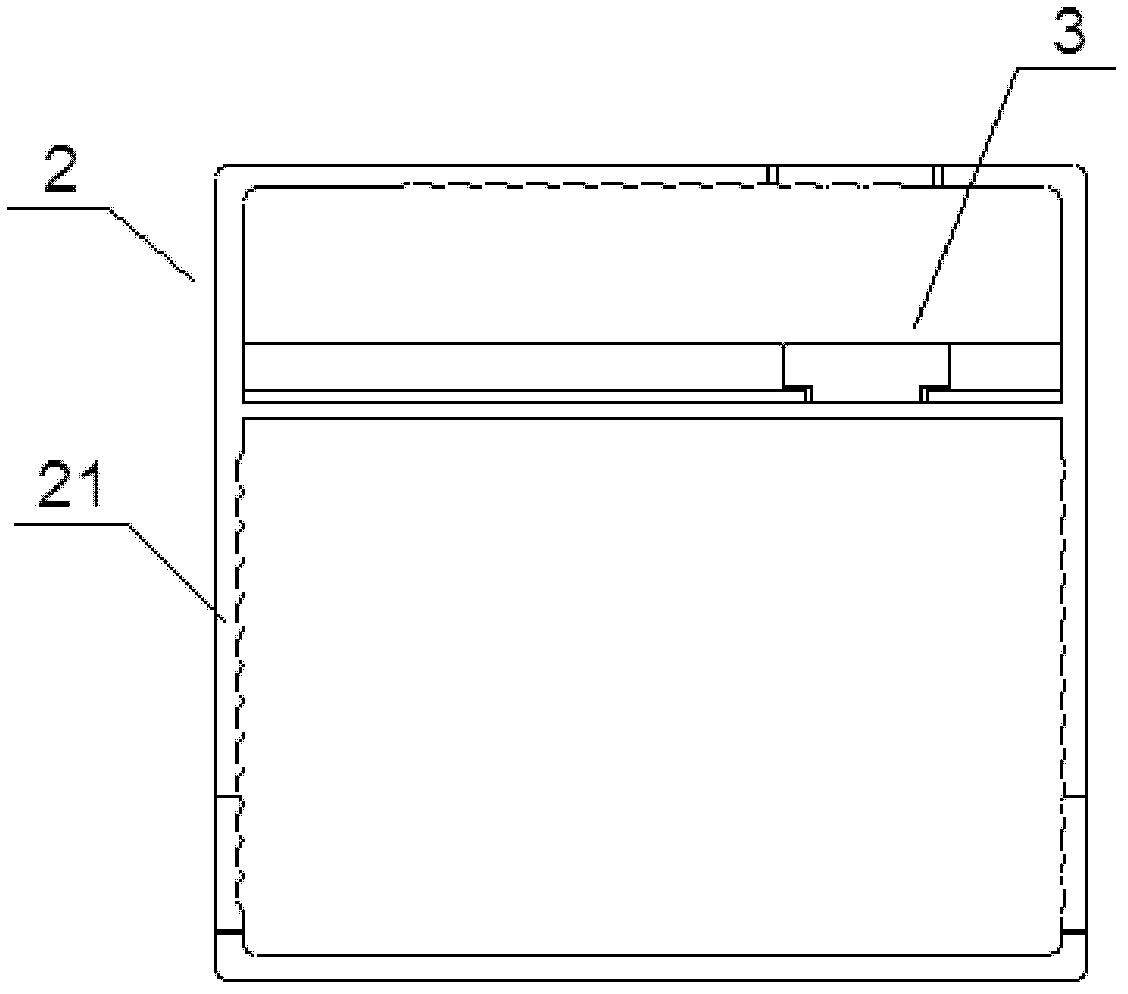

[0029] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

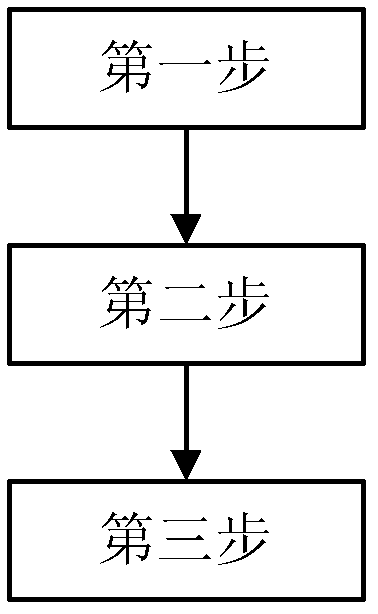

[0030] refer to figure 1 , the manufacturing process of in-mold inserting injection molding circuit, comprising the following steps:

[0031] The first step is the manufacturing process of the printed circuit film, including: using nano-scale silver paste ink to screen-print on the matching 0.05-0.25 film to form a printed circuit, and a layer can be printed on the printed circuit according to different purposes. Insulating ink, forming an insulating layer. Hot-melt adhesive can also be printed on the insulating layer to form a layer of adhesive, which is used to bond with molten plastic under the high temperature conditions of injection molding.

[0032] The second step is the shaping process of the printed circuit film, including: according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com