Anti-fog resin lens with hydrophilic factors in surface film layer and preparation method of anti-fog resin lens

A technology of hydrophilic factor and resin lens, applied in coatings, instruments, optics, etc., can solve the problems of non-hydrophilicity, lack of anti-fog effect, low hardness, etc., and achieve the effect of delaying the release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

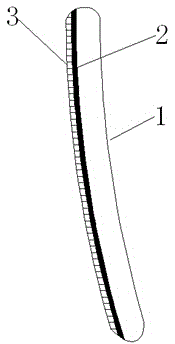

[0016] From figure 1 , figure 2 It is well known that an anti-fog resin lens with a hydrophilic factor storage function on the lens surface of the present invention is composed of a resin substrate 1, a hardened storage grid film layer 2, and a slow-release anti-fog film layer 3 of a hydrophilic factor. The hardened storage grid film layer is printed on the surface of the resin substrate, and the surface of the hardened storage grid film layer is dip-coated with a hydrophilic factor slow-release anti-fog film layer to form a hydrophilic factor slow-release anti-fog film layer.

[0017] Its production and production methods are described as follows:

[0018] 1. Prepare the silicon dioxide surface hardening liquid for printing and hardening the storage grid film layer 2: take 100ml of tetraethyl orthosilicate (28.4% solid content), 100ml of coupling agent KH570, 500ml of ethanol, and fully magnetically stir at room temperature Mix for 30 minutes, then add 6ml of deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com